On-Demand Microwave-Assisted Fabrication of Gelatin Foams

Abstract

:1. Introduction

2. Results

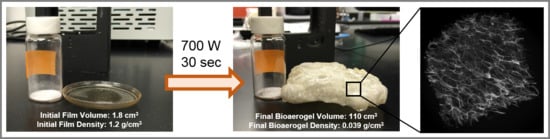

2.1. Gelatin Foam and Pore Morphology

2.2. Helical Structure of Gelatin Powder, Films, and Foam Structures

2.3. Water Content Analysis

2.3.1. Thermogravimetric Analysis

2.3.2. Differential Scanning Calorimetry

3. Discussion

4. Materials and Methods

4.1. Gelatin Film Preparation

4.2. Foam Fabrication

4.3. X-ray Diffraction

4.4. Thermogravimetric Analysis

4.5. Differential Scanning Calorimetry

4.6. Thermal Imaging

4.7. Density and Porosity Measurements of Foams

4.8. Characterization of Foam Morphology

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hegge, A.B.; Anderson, T.; Melvik, J.E.; Kristensen, S.; Tønnesen, H.H. Evaluation of Novel Algniate Foams as Drug Delivery Systems in Antimicrobial Photodynamic Therapy (aPDT) of Infected Wounds—An In Vitro Study: Studies on Curcumin and Curcuminoides XL. J. Pharm. Sci. 2010, 99, 3499–3513. [Google Scholar] [CrossRef] [PubMed]

- Thompson, C.R.; Marin, P.; Díez, F.V.; Ordóñez, S. Evaluation of the use of ceramic foams as catalyst supports for reverse-flow combustors. Chem. Eng. J. 2013, 221, 44–54. [Google Scholar] [CrossRef]

- Yang, Y.; Deng, Y.; Tong, Z.; Wang, C. Multifunctional foams derived from poly(melamine formaldehyde) as recyclable oil absorbents. J. Mater. Chem. A 2014, 2, 9994–9999. [Google Scholar] [CrossRef]

- Basso, M.C.; Li, X.; Fierro, V.; Pizzi, A.; Giovando, S.; Celzard, A. Green, formaldehyde-free, foams for thermal insulation. Adv. Mater. Lett. 2011, 2, 378–382. [Google Scholar] [CrossRef]

- Hu, W.; Chen, R.; Xie, W.; Zou, L.; Qin, N.; Bao, D. CoNi2S4 Nanosheet Arrays Supported on Nickel Foams with Ultrahigh Capacitance for Aqueous Asymmetric Supercapacitor Applications. ACS Appl. Mater. Interfaces 2014, 6, 19318–19326. [Google Scholar] [CrossRef] [PubMed]

- Nieh, T.G.; Higashi, K.; Wadsworth, J. Effect of cell morphology on the compressive properties of open-cell aluminum foams. Mater. Sci. Eng. A 2000, 283, 105–110. [Google Scholar] [CrossRef]

- Han, X.; Zeng, C.; Lee, L.J.; Koelling, K.W.; Tomasko, D.L. Extrusion of polystyrene nanocomposite foams with supercritical CO2. Polym. Eng. Sci. 2003, 43, 1261–1275. [Google Scholar] [CrossRef]

- Kuhn, J.; Ebert, H.P.; Arduini-Schuster, M.C.; Büttner, D.; Fricke, J. Thermal transport in polystyrene and polyurethane foam insulations. Int. J. Heat Mass Transf. 1992, 35, 1795–1801. [Google Scholar] [CrossRef]

- Hanssen, A.G.; Enstock, L.; Langseth, M. Close-range blast loading of aluminum foam panels. Int. J. Impact Eng. 2002, 27, 593–618. [Google Scholar] [CrossRef]

- Blaker, J.J.; Maquet, V.; Jérôme, R.; Boccaccini, A.R.; Nazhat, S.N. Mechanical properties of highly porous PDLLA/Bioglass® composite foams as scaffolds for bone tissue engineering. Acta Biomater. 2005, 1, 643–652. [Google Scholar] [CrossRef] [PubMed]

- Sepulveda, P.; Ortega, F.S.; Innocentini, M.D.M.; Pandolfelli, V.C. Properties of Highly Porous Hydroxyapatite Obtained by the Gelcasting of Foams. J. Am. Ceram. Soc. 2004, 83, 3021–3024. [Google Scholar] [CrossRef]

- Jiang, B.; He, C.; Zhao, N.; Nash, P.; Shi, C.; Wang, Z. Ultralight metal foams. Sci. Rep. 2015, 5, 13825. [Google Scholar] [CrossRef] [PubMed]

- Sehaqui, H.; Salajková, M.; Zhou, Q.; Berglund, L.A. Mechanical performance tailoring of tough ultra-high porosity foams prepared from cellulose I nanofiber suspensions. Soft Matter 2010, 8, 1824–1832. [Google Scholar] [CrossRef]

- Dash, R.; Li, Y.; Ragauskas, A.J. Cellulose nanowhisker foams by freeze casting. Carbohydr. Polym. 2012, 88, 789–792. [Google Scholar] [CrossRef]

- Vincent, T.; Dumarzert, L.; Dufourg, L.; Cucherat, C.; Sonnier, R.; Guibal, E. New alginate foams: Box-Behnken design of their manufacturing; fire retardant and thermal insulating properties. J. Appl. Polym. Sci. 2017, 135, 45868. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Y.; Sánchez-Soto, M.; Schiraldi, D.A. Low flammability, foam-like materials based on ammonium alginate and sodium montmorillonite clay. Polymer 2012, 53, 5825–5831. [Google Scholar] [CrossRef]

- Panzavolta, S.; Torricelli, P.; Casolari, S.; Parrilli, A.; Amadori, S.; Fini, M.; Bigi, A. Gelatin Porous Scaffolds as Delivery Systems of Calcium Alendronate. Macromol. Biosci. 2017, 17, 1600272. [Google Scholar] [CrossRef] [PubMed]

- Amadori, S.; Torricelli, P.; Panzavolta, S.; Parrilli, A.; Fini, M.; Bigi, A. Highly Porous Gelatin Reinforced 3D Scaffolds for Articular Cartilage Regeneration. Macromol. Biosci. 2015, 15, 941–952. [Google Scholar] [CrossRef] [PubMed]

- Salgado, P.R.; Schmidt, V.C.; Molina Ortiz, S.E.; Mauri, A.N.; Laurindo, J.B. Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. J. Food Eng. 2008, 85, 435–443. [Google Scholar] [CrossRef]

- Wang, H.J.; Rong, M.Z.; Zhang, M.Q.; Hu, J.; Chen, H.W.; Czigány, T. Biodegradable Foam Plastics Based on Castor Oil. Biomacromolecules 2008, 9, 615–623. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C. Preparation of bio-based rigid polyurethane foam using hydrolytically depolymerized Kraft lignin via direct replacement or oxypropylation. Eur. Polym. J. 2015, 68, 1–9. [Google Scholar] [CrossRef]

- Frazier, S.D.; Srubar, W.V. Evaporation-based method for preparing gelatin foams with aligned tubular pore structures. Mater. Sci. Eng. C 2016, 62, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Etxabide, A.; Uranga, J.; Guerrero, P.; de la Caba, K. Development of active gelatin films by means of valorisation of food processing waste: A review. Food Hydrocoll. 2017, 68, 192–198. [Google Scholar] [CrossRef]

- García-González, C.A.; Jin, M.; Gerth, J.; Alvarez-Lorenzo, C.; Smirnova, I. Polysaccharide-based aerogel microspheres for oral drug delivery. Carbohydr. Polym. 2015, 117, 797–806. [Google Scholar] [CrossRef] [PubMed]

- Su, K.; Wang, C. Recent advances in the use of gelatin in biomedical research. Biotechnol. Lett. 2015, 37, 2139–2145. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Guillén, M.C.; Pérez-Mateos, M.; Gómez-Estaca, J.; López-Caballero, E.; Giménez, B.; Montero, P. Fish gelatin: A renewable material for developing active biodegradable films. Trends Food Sci. Technol. 2009, 20, 3–16. [Google Scholar] [CrossRef] [Green Version]

- Hafidz, R.; Yaakob, C. Chemical and functional properties of bovine and porcine skin gelatin. Int. Food Res. J. 2011, 817, 813–817. [Google Scholar]

- Gioffrè, M.; Torricelli, P.; Panzavolta, S.; Rubini, K.; Bigi, A. Role of pH on stability and mechanical properties of gelatin films. J. Bioact. Compat. Polym. 2012, 27, 67–77. [Google Scholar] [CrossRef]

- Zhang, F.; He, C.; Cao, L.; Feng, W.; Wang, H.; Mo, X.; Wang, J. Fabrication of gelatin-hyaluronic acid hybrid scaffolds with tunable porous structures for soft tissue engineering. Int. J. Biol. Macromol. 2011, 48, 474–481. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Tabata, Y.; Ikada, Y. Fabrication of porous gelatin scaffolds for tissue engineering. Biomaterials 1999, 20, 1339–1344. [Google Scholar] [CrossRef]

- Ren, L.; Tsuru, K.; Hayakawa, S.; Osaka, A. Novel approach to fabricate porous gelatin-siloxane hybrids for bone tissue engineering. Biomaterials 2002, 23, 4765–4773. [Google Scholar] [CrossRef]

- Islam, M.M.; Khan, M.A.; Rahman, M.M. Preparation of gelatin based porous biocomposite for bone tissue engineering and evaluation of gamma irradiation effect on its properties. Mater. Sci. Eng. C 2015, 49, 648–655. [Google Scholar] [CrossRef] [PubMed]

- Gentile, P.; Mattioli-Belmonte, M.; Chiono, V.; Ferretti, C.; Baino, F.; Tonda-Turo, C.; Vitale-Brovarone, C.; Pashkuleva, I.; Reis, R.L.; Ciardelli, G. Bioactive glass polymer composite scaffolds mimicking bone tissue. J. Biomed. Mater. Res. A. 2012, 100, 2654–2667. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Wang, H.; He, B.; Chen, J. A preliminary in vitro study on the fabrication and tissue engineering applications of a novel chitosan bilayer material as a scaffold of human neofetal dermal fibroblasts. Biomaterials 2001, 22, 331–336. [Google Scholar] [CrossRef]

- Nazarov, R.; Jin, H.; Kaplan, D.L. Porous 3-D scaffolds from regenerated silk fibroin. Biomacromolecules 2004, 5, 718–726. [Google Scholar] [CrossRef] [PubMed]

- Poursamar, S.A.; Hatami, J.; Lehner, A.N.; Silva, C.L.; Ferreira, F.C.; Antunes, A.P.M. Gelatin porous scaffolds fabricated using a modified gas foaming technique: Characterisation and cytotoxicity assessment. Mater. Sci. Eng. C 2015, 48, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ma, P.X. Phase separation, pore structure, and properties of nanofibrous gelatin scaffolds. Biomaterials 2009, 30, 4094–4103. [Google Scholar] [CrossRef] [PubMed]

- Powell, H.M.; Boyce, S.T. Fiber density of electrospun gelatin scaffolds regulates morphogenesis of dermal-epidermal skin substitutes. J. Biomed. Mater. Res. A 2008, 84, 1078–1086. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Teoh, J.E.M.; Suntornnond, R.; Chua, C.K. Design and 3D Printing of Scaffolds and Tissues. Engineering 2015, 1, 261–268. [Google Scholar] [CrossRef]

- Yakimets, I.; Wellner, N.; Smith, A.C.; Wilson, R.H.; Farhat, I.; Mitchell, J. Mechanical properties with respect to water content of gelatin films in glassy state. Polymer 2005, 46, 12577–12585. [Google Scholar] [CrossRef]

- Bigi, A.; Panzavolta, S.; Rubini, K. Relationship between triple-helix content and mechanical properties of gelatin films. Biomaterials 2004, 25, 5675–5680. [Google Scholar] [CrossRef] [PubMed]

- Peña, C.; de la Caba, K.; Eceiza, A.; Ruseckaite, R.; Mondragon, I. Enhancing water repellence and mechanical properties of gelatin films by tannin addition. Bioresour. Technol. 2010, 101, 6836–6842. [Google Scholar] [CrossRef] [PubMed]

- Schiraldi, D.A. Green Polymer Aerogels. In Green Polymer Chemistry: Biobased Materials and Biocatalysis; Gross, R.A., Cheng, H.N., Smith, P.B., Eds.; American Chemical Society: Washington, DC, USA, 2015; Volume 1192, pp. 471–482. ISBN 9780841230651. [Google Scholar]

- Barreto, P.L.M.; Pires, A.T.N.; Soldi, V. Thermal degradation of edible films based on milk proteins and gelatin in inert atmosphere. Polym. Degrad. Stab. 2003, 79, 147–152. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Saidi, G.; Guizani, N.; Abdullah, A. Development of state diagram of bovine gelatin by measuring thermal characteristics using differential scanning calorimetry (DSC) and cooling curve method. Thermochim. Acta 2010, 509, 111–119. [Google Scholar] [CrossRef]

- Dorr, D.N.; Frazier, S.D.; Hess, K.M.; Traeger, L.S.; Srubar, W.V., III. Bond strength of biodegradable gelatin-based wood adhesives. J. Renew. Mater. 2015, 3, 195–204. [Google Scholar] [CrossRef]

- Gomez-Guillen, M.C.; Gimenez, B.; Lopez-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef] [Green Version]

- Tseretely, G.I.; Smirnova, O.I. DSC study of melting and glass transition in gelatins. J. Therm. Anal. 1992, 38, 1189–1201. [Google Scholar] [CrossRef]

- Djabourov, M.; Leblond, J.; Papon, P.; Djabourov, M.; Leblond, J.; Papon, P. Gelation of aqueous gelatin solutions. I. Structural investigation. J. Phys. 1988, 49, 319–332. [Google Scholar] [CrossRef]

- Panzavolta, S.; Gioffrè, M.; Focarete, M.L.; Gualandi, C.; Foroni, L.; Bigi, A. Electrospun gelatin nanofibers: Optimization of genipin cross-linking to preserve fiber morphology after exposure to water. Acta Biomater. 2011, 7, 1702–1709. [Google Scholar] [CrossRef] [PubMed]

- Okuyama, K. Revisiting the molecular structure of collagen. Connect. Tissue Res. 2008, 49, 299–310. [Google Scholar] [CrossRef] [PubMed]

- Apostolov, A.A.; Fakirov, S.; Vassileva, E.; Patil, R.D.; Mark, J.E. DSC and TGA studies of the behavior of water in native and crosslinked gelatin. J. Appl. Polym. Sci. 1999, 71, 465–470. [Google Scholar] [CrossRef]

- Vollmer, M. Physics of the microwave oven. Phys. Educ. 2003, 39, 74–81. [Google Scholar] [CrossRef]

- Zhou, J.; Song, J.; Parker, R. Structure and properties of starch-based foams prepared by microwave heating from extruded pellets. Carbohydr. Polym. 2006, 63, 466–475. [Google Scholar] [CrossRef]

- Lopez-Gil, A.; Silva-Bellucci, F.; Velasco, D.; Ardanuy, M.; Rodriguez-Perez, M.A. Cellular structure and mechanical properties of starch-based foamed blocks reinforced with natural fibers and produced by microwave heating. Ind. Crops Prod. 2015, 66, 194–205. [Google Scholar] [CrossRef]

- Torres, F.G.; Boccaccini, A.R.; Troncoso, O.P. Microwave Processing of Starch-Based Porous Structures for Tissue Engineering Scaffolds. J. Appl. Polym. Sci. 2006, 103, 1332–1339. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Y.; Wen, P.; Zhang, Y.; Long, Y.; Wang, X.; Guo, Y.; Xing, F.; Gao, J. Preparation of aligned porous gelatin scaffolds by unidirectional freeze-drying method. Acta Biomater. 2010, 6, 1167–1177. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Not available. |

| Property | Value |

|---|---|

| Density (g/cm3) | 0.039–0.056 |

| Average porosity (%) | 95 ± 1 |

| Pore size perpendicular to skin (μm) | 1337 ± 260 |

| Pore size parallel to skin (μm) | 1037 ± 289 |

| Skin thickness (μm) | 14 ± 8 |

| Edge thickness (μm) | 10 ± 5 |

| Sample | Average Enthalpy (J/g) of Loosely Bound Water | Average Peak Temperature (°C) of Loosely Bound Water | Average Onset Temperature (°C) of Tightly Bound Water |

|---|---|---|---|

| PG powder | 11.90 | 118.2 | 151.2 |

| PG film | 34.83 | 104.3 | 147.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frazier, S.D.; Aday, A.N.; Srubar, W.V., III. On-Demand Microwave-Assisted Fabrication of Gelatin Foams. Molecules 2018, 23, 1121. https://doi.org/10.3390/molecules23051121

Frazier SD, Aday AN, Srubar WV III. On-Demand Microwave-Assisted Fabrication of Gelatin Foams. Molecules. 2018; 23(5):1121. https://doi.org/10.3390/molecules23051121

Chicago/Turabian StyleFrazier, Shane D., Anastasia N. Aday, and Wil V. Srubar, III. 2018. "On-Demand Microwave-Assisted Fabrication of Gelatin Foams" Molecules 23, no. 5: 1121. https://doi.org/10.3390/molecules23051121

APA StyleFrazier, S. D., Aday, A. N., & Srubar, W. V., III. (2018). On-Demand Microwave-Assisted Fabrication of Gelatin Foams. Molecules, 23(5), 1121. https://doi.org/10.3390/molecules23051121