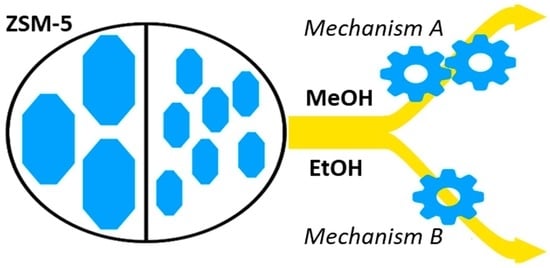

Influence of ZSM-5 Crystal Size on Methanol-to-Olefin (MTO) vs. Ethanol-to-Aromatics (ETA) Conversion

Abstract

:1. Introduction

2. Results and Discussion

2.1. Physicochemical Properties of the Catalysts

2.2. Methanol-to-Olefin (MTO) and Ethanol-to-Aromatics (ETA) Conversion

3. Materials and Methods

3.1. Sample Preparation

3.2. Characterization Methods

3.3. Catalytic Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dehertog, W.J.H.; Froment, G.F. Production of light alkenes from methanol on ZSM-5 catalysts. Appl. Catal. 1991, 71, 153–165. [Google Scholar] [CrossRef]

- Schulz, H. “Coking” of zeolites during methanol conversion: Basic reactions of the MTO-, MTP- and MTG processes. Catal. Today 2010, 154, 183–194. [Google Scholar] [CrossRef]

- Stöcker, M. Methanol-to-hydrocarbons: Catalytic materials and their behavior. Microporous Mesoporous Mater. 1999, 29, 3–48. [Google Scholar] [CrossRef]

- Sushkevich, V.L.; Palagin, D.; Ranocchiari, M.; van Bokhoven, J.A. Selective anaerobic oxidation of methane enables direct synthesis of methanol. Science 2017, 356, 523–527. [Google Scholar] [CrossRef] [PubMed]

- Dyballa, M.; Thorshaug, K.; Pappas, D.K.; Borfecchia, E.; Kvande, K.; Bordiga, S.; Berlier, G.; Lazzarini, A.; Olsbye, U.; Beato, P.; et al. Zeolite Surface Methoxy Groups as Key Intermediates in the Stepwise Conversion of Methane to Methanol. ChemCatChem 2019, 11, 5022–5026. [Google Scholar] [CrossRef]

- Tomkins, P.; Mansouri, A.; Sushkevich, V.L.; van der Wal, L.I.; Bozbag, S.E.; Krumeich, F.; Ranocchiari, M.; van Bokhoven, J.A. Increasing the activity of copper exchanged mordenite in the direct isothermal conversion of methane to methanol by Pt and Pd doping. Chem. Sci. 2019, 10, 167–171. [Google Scholar] [CrossRef]

- Bjørgen, M.; Svelle, S.; Joensen, F.; Nerlov, J.; Kolboe, S.; Bonino, F.; Palumbo, L.; Bordiga, S.; Olsbye, U. Conversion of methanol to hydrocarbons over zeolite H-ZSM-5: On the origin of the olefinic species. J. Catal. 2007, 249, 195–207. [Google Scholar] [CrossRef]

- Svelle, S.; Joensen, F.; Nerlov, J.; Olsbye, U.; Lillerud, K.-P.; Kolboe, S.; Bjørgen, M. Conversion of Methanol into Hydrocarbons over Zeolite H-ZSM-5: Ethene Formation Is Mechanistically Separated from the Formation of Higher Alkenes. J. Am. Chem. Soc. 2006, 128, 14770–14771. [Google Scholar] [CrossRef]

- Svelle, S.; Olsbye, U.; Joensen, F.; Bjørgen, M. Conversion of Methanol to Alkenes over Medium- and Large-Pore Acidic Zeolites: Steric Manipulation of the Reaction Intermediates Governs the Ethene/Propene Product Selectivity. J. Phys. Chem. C 2007, 111, 17981–17984. [Google Scholar] [CrossRef]

- Olsbye, U.; Svelle, S.; Bjorgen, M.; Beato, P.; Janssens, T.V.; Joensen, F.; Bordiga, S.; Lillerud, K.P. Conversion of methanol to hydrocarbons: How zeolite cavity and pore size controls product selectivity. Angew. Chem. 2012, 51, 5810–5831. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y. Recent Advances in Catalytic Conversion of Ethanol to Chemicals. ACS Catal. 2014, 4, 1078–1090. [Google Scholar] [CrossRef]

- Dodds, D.; Humphreys, B. Production of Aromatic Chemicals from Biobased Feedstock. In Catalytic Process Development for Renewable Materials; Wiley VCH: Weinheim, Germany, 2013; pp. 183–237. [Google Scholar]

- Farrell, A.E.; Plevin, R.J.; Turner, B.T.; Jones, A.D.; O’Hare, M.; Kammen, D.M. Ethanol Can Contribute to Energy and Environmental Goals. Science 2006, 311, 506–508. [Google Scholar] [CrossRef] [PubMed]

- Dittmann, D.; Kaya, E.; Dyballa, M. Desilicated ZSM-5 Catalysts: Properties and Ethanol to Aromatics (ETA) Performance. ChemCatChem 2023, e202300716. [Google Scholar] [CrossRef]

- Dittmann, D.; Rieg, C.; Li, Z.; Kaya, E.; Dyballa, M. Better Performance in C2-Conversion to Aromatics by Optimized Feed and Catalysts. Energy Fuels 2023, 37, 4566–4579. [Google Scholar] [CrossRef]

- Eagan, N.M.; Kumbhalkar, M.D.; Buchanan, J.S.; Dumesic, J.A.; Huber, G.W. Chemistries and processes for the conversion of ethanol into middle-distillate fuels. Nat. Rev. Chem. 2019, 3, 223–249. [Google Scholar] [CrossRef]

- Seifert, M.; Marschall, M.S.; Gille, T.; Jonscher, C.; Busse, O.; Paasch, S.; Brunner, E.; Reschetilowski, W.; Weigand, J.J. Ethanol to Aromatics on Modified H-ZSM-5 Part I: Interdependent Dealumination Actions. ChemCatChem 2020, 12, 6301–6310. [Google Scholar] [CrossRef]

- Seifert, M.; Marschall, M.S.; Gille, T.; Jonscher, C.; Royla, P.; Busse, O.; Reschetilowski, W.; Weigand, J.J. Ethanol to Aromatics on Modified H-ZSM-5 Part II: An Unexpected Low Coking. Chem. Asian J. 2020, 15, 3878–3885. [Google Scholar] [CrossRef]

- Wang, W.; Buchholz, A.; Seiler, M.; Hunger, M. Evidence for an Initiation of the Methanol-to-Olefin Process by Reactive Surface Methoxy Groups on Acidic Zeolite Catalysts. J. Am. Chem. Soc. 2003, 125, 15260–15267. [Google Scholar] [CrossRef]

- Derouane, E.G.; Nagy, J.B.; Dejaifve, P.; van Hooff, J.H.C.; Spekman, B.P.; Védrine, J.C.; Naccache, C. Elucidation of the mechanism of conversion of methanol and ethanol to hydrocarbons on a new type of synthetic zeolite. J. Catal. 1978, 53, 40–55. [Google Scholar] [CrossRef]

- Chowdhury, A.D.; Lucini Paioni, A.; Whiting, G.T.; Fu, D.; Baldus, M.; Weckhuysen, B.M. Unraveling the Homologation Reaction Sequence of the Zeolite-Catalyzed Ethanol-to-Hydrocarbons Process. Angew. Chem. Int. Ed. 2019, 58, 3908–3912. [Google Scholar] [CrossRef]

- Schulz, J.; Bandermann, F. Conversion of ethanol over zeolite H-ZSM-5. Chem. Eng. Technol. 1994, 17, 179–186. [Google Scholar] [CrossRef]

- Van der Borght, K.; Batchu, R.; Galvita, V.V.; Alexopoulos, K.; Reyniers, M.-F.; Thybaut, J.W.; Marin, G.B. Insights into the Reaction Mechanism of Ethanol Conversion into Hydrocarbons on H-ZSM-5. Angew. Chem. Int. Ed. 2016, 55, 12817–12821. [Google Scholar] [CrossRef] [PubMed]

- Ilias, S.; Bhan, A. Mechanism of the Catalytic Conversion of Methanol to Hydrocarbons. ACS Catal. 2013, 3, 18–31. [Google Scholar] [CrossRef]

- Ramasamy, K.K.; Gerber, M.A.; Flake, M.; Zhang, H.; Wang, Y. Conversion of biomass-derived small oxygenates over HZSM-5 and its deactivation mechanism. Green Chem. 2014, 16, 748–760. [Google Scholar] [CrossRef]

- Dyballa, M.; Becker, P.; Trefz, D.; Klemm, E.; Fischer, A.; Jakob, H.; Hunger, M. Parameters influencing the selectivity to propene in the MTO conversion on 10-ring zeolites: Directly synthesized zeolites ZSM-5, ZSM-11, and ZSM-22. Appl. Catal. A Gen. 2016, 510, 233–243. [Google Scholar] [CrossRef]

- Müller, S.; Liu, Y.; Kirchberger, F.M.; Tonigold, M.; Sanchez-Sanchez, M.; Lercher, J.A. Hydrogen Transfer Pathways during Zeolite Catalyzed Methanol Conversion to Hydrocarbons. J. Am. Chem. Soc. 2016, 138, 15994–16003. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Kamble, R.; Viswanadham, N. Effect of Crystal Size on Physico-Chemical Properties of ZSM-5. Catal. Lett. 2008, 120, 288–293. [Google Scholar] [CrossRef]

- Dyballa, M.; Obenaus, U.; Rosenberger, M.; Fischer, A.; Jakob, H.; Klemm, E.; Hunger, M. Post-synthetic improvement of H-ZSM-22 zeolites for the methanol-to-olefin conversion. Microporous Mesoporous Mater. 2016, 233, 26–30. [Google Scholar] [CrossRef]

- Molino, A.; Łukaszuk, K.A.; Rojo-Gama, D.; Lillerud, K.P.; Olsbye, U.; Bordiga, S.; Svelle, S.; Beato, P. Conversion of methanol to hydrocarbons over zeolite ZSM-23 (MTT): Exceptional effects of particle size on catalyst lifetime. Chem. Commun. 2017, 53, 6816–6819. [Google Scholar] [CrossRef]

- Wang, J.; Xu, S.; Li, J.; Zhi, Y.; Zhang, M.; He, Y.; Wei, Y.; Guo, X.; Liu, Z. An approach to prepare nanosized HZSM-22 with enhanced lifetime in the methanol to hydrocarbon (MTH) reaction. RSC Adv. 2015, 5, 88928–88935. [Google Scholar] [CrossRef]

- Khare, R.; Millar, D.; Bhan, A. A mechanistic basis for the effects of crystallite size on light olefin selectivity in methanol-to-hydrocarbons conversion on MFI. J. Catal. 2015, 321, 23–31. [Google Scholar] [CrossRef]

- Shao, J.; Fu, T.-J.; Chang, J.-W.; Wan, W.-L.; Qi, R.-Y.; Li, Z. Effect of ZSM-5 crystal size on its catalytic properties for conversion of methanol to gasoline. J. Fuel Chem. Technol. 2017, 45, 75–83. [Google Scholar] [CrossRef]

- Firoozi, M.; Baghalha, M.; Asadi, M. The effect of micro and nano particle sizes of H-ZSM-5 on the selectivity of MTP reaction. Catal. Commun. 2009, 10, 1582–1585. [Google Scholar] [CrossRef]

- Rownaghi, A.A.; Rezaei, F.; Hedlund, J. Yield of gasoline-range hydrocarbons as a function of uniform ZSM-5 crystal size. Catal. Commun. 2011, 14, 37–41. [Google Scholar] [CrossRef]

- Jang, H.-G.; Min, H.-K.; Lee, J.K.; Hong, S.B.; Seo, G. SAPO-34 and ZSM-5 nanocrystals’ size effects on their catalysis of methanol-to-olefin reactions. Appl. Catal. A Gen. 2012, 437–438, 120–130. [Google Scholar] [CrossRef]

- Barbera, K.; Bonino, F.; Bordiga, S.; Janssens, T.V.W.; Beato, P. Structure–deactivation relationship for ZSM-5 catalysts governed by framework defects. J. Catal. 2011, 280, 196–205. [Google Scholar] [CrossRef]

- Gehring, B.; Traa, Y.; Hunger, M. Elucidation of the versatile Brønsted acidity of nanosized ZSM-5 materials. Microporous Mesoporous Mater. 2021, 317, 110978. [Google Scholar] [CrossRef]

- Bleken, F.L.; Janssens, T.V.W.; Svelle, S.; Olsbye, U. Product yield in methanol conversion over ZSM-5 is predominantly independent of coke content. Microporous Mesoporous Mater. 2012, 164, 190–198. [Google Scholar] [CrossRef]

- Losch, P.; Pinar, A.B.; Willinger, M.G.; Soukup, K.; Chavan, S.; Vincent, B.; Pale, P.; Louis, B. H-ZSM-5 zeolite model crystals: Structure-diffusion-activity relationship in methanol-to-olefins catalysis. J. Catal. 2017, 345, 11–23. [Google Scholar] [CrossRef]

- Dai, W.; Wu, G.; Li, L.; Guan, N.; Hunger, M. Mechanisms of the Deactivation of SAPO-34 Materials with Different Crystal Sizes Applied as MTO Catalysts. ACS Catal. 2013, 3, 588–596. [Google Scholar] [CrossRef]

- Meng, T.; Mao, D.; Guo, Q.; Lu, G. The effect of crystal sizes of HZSM-5 zeolites in ethanol conversion to propylene. Catal. Commun. 2012, 21, 52–57. [Google Scholar] [CrossRef]

- Kornatowski, J. Growth of large crystals of ZSM-5 zeolite. Zeolites 1988, 8, 77–78. [Google Scholar] [CrossRef]

- Mores, D.; Kornatowski, J.; Olsbye, U.; Weckhuysen, B.M. Coke formation during the methanol-to-olefin conversion: In situ microspectroscopy on individual H-ZSM-5 crystals with different Bronsted acidity. Chem. Eur. J. 2011, 17, 2874–2884. [Google Scholar] [CrossRef] [PubMed]

- Chao, K.-J.; Chern, J.-Y. Aluminium distribution in large ZSM-5 crystals. Zeolites 1988, 8, 82–85. [Google Scholar] [CrossRef]

- Dyballa, M.; Obenaus, U.; Blum, M.; Dai, W. Alkali metal ion exchanged ZSM-5 catalysts: On acidity and methanol-to-olefin performance. Catal. Sci. Technol. 2018, 8, 4440–4449. [Google Scholar] [CrossRef]

- Dyballa, M.; Klemm, E.; Weitkamp, J.; Hunger, M. Effect of Phosphate Modification on the Brønsted Acidity and Methanol-to-Olefin Conversion Activity of Zeolite ZSM-5. Chem. Ing. Tech. 2013, 85, 1719–1725. [Google Scholar] [CrossRef]

- Jiang, Y.; Huang, J.; Dai, W.; Hunger, M. Solid-state nuclear magnetic resonance investigations of the nature, property, and activity of acid sites on solid catalysts. Solid State Nucl. Magn. Reson. 2011, 39, 116–141. [Google Scholar] [CrossRef] [PubMed]

- Dyballa, M.; Pappas, D.K.; Borfecchia, E.; Beato, P.; Olsbye, U.; Lillerud, K.P.; Arstad, B.; Svelle, S. Tuning the material and catalytic properties of SUZ-4 zeolites for the conversion of methanol or methane. Microporous Mesoporous Mater. 2018, 265, 112–122. [Google Scholar] [CrossRef]

- Lang, S.; Benz, M.; Obenaus, U.; Himmelmann, R.; Hunger, M. Novel Approach for the Characterization of Lewis Acidic Solid Catalysts by Solid-State NMR Spectroscopy. ChemCatChem 2016, 8, 2031–2036. [Google Scholar] [CrossRef]

- Haw, J.F.; Hall, M.B.; Alvarado-Swaisgood, A.E.; Munson, E.J.; Lin, Z.; Beck, L.W.; Howard, T. Integrated NMR and Ab Initio Study of Acetonitrile in Zeolites: A Reactive Complex Model of Zeolite Acidity. J. Am. Chem. Soc. 1994, 116, 7308–7318. [Google Scholar] [CrossRef]

- Bleken, F.L.; Chavan, S.; Olsbye, U.; Boltz, M.; Ocampo, F.; Louis, B. Conversion of methanol into light olefins over ZSM-5 zeolite: Strategy to enhance propene selectivity. Appl. Catal. A Gen. 2012, 447–448, 178–185. [Google Scholar] [CrossRef]

- Dai, W.; Kouvatas, C.; Tai, W.; Wu, G.; Guan, N.; Li, L.; Valtchev, V. Platelike MFI Crystals with Controlled Crystal Faces Aspect Ratio. J. Am. Chem. Soc. 2021, 143, 1993–2004. [Google Scholar] [CrossRef] [PubMed]

- Kärger, J.; Pfeifer, H.; Caro, J.; Bülow, M.; Schlodder, H.; Mostowicz, R.; Völter, J. Controlled coke deposition on zeolite ZSM5 and its influence on molecular transport. Appl. Catal. 1987, 29, 21–30. [Google Scholar] [CrossRef]

| Catalyst | nSi/nAl Ratio a | Theoretical BAS Density [mmol/g] a | Measured BAS Density [mmol/g] b | Crystal Size c [µm] | Rel. Crystallinity d [%] | BET [m2/g] | Micropore Volume [mL/g] | Micropore Area [m2/g] | Total Pore Volume [mL/g] |

|---|---|---|---|---|---|---|---|---|---|

| S60/2 | 60 | 0.27 | 0.27 | <2 × 1 × 1 | 99 | 387 | 0.13 | 244 | 0.21 |

| S60/60 | 60 | 0.27 | 0.22 | 60 × 30 × 30 | 95 | 394 | 0.11 | 205 | 0.21 |

| Catalyst | Disturbed Bridging Si(OH)Al Groups (~5.0 ppm) | Bridging Si(OH)Al Groups (3.9 ppm) | Internal Si(OH) Groups (2.6 ppm) | Si(OH) Groups (1.8 ppm) |

|---|---|---|---|---|

| S60/2 | 0.16 | 0.11 | 0.11 | 0.18 |

| S60/60 | 0.11 | 0.11 | 0.07 | 0.10 |

| Catalyst | SAlkanesC1-C4 | SEthylene | SPropylene | SButenes | SC5+ | SBTEX | C3=/C3 | HTI C4 | Coke a [wt%] |

|---|---|---|---|---|---|---|---|---|---|

| Methanol-to-Olefin (MTO) | |||||||||

| S60/2 | 4 | 8 | 41 | 27 | 15 | 5 | 32 | 0.07 | 7 |

| S60/60 | 6 | 13 | 36 | 22 | 15 | 8 | 24 | 0.12 | 7 |

| Ethanol-to-Aromatics (ETA) | |||||||||

| S60/2 | 13 | 13 | 11 | 19 | 25 | 19 | 2.8 | 0.29 | 8 |

| S60/60 | 13 | 14 | 11 | 19 | 23 | 20 | 2.8 | 0.31 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dittmann, D.; Kaya, E.; Strassheim, D.; Dyballa, M. Influence of ZSM-5 Crystal Size on Methanol-to-Olefin (MTO) vs. Ethanol-to-Aromatics (ETA) Conversion. Molecules 2023, 28, 8046. https://doi.org/10.3390/molecules28248046

Dittmann D, Kaya E, Strassheim D, Dyballa M. Influence of ZSM-5 Crystal Size on Methanol-to-Olefin (MTO) vs. Ethanol-to-Aromatics (ETA) Conversion. Molecules. 2023; 28(24):8046. https://doi.org/10.3390/molecules28248046

Chicago/Turabian StyleDittmann, Daniel, Elif Kaya, Dennis Strassheim, and Michael Dyballa. 2023. "Influence of ZSM-5 Crystal Size on Methanol-to-Olefin (MTO) vs. Ethanol-to-Aromatics (ETA) Conversion" Molecules 28, no. 24: 8046. https://doi.org/10.3390/molecules28248046

APA StyleDittmann, D., Kaya, E., Strassheim, D., & Dyballa, M. (2023). Influence of ZSM-5 Crystal Size on Methanol-to-Olefin (MTO) vs. Ethanol-to-Aromatics (ETA) Conversion. Molecules, 28(24), 8046. https://doi.org/10.3390/molecules28248046