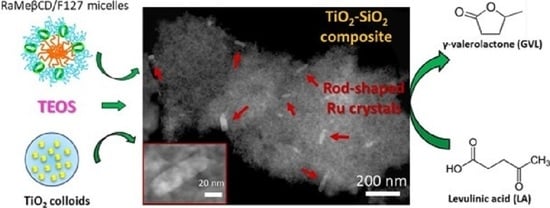

Robust Ruthenium Catalysts Supported on Mesoporous Cyclodextrin-Templated TiO2-SiO2 Mixed Oxides for the Hydrogenation of Levulinic Acid to γ-Valerolactone

Abstract

:1. Introduction

2. Results

2.1. Method for the Preparation of the Catalysts

2.2. Characterization of the Supports

2.3. Characterization of the Supported Catalysts

2.4. Catalytic Tests

3. Materials and Methods

3.1. Chemicals

3.2. Preparation of Mesoporous TiO2 and SiO2-TiO2 Materials

3.3. Preparation of RuO2@TiO2 and RuO2@TiO2-SiO2 Catalysts

3.4. Characterization Methods

3.5. Catalytic Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CD | Cyclodextrin |

| RaMeβCD | Randomly methylated β-cyclodextrin |

| GVL | γ-valerolactone |

| 4-HPA | 4-hydroxypentanoic acid |

| LA | Levulinic acid |

| TEOS | Tetraethyl orthosilicate |

| Ti(OiPr)4 | Titanium isopropoxyde |

| DLS | Dynamic light scattering |

| JCPDS | Joint committee on powder diffraction standards |

| XRD | X-ray diffraction |

| SBET | Surface area determined by the Brunauer, Emmett, and Teller method |

| BJH | Barrett, Joyner, and Halenda |

| TPR | Temperature programmed reduction |

| XRF | X-ray fluorescence |

| HR-TEM | High-resolution transmission electron microscopy |

| HAABF-STEM | High-angle annular bright-field scanning TEM |

| HAADF-STEM | High-angle annular dark-field scanning TEM |

| EDS | Energy dispersive X-ray spectrometry |

| ICP-OES | Inductive coupled plasma optical emission spectroscopy |

| NMR | Nuclear magnetic resonance |

| GC | Gas chromatography |

References

- Besson, M.; Gallezot, P.; Pinel, C. Conversion of Biomass into Chemicals over Metal Catalysts. Chem. Rev. 2014, 114, 1827–1870. [Google Scholar] [CrossRef] [PubMed]

- Alonso, D.M.; Wettstein S., G.; Dumesic, J.A. Gamma-valerolactone, a sustainable platform molecule derived from lignocellulosic biomass. Green Chem. 2013, 15, 584–595. [Google Scholar] [CrossRef]

- Lin, Y.C.; Huber, G.W. The critical role of heterogeneous catalysis in lignocellulosic biomass conversion. Energy Environ. Sci. 2009, 2, 68–80. [Google Scholar] [CrossRef] [Green Version]

- Horvath, I.T.; Mehdi, H.; Fabos, V.; Boda, L.; Mika, L.T. γ-Valerolactone-a sustainable liquid for energy and carbon-based chemicals. Green Chem. 2008, 10, 238–242. [Google Scholar] [CrossRef]

- Schuette, H.A.; Thomas, R.A. Normal Valerolactone. III. Preparation by the catalytic reduction of levulinic acid with hydrogen in the presence of platinum oxide. J. Am. Chem Soc. 1930, 52, 3010–3012. [Google Scholar] [CrossRef]

- Luo, W.; Sankar, M.; Beale, A.M.; He, Q.; Kiely, C.J.; Bruijnincx, P.C.A.; Weckhuysen, B.M. High performing and stable supported nano-alloys for the catalytic hydrogenation of levulinic acid to g-valerolactone. Nat. Commun. 2015, 6, 6540. [Google Scholar] [CrossRef]

- Lee, J.; Xu, Y.; Huber, G.W. High-throughput screening of monometallic catalysts for aqueous-phase hydrogenation of biomass-derived oxygenates. Appl. Catal. B 2013, 140, 98–107. [Google Scholar] [CrossRef]

- Upare, P.P.; Lee, J.-M.; Hwang, D.W.; Halligudi, S.B.; Hwang, Y.K.; Chang, J.-S. Selective hydrogenation of levulinic acid to γ-valerolactone over carbon-supported noble metal catalysts. Ind. Eng. Chem. 2011, 17, 287–292. [Google Scholar] [CrossRef]

- Corbel-Demailly, L.; Ly, B.-K.; Minh, D.-P.; Tapin, B.; Especel, C.; Epron, F.; Cabiac, A.; Guillon, E.; Besson, M.; Pinel, C. Heterogeneous catalytic hydrogenation of biobased levulinic and succinic acids in aqueous solutions. ChemSusChem 2013, 6, 2388–2395. [Google Scholar] [CrossRef]

- Tukacs, J.M.; Jones, R.V.; Darvas, F.; Dibo, G.; Lezsak, G.; Mika, L.T. Synthesis of γ-valerolactone using a continuous-flow reactor. RSC Adv. 2013, 3, 16283–16287. [Google Scholar] [CrossRef]

- Manzer, L.E. Catalytic synthesis of α-methylene-γ-valerolactone: A biomass-derived acrylic monomer. Appl. Catal. A 2004, 272, 249–256. [Google Scholar] [CrossRef]

- Rimar, N.N.; Pirogova, G.N. Hydrogenation of acetone on technetium catalysts. Russ. Chem. Bull. 1998, 47, 398–401. [Google Scholar] [CrossRef]

- Michel, C.; Zaffran, J.; Ruppert, A.M.; Matras-Michalska, J.; Jedrzejczyk, M.; Grams, J.; Sautet, P. Role of water in metal catalyst performance for ketone hydrogenation: A joint experimental and theoretical study on levulinic acid conversion into gamma-valerolactone. Chem. Commun. 2014, 50, 12450–12453. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akpa, B.S.; D’Agostino, C.; Gladden, L.F.; Hindle, K.; Manyar, H.; McGregor, J.; Li, R.; Neurock, M.; Sinha, N.; Stitt, E.H.; et al. Solvent effects in the hydrogenation of 2-butanone. J. Catal. 2012, 289, 30–41. [Google Scholar] [CrossRef]

- Michel, C.; Gallezot, P. Why Is Ruthenium an Efficient Catalyst for the Aqueous-Phase Hydrogenation of Biosourced Carbonyl Compounds. ACS Catal. 2015, 5, 4130–4132. [Google Scholar] [CrossRef]

- Kim, Y.; Moon, E.-S.; Shin, S.; Kang, H. Acidic Water Monolayer on Ruthenium (0001). Angew. Chem. Int. Ed. 2012, 51, 12806–12809. [Google Scholar] [CrossRef]

- Cao, W.; Luo, W.; Ge, H.; Su, Y.; Wang, A.; Zhang, T. UiO-66 derived Ru/ZrO2@C as a highly stable catalyst for hydrogenation of levulinic acid to γ-valerolactone. Green Chem. 2017, 19, 2201–2211. [Google Scholar] [CrossRef]

- Yan, L.; Yao, Q.; Fu, Y. Conversion of levulinic acid and alkyl levulinates into biofuels and high value chemicals. Green Chem. 2017, 19, 5527–5547. [Google Scholar] [CrossRef]

- Wojciechowska, J.; Jędrzejczyk, M.; Grams, J.; Keller, N.; Ruppert, A.M. Enhanced production of γ-valerolactone with an internal source of hydrogen on Ca-modified TiO2 supported Ru catalysts. ChemSusChem 2019, 12, 639–650. [Google Scholar] [CrossRef] [Green Version]

- Rivas, S.; Raspolli Galletti, A.M.; Antonetti, C.; Licursi, D.; Santos, V.; Parajó, J.C. A Biorefinery cascade conversion of hemicellulose-free eucalyptus globulus wood: Production of concentrated levulinic acid solutions for γ-valerolactone sustainable preparation. Catalysts 2018, 18, 169. [Google Scholar] [CrossRef] [Green Version]

- Al-Shaal, M.G.; Wright, W.R.H.; Palkovits, R. Exploring the ruthenium catalysed synthesis of γ-valerolactone in alcohols and utilisation of mild solvent-free reaction conditions. Green Chem. 2012, 14, 1260–1263. [Google Scholar] [CrossRef]

- Lange, J.-P. Renewable feedstocks: The problem of catalyst deactivation and its mitigation. Angew. Chem. Int. Ed. 2015, 54, 13186–13197. [Google Scholar] [CrossRef]

- Lange, J.-P.; Price, R.; Ayoub, P.M.; Louis, J.; Petrus, L.; Clarke, L.; Gosselink, H. Valeric biofuels: A platform of cellulosic transportation fuels. Angew. Chem. Int. Ed. 2010, 49, 4479–4483. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.; Cui, J.; Deng, T.; Cui, X.; Ding, G.; Zhu, Y.; Li, Y. Water-Promoted Hydrogenation of Levulinic Acid to γ-Valerolactone on Supported Ruthenium Catalyst. ChemCatChem 2015, 7, 508–512. [Google Scholar] [CrossRef]

- Zhang, S.T.; Li, C.M.; Yan, H.; Wei, M.; Evans, D.G.; Duan, X. Density Functional Theory Study on the Metal-Support Interaction between Ru Cluster and Anatase TiO2(101) Surface. J. Phys. Chem. C 2014, 118, 3514–3522. [Google Scholar] [CrossRef]

- Piskun, A.S.; Ftouni, J.; Tang, Z.; Weckhuysen, B.M.; Bruijnincx, P.C.A.; Heeres, H.J. Hydrogenation of levulinic acid to γ-valerolactone over anatase-supported Ru catalysts: Effect of catalyst synthesis protocols on activity. Appl. Catal. A Gen. 2018, 549, 197–206. [Google Scholar] [CrossRef]

- Li, C.M.; Zhang, S.T.; Zhang, B.S.; Su, D.S.; Duan, X. Photohole-oxidation-assisted anchoring of ultra-small Ru clusters onto TiO2 with excellent catalytic activity and stability. J. Mater. Chem. A 2013, 1, 2461–2467. [Google Scholar] [CrossRef]

- Yin, A.X.; Liu, W.C.; Ke, J.; Zhu, W.; Gu, J.; Zhang, Y.W.; Yan, C.H. Ru nanocrystals with shape-dependent surface-enhanced Raman spectra and catalytic properties: Controlled synthesis and DFT calculations. J. Am. Chem. Soc. 2012, 134, 20479–20489. [Google Scholar] [CrossRef]

- Alvarez-Rodrguez, J.; Rodrguez-Ramos, I.; Guerrero-Ruiz, A.; Gallegos-Suarez, E.; Arcoya, A. Influence of the nature of support on Ru-supported catalysts for selective hydrogenation of citral. Chem. Eng. J. 2012, 169–178. [Google Scholar] [CrossRef]

- Coq, B.; Kumbhar, P.S.; Moreau, C.; Figueras, F. Zirconia-supported monometallic Ru and bimetallic Ru-Sn, Ru-Fe catalysts: Role of metal support interaction in the hydrogenation of cinnamaldehyde. J. Phys. Chem. 1994, 98, 10180–10188. [Google Scholar] [CrossRef]

- Ruppert, A.M.; Grams, J.; Jędrzejczyk, M.; Matras-Michalska, J.; Keller, M.; Ostojska, K.; Sautet, P. Titania-supported catalysts for levulinic acid hydrogenation: Influence of support and its impact on γ-valerolactone yield. ChemSusChem 2015, 8, 1538–1547. [Google Scholar] [CrossRef]

- Szejtli, J. Introduction and general overview of cyclodextrin chemistry. Chem. Rev. 1998, 98, 1743–1753. [Google Scholar] [CrossRef]

- Breslow, R.; Dong, S.D. Biomimetic reactions catalyzed by cyclodextrins and their derivatives. Chem. Rev. 1998, 98, 1997–2011. [Google Scholar] [CrossRef]

- Polarz, S.; Smarsly, B.; Bronstein, L.; Antonietti, M. From cyclodextrin assemblies to porous materials by silica templating. Angew. Chem. Int. Ed. 2001, 40, 4417–4421. [Google Scholar] [CrossRef]

- Han, B.H.; Antonietti, M. Cyclodextrin-based pseudopolyrotaxanes as templates for the generation of porous silica materials. Chem. Mater. 2002, 14, 3477–3485. [Google Scholar] [CrossRef]

- Han, B.H.; Smarsly, B.; Gruber, C.; Wenz, G. Towards porous silica materials via nanocasting of stable pseudopolyrotaxanes from alpha-cyclodextrin and polyamines. Microporous Mesoporous Mater. 2003, 66, 127–132. [Google Scholar] [CrossRef]

- Bleta, R.; Menuel, S.; Léger, B.; Da Costa, A.; Monflier, E.; Ponchel, A. Evidence for the existence of crosslinked crystalline domains within cyclodextrin-based supramolecular hydrogels through sol-gel replication. RSC Adv. 2014, 4, 8200–8208. [Google Scholar] [CrossRef]

- Bleta, R.; Machut, C.; Léger, B.; Monflier, E.; Ponchel, A. Coassembly of block copolymer and randomly methylated β-cyclodextrin: From swollen micelles to mesoporous alumina with tunable pore size. Macromolecules 2013, 46, 5672–5683. [Google Scholar] [CrossRef]

- Bleta, R.; Machut, C.; Léger, B.; Monflier, E.; Ponchel, A. Investigating the effect of randomly methylated β-cyclodextrin/block copolymer molar ratio on the template-directed preparation of mesoporous alumina with tailored porosity. J. Incl. Phenom. Macrocycl. Chem. 2014, 80, 323–335. [Google Scholar] [CrossRef]

- Bleta, R.; Lannoy, A.; Machut, C.; Monflier, E.; Ponchel, A. Understanding the role of cyclodextrins in the self-assembly, crystallinity, and porosity of titania nanostructures. Langmuir 2014, 30, 11812–11822. [Google Scholar] [CrossRef]

- Lannoy, A.; Bleta, R.; Machut, C.; Monflier, E.; Ponchel, A. Block copolymer-cyclodextrin supramolecular assemblies as soft templates for the synthesis of titania materials with controlled crystallinity, porosity and photocatalytic activity. RSC Adv. 2014, 4, 40061–40070. [Google Scholar] [CrossRef]

- Lannoy, A.; Bleta, R.; Machut-Binkowski, C.; Addad, A.; Monflier, E.; Ponchel, A. Cyclodextrin-directed synthesis of gold-modified TiO2 materials and evaluation of their photocatalytic activity in the removal of a pesticide from water: Effect of porosity and particle size. ACS Sustain. Chem. Eng. 2017, 5, 3623–3630. [Google Scholar] [CrossRef]

- Bleta, R.; Noël, S.; Addad, A.; Ponchel, A.; Monflier, E. Mesoporous RuO2/TiO2 composites prepared by cyclodextrin-assisted colloidal self-assembly: Towards efficient catalysts for the hydrogenation of methyl oleate. RSC Adv. 2016, 6, 14570–14579. [Google Scholar] [CrossRef]

- Bleta, R.; Schiavo, B.; Corsaro, N.; Costa, P.; Giaconia, A.; Interrante, L.; Monflier, E.; Pipitone, G.; Ponchel, A.; Sau, S.; et al. Robust mesoporous CoMo/γ-Al2O3 catalysts from cyclodextrin-based supramolecular assemblies for hydrothermal processing of microalgae: Effect of the preparation method. ACS Appl. Mater. Interfaces 2018, 10, 12562–12579. [Google Scholar] [CrossRef]

- Bleta, R.; Ponchel, A.; Monflier, E. Cyclodextrin-based supramolecular assemblies: A versatile toolbox for the preparation of functional porous materials. Environ. Chem. Lett. 2018, 16, 1393–1413. [Google Scholar] [CrossRef]

- Bleta, R.; Monflier, E.; Ponchel, A. Cyclodextrins and nanostructured porous inorganic materials. In Cyclodextrin Fundamentals, Reactivity and Analysis; Lichtfouse, E., Fourmentin, S., Crini, G., Eds.; (Environmental Chemistry for a Sustainable World Series); Springer: Berlin/Heidelberg, Germany, 2018; pp. 105–153. ISBN 9783319761589. [Google Scholar]

- Decarpigny, C.; Bleta, R.; Ponchel, A.; Monflier, E. Confinement of Candida antarctica lipase B in a multifunctional cyclodextrin-derived silicified hydrogel and its application as enzymatic nanoreactor. ACS Appl. Bio Mater. 2019, 2, 5568–5581. [Google Scholar] [CrossRef]

- Zhang, H.; Banfield, J.F. Thermodynamic analysis of phase stability of nanocrystalline titania. J. Mater. Chem. 1998, 8, 2073–2076. [Google Scholar] [CrossRef]

- Navrotsky, A.; Kleppla, O.J. Enthalpy of the anatase-rutile transformation. J. Am. Ceram. Soc. 1967, 50, 626. [Google Scholar] [CrossRef]

- Reidy, D.J.; Holmes, J.D.; Morris, M.A. The critical size mechanism for the anatase to rutile transformation in TiO2 and doped-TiO2. J. Eur. Ceram. Soc. 2006, 26, 1527–1534. [Google Scholar] [CrossRef]

- Alexandridis, P.; Holzwarth, J.F.; Hatton, T.A. Micellization of poly (ethylene oxide)-poly (propylene oxide)-poly (ethylene oxide) triblock copolymers in aqueous solutions: Thermodynamics of copolymer association. Macromolecules 1994, 27, 2414–2425. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Feng, Z.; Chen, J.; Li, C. UV Raman Spectroscopic Study on TiO2. I. Phase Transformation at the Surface and in the Bulk. J. Phys. Chem. B 2006, 110, 927–935. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Q.; Li, M.; Feng, Z.; Li, C. UV Raman Spectroscopic Study on TiO2. II. Effect of Nanoparticle Size on the Outer/Inner Phase Transformations. J. Phys. Chem. C 2009, 11, 1698–1704. [Google Scholar] [CrossRef]

- Xiang, G.; Shi, X.; Wu, Y.; Zhuang, J.; Wang, X. Size effects in Atomic-Level Epitaxial Redistribution Process of RuO2 over TiO2. Sci. Rep. 2012, 2, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Kadu, B.S.; Hengne, A.M.; Biradar, N.S.; Rode, C.V.; Chikate, R.C. Reductive cyclization of levulinic acid to γ-valerolactone over non-noble bimetallic nanocomposite. Ind. Eng. Chem. Res. 2016, 55, 13032–13039. [Google Scholar] [CrossRef]

- Luo, W.; Deka, U.; Beale, A.M.; van Eck, E.R.H.; Bruijnincx, P.C.A.; Weckhuysen, B.M. Ruthenium-catalyzed hydrogenation of levulinic acid: Influence of the support and solvent on catalyst selectivity and stability. J. Catal. 2013, 301, 175–186. [Google Scholar] [CrossRef]

- Geilen, F.M.A.; Engendahl, B.; Harwardt, A.; Marquardt, W.; Klankermayer, J.; Leitner, W. Selective and flexible transformation of biomass-derived platform chemicals by a multifunctional catalytic system. Angew. Chem. Int. Ed. 2010, 49, 5510–5514. [Google Scholar] [CrossRef]

- Yan, K.; Liao, J.; Wu, X.; Xie, X. A noble-metal free Cu-catalyst derived from hydrotalcite for highly efficient hydrogenation of biomass-derived furfural and levulinic acid. RSC Adv. 2013, 3, 3853–3856. [Google Scholar] [CrossRef]

- Piskun, A.S.; van de Bovenkamp, H.H.; Rasrendra, C.B.; Winkelman, J.G.M.; Heeres, H.J. Kinetic modeling of levulinic acid hydrogenation to γ-valerolactone in water using a carbon supported Ru catalyst. Appl. Catal. A Gen. 2016, 525, 1–10. [Google Scholar] [CrossRef]

- Almeida, L.D.; Rocha, A.L.A.; Rodrigues, T.S.; Robles-Azocar, P.A. Highly selective hydrogenation of levulinic acid catalyzed by Ru on TiO2-SiO2 hybrid support. Catal. Today 2020, 344, 158–165. [Google Scholar] [CrossRef]

- Sudhakar, M.; Lakshmi Kantam, M.; Swarna Jaya, V.; Kishore, R.; Ramanujachary, K.V.; Venugopal, A. Hydroxyapatite as a novel support for Ru in the hydrogenation of levulinic acid to γ-valerolactone. Catal. Comm. 2014, 50, 101–104. [Google Scholar] [CrossRef]

- Putrakumar, B.; Nagaraju, N.; Pavan Kumar, V.; Chary, K.V.R. Hydrogenation of levulinic acid to γ-valerolactone over coppercatalysts supported on γ-Al2O3. Catal. Today 2015, 250, 209–217. [Google Scholar] [CrossRef]

- Jones, D.R.; Iqbal, S.; Miedziak, P.J.; Morgan, D.J.; Edwards, J.K.; He, Q.; Hutchings, G.J. Selective Hydrogenation of Levulinic Acid Using Ru/C Catalysts Prepared by Sol-Immobilisation. Top. Catal. 2018, 61, 833–843. [Google Scholar] [CrossRef] [Green Version]

- Merte, L.R.; Peng, G.W.; Bechstein, R.; Rieboldt, F.; Farberow, C.A.; Grabow, L.C.; Kudernatsch, W.; Wendt, S.; Lægsgaard, E.; Mavrikakis, M.; et al. Water-mediated proton hopping on an iron oxide surface. Science 2012, 336, 889–893. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lueking, A.D. Effect of surface oxygen groups and water on hydrogen spillover in Pt-doped activated carbon. J. Phys. Chem. C 2011, 115, 4273–4282. [Google Scholar] [CrossRef]

- Zhao, M.; Xu, L.; Vara, M.; Elnabawy, A.O.; Gilroy, K.D.; Hood, Z.D.; Zhou, S.; Figueroa-Cosme, L.; Chi, M.; Mavrikakis, M.; et al. Synthesis of Ru Icosahedral Nanocages with a Face-Centered-Cubic Structure and Evaluation of Their Catalytic Properties. ACS Catal. 2018, 8, 6948–6960. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, Z.; Lyu, Z.; Hood, Z.D.; Xie, M.; Vara, M.; Chi, M.; Xia, Y. Ru Octahedral Nanocrystals with a Face-Centered Cubic Structure, {111} Facets, Thermal Stability up to 400 °C, and Enhanced Catalytic Activity. J. Am. Chem. Soc. 2019, 141, 7028–7036. [Google Scholar] [CrossRef]

- Bonelli, B.; Cozzolino, M.; Tesser, R.; Di Serio, M.; Piumetti, M.; Garrone, E.; Santacesari, E. Study of the surface acidity of TiO2/SiO2 catalysts by means of FTIR measurements of CO and NH3 adsorption. J. Catal. 2007, 246, 293–300. [Google Scholar] [CrossRef]

- Kumar, V.V.; Naresh, G.; Sudhakar, M.; Tardio, J.; Bhargava, S.K.; Venugopal, A. Role of Brønsted and Lewis acid sites on Ni/TiO2 catalyst for vapour phase hydrogenation of levulinic acid: Kinetic and mechanistic study. Appl. Catal. A 2015, 505, 217–223. [Google Scholar] [CrossRef]

- Kumar, V.V.; Naresh, G.; Deepa, S.; Bhavani, P.G.; Nagaraju, M.; Sudhakar, M.; Chary, K.V.R.; Tardio, J.; Venugopal, A. Influence of W on the reduction behaviour and Brønsted acidity of Ni/TiO2 catalyst in the hydrogenation of levulinic acid to valeric acid: Pyridine adsorbed DRIFTS study. Appl. Catal. A 2017, 531, 169–176. [Google Scholar] [CrossRef]

- Notari, B.; Willey, R.J.; Panizza, M.; Busca, G. Which sites are the active sites in TiO2-SiO2 mixed oxides? Catal. Today 2006, 116, 99–110. [Google Scholar] [CrossRef]

- Lu, J.; Kosuda, K.M.; Van Duyne, R.P.; Stair, P.C. Surface Acidity and Properties of TiO2/SiO2 Catalysts Prepared by Atomic Layer Deposition: UV-visible Diffuse Reflectance, DRIFTS, and Visible Raman Spectroscopy Studies. J. Phys. Chem. C 2009, 113, 12412–12418. [Google Scholar] [CrossRef] [Green Version]

- Bleta, R.; Alphonse, P.; Lorenzato, L. Nanoparticle Route for the Preparation in Aqueous Medium of Mesoporous TiO2 with Controlled Porosity and Crystalline Framework. J. Phys. Chem. C 2010, 114, 2039–2048. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. FULLPROF: A Program for Rietveld Refinement and Pattern Matching Analysis. In Abstracts of the Satellite Meeting on Powder Diffraction, Proceedings of the XV Congress of the IUCR, Toulouse, France, 19–28 July 1990; International Union of Crystallography: Chester, UK, 1990; p. 127. [Google Scholar]

- Roisnel, T.; Rodriguez-Carvajal, J. WinPLOTR A Windows Tool for Powder Diffraction Pattern Analysis. In Materials Science Forum, Proceedings of the 7th European Powder Diffraction Conference (EPDIC 7), Barcelona, Spain, 20–23 May 2000; Delhez, R., Mittenmeijer, E.J., Eds.; Trans Tech Publications: Zurich, Switzerland, 2000; pp. 118–123. [Google Scholar]

- Scherrer, P. Bestimmung der Grosse und der Inneren Struktur von Kolloidteilchen Mittels Rontgenstrahlen. Nachr. Ges. Wiss. Göttingen Math. Phys. Kl. 1918, 2, 98–100. [Google Scholar]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

| Sample | SBET a (m2 g−1) | Vcum b (cm3 g−1) | PS c (nm) | Crystallite Size d (nm) | ||

|---|---|---|---|---|---|---|

| Anatase TiO2 | Brookite TiO2 | Rutile TiO2 | ||||

| TiO2-sg | 21 ± 1 | 0.030 ± 0.002 | <2.0 ± 0.4 | 36.4 ± 2.9 | 18.7 ± 1.5 | 60.4 ± 4.8 |

| TiO2-ns | 80 ± 4 | 0.20 ± 0.01 | 7.4 ± 1.5 | 11.0 ± 0.9 | 4.5 ± 0.4 | 11.5 ± 0.9 |

| TiO2-SiO2 3:1-ns | 169 ± 8 | 0.49 ± 0.02 | 11.1 ± 2.2 | 10.3 ± 0.8 | 4.4 ± 0.4 | 9.5 ± 0.8 |

| TiO2-SiO2 3:2-ns | 198 ± 10 | 0.93 ± 0.05 | 18.1 ± 3.6 | 6.2 ± 0.5 | 2.7 ± 0.2 | - |

| TiO2-SiO2 3:3-ns | 193 ± 10 | 1.17 ± 0.06 | 24.0 ± 4.8 | 6.1 ± 0.5 | 2.7 ± 0.2 | - |

| Sample | SBET a (m2 g−1) | Vcum b (cm3 g−1) | PS c (nm) | RuO2 Size d (nm) |

|---|---|---|---|---|

| RuO2@TiO2-sg | 8 ± 0.4 | 0.015 ± 0.00 | <2.0 ± 0.4 | 15.8 ± 1.6 |

| RuO2@TiO2-ns | 65 ± 3.2 | 0.18 ± 0.01 | 6.1 ± 1.2 | 9.9 ± 1.0 |

| RuO2@TiO2-SiO2 3:1-ns | 162 ± 8.1 | 0.43 ± 0.021 | 10.6 ± 2.1 | 9.0 ± 0.9 |

| RuO2@TiO2-SiO2 3:2-ns | 138 ± 6.9 | 0.50 ± 0.03 | 15.0 ± 3.0 | - |

| RuO2@TiO2-SiO2 3:3-ns | 156 ± 7.8 | 0.72 ± 0.04 | 15.1 ± 3.0 | - |

| ||||||

|---|---|---|---|---|---|---|

| Entry | Catalyst | TiO2 (%) b | SiO2 (%) b | LA Conversion (%) c | GVL Yield (%) c | Productivity (molGVL g−1metal h−1) d |

| 1 | TiO2-ns | 100 | 0 | <3 | 0 | - |

| 2 | TiO2-SiO2 3:3-ns | 66 | 34 | <3 | 0 | - |

| 3 | Ru@TiO2-sg | 100 | 0 | 65 | 46 | 4.0434 |

| 4 | Ru@TiO2-ns | 100 | 0 | 79 | 58 | 5.0983 |

| 5 | Ru@TiO2-SiO2 3:1-ns | 87 | 13 | 82 | 75 | 6.5926 |

| 6 | Ru@TiO2-SiO2 3:2-ns | 76 | 24 | 88 | 76 | 6.6805 |

| 7 | Ru@TiO2-SiO2 3:3-ns | 66 | 34 | 91 | 78 | 6.8563 |

| 8 | Ru@TiO2-SiO2 3:3-sg | 68 | 32 | 73 | 56 | 4.9225 |

| 9 | Ru@C | - | - | 99 | 66 | 5.8015 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Decarpigny, C.; Noël, S.; Addad, A.; Ponchel, A.; Monflier, E.; Bleta, R. Robust Ruthenium Catalysts Supported on Mesoporous Cyclodextrin-Templated TiO2-SiO2 Mixed Oxides for the Hydrogenation of Levulinic Acid to γ-Valerolactone. Int. J. Mol. Sci. 2021, 22, 1721. https://doi.org/10.3390/ijms22041721

Decarpigny C, Noël S, Addad A, Ponchel A, Monflier E, Bleta R. Robust Ruthenium Catalysts Supported on Mesoporous Cyclodextrin-Templated TiO2-SiO2 Mixed Oxides for the Hydrogenation of Levulinic Acid to γ-Valerolactone. International Journal of Molecular Sciences. 2021; 22(4):1721. https://doi.org/10.3390/ijms22041721

Chicago/Turabian StyleDecarpigny, Cédric, Sébastien Noël, Ahmed Addad, Anne Ponchel, Eric Monflier, and Rudina Bleta. 2021. "Robust Ruthenium Catalysts Supported on Mesoporous Cyclodextrin-Templated TiO2-SiO2 Mixed Oxides for the Hydrogenation of Levulinic Acid to γ-Valerolactone" International Journal of Molecular Sciences 22, no. 4: 1721. https://doi.org/10.3390/ijms22041721

APA StyleDecarpigny, C., Noël, S., Addad, A., Ponchel, A., Monflier, E., & Bleta, R. (2021). Robust Ruthenium Catalysts Supported on Mesoporous Cyclodextrin-Templated TiO2-SiO2 Mixed Oxides for the Hydrogenation of Levulinic Acid to γ-Valerolactone. International Journal of Molecular Sciences, 22(4), 1721. https://doi.org/10.3390/ijms22041721