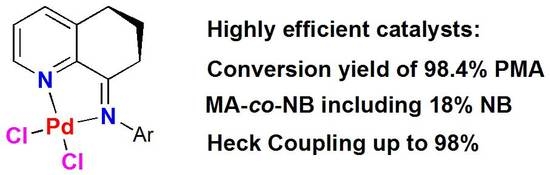

Geometry Constrained N-(5,6,7-Trihydroquinolin-8-ylidene)arylaminopalladium Dichloride Complexes: Catalytic Behavior toward Methyl Acrylate (MA), Methyl Acrylate-co-Norbornene (MA-co-NB) Polymerization and Heck Coupling

Abstract

:1. Introduction

2. Results and Discussion

2.1. Synthesis and Characterization of Palladium Complexes

2.2. Single Crystal X-ray Diffraction Study

2.3. Polymerization of MA and Copolymerization of MA/NB

2.4. Heck Coupling Reaction

3. Experimental Section

3.1. General Information

3.2. Synthesis of Ligands L1–L5

3.3. Synthesis of Palladium Complexes

3.4. Homopolymerization of MA

3.5. Copolymerization of MA and NB

3.6. Heck Reaction

3.7. X-ray Crystallographic Study

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sivaramakrishna, A.; Clayton, H.S.; Mogorosi, M.M.; Moss, J.R. Hydrocarbon (π- and δ-) complexes of nickel, palladium and platinum: Synthesis, reactivity and applications. Coord. Chem. Rev. 2010, 254, 2904–2932. [Google Scholar] [CrossRef]

- Budagumpi, S.; Haque, R.A.; Salman, A.W. Stereochemical and structural characteristics of single- and double-site Pd(II)–N-heterocyclic carbene complexes: Promising catalysts in organic syntheses ranging from C–C coupling to olefin polymerizations. Coord. Chem. Rev. 2012, 256, 1787–1830. [Google Scholar] [CrossRef]

- Mirica, L.M.; Khusnutdinova, J.R. Structure and electronic properties of Pd(III) complexes. Coord. Chem. Rev. 2013, 257, 299–314. [Google Scholar] [CrossRef]

- Alonso, F.; Beletskaya, I.P.; Yus, M. Non-conventional methodologies for transition-metal catalysed carbon–carbon coupling: A critical overview. Part 1: The Heck reaction. Tetrahedron 2005, 61, 11771–11835. [Google Scholar] [CrossRef]

- Whitcombe, N.J.; Hii, K.K.; Gibson, S.E. Advances in the hecking chemistry of aryl bromides and chlorides. Tetrahedron 2001, 57, 7449–7476. [Google Scholar] [CrossRef]

- Beletskaya, I.P.; Cheprakov, A.V. The Heck Reaction as a Sharpening Stone of Palladium Catalysis. Chem. Rev. 2000, 100, 3009–3066. [Google Scholar] [CrossRef] [PubMed]

- Crisp, G.T. Variations on a theme-recent developments on the mechanism of the Heck reaction and their implications for synthesis. Chem. Soc. Rev. 1998, 27, 427–436. [Google Scholar] [CrossRef]

- Cabri, W.; Candiani, I. Recent developments and new Perspectives in the Heck Reaction. Acc. Chem. Res. 1995, 28, 2–7. [Google Scholar] [CrossRef]

- Mizoroki, T.; Mori, K.; Ozaki, A. Arylation of olefin with aryl iodide catalyzed by palladium. Bull. Chem. Soc. Jpn. 1971, 44, 581. [Google Scholar] [CrossRef]

- Dieck, H.A.; Heck, R.F. Organophosphinepalladium complexes as catalysts for vinylic hydrogen substitution reactions. J. Am. Chem. Soc. 1974, 96, 1133–1136. [Google Scholar] [CrossRef]

- Dieck, H.A.; Heck, R.F. A palladium-catalyzed conjugated diene synthesis from vinylic halides and olefinic compounds. J. Org. Chem. 1975, 40, 1083–1090. [Google Scholar] [CrossRef]

- Minto, R.E.; Blacklock, B.J. Biosynthesis and function of polyacetylenes and allied natural products. Prog. Lipid Res. 2008, 47, 233–306. [Google Scholar] [CrossRef] [PubMed]

- Goa, K.L.; Wagstaff, A. A review of its pharmacology, clinical efficacy and tolerability in the management of hypertension. J. Drugs 1996, 51, 820–845. [Google Scholar] [CrossRef]

- Vries, J.G. The heck reaction in the production of fine chemicals. Can. J. Chem. 2001, 79, 1086–1092. [Google Scholar] [CrossRef]

- Sun, L.; Zou, Y.; Liang, Z.; Yu, J.; Xu, R. A one-pot synthetic strategy via tandem Suzuki–Heck reactions for the construction of luminescent microporous organic polymers. Polym. Chem. 2014, 5, 471–478. [Google Scholar] [CrossRef]

- Rafiee, E.; Ataei, A.; Nadri, S.; Joshaghani, M.; Eavani, S. Combination of palladium and oleic acid coated-magnetite particles: Characterization and using in Heck coupling reaction with magnetic recyclability. Inorg. Chim. Acta 2014, 409, 302–307. [Google Scholar] [CrossRef]

- Chaudhari, T.Y.; Hossian, A.; Manna, M.K.; Jana, R. Chemo-, regio-, and stereoselective Heck–Matsuda arylation of allylic alcohols under mild conditions. Org. Biomol. Chem. 2015, 13, 4841–4845. [Google Scholar] [CrossRef] [PubMed]

- Sabouncheia, S.J.; Ahmadia, M.; Panahimehra, M.; Bagherjeria, F.A.; Nasri, Z. Phosphine mono- and bis-ylide palladacycles as homogeneous molecular precatalysts: Simple and efficient protocol greatly facilitate Suzuki and Heck coupling reactions. J. Mol. Catal. A Chem. 2014, 383–384, 249–259. [Google Scholar] [CrossRef]

- Hajipour, A.R.; Azizi, G. Immobilized Pd nanoparticles on Tris-modified SiO2: Synthesis, characterization, and catalytic activity in Heck cross-coupling reactions. Chin. J. Catal. 2014, 35, 1547–1554. [Google Scholar] [CrossRef]

- Bachmann, D.G.; Wittwer, C.C.; Gillingham, D.G. Stereoselective Heck Reactions with Vinyl Sulfoxides, Sulfides and Sulfones. Adv. Synth. Catal. 2013, 355, 3703–3707. [Google Scholar] [CrossRef]

- Potier, J.; Menuel, S.; Rousseau, J.; Tumkevicius, S.; Hapiot, F.; Monflier, E. Multifunctional cyclodextrin-based N,N-bidentate ligands for aqueous Heck arylation. Appl. Catal. A 2014, 479, 1–8. [Google Scholar] [CrossRef]

- Quinteros, G.J.; Uberman, P.M.; Martín, S.E. Bulky monodentate biphenylarsine ligands: Synthesis and evaluation of their structure effects in the palladium-catalyzed heck reaction. Eur. J. Org. Chem. 2015, 2015, 2698–2705. [Google Scholar] [CrossRef]

- Chou, C.; Yang, C.; Syu, H.; Kuo, T. Monomeric Pd(II) complexes with trans-chelated pyrazole ligands as effective pre-catalysts for Heck cross-coupling reaction under mild aerobic conditions. J. Organomet. Chem. 2013, 745–746, 387–392. [Google Scholar] [CrossRef]

- Ye, J.; Ye, Z.; Zhu, S. Synthesis and characterization of hyperbranched polyethylenes containing cross-linking structures by chain walking copolymerization of ethylene with diacrylate comonomer. Polymer 2008, 49, 3382–3392. [Google Scholar] [CrossRef]

- Dong, Z.; Ye, Z. Hyperbranched polyethylenes by chain walking polymerization: Synthesis, properties, functionalization, and applications. Polym. Chem. 2012, 3, 286–301. [Google Scholar] [CrossRef]

- Ye, Z.; Xu, L.; Dong, Z.; Xiang, P. Designing polyethylenes of complex chain architectures via Pd–diimine-catalyzed “living” ethylene polymerization. Chem. Commun. 2013, 49, 6235–6255. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, K.; Ye, Z. One-Pot Synthesis of Hyperbranched Polyethylenes Tethered with Polymerizable Methacryloyl Groups via Selective Ethylene Copolymerization with Heterobifunctional Comonomers by Chain Walking Pd-Diimine Catalysis. Macromolecules 2008, 41, 2290–2293. [Google Scholar] [CrossRef]

- Wang, J.; Ye, Z.; Joly, H. Synthesis and characterization of hyperbranched polyethylenes tethered with polyhedral oligomeric sSilsesquioxane (POSS) nanoparticles by chain walking ethylene copolymerization with acryloisobutyl-POSS. Macromolecules 2007, 40, 6150–6163. [Google Scholar] [CrossRef]

- Morgan, S.; Ye, Z.; Zhang, K.; Subramanian, R. One-pot synthesis of hyperbranched polyethylenes tethered with pendant acryloyl functionalities by chain walking copolymerizations. Macromol. Chem. Phys. 2008, 209, 2232–2240. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, J.; Subramanian, R.; Ye, Z.; Lu, J.; Yu, Q. Chain walking ethylene copolymerization with an ATRP inimer for one-Pot synthesis of hyperbranched polyethylenes tethered with ATRP initiating sites. Macromol. Rapid Commun. 2007, 28, 2185–2191. [Google Scholar] [CrossRef]

- Boffa, L.S.; Novak, B.M. Copolymerization of polar monomers with olefins using transition-metal complexes. Chem. Rev. 2000, 100, 1479–1494. [Google Scholar] [CrossRef] [PubMed]

- Gibson, V.C.; Sptzmesser, S.K. Advances in non-metallocene olefin polymerization catalysis. Chem. Rev. 2003, 103, 283–316. [Google Scholar] [CrossRef] [PubMed]

- Berkefeld, A.; Mecking, S. Coordination Copolymerization of Polar Vinyl Monomers H2C=CHX. Angew. Chem. Int. Ed. 2008, 47, 2538–2542. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.F.; Wang, S.K.; Kuo, S.W.; Huang, W.J.; Chang, F.C. Homopolymerization and copolymerization of tert-butyl methacrylate and norbornene with nickel-based methylaluminoxane catalysts. J. Appl. Polym. Sci. 2004, 92, 1824–1833. [Google Scholar] [CrossRef]

- Liu, S.; Elyashiv, S.; Sen, A. Copper-mediated controlled copolymerization of methyl acrylate with 1-alkenes under mild conditions. J. Am. Chem. Soc. 2001, 123, 12738–12739. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.Y.; Li, Y.F.; Zhu, F.M.; Wu, Q. Copolymerization of norbornene and methyl acrylate by β-ketoiminato Palladium complexes/MAO. Polym. Bull. 2006, 57, 73–81. [Google Scholar] [CrossRef]

- Gao, H.; Liu, X.; Pei, L.; Wu, Q. Bis(b-ketoamino)copper(II)/methylaluminoxane systems for homo- and copolymerizations of methyl acrylate and 1-Hexene. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 1113–1121. [Google Scholar] [CrossRef]

- Chen, B.; Fang, J.; Cong, Y.; Shao, D.; Hu, M.; Wang, J.; Yang, J.; Gao, H. Copolymerization of norborene and methyl acrylate catalyzed by Nd(naph)3-Al(i-Bu)3. Polym. Bull. 2011, 67, 975–983. [Google Scholar] [CrossRef]

- Gu, B.; Liu, S.; Leber, J.D.; Sen, A. Nitroxide-mediated copolymerization of methyl acrylate with 1-alkenes and norbornenes. Macromoleculars 2004, 37, 5142–5144. [Google Scholar] [CrossRef]

- Morris, J.R. Substituted Norbornene Compounds. U.S. Patent 3,536,681, 27 October 1970. [Google Scholar]

- Goodall, B.L.; McIntosh, H.L., III. Polycyclic Copolymer Compositions. U.S. Patent 6,303,724, 16 October 2001. [Google Scholar]

- Hennis, A.D.; Sen, A. Palladium(II) Catalyzed Copolymerization of Norbornene with Polar Vinyl Monomers. Am. Chem. Soc. Polym. Prepr. 2000, 41, 1383. [Google Scholar]

- Hennis, A.D.; Hilt, D.C.; Kacker, S.; Sen, A. Palladium(II) Catalyzed Copolymerization of Norbornene and Methyl Acrylate. Am. Chem. Soc. Polym. Prepr. 1998, 39, 412. [Google Scholar]

- Nakano, R.; Nozaki, K. Copolymerization of propylene and polar monomers using Pd/IzQO catalysts. J. Am. Chem. Soc. 2015, 137, 10934–10937. [Google Scholar] [CrossRef] [PubMed]

- Dai, S.; Sui, X.; Chen, C. Highly robust palladium(II) a-diimine catalysts for slow-chain walking polymerization of ethylene and copolymerization with methyl acrylate. Angew. Chem. Int. Ed. 2015, 54, 9948–9953. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Zeng, Y.; Huang, W.; Hao, X.; Sun, W.-H. N-(5,6,7-trihydroquinolin-8-ylidene)arylaminonickel dichlorides as highly active single-site pro-catalysts in ethylene polymerization. Dalton Trans. 2011, 40, 8436–8443. [Google Scholar] [CrossRef] [PubMed]

- Huang, F.; Sun, Z.; Du, S.; Yue, E.; Ba, J.; Hu, X.; Liang, T.; Galland, G.B.; Sun, W.-H. Ring-tension adjusted ethylene polymerization by aryliminocycloheptapyridyl nickel complexes. Dalton Trans. 2015, 44, 14281–14292. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Zeng, Y.; Hu, Q.; Huang, F.; Jin, L.; Mo, W.; Sun, N.; Hu, B.; Shen, Z.; Hu, X.; et al. Efficient catalyst for both suzuki and heck cross-coupling reactions: Synthesis and catalytic behaviour of ceometry constrained iminopyridylpalladium chlorides. Adv. Synth. Catal. 2016, 358, 2642–2651. [Google Scholar] [CrossRef]

- Lavery, A.; Nelson, S.M. Dinuclear intermediates in the oxidation of pendant olefinic groups of palladium(II)—co-ordinated schiff-base ligands. Dalton Trans. 1984, 4, 615–620. [Google Scholar] [CrossRef]

- Chen, R.; Bacsa, J.; Mapolie, S.F. {N-alkyl-N-[pyridin-2-ylmethylene] amine}dichloro palladium(II) complexes: Synthesis, crystal structures and evaluation of their catalytic activities for ethylene polymerization. Polyhedron 2003, 22, 2855–2861. [Google Scholar] [CrossRef]

- Mahdavi, H.; Zirakzadeh, A.; Amani, J. Modified cross-linked polyacrylamide supported palladium salts as a new heterogeneous catalyst for Heck reaction. React. Funct. Polym. 2007, 67, 716–722. [Google Scholar] [CrossRef]

- Chen, W.; Xi, C.; Yang, K. 2-Iminopyridylpalladium dichloride as highly active catalyst for the Heck reaction. Appl. Organomet. Chem. 2007, 21, 641–644. [Google Scholar] [CrossRef]

- Ban, Q.; Zhang, J.; Liang, T.; Redshaw, C.; Sun, W.-H. 2,6-Dibenzhydryl-N-(2-aryliminoacenaphthylenylidene)-4-chlorobenzenaminopalladium dichlorides: Synthesis, characterization, and use as catalysts in the Heck-reaction. J. Organomet. Chem. 2012, 713, 151–156. [Google Scholar] [CrossRef]

- Ye, B.; Wang, L.; Hu, X.; Redshaw, C.; Sun, W.-H. 2-(1-Aryliminoethyl)cycloheptapyridylpalladium complexes: Synthesis, characterization and the use in the Heck-reaction. Inorg. Chim. Acta 2013, 407, 281–288. [Google Scholar] [CrossRef]

- Kong, S.; Liu, Q.; Sun, W.-H.; Redshaw, C. Dichloropalladium complexes ligated by 4,5-bis(arylimino)pyrenylidenes: Synthesis, characterization, and catalytic behavior towards Heck-reaction. J. Organomet. Chem. 2014, 751, 453–457. [Google Scholar]

- Zhao, T.; Xing, Q.; Song, K.; Ban, Q.; Liang, T.; Liu, Q.; Sun, W.-H. Enhancing catalytic activity towards Heck-reaction by using 4,5,9,10-tetra(arylimino)-pyrenylidenyldipalladium tetrachlorides. RSC Adv. 2015, 5, 14228–14234. [Google Scholar] [CrossRef]

- Laine, T.V.; Klinga, M.; Leskelä, M. Synthesis and X-ray Structures of New mononuclear and dinuclear diimine complexes of late transition metals. Eur. J. Inorg. Chem. 1999, 6, 959–964. [Google Scholar] [CrossRef]

- Nagel, M.; Paxton, W.F.; Sen, A.; Zakharov, L.; Rheingold, A.L. Metal-mediated polymerization of acrylates: Relevance of radical traps? Macromolecules 2004, 37, 9305–9307. [Google Scholar] [CrossRef]

- Elyashiv, S.; Greinert, N.; Sen, A. Copolymerization of methyl acrylate with Nnorbornene derivatives by atom transfer radical polymerization. Macromolecules 2002, 35, 7521–7526. [Google Scholar] [CrossRef]

- Lopez-Fernandez, R.; Carrera, N.; Albeniz, A.C.; Espinet, P. Dual behavior of cationic palladium pentafluorophenyl complexes as catalysts for the homopolymerization of acrylates and of nonpolar olefins. Organometallics 2009, 28, 4996–5001. [Google Scholar] [CrossRef]

- Xiang, P.; Ye, Z. Homo- and Co-polymerization of norbornene and methyl acrylate with Pd-diimine catalysts. J. Organomet. Chem. 2015, 798, 429–436. [Google Scholar] [CrossRef]

- Tian, G.; Novak, B.M. Neutral palladium complexes as catalysts for olefin–methyl acrylate copolymerization: A cautionary tale. Macromolecules 2001, 34, 7656–7663. [Google Scholar] [CrossRef]

- Matsuzaki, K.; Uryu, T.; Ishida, A. Stereoregularity of poly(methy1 acrylate) stereoregularity of poly(methy1 Acrylate). J. Polym. Sci. Part A Polym. Chem. 1967, 5, 2167–2177. [Google Scholar] [CrossRef]

- Uryu, T.; Shiroki, H.; Okada, M.; Hosonuma, K.; Matsuzaki, K. Stereoregularity of radically polymerized poly(alkyl acrylates) and poly(trimethylsilyl acrylates) and the preparation of syndiotactic poly(methyl acrylate). J. Polym. Sci. Part A Polym. Chem. 1971, 9, 2335–2342. [Google Scholar] [CrossRef]

- Kawamura, T.; Toshima, N.; Matsuzaki, K. Assignment of finely resolved l3C-NMR spectra of polyacrylates. Macromol. Chem. Phys. 1995, 196, 3415–3424. [Google Scholar] [CrossRef]

- Dong, Z.; Ye, Z. Heterogeneous palladium catalyst constructed with cross-linked hyperbranched poly(phenylacetylene) as polymer support: A reusable highly active ppm-level catalyst for multiple cross-coupling reactions. Appl. Catal. A Gen. 2015, 489, 61–71. [Google Scholar] [CrossRef]

- Mahmood, Q.; Yue, E.; Zhang, W.; Solan, G.A.; Liang, T.; Sun, W.-H. Bisimino-functionalized dibenzo[a,c]acridines as highly conjugated pincer frameworks for palladium(II): Synthesis, characterization and catalytic performance in Heck coupling. Org. Chem. Front. 2016, 3, 1668–1679. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, Q.; He, X.; Wu, J. Palladium-catalyzed decarboxylative cross-coupling reaction of cinnamic acid with aryl iodide. Org. Biomol. Chem. 2009, 7, 863–865. [Google Scholar] [CrossRef] [PubMed]

- Sawant, D.; Wagh, Y.; Bhatte, K.; Panda, A.; Bhanage, B. Palladium polyether diphosphinite complex anchored in polyethylene glycol as an efficient homogeneous recyclable catalyst for the Heck reactions. Tetrahedron Lett. 2011, 52, 2390–2393. [Google Scholar] [CrossRef]

- Kantam, M.L.; Reddy, P.V.; Srinivas, P.; Bhargava, S. Ligand and base-free Heck reaction with heteroaryl halides. Tetrahedron Lett. 2011, 52, 4490–4493. [Google Scholar] [CrossRef]

- Sheldrick, G.M. SHELXTL-97, Program for the Refinement of Crystal Structures; University of Göttingen: Göttingen, Germany, 1997. [Google Scholar]

- Sample Availability: Samples of the Pd1–Pd5 complexes and polymers are available from the authors.

| Run | Pre-Catalyst | T (°C) | Time (h) | Yield (g) | Conversion (%) b | Mw c (kg∙mol−1) | Mw/Mn c |

|---|---|---|---|---|---|---|---|

| 1 | Pd3 | 80 | 4 | 7.30 | 77.0 | 1498 | 2.33 |

| 2 | Pd3 | 100 | 4 | 9.01 | 95.0 | 2252 | 11.5 |

| 3 | Pd3 | 120 | 4 | 6.01 | 63.4 | 1091 | 1.74 |

| 4 | Pd3 | 100 | 1 | 2.21 | 24.2 | 1534 | 3.54 |

| 5 | Pd3 | 100 | 2 | 5.22 | 56.1 | 1734 | 2.39 |

| 6 | Pd3 | 100 | 3 | 7.44 | 79.4 | 1830 | 3.46 |

| 7 | Pd1 | 100 | 4 | 7.70 | 82.0 | 1936 | 3.21 |

| 8 | Pd2 | 100 | 4 | 8.76 | 93.4 | 1163 | 3.79 |

| 9 | Pd4 | 100 | 4 | 9.15 | 97.2 | 1596 | 3.98 |

| 10 | Pd5 | 100 | 4 | 9.28 | 98.4 | 6282 | 3.73 |

| 11 d | Pd3 | 100 | 4 | - | - | - | - |

| Run a | MA/NBE | Yield (g) | Conversion of MA (%) b | NB/MA b | Mw c/kg∙mol−1 | Mw/Mn c |

|---|---|---|---|---|---|---|

| 1 | 1:0 | 9.01 | 95 | - | 2252 | 1.74 |

| 2 | 9:1 | 7.38 | 68 | 8 | 1699 | 2.69 |

| 3 | 7:3 | 5.21 | 49 | 16 | 202 | 5.74 |

| 4 | 5:5 | 3.49 | 30 | 18 | 152 | 4.59 |

| 5 | 0:1 | - | - | - | - | - |

| Run | Catalyst | Base | T (°C) | Solvent | Time (h) | Conversion (%) b | ToF c |

|---|---|---|---|---|---|---|---|

| 1 | Pd5 | K2CO3 | 150 | DMA | 8 | 93 | 5813 |

| 2 | Pd5 | Na2CO3 | 150 | DMA | 8 | 72 | 4500 |

| 3 | Pd5 | NaHCO3 | 150 | DMA | 8 | 74 | 4625 |

| 4 | Pd5 | NaOAc | 150 | DMA | 8 | 82 | 5125 |

| 5 | Pd5 | NaOH | 150 | DMA | 8 | 70 | 4375 |

| 6 | Pd5 | K2CO3 | 150 | DMF | 8 | 92 | 5750 |

| 7 | Pd5 | K2CO3 | 100 | Toluene | 8 | - | - |

| 8 | Pd5 | K2CO3 | 60 | CH3CN | 8 | - | - |

| 9 | Pd5 | K2CO3 | 100 | DMA | 8 | - | - |

| 10 | Pd5 | K2CO3 | 60 | DMA | 8 | - | - |

| 11 | Pd5 | K2CO3 | 150 | DMA | 2 | 86 | 21500 |

| 12 | Pd5 | K2CO3 | 150 | DMA | 4 | 88 | 11000 |

| 13 | Pd5 | K2CO3 | 150 | DMA | 12 | 98 | 4083 |

| 14 | Pd4 | K2CO3 | 150 | DMA | 08 | 93 | 5813 |

| 15 d | PdCl2 | K2CO3 | 150 | DMA | 08 | 22 | 28 |

| 16 d | Pd(OAc)2 | K2CO3 | 150 | DMA | 08 | 41 | 50 |

| Run | Ar–X | Yield (%) b | Conversion (%) c | ToF d |

|---|---|---|---|---|

| 1 |  | 74 | 81 | 3905 |

| 2 |  | - | 3.6 | 225 |

| 3 |  | 31 (15) | 43 (21) | 1938 (938) |

| 4 |  | 64 | 77 | 4000 |

| 5 |  | 65 | 76 | 3847 |

| 6 |  | 37 | 53 | 2312 |

| 7 |  | - | 6 | 375 |

| 8 |  | - | 8 | 500 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.; Mahmood, Q.; Liang, T.; Sun, W.-H. Geometry Constrained N-(5,6,7-Trihydroquinolin-8-ylidene)arylaminopalladium Dichloride Complexes: Catalytic Behavior toward Methyl Acrylate (MA), Methyl Acrylate-co-Norbornene (MA-co-NB) Polymerization and Heck Coupling. Molecules 2016, 21, 1686. https://doi.org/10.3390/molecules21121686

Zeng Y, Mahmood Q, Liang T, Sun W-H. Geometry Constrained N-(5,6,7-Trihydroquinolin-8-ylidene)arylaminopalladium Dichloride Complexes: Catalytic Behavior toward Methyl Acrylate (MA), Methyl Acrylate-co-Norbornene (MA-co-NB) Polymerization and Heck Coupling. Molecules. 2016; 21(12):1686. https://doi.org/10.3390/molecules21121686

Chicago/Turabian StyleZeng, Yanning, Qaiser Mahmood, Tongling Liang, and Wen-Hua Sun. 2016. "Geometry Constrained N-(5,6,7-Trihydroquinolin-8-ylidene)arylaminopalladium Dichloride Complexes: Catalytic Behavior toward Methyl Acrylate (MA), Methyl Acrylate-co-Norbornene (MA-co-NB) Polymerization and Heck Coupling" Molecules 21, no. 12: 1686. https://doi.org/10.3390/molecules21121686

APA StyleZeng, Y., Mahmood, Q., Liang, T., & Sun, W. -H. (2016). Geometry Constrained N-(5,6,7-Trihydroquinolin-8-ylidene)arylaminopalladium Dichloride Complexes: Catalytic Behavior toward Methyl Acrylate (MA), Methyl Acrylate-co-Norbornene (MA-co-NB) Polymerization and Heck Coupling. Molecules, 21(12), 1686. https://doi.org/10.3390/molecules21121686