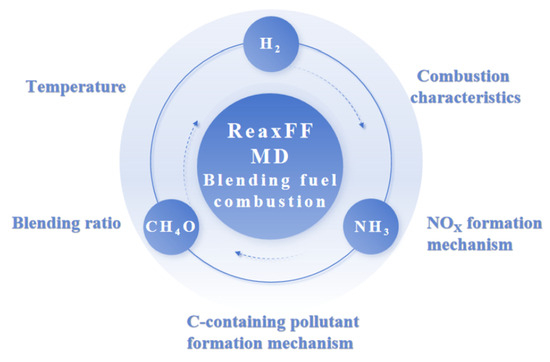

Reactive Molecular Dynamics Study of Pollutant Formation Mechanism in Hydrogen/Ammonia/Methanol Ternary Carbon-Neutral Fuel Blend Combustion

Abstract

:1. Introduction

2. Results and Discussion

2.1. Temperature Effects on Ternary Blended Combustion Components and Pollutant Formation

2.1.1. Temperature Effects on Ternary Blended Combustion Components and Free Radicals

2.1.2. Temperature Effects on CO and CO2 Formation in Blended Combustion

2.1.3. Temperature Effects on NOX Formation from the Blended Combustion of Ternary Carbon-Neutral Fuels

2.2. Influence of Blending Ratio on Combustion Composition and Pollutant Formation

2.2.1. Influence of Blending Ratio on Combustion Components and Free Radicals

2.2.2. Influence of the Blending Ratio on CO and CO2 Formation in Blended Combustion

2.2.3. Influence of Blending Ratio on NOX Formation in Blended Combustion

2.3. Analysis of the Mechanisms of CO, CO2, and NOX Formation in the Combustion of Blended Fuels as Affected by Temperature

2.4. Mechanism and Reaction Path Analysis of CO, CO2, and NOX Formation in Blended Fuel Combustion as Affected by Blending Ratio

3. Materials and Methods

3.1. Reactive Force-Field Molecular Dynamics (ReaxFF MD)

3.2. Case Set-Ups

3.3. Computational Details and Post-Processing

3.4. Validation of the ReaxFF MD Method

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AMS | Amsterdam Modeling Suite | N2 | Nitrogen |

| CH4O | Methanol | NH3 | Ammonia |

| CH3O | Methoxy | NH2 | Ammonia radical |

| CH2O | Formaldehyde | NO | Nitric oxide |

| CNG | Compressed natural gas | NO2 | Nitrogen dioxide |

| CO | Carbon monoxide | NO3 | Nitrogen trioxide |

| CO2 | Carbon dioxide | NOx | Nitrogen oxide |

| DGE | Diethylene glycol ether | NVT | Constant number of atoms, constant volume, and controlled temperature |

| H2 | Hydrogen | ReaxFF MD | Reactive molecular dynamics simulation |

| HC | Total hydrocarbons | PAH | Polycyclic aromatic hydrocarbons |

| HNO | Nitric acid | PM | Particulate matter |

| HO2 | Hydrogen peroxide radical | φ | Equivalent ratio |

| LNG | Liquefied natural gas | ρ | System density |

References

- Jisoo, S.; Sungwook, P. Numerical analysis for optimizing combustion strategy in an ammonia-diesel dual-fuel engine. Energy Convers. Manag. 2023, 284, 116980. [Google Scholar]

- Zhang, L.; Sun, R.; Wang, Z.; Zhu, W.; Wang, X.; Qi, H. Application of experiments and density function theory on the formation mechanism of NH during O/Ar and O/HO combustion process of demineralized coals. Fuel 2023, 331, 125730. [Google Scholar] [CrossRef]

- Chen, Z.; Li, P.; Anderson, R.; Wang, X.; Zhang, X.; Robison, L.; Redfern, L.R.; Moribe, S.; Islamoglu, T.; Gómez-Gualdrón, D.A.; et al. Balancing volumetric and gravimetric uptake in highly porous materials for clean energy. Science 2020, 368, 297–303. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Yang, Y.; Li, Q.; Yan, Y.; Tian, Z.; Song, C.; Huang, Z. Study on effects of NH3 and/or H2 addition on the characteristics of soot formation and gas emissions in a laminar ethylene diffusion flame. Fuel Process. Technol. 2023, 242, 107633. [Google Scholar] [CrossRef]

- Xuan, J.; He, L.; Wen, W.; Feng, Y. Hydrogenase and Nitrogenase: Key Catalysts in Biohydrogen Production. Molecules 2023, 28, 1392. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Gu, M.; Zhu, Y.; Cao, L.; Zhu, B.; Wu, J.; Lin, Y.; Huang, X. A review of the effects of hydrogen, carbon dioxide, and water vapor addition on soot formation in hydrocarbon flames. Int. J. Hydrogen Energy 2021, 46, 31400–31427. [Google Scholar] [CrossRef]

- Zhang, F.; Li, S.; Liu, Q.; Sun, J.; Wei, X.; Gu, M.; Wang, Y.; Huang, X. Effect of ammonia on the soot surface characteristics in ammonia/ethylene co-flow diffusion flames. Fuel 2023, 341, 127633. [Google Scholar] [CrossRef]

- Dimitriou, P.; Javaid, R. A review of ammonia as a compression ignition engine fuel. Int. J. Hydrogen Energy 2020, 45, 98–118. [Google Scholar] [CrossRef]

- Emir, E.; Yasin, A. Evaluation of ammonia fueled engine for a bulk carrier in marine decarbonization pathways. J. Clean. Prod. 2022, 379, 134688. [Google Scholar]

- Sanchez, A.; Castellano, E.; Martín, M.; Vega, P. Evaluating ammonia as green fuel for power formation: A thermo-chemical perspective. Appl. Energy 2021, 293, 116956. [Google Scholar] [CrossRef]

- Fenghour, A.; Wakeham, A.; Vesovic, V.; Watson, J.; Millat, J.; Vogel, E. The viscosity of ammonia. J. Phys. Chem. Ref. Data 1995, 24, 1649–1667. [Google Scholar] [CrossRef]

- Frigo, S.; Gentili, R. Analysis of the behaviour of a 4-stroke Si engine fuelled with ammonia and hydrogen. Int. J. Hydrogen Energy 2013, 38, 1607–1615. [Google Scholar] [CrossRef]

- Chai, W.; Bao, Y.; Jin, P.; Tang, G.; Zhou, L. A review on ammonia, ammonia-hydrogen and ammonia-methane fuels. Renew. Sustain. Energy Rev. 2021, 147, 111254. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, L.; Wei, H.; Li, J.; Chen, R.; Pana, J. Understanding the difference in combustion and flame propagation characteristics between ammonia and methane using an optical SI engine. Fuel 2022, 324, 124794. [Google Scholar] [CrossRef]

- Nozari, H.; Karabeyouglu, A. Numerical study of combustion characteristics of ammonia as a renewable fuel and establishment of reduced reaction mechanisms. Fuel 2015, 159, 223–233. [Google Scholar] [CrossRef]

- Charles, L.; Pierre, B.; Francesco, C.; Christine, M. Experimental investigation on ammonia combustion behavior in a spark-ignition engine by means of laminar and turbulent expanding flames. Proc. Combust. Inst. 2021, 38, 5859–5868. [Google Scholar]

- Qi, Y.; Liu, W.; Liu, S.; Wang, W.; Peng, Y.; Wang, Z. A review on ammonia-hydrogen fueled internal combustion engines. eTransportation 2023, 18, 100288. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Lv, J.; Liu, Z.; Gao, S.; Hu, J.; Zhang, J.; Zhong, W.; Zhao, Z. Evaluation of hydrogen addition on combustion and emission characteristics of dual-fuel diesel engines with different compression ratios. Processes 2023, 11, 2675. [Google Scholar] [CrossRef]

- Caneon, K.; Mayank, M. Review on the production and utilization of green ammonia as an alternate fuel in dual-fuel compression ignition engines. Energy Convers. Manag. 2022, 251, 114990. [Google Scholar]

- Wang, W.; Herreros, J.; Tsolakis, A.; York, A. Ammonia as hydrogen carrier for transportation; investigation of the ammonia exhaust gas fuel reforming. Int. J. Hydrogen Energy 2013, 38, 9907–9917. [Google Scholar] [CrossRef]

- Alam, M.; Goto, S.; Sugiyama, K.; Kajiwara, M.; Mori, M.; Konno, M.; Motohashi, M.; Oyama, K. Performance and emissions of a DI diesel engine operated with LPG and ignition improving additives. SAE Int. J. Engines 2001, 1, 3680. [Google Scholar]

- Miller, J.; Nagarajan, G.; Renganarayanan, S. LPG fueled diesel engine using diethyl ether with exhaust gas recirculation. Int. J. Therm. Sci. 2008, 47, 450–457. [Google Scholar] [CrossRef]

- Karabektas, M.; Ergen, G.; Hosoz, M. The effects of using diethylether as additive on the performance and emissions of a diesel engine fuelled with CNG. Fuel 2014, 115, 855–860. [Google Scholar] [CrossRef]

- Wang, Z.; Li, L. Effects of different ethanol/diesel blending ratios on combustion and emission characteristics of a medium-speed diesel engine. Processes 2022, 10, 173. [Google Scholar] [CrossRef]

- Feng, H.; Chen, X.; Sun, L.; Ma, R.; Zhang, X.; Zhu, L.; Yang, C. The effect of methanol/diesel fuel blends with co-solvent on diesel engine combustion based on experiment and exergy analysis. Energy 2023, 282, 128792. [Google Scholar] [CrossRef]

- Wang, W.; Herreros, J.; Tsolakis, A.; York, A. Reducing CO2 footprint through synergies in carbon-free energy vectors and low carbon fuels. Energy 2016, 112, 976–983. [Google Scholar] [CrossRef]

- Li, M.; He, X.; Hashemi, H.; Glarborg, P.; Lowe, V.M.; Marshall, P.; Fernandes, R.; Shu, B. An experimental and modeling study on auto-ignition kinetics of ammonia/methanol mixtures at intermediate temperature and high pressure. Combust. Flame 2022, 242, 112160. [Google Scholar] [CrossRef]

- Xu, H.; Wang, J.; Zhang, C.; Dai, L.; He, Z.; Wang, Q. Numerical study on laminar burning velocity of ammonia flame with methanol addition. Int. J. Hydrogen Energy 2022, 47, 28152–28164. [Google Scholar] [CrossRef]

- Lu, M.; Dong, D.; Wei, F.; Long, W.; Wang, Y.; Cong, L.; Dong, P.; Tian, H.; Wang, P. Chemical mechanism of ammonia-methanol combustion and chemical reaction kinetics analysis for different methanol blends. Fuel 2023, 341, 127697. [Google Scholar] [CrossRef]

- Yang, W.; Ranga, D.; Luo, K.; Thevenin, D. Direct numerical simulation of turbulent premixed ammonia and ammonia-hydrogen combustion under engine-relevant conditions. Int. J. Hydrogen Energy 2022, 47, 11083–11100. [Google Scholar] [CrossRef]

- Hong, C.; Ji, C.; Wang, S.; Xin, G.; Wang, Z.; Meng, H.; Yang, J. An experimental study of various load control strategies for an ammonia/hydrogen dual-fuel engine with the Miller cycle. Fuel Process. Technol. 2023, 247, 107780. [Google Scholar] [CrossRef]

- van Duin, A.; Dasgupta, S.; Lorant, F.; Goddard, W.A. ReaxFF: A reactive force field for hydrocarbons. J. Phys. Chem. A 2001, 105, 9396–9409. [Google Scholar] [CrossRef]

- Liu, J.; Guo, X. ReaxFF molecular dynamics simulation of pyrolysis and combustion of pyridine. Fuel Process. Technol. 2017, 161, 107–115. [Google Scholar] [CrossRef]

- Guo, F.; Cheng, X.; Zhang, H. ReaxFF molecular dynamics study of initial mechanism of JP-10 combustion. Combust. Sci. Technol. 2012, 184, 1233–1243. [Google Scholar] [CrossRef]

- Hong, D.; Liu, L.; Huang, Y.; Zheng, C.; Guo, X. Chemical effect of H2O on CH4 oxidation during combustion in O2/H2O environments. Energy Fuels 2016, 30, 8491–8498. [Google Scholar] [CrossRef]

- Chowdhury, A.; van Duin, A. Extension of the ReaxFF combustion force field toward syngas combustion and initial oxidation kinetics. J. Phys. Chem. A 2017, 121, 1051–1068. [Google Scholar]

- Liu, B.; Lusk, M.; Ely, J. Reactive molecular dynamic simulations of hydrocarbon dissociations on Ni(111) surfaces. Surf. Sci. 2012, 606, 615–623. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, X.; Luo, K. Exploring reaction mechanism for ammonia/methane combustion via reactive molecular dynamics simulations. Fuel 2023, 331, 125806. [Google Scholar] [CrossRef]

- Kwon, H.; Shabnam, S.; van Duin, A.; Xuan, Y. Numerical simulations of yield-based sooting tendencies of aromatic fuels using ReaxFF molecular dynamics. Fuel 2020, 262, 116545. [Google Scholar] [CrossRef]

- Mortier, W.; Ghosh, S.; Shankar, S. Electronegativity equalization method for the calculation of atomic charges in molecules. Cheminform 1986, 108, 4315–4320. [Google Scholar] [CrossRef]

- Chenoweth, K.; van Duin, A.; Goddard, W. ReaxFF reactive force field for molecular dynamics simulations of hydrocarbon oxidation. J. Phys. Chem. A 2008, 112, 1040–1053. [Google Scholar] [CrossRef] [PubMed]

- Bhoi, S.; Banerjee, T.; Mohanty, K. Molecular dynamic simulation of spontaneous combustion and pyrolysis of brown coal using ReaxFF. Fuel 2014, 136, 326–333. [Google Scholar] [CrossRef]

- Lele, A.; Kwon, H.; Ganeshan, K.; Xuan, Y.; van Duin, A. ReaxFF molecular dynamics study on pyrolysis of bicyclic compounds for aviation fuel. Fuel 2021, 297, 120724. [Google Scholar] [CrossRef]

- Senda, T.; Yamada, Y.; Morimoto, M.; Nono, N.; Sogabe, T.; Kubo, S.; Sato, S. Analyses of oxidation process for isotropic pitch-based carbon fibers using model compounds. Carbon 2019, 142, 311–326. [Google Scholar] [CrossRef]

- Wang, Y.; Gong, S.; Wang, H.; Li, L.; Liu, G. High-temperature pyrolysis of isoprenoid hydrocarbon p-menthane using ReaxFF molecular dynamics simulation. J. Anal. Appl. Pyrol. 2021, 155, 105045. [Google Scholar] [CrossRef]

- Zhang, L.; Zybin, S.; van Duin, A.; Dasgupta, S.; GoddardIII, W. Carbon cluster formation during thermal decomposition of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine and 1,3,5-Triamino-2,4,6-trinitrobenzene high explosives from ReaxFF reactive molecular dynamics simulations. J. Phys. Chem. A 2009, 113, 10619–10640. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.; Jiang, Y.; Liu, C.; Chen, L.; Zhang, W.; Ding, J.; Li, J. Controllable NO emission and high flame performance of ammonia combustion assisted by non-equilibrium plasma. Fuel 2022, 319, 123818. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, M.; Zhu, Y.; Cao, L.; Wu, J.; Lin, Y.; Huang, X. Analysis of soot formation of CH4 and C2H4 with H2 addition via ReaxFF molecular dynamics and pyrolysis–gas chromatography/mass spectrometry. J. Energy Inst. 2022, 100, 177–188. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, W.; Zhao, L. High-temperature and high-pressure pyrolysis of hexadecane: Molecular dynamic simulation based on reactive force field (ReaxFF). J. Phys. Chem. A 2017, 121, 2069–2078. [Google Scholar] [CrossRef]

- Senftle, T.P.; Hong, S.; Islam, M.; Kylasa, S.B.; Zheng, Y.; Shin, Y.K.; Junkermeier, C.; Engel-Herbert, R.; Janik, M.J.; Aktulga, H.M.; et al. The ReaxFF reactive force-field: Development, applications and future directions. NPJ Comput. Mater. 2016, 2, 15011. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Ding, J. Chemical effect of NO on CH4 oxidation during combustion in O2/NO environments. Chem. Phys. Lett. 2019, 727, 59–65. [Google Scholar] [CrossRef]

| Case | H2 | NH3 | CH4O | O2 | ρ, g/cm3 | T, K | φ |

|---|---|---|---|---|---|---|---|

| 1 | 40 | 40 | 40 | 220 | 0.05 | 2000 | 0.5 |

| 2 | 40 | 40 | 40 | 220 | 0.05 | 1000 | 0.5 |

| 3 | 40 | 40 | 40 | 220 | 0.05 | 1500 | 0.5 |

| 4 | 40 | 40 | 40 | 220 | 0.05 | 2500 | 0.5 |

| 5 | 40 | 40 | 40 | 220 | 0.05 | 3000 | 0.5 |

| 6 | 20 | 40 | 60 | 260 | 0.05 | 2000 | 0.5 |

| 7 | 20 | 60 | 40 | 230 | 0.05 | 2000 | 0.5 |

| 8 | 40 | 20 | 60 | 250 | 0.05 | 2000 | 0.5 |

| 9 | 40 | 60 | 20 | 190 | 0.05 | 2000 | 0.5 |

| 10 | 60 | 20 | 40 | 210 | 0.05 | 2000 | 0.5 |

| 11 | 60 | 40 | 20 | 280 | 0.05 | 2000 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Liu, Q.; Wang, Y.; Gu, M.; Huang, X. Reactive Molecular Dynamics Study of Pollutant Formation Mechanism in Hydrogen/Ammonia/Methanol Ternary Carbon-Neutral Fuel Blend Combustion. Molecules 2023, 28, 8140. https://doi.org/10.3390/molecules28248140

Sun J, Liu Q, Wang Y, Gu M, Huang X. Reactive Molecular Dynamics Study of Pollutant Formation Mechanism in Hydrogen/Ammonia/Methanol Ternary Carbon-Neutral Fuel Blend Combustion. Molecules. 2023; 28(24):8140. https://doi.org/10.3390/molecules28248140

Chicago/Turabian StyleSun, Jingyun, Qianqian Liu, Yang Wang, Mingyan Gu, and Xiangyong Huang. 2023. "Reactive Molecular Dynamics Study of Pollutant Formation Mechanism in Hydrogen/Ammonia/Methanol Ternary Carbon-Neutral Fuel Blend Combustion" Molecules 28, no. 24: 8140. https://doi.org/10.3390/molecules28248140

APA StyleSun, J., Liu, Q., Wang, Y., Gu, M., & Huang, X. (2023). Reactive Molecular Dynamics Study of Pollutant Formation Mechanism in Hydrogen/Ammonia/Methanol Ternary Carbon-Neutral Fuel Blend Combustion. Molecules, 28(24), 8140. https://doi.org/10.3390/molecules28248140