Solution/Ammonolysis Syntheses of Unsupported and Silica-Supported Copper(I) Nitride Nanostructures from Oxidic Precursors

Abstract

:1. Introduction

2. Results and Discussion

2.1. Synthesis and Ammonolysis Reactions

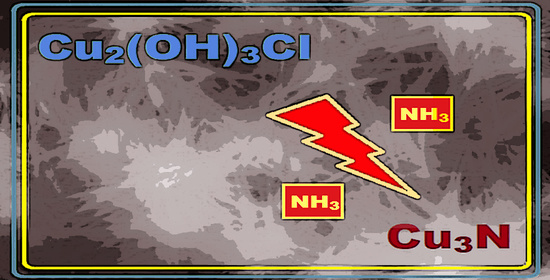

2.2. Characterization and Ammonolysis Reaction of Copper(II) Hydroxide Chloride Nanoparticles

2.3. Characterization and Ammonolysis Reaction of Copper(II) Oxide and Copper(II) Hydroxide Nanoparticles

2.4. Synthesis of Cu3N/SiO2 Composites

3. Materials and Methods

3.1. Starting Materials

3.2. Materials Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Ścigała, A.; Szłyk, E.; Dobrzańska, L.; Gregory, D.H.; Szczęsny, R. From binary to multinary copper based nitrides–Unlocking the potential of new applications. Coord. Chem. Rev. 2021, 436, 213791. [Google Scholar] [CrossRef]

- Reichert, M.D.; White, M.A.; Thompson, M.J.; Miller, G.J.; Vela, J. Preparation and instability of nanocrystalline cuprous nitride. Inorg. Chem. 2015, 54, 6356–6362. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Szczęsny, R.; Szłyk, E.; Wiśniewski, M.; Hoang, T.K.A.; Gregory, D.H. Facile preparation of copper nitride powders and nanostructured films. J. Mater. Chem. C 2016, 4, 5031–5037. [Google Scholar] [CrossRef] [Green Version]

- Ji, Z.; Zhang, Y.; Yuan, Y.; Wang, C. Reactive DC magnetron deposition of copper nitride films for write-once optical recording. Mater. Lett. 2006, 60, 3758–3760. [Google Scholar] [CrossRef]

- Cremer, R.; Witthaut, M.; Neuschütz, D.; Trappe, C.; Laurenzis, M.; Winkler, O.; Kurz, H. Deposition and Characterization of Metastable Cu3N Layers for Applications in Optical Data Storage. Mikrochim. Acta 2000, 133, 299–302. [Google Scholar] [CrossRef]

- Cui, X.Y.; Soon, A.; Phillips, A.E.; Zheng, R.K.; Liu, Z.W.; Delley, B.; Ringer, S.P.; Stampil, C. First principles study of 3d transition metal doped Cu3N. J. Magn. Magn. Mater. 2012, 324, 3138–3143. [Google Scholar] [CrossRef]

- Yue, G.H.; Yan, P.X.; Liu, J.Z.; Wang, M.X.; Li, M.; Yuan, X.M. Copper nitride thin film prepared by reactive radio-frequency magnetron sputtering. J. Appl. Phys. 2005, 98, 103506. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, J.; Yang, T.; Zhang, J.; Yang, J.; Li, X. Enhanced write-once optical storage capacity of Cu3N film by coupling with an Al2O3 protective layer. Ceram. Int. 2016, 42, 4486–4490. [Google Scholar] [CrossRef]

- Hirjibehedin, C.F.; Lutz, C.P.; Heinrich, A.J. Spin coupling in engineered atomic structures. Science 2006, 312, 1021–1024. [Google Scholar] [CrossRef]

- Navio, C.; Alvarez, J.; Capitan, M.J.; Camarero, J.; Miranda, R. Thermal stability of Cu and Fe nitrides and their applications for writing locally spin valves. Appl. Phys. Lett. 2009, 94, 263112. [Google Scholar] [CrossRef] [Green Version]

- Pereira, N.; Dupont, L.; Tarascon, J.M.; Klein, L.C.; Amatucci, G.G. Electrochemistry of Cu3 N with lithium: A complex system with parallel processes. J. Electrochem. Soc. 2003, 150, A1273–A1280. [Google Scholar] [CrossRef]

- Xianji, L.; Hector, A.L.; Owen, J.R. Evaluation of Cu3N and CuO as negative electrode materials for sodium batteries. J. Phys. Chem. C 2014, 118, 29568–29573. [Google Scholar]

- Chen, W.; Zhang, H.; Yang, B.; Li, B.; Li, Z. Characterization of Cu3N/CuO thin films derived from annealed Cu3N for electrode application in Li-ion batteries. Thin Solid Films 2019, 672, 157–164. [Google Scholar] [CrossRef]

- Lee, D.; Sun, S.; Kwon, J.; Park, H.; Jang, M.; Park, E.; Son, B.; Jung, Y.; Song, T.; Paik, U. Copper nitride nanowires printed Li with stable cycling for Li metal batteries in carbonate electrolytes. Adv. Mater. 2020, 32, 1905573. [Google Scholar] [CrossRef]

- Xi, P.; Xu, Z.; Gao, D.; Chen, F.; Xue, D.; Tao, C.-L.; Chen, Z.-N. Solvothermal synthesis of magnetic copper nitride nanocubes with highly electrocatalytic reduction properties. RSC Adv. 2014, 4, 14206–14209. [Google Scholar] [CrossRef]

- Su, C.-Y.; Liu, B.-H.; Lin, T.-J.; Chi, Y.-M.; Kei, C.-C.; Wang, K.-W.; Perng, T.-P. Carbon nanotube-supported Cu3N nanocrystals as a highly active catalyst for oxygen reduction reaction. Mater. Chem. A 2015, 3, 18983–18990. [Google Scholar] [CrossRef]

- Yin, Z.; Yu, C.; Zhao, Z.; Guo, X.; Shen, M.; Li, N.; Muzzio, M.; Li, J.; Liu, H.; Lin, H.; et al. Cu3N Nanocubes for Selective Electrochemical Reduction of CO2 to Ethylene. Nano Lett. 2019, 19, 8658–8663. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Zhang, Z.; Zhao, X.; Xiao, J.; Manoj, D.; Wei, F.; Xiao, F.; Wang, H.; Wang, S. MOF-derived copper nitride/phosphide heterostructure coated by multi-doped carbon as electrocatalyst for efficient water splitting and neutral-pH hydrogen evolution reaction. ChemElectroChem 2020, 7, 289–298. [Google Scholar] [CrossRef]

- Liang, Z.-Q.; Zhuang, T.-T.; Seifitokaldani, A.; Li, J.; Huang, C.-W.; Tan, C.-S.; Li, Y.; De Luna, P.; Dinh, C.T.; Hu, Y.; et al. Copper-on-nitride enhances the stable electrosynthesis of multi-carbon products from CO2. Nat. Commun. 2018, 9, 3828. [Google Scholar] [CrossRef]

- Nosaka, T.; Yoshitakea, M.; Okamoto, A.; Ogawa, S.; Nakayama, Y. Thermal decomposition of copper nitride thin films and dots formation by electron beam writing. Appl. Surf. Sci. 2001, 169–170, 358–361. [Google Scholar] [CrossRef]

- Maruyama, T.; Morishita, T. Copper nitride and tin nitride thin films for write-once optical recording media. Appl. Phys. Lett. 1996, 69, 890–891. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Liu, Z.; Zuo, A.; Yuan, Z.; Yang, J.; Yao, K. Properties of Al-doped copper nitride films prepared by reactive magnetron sputtering. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2007, 22, 446–449. [Google Scholar] [CrossRef]

- Borsa, D.M.; Grachev, S.; Presura, C.; Boerma, D.O. Growth and properties of Cu3N films and Cu3N/γ′-Fe4N bilayers. Appl. Phys. Lett. 2002, 80, 1823–1825. [Google Scholar] [CrossRef] [Green Version]

- Du, Y.; Yin, Y.; Wang, J.; Wang, Z.; Li, C.; Baunack, S.; Ma, L.; Schmidt, O.G. Nanoporous copper pattern fabricated by electron beam irradiation on Cu3N film for SERS application. Phys. Status Solidi B 2019, 256, 1800378. [Google Scholar] [CrossRef]

- Pierson, J.F.; Horwat, D. Addition of silver in copper nitride films deposited by reactive magnetron sputtering. Script. Mater. 2008, 58, 568–570. [Google Scholar] [CrossRef]

- Hahn, U.; Weber, W. Electronic structure and chemical-bonding mechanism of Cu3N, Cui3NPd, and related Cu(I) compounds. Phys. Rev. B 1996, 53, 12684–12693. [Google Scholar] [CrossRef]

- Ding, J.-N.; Yuan, N.-Y.; Li, F.; Ding, G.-Q.; Chen, Z.G.; Chen, X.S.; Lu, W. Geometry and stability of CunN (n=1–6), and CunN (n=1–5) clusters. J. Chem. Phys. 2009, 131, 174102. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.Q.; Wang, W.J.; Wang, T.M.; Chao, S.; Zheng, S.K. Thermal stability of copper nitride films prepared by rf magnetron sputtering. Thin Solid Films 1998, 325, 55–59. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.T.; Yuan, X.M.; Wu, Z.G.; Miao, B.B.; Yan, P.X. Copper nitride (Cu3N) thin films deposited by RF magnetron sputtering. J. Cryst. Growth 2006, 286, 407–412. [Google Scholar] [CrossRef]

- Wilczopolska, M.; Nowakowska-Langier, K.; Okrasa, S.; Skowronski, L.; Minikayev, R.; Strzelecki, G.W.; Chodun, R.; Zdunek, K. Synthesis of copper nitride layers by the pulsed magnetron sputtering method carried out under various operating conditions. Materials 2021, 14, 2694. [Google Scholar] [CrossRef]

- Soto, G.; Díaz, J.A.; de la Cruz, W. Copper nitride films produced by reactive pulsed laser deposition. Mater. Lett. 2003, 57, 4130–4133. [Google Scholar] [CrossRef]

- Gallardo-Vega, C.; de la Cruz, W. Study of the structure and electrical properties of the copper nitride thin films deposited by pulsed laser deposition. Appl. Surf. Sci. 2006, 252, 8001–8004. [Google Scholar] [CrossRef]

- Juza, R.; Hahn, H. Antisomorphie von Cu3N mit ReO3. Z. Anorg. Allg. Chem. 1939, 241, 172–178. [Google Scholar] [CrossRef]

- Paniconi, G.; Stoeva, Z.; Doberstein, H.; Smith, R.I.; Gallagher, B.L.; Gregory, D.H. Structural chemistry of Cu3N powders obtained by ammonolysis reactions. Sol. State Sci. 2007, 9, 907–913. [Google Scholar] [CrossRef]

- Zachwieja, U.; Jacobs, H. Ammonothermalsynthese von kupfernitrid, Cu3N. J. Less-Common Met. 1990, 161, 175–184. [Google Scholar] [CrossRef]

- Scigala, A.; Szłyk, E.; Rerek, T.; Wiśniewski, M.; Skowronski, L.; Trzcinski, M.; Szczesny, R. Copper nitride nanowire arrays—comparison of synthetic approaches. Materials 2021, 14, 603. [Google Scholar] [CrossRef]

- Sithole, R.K.; Machogo, L.F.E.; Moloto, M.J.; Gqoba, S.S.; Mubiayi, K.P.; Van Wyk, J.; Moloto, N. One-step synthesis of Cu3N, Cu2S and Cu9S5 and photocatalytic degradation of methyl orange and methylene blue. J. Photochem. Photobiol. A Chem. 2020, 397, 112577. [Google Scholar] [CrossRef]

- Choi, J.; Gillan, E.G. Solvothermal synthesis of nanocrystalline copper nitride from an energetically unstable copper azide precursor. Inorg. Chem. 2005, 44, 7385–7393. [Google Scholar] [CrossRef]

- Wu, H.; Chen, W. Copper nitride nanocubes: Size-controlled synthesis and application as cathode catalyst in alkaline fuel cells. J. Am. Chem. Soc. 2011, 133, 15236–15239. [Google Scholar] [CrossRef] [PubMed]

- Kadzutu-Sithole, R.; Machogo-Phao, L.F.E.; Kolokoto, T.; Zimuwandeyi, M.; Gqoba, S.S.; Mubiayi, K.P.; Moloto, M.J.; Van Wyk, J.; Moloto, N. Elucidating the effect of precursor decomposition time on the structural and optical properties of copper(I) nitride nanocubes. RSC Adv. 2020, 10, 34231–34246. [Google Scholar] [CrossRef]

- Barman, D.; Paul, S.; Ghosh, S.; De, S.K. Cu3N nanocrystals decorated with Au nanoparticles for photocatalytic degradation of organic dyes. ACS Appl. Nano Mater. 2019, 2, 5009–5019. [Google Scholar] [CrossRef]

- Nakamura, T.; Hayashi, H.; Hanaoka, T.; Ebina, T. Preparation of copper nitride (Cu3N) nanoparticles in long-chain alcohols at 130–200 °C and nitridation mechanism. Inorg. Chem. 2014, 53, 710–715. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh, R.; Zeng, G.; Tervoort, E.; Staniuk, M.; Wood, D.; Niederberger, M. Ultrasmall Cu3N nanoparticles: Surfactant-Free solution-phase synthesis, nitridation mechanism, and application for lithium storage. Chem. Mater. 2015, 27, 8282–8288. [Google Scholar] [CrossRef]

- Mondal, S.; Raj, C.R. Copper nitride nanostructure for the electrocatalytic reduction of oxygen: Kinetics and reaction pathway. J. Phys. Chem. C 2018, 122, 18468–18475. [Google Scholar] [CrossRef]

- Nakamura, T.; Hayashi, H.; Ebina, T. Preparation of copper nitride nanoparticles using urea as a nitrogen source in a long-chain alcohol. J. Nanoparticle Res. 2014, 16, 2699. [Google Scholar] [CrossRef]

- Marinho, J.Z.; Romeiro, F.C.; Lemos, S.C.S.; Motta, F.V.; Riccardi, C.S.; Li, M.S.; Longo, E.; Lima, R.C. Urea-based synthesis of zinc oxide nanostructures at low temperature. J. Nanomater. 2012, 2012, 427172. [Google Scholar] [CrossRef]

- Sreekanth, T.V.M.; Nagajyothi, P.C.; Reddy, G.R.; Shim, J.; Yoo, K. Urea assisted ceria nanocubes for efficient removal of malachite green organic dye from aqueous system. Sci. Rep. 2019, 9, 14477. [Google Scholar] [CrossRef] [Green Version]

- Hai, C.; Li, S.; Zhou, Y.; Zeng, J.; Ren, X.; Li, X. Roles of ethylene glycol solvent and polymers in preparing uniformly distributed MgO nanoparticles. J. Asian Ceram. Soc. 2017, 5, 176–182. [Google Scholar] [CrossRef] [Green Version]

- Gokulakrishnan, N.; Parmentier, J.; Trzpit, M.; Vonna, L.; Paillaud, J.-L.; Soulard, M. Intrusion/extrusion of water into organic grafted SBA-15 silica materials for energy storage. J. Nanosci. Nanotechnol. 2013, 13, 2847–2852. [Google Scholar] [CrossRef]

- Capel-Sanchez, M.C.; Barrio, L.; Campos-Martin, J.M.; Fierro, J.L.G. Silylation and surface properties of chemically grafted hydrophobic silica. J. Colloid Interface Sci. 2004, 277, 146–153. [Google Scholar] [CrossRef]

- Belyakova, L.A.; Varvarin, A.M. Surfaces properties of silica gels modified with hydrophobic groups. Colloids Surf. A Physicochem. Eng. Asp. 1999, 154, 285–294. [Google Scholar] [CrossRef]

- Pollard, A.M.; Thomas, R.G. Synthesis and stabilities of the basic copper(II) chlorides atacamite, paratacamite and botallackite. Mineralog. Mag. 1989, 53, 557–563. [Google Scholar] [CrossRef]

- Lee, S.C.; Park, S.-H.; Lee, S.M.; Lee, J.B.; Kim, H.J. Synthesis and H2 uptake of Cu2(OH)3Cl, Cu(OH)2 and CuO nanocrystal aggregate. Catal. Tod. 2007, 120, 358–362. [Google Scholar] [CrossRef]

- Anthony, J.W.; Bideaux, R.A.; Bladh, K.W.; Nichols, M.C. Handbook of Mineralogy; Mineralogical Society of America: Chantilly, VA, USA; Available online: http://www.handbookofmineralogy.org/ (accessed on 28 June 2021).

- Yang, X.; Zhang, Q.; Gu, W.; Teng, F. Facile self-assembly of uniform Cu2Cl(OH)3 nanoflowers and its photo-Fenton degradation performance for dye wastewater. J. Cryst. Growth 2020, 541, 125681. [Google Scholar] [CrossRef]

- Zhu, C.; Chen, C.; Hao, L.Y.; Hu, Y.; Chen, Z.Y. Template-free synthesis of Cu2Cl(OH)3 nanoribbons and use as sacrificial template for CuO nanoribbon. J. Cryst. Growth 2004, 263, 473–479. [Google Scholar] [CrossRef]

- Jia, W.; Reitz, E.; Sun, H.; Li, B.; Zhang, H.; Lei, Y. From Cu2(OH)3Cl to nanostructured sisal-like Cu(OH)2 and CuO: Synthesis and characterization. J. Appl. Phys. 2009, 105, 064917. [Google Scholar] [CrossRef]

- Margraf, G.; Bats, J.W.; Bolte, M.; Lerner, H.W.; Wagner, M. One- and three-dimensional infinite arrays of Cu(I) ions exhibited by [Cu(NH3)2]Br and [Cu(NH3)Cl] in the solid state. Chem. Commun. 2003, 956–957. [Google Scholar] [CrossRef]

- Kraus, W.; Nolze, G. POWDER CELL–A program for the representation and manipulation of crystal structures and calculation of the resulting X-ray powder patterns. J. Appl. Cryst. 1996, 29, 301–303. [Google Scholar] [CrossRef]

- Patil, K.C.; Secco, E.A. Metal halide ammines. II. thermal analyses, calorimetry and infrared spectra of fluoride ammines and hydrates of bivalent metals. Can. J. Chem. 1972, 50, 567–573. [Google Scholar] [CrossRef] [Green Version]

- Nakamoto, K. Infrared and Raman Spectra of Inorganic and Coordination Compounds. Part B: Applications in Coordination, Organometallic, and Bioinorganic Chemistry, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, H.J. Unidirectionally aligned copper hydroxide crystalline nanorods from two-dimensional copper hydroxy nitrate. J. Am. Chem. Soc. 2004, 126, 14368–14369. [Google Scholar] [CrossRef]

- Engelbrekt, C.; Malcho, P.; Andersen, J.; Zhang, L.; Ståhl, K.; Li, B.; Hu, J.; Zhang, J. Selective synthesis of clinoatacamite Cu2(OH)3Cl and tenorite CuO nanoparticles by pH control. J. Nanopart. Res. 2014, 16, 2562. [Google Scholar] [CrossRef]

- Mahmoud, B.G.; Khairy, M.; Rashwan, F.A.; Foster, C.W.; Banks, C.E. Self-assembly of porous copper oxide hierarchical nanostructures for selective determinations of glucose and ascorbic acid. RSC Adv. 2016, 6, 14474–14482. [Google Scholar] [CrossRef] [Green Version]

- Gregg, S.J.; Sing, K.S.W. Adsorption, Surface Area and Porosity, 2nd ed.; Academic Press: London, UK, 1982; pp. 41–110. [Google Scholar]

- Lee, B.S.; Yi, M.; Chu, S.Y.; Lee, J.Y.; Kwon, H.R.; Lee, K.R.; Kang, D.; Kim, W.S.; Lim, H.B.; Lee, J.; et al. Copper nitridenanoparticles supported on a superparamagnetic mesoporous microsphere for toxic-free click chemistry. Chem. Commun. 2010, 46, 3935–3937. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh, R.; Schubert, U. Synthesis of CuO and Cu3N nanoparticles in and on hollow silica spheres. Eur. J. Inorg. Chem. 2013, 2498–2504. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zervos, M.; Othonos, A.; Sergides, M.; Pavloudis, T.; Kioseoglou, J. Observation of the direct energy band gaps of defect-tolerant Cu3N by ultrafast pump-probe spectroscopy. J. Phys. Chem. C 2020, 124, 3459–3469. [Google Scholar] [CrossRef]

- Li, H.; Ban, L.; Wang, Z.; Meng, P.; Zhang, Y.; Wu, R.; Zhao, Y. Regulation of Cu species in CuO/SiO2 and its structural evolution in ethynylation reaction. Nanomaterials 2019, 9, 842. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Kang, S.W.; Kim, A.; Yusuf, M.; Park, J.C.; Park, K.H. A highly efficient nano-sized Cu2O/SiO2 egg-shell catalyst for C–C coupling reactions. RSC Adv. 2018, 8, 6200–6205. [Google Scholar] [CrossRef] [Green Version]

| Sample No. | Precursor | Temperature/°C | Time/min | Product Phases from PXD (wt%) * |

|---|---|---|---|---|

| 1a | Cu2(OH)3Cl | 240 | 240 | Cu3N (38) > Cu(NH3)Cl (62) |

| 1b | Cu2(OH)3Cl | 300 | 240 | Cu3N > Cu(NH3)Cl |

| 1c | Cu2(OH)3Cl | 330 | 240 | Cu3N (41) > Cu(NH3)Cl (59) |

| 2a | CuO | 280 | 180 | Cu3N (69) > CuO (31) |

| 2b | CuO | 310 | 300 | Cu3N |

| 2c | CuO | 330 | 240 | Cu3N > Cu |

| 3a | Cu(OH)2 | 300 | 240 | Cu3N (77) > CuO (23) |

| 3b | Cu(OH)2 | 310 | 300 | Cu3N |

| 3c | Cu(OH)2 | 330 | 240 | Cu3N > Cu |

| 4 | Cu(OH)2 | 310 | 300 | Cu3N (55)/CuO (33)/Cu (12) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczęsny, R.; Hoang, T.K.A.; Dobrzańska, L.; Gregory, D.H. Solution/Ammonolysis Syntheses of Unsupported and Silica-Supported Copper(I) Nitride Nanostructures from Oxidic Precursors. Molecules 2021, 26, 4926. https://doi.org/10.3390/molecules26164926

Szczęsny R, Hoang TKA, Dobrzańska L, Gregory DH. Solution/Ammonolysis Syntheses of Unsupported and Silica-Supported Copper(I) Nitride Nanostructures from Oxidic Precursors. Molecules. 2021; 26(16):4926. https://doi.org/10.3390/molecules26164926

Chicago/Turabian StyleSzczęsny, Robert, Tuan K. A. Hoang, Liliana Dobrzańska, and Duncan H. Gregory. 2021. "Solution/Ammonolysis Syntheses of Unsupported and Silica-Supported Copper(I) Nitride Nanostructures from Oxidic Precursors" Molecules 26, no. 16: 4926. https://doi.org/10.3390/molecules26164926

APA StyleSzczęsny, R., Hoang, T. K. A., Dobrzańska, L., & Gregory, D. H. (2021). Solution/Ammonolysis Syntheses of Unsupported and Silica-Supported Copper(I) Nitride Nanostructures from Oxidic Precursors. Molecules, 26(16), 4926. https://doi.org/10.3390/molecules26164926