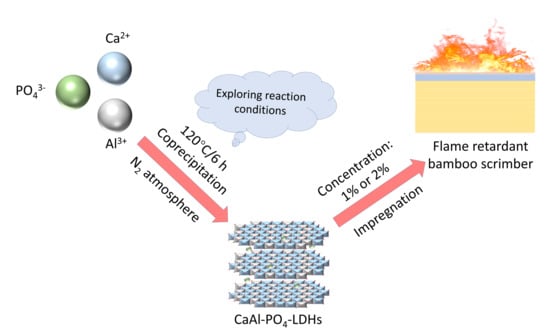

Preparation of PO43−-Intercalated Calcium–Aluminum Hydrotalcites via Coprecipitation Method and Its Flame-Retardant Effect on Bamboo Scrimber

Abstract

:1. Introduction

2. Results and Discussion

2.1. XRD Analysis of CaAl-PO4-LDHs Synthesized via Different Processes

2.2. Effects of Crystallisation Temperature on CaAl-PO4-LDHs

2.3. Effect of the Crystallisation Time on CaAl-PO4-LDHs

2.4. Effect of Different Concentrations of Flame-Retardant CaAl-PO4-LDHs on Bamboo Scrimber

3. Materials and Methods

3.1. Materials

3.2. Preparation of CaAl-PO4-LDHs via Coprecipitation

3.3. CaAl-PO4-LDH Flame-Retardant-Treated Bamboo Scrimber

3.4. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Wang, X.; Zhong, Y.; Luo, X. Compressive failure mechanism of structural bamboo scrimber. Polymers 2021, 13, 4223. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Liu, R.; Wu, H. A comparison of performance of two kinds of waterborne coatings on bamboo and bamboo scrimber. Coatings 2019, 9, 161. [Google Scholar] [CrossRef]

- Pineda, H.; Hu, Y.A.; Semple, K. Computer simulation of the mat formation of bamboo scrimber composites. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106542. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Y.; Zhu, J.; Lin, Y.; Du, H. Experimental investigation of the shear performance of bamboo scrimber beams reinforced with bamboo pins. Constr. Build. Mater. 2023, 365, 130044. [Google Scholar] [CrossRef]

- Huang, Y.; Ji, Y.H.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 25. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, W.; Sun, J. Synergistic effects of modified hydrotalcite on improving the fire resistance of ethylene vinyl acetate containing intumescent flame retardants. Polym. Compos. 2016, 39, 522–528. [Google Scholar] [CrossRef]

- Zhang, H.L.; Jin, L.Z.; Wu, H.J.; Zhang, Z.Y.; Yu, J.X.; Zhang, W.J.; Pan, Y.; Pan, Z.Q. Preparation of a Novel Organic Phosphonic Acid Intercalated Phosphate Tailings Based Hydrotalcite and Its Application in Enhancing Fire Safety for Epoxy Resin. Polymers 2022, 14, 725. [Google Scholar] [CrossRef]

- Gu, X.; Sun, W.; Guo, J. Fabrication of hydrotalcite containing N/P/S and its ternary synergistic efficiency on thermostability and fire resistance of ethylene vinyl acetate (EVA). J. Vinyl Addit. Technol. 2019, 3, 25. [Google Scholar] [CrossRef]

- Zhitova, E.S.; Krivovichev, S.V.; Pekov, I.V. Crystal Chemistry of Chlormagaluminite, Mg4Al2(OH)12Cl2(H2O)2, a Natural Layered Double Hydroxide. Minerals 2019, 9, 221. [Google Scholar] [CrossRef]

- Mills, S.J.; Christy, A.G.; Génin, J.M.R.; Kameda, T.; Colombo, F. Nomenclature of the hydrotalcite supergroup: Natural layered double hydroxides. Mineral. Mag. 2012, 76, 1289–1336. [Google Scholar] [CrossRef]

- Wang, C.Y.; Chen, Y.; Shang, X.P.; Hou, X.J.; Li, H.Q.; Guo, Z.C. Facile synthesis of Ca/Mg/Al/Fe layered double hydroxides using steelmaking slag as raw material. Mater. Lett. 2016, 173, 115–118. [Google Scholar] [CrossRef]

- Hu, A.L.; Du, C.G.; Hua, Y.T. Preparation and Flame Retardant Properties of Calcium–Aluminium Hydrotalcite with Root Cutting Silicate Layers as Bamboo Flame Retardants. Materials 2021, 14, 7319. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Meng, Y. Flame retardant properties of SDBS intercalated hydrotalcite modified epoxy resin. New Build. Mater. 2022, 49, 144–147+155. [Google Scholar]

- Xu, S.; Zhang, M.; Li, S.Y. Intercalation of a novel containing nitrogen and sulfur anion into hydrotalcite and its highly efficient flame retardant performance for polypropylene. Appl. Clay Sci. 2021, 191, 105600. [Google Scholar] [CrossRef]

- Yargici, K.; Nofar, M.; Ghanbari, A. Synergistic Enhancement of Flame Retardancy Behavior of Glass-Fiber Reinforced Polylactide Composites through Using Phosphorus-Based Flame Retardants and Chain Modifiers. Polymers 2022, 14, 5324. [Google Scholar] [CrossRef]

- Qian, X.; Guo, N.; Lu, L. Effect of Phosphorus-Based Flame Retardants and PA6 on the Flame Retardancy and Thermal Degradation of Polypropylene. Polym. Plast. Technol. Eng. 2018, 57, 1567–1575. [Google Scholar] [CrossRef]

- Chu, F.K. Design of Phosphorus-Containing Flame Retardants and Their Performance and Mechanism of Unsaturated Polyester Composites; University of Science and Technology of China: Hefei, China, 2021. [Google Scholar]

- Guérard-Hélaine, C.; Légeret, B.; Fernandes, C. Efficient immobilization of fructose-6-phosphate aldolase in layered double hydroxide: Improved stereoselective synthesis of sugar analogues. New J. Chem. 2011, 35, 776–779. [Google Scholar] [CrossRef]

- Damindarova, V.N.; Tsova, I.G.; Tarasenko, E.A. Tin-Containing Layered Double Hydroxides. Pet. Chem. 2020, 60, 444–450. [Google Scholar] [CrossRef]

- Zhang, X.K. Preparation of Modified Zinc-Aluminum Hydrotalcite and Its Synergistic Expansion of Flame Retardant Polyolefin; Harbin Institute of Technology: Harbin, China, 2015. [Google Scholar]

- Xu, S.; Li, S.Y.; Zhang, M. Effect of P3O105− intercalated hydrotalcite on the flame retardant properties and the degradation mechanism of a novel polypropylene/hydrotalcite system. Appl. Clay Sci. 2018, 163, 196–203. [Google Scholar] [CrossRef]

- Ruan, X.; Chen, Y.; Chen, H.; Qian, G.; Frost, R.L. Sorption behavior of methyl orange from aqueous solution on organic matter and reduced graphene oxides modified Ni–Cr layered double hydroxides. Chem. Eng. 2016, 297, 295–303. [Google Scholar] [CrossRef]

- Lakraimi, M.; Legrouri, A.; Barroug, A.; De, R.A.; Besse, J.P. Preparation of a new stable hybrid material by chloride-2, 4-dichlorophenoxyacetate ion exchange into the zinc-aluminium-chloride layered double hydroxide. Mater. Chem. 2000, 10, 1007–1010. [Google Scholar] [CrossRef]

- Chang, P.; Chang, Y.; Lai, Y.; Chen, S. Characterization and high temperature CO2 capture capacity of nanoscale Ca-based layered double hydroxides via reverse microemulsion. J. Alloy. Compd. 2014, 586, S498–S505. [Google Scholar] [CrossRef]

- Panda, H.S.; Srivastava, R.; Bahadur, D. Stacking of lamellae in Mg/Al hydrotalcites: Effect of metal ion concentrations on morphology. Mater. Res. Bull 2008, 43, 1448–1455. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, F.; Fang, L.; Guan, T.; Hu, J.; Zhang, S. A comparative study and optimization of corrosion resistance of ZnAl layered double hydroxides films intercalated with different anions on AZ31 Mg alloys. Surf. Coat. Technol. 2019, 358, 594–603. [Google Scholar] [CrossRef]

- Li, J.; Zeng, H.; Du, J. Intercalation of organic and inorganic anions into layered double hydroxides for polymer flame retardancy. Appl. Clay Sci. 2020, 187, 105481. [Google Scholar]

- Hua, Y.T. Preparation, Characterization and Flame Retardant Properties of Calcium-Aluminum Hydrotalcite with Silicate Intercalation for Flame Retardant Bamboo Materials; Zhejiang Agriculture and Forestry University: Hangzhou, China, 2020. [Google Scholar]

- Smalenskaite, A.; Salak, A.N.; Kareiva, A. Induced neodymium luminescence in solgel derived layered double hydroxides. Mendeleev Commun. 2018, 28, 493–494. [Google Scholar] [CrossRef]

- Palmer, S.J.; Soisonard, A.; Frost, R.L. Determination of the mechanism(s) for the inclusion of arsenate, vanadate, or molybdate anions into hydrotalcites with variable cationic ratio. J. Colloid Interface Sci. 2009, 329, 404–409. [Google Scholar] [CrossRef]

- Wang, L.; Li, B.; Zhang, X. Effect of intercalated anions on the performance of Ni–Al LDH nanofiller of ethylene vinyl acetate composites. Appl. Clay Sci. 2012, 56, 110–119. [Google Scholar] [CrossRef]

- Zhitova, E.S.; Greenwell, H.C.; Krzhizhanovskaya, M.G.; Apperley, D.C.; Pekov, I.V.; Yakovenchuk, V.N. Thermal Evolution of Natural Layered Double Hydroxides: Insight from Quintinite, Hydrotalcite, Stichtite, and Iowaite as Reference Samples for CO3− and Cl-Members of the Hydrotalcite Supergroup. Minerals 2020, 10, 961. [Google Scholar] [CrossRef]

- Qiu, L.; Gao, Y.; Zhang, C. Synthesis of highly efficient flame retardant polypropylene nanocomposites with surfactant intercalated layered double hydroxides. Dalton Trans. 2017, 10, 1039. [Google Scholar] [CrossRef]

- Du, Y.L.; Xie, X.M.; Wu, X.; Wang, Z.Z. Application of TG-DTA technique in the study of thermal decomposition of hydrotalcite-like compounds. Appl. Chem. 2005, 9, 12–15. [Google Scholar]

- Ansalin, G.S.; Mandal, S.; Prasanna, R. Phosphate intercalated Mg/Al layered double hydroxide nanosheets as a novel flame retardant for leather: Synthesis, characterization, and application studies. Appl. Clay Sci. 2022, 230, 106714. [Google Scholar]

- Du, C.; Yu, H.; Zhou, Z.; Yao, X.; Huang, Q. Flame retardant performance of flame retardant bamboo flooring. For. Prod. Ind. 2017, 44, 7–11. [Google Scholar]

- Jian, L.; Wu, S. A Study on the Fire Retardancy of Frw Fire Retardant for Wood by Cone Calorimeter. Sci. Silvae Sinicae 2002, 5, 108–114. [Google Scholar]

- Zhiwei, H.; Mingjie, G. Cone calorimeter analysis of bamboo floor combustion characteristics. Southwest Univ. 2017, 39, 187–192. [Google Scholar]

- Huang, Z.; Wang, Q.; Wu, Y. Phosphotungstic acid intercalated Zn, Al-layered double hydroxides/nanocellulose based 3D lightweight foam thermal insulation materials. Mater. Res. Express 2021, 8, 025009. [Google Scholar] [CrossRef]

- Mei, Y.J.; Xu, J.X.; Jiang, L.H.; Chen, P.; Tan, Q.P. Protecting of steel from chloride-induced corrosion by cement slurry coatings with calcined Mg-Al layered double hydroxides. Mater. Rev 2018, 32, 3941–3947. [Google Scholar]

- Liu, L.; Hu, J.; Zhuo, J.; Jiao, C.; Chen, X.; Li, S. Synergistic flame retardant effects between hollow glass microspheres and magnesium hydroxide in ethylene-vinyl acetate composites. Polym. Degrad. Stab. 2014, 104, 87–94. [Google Scholar] [CrossRef]

| Sample | d003 (Å) | d006 (Å) | d110 (Å) |

|---|---|---|---|

| S80-4 | 8.54 | 4.30 | 2.78 |

| S80-6 | 8.56 | 4.30 | 2.77 |

| S80-8 | 8.63 | 4.32 | 2.87 |

| S100-4 | 8.61 | 4.32 | 2.87 |

| S100-6 | 8.80 | 4.42 | 2.87 |

| S100-8 | 8.73 | 4.35 | 2.87 |

| S120-4 | 8.71 | 4.34 | 2.89 |

| S120-6 | 8.68 | 4.30 | 2.87 |

| S120-8 | 8.64 | 4.31 | 2.85 |

| PDF#50-0652 | 8.60 | 4.31 | 2.87 |

| Sample | Mean | |||

|---|---|---|---|---|

| HRR (kW/m2) | pHRR (kW/m2) | TTI (s) | Mass Reduction (%) | |

| Non-flame-retardant-treated bamboo scrimber | 122.95 ± 3.65 | 359.99 ± 12.40 | 20 ± 0 | 22.63 ± 0.01 |

| Bamboo scrimber treated with the S120-6-1 | 117.41 ± 1.44 | 310.71 ± 8.23 | 26 ± 6 | 21.12 ± 0.73 |

| Bamboo scrimber treated with the S120-6-2 | 115.74 ± 0.62 | 324.21 ± 11.61 | 28 ± 1 | 24.32 ± 0.71 |

| Sample | CO Yield | CO2 Yield | ||||

|---|---|---|---|---|---|---|

| Mean (kg/kg) | Peak (kg/kg) | Time to Peak (s) | Mean (kg/kg) | Peak (kg/kg) | Time to Peak (s) | |

| Non-flame-retardant-treated bamboo scrimber | 3.10 ± 0.08 | 49.54 ± 1.36 | 1116 ± 116 | 4.46 ± 0.10 | 90.06 ± 10.47 | 854 ± 14 |

| Bamboo scrimber treated with the S120-6-1 | 2.51 ± 0.03 | 46.5 ± 3.34 | 1413 ± 156 | 3.96 ± 0.01 | 90.18 ± 8.66 | 1067 ± 6 |

| Bamboo scrimber treated with the S120-6-2 | 2.281 ± 0.13 | 46.81 ± 0.13 | 1369 ± 134 | 3.81 ± 0.25 | 93.92 ± 5.19 | 1122 ± 45 |

| Sample Number | Crystallization Temperatures | Crystallization Times | Mass Percentage Concentration |

|---|---|---|---|

| S80-4 | 80 °C | 4 h | - |

| S80-6 | 80 °C | 6 h | - |

| S80-6 | 80 °C | 8 h | - |

| S100-4 | 100 °C | 4 h | - |

| S100-6 | 100 °C | 6 h | - |

| S100-8 | 100 °C | 8 h | - |

| S120-4 | 120 °C | 4 h | - |

| S120-6 | 120 °C | 6 h | - |

| S120-8 | 120 °C | 8 h | - |

| S120-6-1 | 120 °C | 6 h | 1% |

| S120-6-2 | 120 °C | 6 h | 2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, Y.; Hu, A.; Yang, F.; Du, C.; Zhu, J.; Shao, Y.; Wang, Y.; Bao, Q. Preparation of PO43−-Intercalated Calcium–Aluminum Hydrotalcites via Coprecipitation Method and Its Flame-Retardant Effect on Bamboo Scrimber. Molecules 2023, 28, 4093. https://doi.org/10.3390/molecules28104093

Ran Y, Hu A, Yang F, Du C, Zhu J, Shao Y, Wang Y, Bao Q. Preparation of PO43−-Intercalated Calcium–Aluminum Hydrotalcites via Coprecipitation Method and Its Flame-Retardant Effect on Bamboo Scrimber. Molecules. 2023; 28(10):4093. https://doi.org/10.3390/molecules28104093

Chicago/Turabian StyleRan, Ying, Ailian Hu, Fei Yang, Chungui Du, Jiawei Zhu, Yuran Shao, Yuting Wang, and Qichao Bao. 2023. "Preparation of PO43−-Intercalated Calcium–Aluminum Hydrotalcites via Coprecipitation Method and Its Flame-Retardant Effect on Bamboo Scrimber" Molecules 28, no. 10: 4093. https://doi.org/10.3390/molecules28104093

APA StyleRan, Y., Hu, A., Yang, F., Du, C., Zhu, J., Shao, Y., Wang, Y., & Bao, Q. (2023). Preparation of PO43−-Intercalated Calcium–Aluminum Hydrotalcites via Coprecipitation Method and Its Flame-Retardant Effect on Bamboo Scrimber. Molecules, 28(10), 4093. https://doi.org/10.3390/molecules28104093