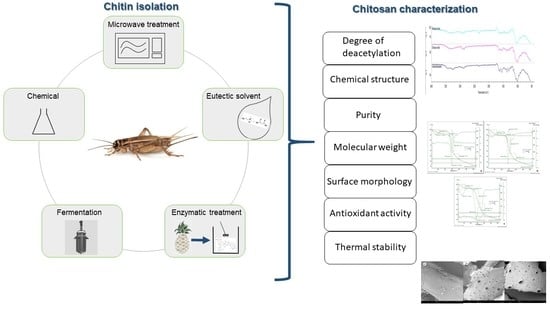

Chitin Isolation and Chitosan Production from House Crickets (Acheta domesticus) by Environmentally Friendly Methods

Abstract

:1. Introduction

2. Results and Discussion

2.1. Evaluation of Methods for Chitin Isolation

2.1.1. Comparison of the %DDM

2.1.2. Evaluation of Chitin Content of Materials Subjected to Different Methods for Deproteinization and Chitin Extraction

2.2. Selection of an Alternative Process for Chitin Isolation

2.3. Characterization of Chitinous Materials and Chitosan

2.3.1. Properties of Chitosan

2.3.2. Characterization of Structure (FTIR)

2.3.3. Thermal Stability (TGA)

2.3.4. Morphology (SEM)

3. Materials and Methods

3.1. Insect Flour and Defatting

3.2. Chitin Isolation and Purification

3.2.1. Deproteinization Processes

Chemical Deproteinization

Papain-Assisted Deproteinization

Bromelain-Assisted Deproteinization

3.2.2. Demineralization Processes

Chemical Demineralization

Microwave-Assisted Demineralization

Citric Acid Demineralization

Lactic Acid Demineralization

3.2.3. Single-Step Chitin Isolation

Fermentation with B. subtilis

Eutectic Solvents

3.2.4. Degree of Demineralization

3.2.5. Determination of Chitin Content

3.3. Chitosan Production and Characterization

3.3.1. Selected Processes for the Isolation of a Chitin-Rich Fraction

3.3.2. Deacetylation of Products

3.3.3. Characterization of Chitin-Rich Fractions

Chitosan Content

Fourier-Transform Infrared Spectrometry (FTIR)

Scanning Electron Microscopy (SEM)

3.3.4. Characterization of the Produced Chitosan Materials

Chitosan Content

Fourier-Transform Infrared Spectrometry (FTIR)

Thermogravimetric Analysis (TGA)

Scanning Electron Microscopy (SEM)

Antioxidant Activity

Determination of Molecular Weight

3.4. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Van Huis, A. Potential of insects as food and feed in assuring food security. Annu. Rev. Entomol. 2013, 58, 563–583. [Google Scholar] [CrossRef] [PubMed]

- Springmann, M.; Clark, M.; Mason-D’Croz, D.; Wiebe, K.; Bodirsky, B.L.; Lassaletta, L.; De Vries, W.; Vermeulen, S.J.; Herrero, M.; Carlson, K.M. Options for keeping the food system within environmental limits. Nature 2018, 562, 519–525. [Google Scholar] [CrossRef] [PubMed]

- van Huis, A.; Oonincx, D.G. The environmental sustainability of insects as food and feed. A review. Agron. Sustain. Dev. 2017, 37, 43. [Google Scholar] [CrossRef] [Green Version]

- Rumpold, B.A.; Schlüter, O.K. Nutritional composition and safety aspects of edible insects. Mol. Nutr. Food Res. 2013, 57, 802–823. [Google Scholar] [CrossRef]

- Finke, M.D. Estimate of chitin in raw whole insects. Zoo Biol. 2007, 26, 105–115. [Google Scholar] [CrossRef] [PubMed]

- Khor, E. Chitin: Fulfilling a Biomaterials Promise; Elsevier: Waltham, MA, USA; Oxford, UK, 2014. [Google Scholar]

- Tang, W.J.; Fernandez, J.G.; Sohn, J.J.; Amemiya, C.T. Chitin is endogenously produced in vertebrates. Curr. Biol. 2015, 25, 897–900. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghorbel-Bellaaj, O.; Younes, I.; Maâlej, H.; Hajji, S.; Nasri, M. Chitin extraction from shrimp shell waste using bacillus bacteria. Int. J. Biol. Macromol. 2012, 51, 1196–1201. [Google Scholar] [CrossRef]

- Younes, I.; Hajji, S.; Frachet, V.; Rinaudo, M.; Jellouli, K.; Nasri, M. Chitin extraction from shrimp shell using enzymatic treatment. Antitumor, antioxidant and antimicrobial activities of chitosan. Int. J. Biol. Macromol. 2014, 69, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Mohan, K.; Ganesan, A.R.; Muralisankar, T.; Jayakumar, R.; Sathishkumar, P.; Uthayakumar, V.; Chandirasekar, R.; Revathi, N. Recent insights into the extraction, characterization, and bioactivities of chitin and chitosan from insects. Trends Food Sci. Technol. 2020, 105, 17–42. [Google Scholar] [CrossRef]

- Kaur, S.; Dhillon, G.S. Recent trends in biological extraction of chitin from marine shell wastes: A review. Crit. Rev. Biotechnol. 2015, 35, 44–61. [Google Scholar] [CrossRef]

- Healy, M.; Green, A.; Healy, A. Bioprocessing of marine crustacean shell waste. Acta Biotechnol. 2003, 23, 151–160. [Google Scholar] [CrossRef]

- Bradić, B.; Novak, U.; Likozar, B. Crustacean shell bio-refining to chitin by natural deep eutectic solvents. Green Processing Synth. 2020, 9, 13–25. [Google Scholar] [CrossRef]

- Ameh, A.O.; Isa, M.T.; Abutu, D.; Danlami, A. Kinetic modelling of the demineralization of shrimp exoskeleton using citric acid. Leonardo Electron. J. Pract. Technol. 2014, 25, 99–108. [Google Scholar]

- Caparros Megido, R.; Haubruge, E.; Francis, F. Small-scale production of crickets and impact on rural livelihoods. In Insects as Food and Feed: From Production to Consumption; FAO: Rome, Italy, 2017. [Google Scholar]

- Belluco, S.; Losasso, C.; Maggioletti, M.; Alonzi, C.C.; Paoletti, M.G.; Ricci, A. Edible insects in a food safety and nutritional perspective: A critical review. Compr. Rev. Food Sci. Food Saf. 2013, 12, 296–313. [Google Scholar] [CrossRef]

- Hirsch, A.; Cho, Y.-H.; Kim, Y.H.B.; Jones, O.G. Contributions of protein and milled chitin extracted from domestic cricket powder to emulsion stabilization. Curr. Res. Food Sci. 2019, 1, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Malm, M.; Liceaga, A.M. Physicochemical properties of chitosan from two commonly reared edible cricket species, and its application as a hypolipidemic and antimicrobial agent. Polysaccharides 2021, 2, 339–353. [Google Scholar] [CrossRef]

- Lidström, P.; Tierney, J.; Watheyb, B.; Westmana, J. Microwave assisted organic synthesis—A review. Tetrahedron 2001, 57, 9225–9283. [Google Scholar] [CrossRef]

- Knidri, H.E.; Dahmani, J.; Addaou, A.; Laajeb, A.; Lahsini, A. Rapid and efficient extraction of chitin and chitosan for scale-up production: Effect of process parameters on deacetylation degree and molecular weight. Int. J. Biol. Macromol. 2019, 139, 1092–1102. [Google Scholar] [CrossRef] [PubMed]

- Aytekin, O.; Elibol, M. Cocultivation of Lactococcus lactis and Teredinobacter turnirae for biological chitin extraction from prawn waste. Bioprocess Biosyst. Eng. 2010, 33, 393–399. [Google Scholar] [CrossRef]

- Udomsil, N.; Imsoonthornruksa, S.; Gosalawit, C.; Ketudat-Cairns, M. Nutritional values and functional properties of house cricket (Acheta domesticus) and field cricket (Gryllus bimaculatus). Food Sci. Technol. Res. 2019, 25, 597–605. [Google Scholar] [CrossRef]

- Nessa, F.; Masum, S.M.; Asaduzzaman, M.; Roy, S.; Hossain, M.; Jahan, M. A process for the preparation of chitin and chitosan from prawn shell waste. Bangladesh J. Sci. Ind. Res. 2010, 45, 323–330. [Google Scholar] [CrossRef] [Green Version]

- da Silva, F.K.P.; Brück, D.W.; Brück, W.M. Isolation of proteolytic bacteria from mealworm (tenebrio molitor) exoskeletons to produce chitinous material. FEMS Microbiol. Lett. 2017, 364, fnx177. [Google Scholar] [CrossRef]

- Zhou, P.; Li, J.; Yan, T.; Wang, X.; Huang, J.; Kuang, Z.; Ye, M.; Pan, M. Selectivity of deproteinization and demineralization using natural deep eutectic solvents for production of insect chitin (hermetia illucens). Carbohydr. Polym. 2019, 225, 115255. [Google Scholar] [CrossRef] [PubMed]

- Lertsutthiwong, P.; How, N.C.; Chandrkrachang, S.; Stevens, W.F. Effect of chemical treatment on the characteristics of shrimp chitosan. J. Met. Mater. Miner. 2002, 12, 11–18. [Google Scholar]

- Kaya, M.; Baran, T.; Asan-Ozusaglam, M.; Cakmak, Y.S.; Tozak, K.O.; Mol, A.; Mentes, A.; Sezen, G. Extraction and characterization of chitin and chitosan with antimicrobial and antioxidant activities from cosmopolitan orthoptera species (insecta). Biotechnol. Bioprocess Eng. 2015, 20, 168–179. [Google Scholar] [CrossRef]

- da Silva Lucas, A.J.; Oreste, E.Q.; Costa, H.L.G.; López, H.M.; Saad, C.D.M.; Prentice, C. Extraction, physicochemical characterization, and morphological properties of chitin and chitosan from cuticles of edible insects. Food Chem. 2021, 343, 128550. [Google Scholar] [CrossRef] [PubMed]

- No, H.K.; Lee, S.H.; Park, N.Y.; Meyers, S.P. Comparison of physicochemical, binding, and antibacterial properties of chitosans prepared without and with deproteinization process. J. Agric. Food Chem. 2003, 51, 7659–7663. [Google Scholar] [CrossRef]

- Roy, J.C.; Salaün, F.; Giraud, S.; Ferri, A.; Chen, G.; Guan, J. Solubility of chitin: Solvents, solution behaviors and their related mechanisms. In Solubility Polysaccharides; IntechOpen: London, UK, 2017. [Google Scholar]

- Wang, S.-L.; Lin, H.-T.; Liang, T.-W.; Chen, Y.-J.; Yen, Y.-H.; Guo, S.-P. Reclamation of chitinous materials by bromelain for the preparation of antitumor and antifungal materials. Bioresour. Technol. 2008, 99, 4386–4393. [Google Scholar] [CrossRef]

- Ibitoye, E.; Lokman, I.; Hezmee, M.; Goh, Y.; Zuki, A.; Jimoh, A. Extraction and physicochemical characterization of chitin and chitosan isolated from house cricket. Biomed. Mater. 2018, 13, 025009. [Google Scholar] [CrossRef] [Green Version]

- Jang, M.K.; Kong, B.G.; Jeong, Y.I.; Lee, C.H.; Nah, J.W. Physicochemical characterization of α-chitin, β-chitin, and γ-chitin separated from natural resources. J. Polym. Sci. Part A: Polym. Chem. 2004, 42, 3423–3432. [Google Scholar] [CrossRef]

- Kasaai, M.R. A review of several reported procedures to determine the degree of n-acetylation for chitin and chitosan using infrared spectroscopy. Carbohydr. Polym. 2008, 71, 497–508. [Google Scholar] [CrossRef]

- Paulino, A.T.; Simionato, J.I.; Garcia, J.C.; Nozaki, J. Characterization of chitosan and chitin produced from silkworm crysalides. Carbohydr. Polym. 2006, 64, 98–103. [Google Scholar] [CrossRef]

- de Britto, D.; Campana-Filho, S.P. Kinetics of the thermal degradation of chitosan. Thermochim. Acta 2007, 465, 73–82. [Google Scholar] [CrossRef]

- Soon, C.Y.; Tee, Y.B.; Tan, C.H.; Rosnita, A.T.; Khalina, A. Extraction and physicochemical characterization of chitin and chitosan from zophobas morio larvae in varying sodium hydroxide concentration. Int. J. Biol. Macromol. 2018, 108, 135–142. [Google Scholar] [CrossRef]

- Kaya, M.; Bitim, B.; Mujtaba, M.; Koyuncu, T. Surface morphology of chitin highly related with the isolated body part of butterfly (argynnis pandora). Int. J. Biol. Macromol. 2015, 81, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Wang, Y.; Han, Q.; Ji, L.; Zhang, H.; Fei, Z.; Wang, Y. Comparison of the physicochemical, rheological, and morphologic properties of chitosan from four insects. Carbohydr. Polym. 2019, 209, 266–275. [Google Scholar] [CrossRef] [PubMed]

- Percot, A.; Viton, C.; Domard, A. Optimization of chitin extraction from shrimp shells. Biomacromolecules 2003, 4, 12–18. [Google Scholar] [CrossRef]

- Gagne, N.; Simpson, B. Use of proteolytic enzymes to facilitate the recovery of chitin from shrimp wastes. Food Biotechnol. 1993, 7, 253–263. [Google Scholar] [CrossRef]

- Rengga, W.D.P.; Salsabiil, K.A.; Oktavia, S.E.; Ansori, M. Flavored powder from shrimp shells with bromelain enzymatic process and adding of flour and spices. J. Phys. Conf. Ser. 2019, 1367, 012080. [Google Scholar] [CrossRef] [Green Version]

- Zamani, A.; Jeihanipour, A.; Edebo, L.; Niklasson, C.; Taherzadeh, M.J. Determination of glucosamine and n-acetyl glucosamine in fungal cell walls. J. Agric. Food Chem. 2008, 56, 8314–8318. [Google Scholar] [CrossRef]

- Tsaih, M.L.; Chen, R.H. The effect of reaction time and temperature during heterogenous alkali deacetylation on degree of deacetylation and molecular weight of resulting chitosan. J. Appl. Polym. Sci. 2003, 88, 2917–2923. [Google Scholar] [CrossRef]

- Brugnerotto, J.; Lizardi, J.; Goycoolea, F.; Argüelles-Monal, W.; Desbrieres, J.; Rinaudo, M. An infrared investigation in relation with chitin and chitosan characterization. Polymer 2001, 42, 3569–3580. [Google Scholar] [CrossRef]

- Hong, P.Z.; Li, S.D.; Ou, C.Y.; Li, C.P.; Yang, L.; Zhang, C.H. Thermogravimetric analysis of chitosan. J. Appl. Polym. Sci. 2007, 105, 547–551. [Google Scholar] [CrossRef]

- Saenz-Mendoza, A.I.; Zamudio-Flores, P.B.; García-Anaya, M.C.; Velasco, C.R.; Acosta-Muñiz, C.H.; de Jesús Ornelas-Paz, J.; Hernández-González, M.; Vargas-Torres, A.; Aguilar-González, M.Á.; Salgado-Delgado, R. Characterization of insect chitosan films from tenebrio molitor and brachystola magna and its comparison with commercial chitosan of different molecular weights. Int. J. Biol. Macromol. 2020, 160, 953–963. [Google Scholar] [CrossRef]

- Roberts, G.A.; Domszy, J.G. Determination of the viscometric constants for chitosan. Int. J. Biol. Macromol. 1982, 4, 374–377. [Google Scholar] [CrossRef]

| Sample | Chitosan Content (mg Chitin Equivalent/100 mg) | Degree of Deacetylation (DD%) | Antioxidant Activity (%) | Molar Mass × 103 (g/Mole) |

|---|---|---|---|---|

| Chitosan 1 | - | 75.1 | 35.00 ± 3.6 a | 471.2 ± 2.5 a |

| Chitosan 2 | 81.9 ± 0.5 a | 66.6 | 59.0 ± 0.6 b | 103.4 ± 2.4 b |

| Chitosan 3 | 88.0 ± 0.1 b | 62.9 | 49.3 ± 5.2 b | 86.8 ± 3.1 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Psarianos, M.; Ojha, S.; Schneider, R.; Schlüter, O.K. Chitin Isolation and Chitosan Production from House Crickets (Acheta domesticus) by Environmentally Friendly Methods. Molecules 2022, 27, 5005. https://doi.org/10.3390/molecules27155005

Psarianos M, Ojha S, Schneider R, Schlüter OK. Chitin Isolation and Chitosan Production from House Crickets (Acheta domesticus) by Environmentally Friendly Methods. Molecules. 2022; 27(15):5005. https://doi.org/10.3390/molecules27155005

Chicago/Turabian StylePsarianos, Marios, Shikha Ojha, Roland Schneider, and Oliver K. Schlüter. 2022. "Chitin Isolation and Chitosan Production from House Crickets (Acheta domesticus) by Environmentally Friendly Methods" Molecules 27, no. 15: 5005. https://doi.org/10.3390/molecules27155005

APA StylePsarianos, M., Ojha, S., Schneider, R., & Schlüter, O. K. (2022). Chitin Isolation and Chitosan Production from House Crickets (Acheta domesticus) by Environmentally Friendly Methods. Molecules, 27(15), 5005. https://doi.org/10.3390/molecules27155005