3. Gas Sensor Based on Graphene Polymer Hybrids

Seekaew

et al. synthesized graphene-poly (3,4-ethylenedioxythiophene):poly (styrenesulfonate) (G-PEDOT:PSS) composite by gradually mixing graphene solution in PEDOT:PSS solution [

22]. Screen printing technique was used to prepare interdigitated Ag electrodes on a flexible and transparent substrate. The G-PEDOT:PSS solution was inkjet printed on these electrodes by using Hewlett Packard (HP) deskjet 2000 printer with resolution of 1200 dots per inch (dpi) to fabricate the NH

3 gas sensor. The sensitivity of the sensor device was assessed while being exposed to different concentrations of NH

3 ranging from 5–1000 ppm. Whereas, selectivity of the sensor was investigated by using ethanol, methanol, toluene, acetone and diethylamine gases. The response of G-PEDOT:PSS sensor towards 500 ppm of NH

3 was 9.6% which is higher than the responses of PEDOT:PSS (4.4%) and pristine graphene (2.4%) gas sensors. Similarly, the G-PEDOT:PSS hybrid sensor exhibited a response time of 3 min, which is fast in comparison to the PEDOT:PSS sensor.

Several sensing mechanisms have been proposed for sensors based on conducting polymers:

- (i)

Redox reactions

- (ii)

Charge transfer

- (iii)

Polymer swelling

(i) According to the first mechanism, the surface of G-PEDOT:PSS trap oxygen species (chemisorbed oxygen O2−) interact with NH3 molecules and release their electrons back to graphene/polymer composite. The holes of the valence band combine with electrons of the conduction band which results in lowering carrier concentrations and, finally, an increase in the resistance of the p-type G-PEDOT:PSS sensing film.

(ii) In the charge transfer process, the holes of conductive G-PEDOT:PSS surface interact with electron donating NH3 analyte after physisorption of NH3 molecules on the sensor surface. The delocalization degree of conjugated pi electrons of sensing films was increased, due to charge transfer from NH3 molecules, which leads to the formation of neutral polymer backbone. Thus, electrical conductivity of the sensing film decreases with a decrease in charge carriers.

(iii) A single PSS chain in PEDOT:PSS polymer film interacts with many PEDOT chains over its length. There is a very short interchain distance which favors the electron hopping process. However, this hopping process becomes difficult because of an increase in interchain distance of PEDOT due to swelling of the polymer with NH3 molecules’ diffusion. Graphene in G-PEDOT:PSS acted as a conductive pathway that favors the electron hopping process. The swelling process disrupts these conductive pathways as well as increases the PEDOT distance leading to a significant increase in resistance of the G-PEDOT:PSS sensor upon NH3 exposure. The resistance of graphene/polymer composite returns to its original value after NH3 desorption by dry air purging.

A surface plasmon resonance (SPR) based fiber optic gas probe was fabricated by utilizing a nanocomposite film based on PMMA and rGO [

23]. The performance of the probe was tested against different gases like ammonia, chlorine, hydrogen, nitrogen, and hydrogen sulphide but the probe was more sensitive to ammonia gas. The GO was prepared by oxidation of graphite powder and it was chemically reduced by using hydrazine hydrate as a reducing agent to prepare rGO. The nanocomposite of PMMA-rGO was prepared by a bulk polymerization technique in which prepolymer MMA was polymerized in the presence of rGO.

The response mechanisms of fiber optic sensor based on PMMA-rGO nanocomposite for different gases can be explained as:

(i) The rGO surface contains polar oxygen functionalities which adsorb polar gas molecules and change its dielectric constant due to charge transfer; (ii) The incorporation of rGO into the polymer matrix creates conducting pathways, and adsorption of gas molecules may increase contact resistance between rGO sheets by increasing distance between rGO sheets. The change in volume of polymer matrix due to gas adsorption also increases the distance between sheets.

A self-assembly technique was used to create a conductive network of chemically reduced graphene oxide (CrGO) between parallel Au electrodes [

24]. Au electrodes were modified with cysteamine hydrochloride to create a positive charge on electrode, which attracts negatively charged GO electrostatically. The GO sheets (assembled on Au electrodes) were directly reduced to rGO by hydrazine and pyrrole vapor to create a sensing platform for target gas molecules. The excellent sensing properties of rGO reduced by pyrrole in comparison to hydrazine reduced GO are attributed to its intrinsic properties as well as adsorbed polypyrrole (PPy) molecules. An ammonia gas sensor was prepared by reducing GO from pyrrole whereas GO was synthesized by a modified Hummers method [

25]. During this reduction process, GO acted as oxidizing agent for oxidative polymerization of pyrrole. In this process, ethanol was used as a solvent which helps in evenly adsorbing PPy molecules on the rGO surface. Pyrrole reduced GO in the absence of ethanol was also produced for the sake of comparison. During this reduction process, the carboxyl (-COOH) groups had been removed from the surface of GO. The sensor devices were also prepared based on PPy nanofibers and rGO reduced by p-phenylenediamine (PPD). The sensor based on pyrrole reduced GO exhibited enhanced sensing behavior compared to PPy nanofibers alone or rGO produced via PPD. The better sensing performance of rGO device is due to the intrinsic properties of rGO sheets as well as adsorbed PPy molecules. The NH

3 molecule is a reducing agent and has a lone pair of electrons which can be easily donated to p-type rGO that leads to an increase in sensor resistance. The response behavior of rGO sheets can be divided into two types: a fast response and a slow response. The fast response of rGO sheets is due to the gas adsorption onto binding sites with low energy (sp

2-bonded carbon) and a slow response is due to high energy binding sites (e.g., vacancies, defects and oxygen functional groups). The sensing performance of this device also depends on the number of PPy molecules attached on the rGO surface. A lower number of PPy molecules on rGO surface allows complete interaction between NH

3 molecules and sp

2-bonded carbon atoms of rGO which leads to fast response of devices. A higher number of PPy molecules on rGO surface hinders the interaction between NH

3 gas and sp

2-bonded carbon, which severely affects the sensing performance.

Aniline was used to reduce GO in order to fabricate NH

3 gas sensor [

26]. rGO obtained in this process is attached to different states of polyaniline (PANI),

i.e., acid-doped PANI attached rGO, dedoped PANI attached rGO and free rGO. The sensing properties of free rGO were much better than acid doped or dedoped rGO. Excellent sensing properties of completely free rGO based sensor is due to intrinsic properties of free rGO. The response of the sensor can be explained because of charge transfer from p-type rGO to adsorb ammonia molecules. In another study, a drop drying method has been utilized to produce ammonia gas sensor based on aniline reduced GO [

27]. A conductive network of rGO sensing material is applied between electrode arrays. The rGO produced by aniline has enhanced sensing behavior in comparison to rGO reduced from hydrazine. The oxidized aniline (polyaniline (PANI)) attached to the rGO surface through π-π interaction and plays a key role in the sensing performance of the sensor device. The resistance of the sensor increases due to depletion of holes when electron donating NH

3 gas interacts with the p-type graphene and causes charge transfer. PPy-rGO composite was prepared by a drop casting method to fabricate an ammonia gas sensor [

28]. The composite based sensor was three times more sensitive than PPy thin film sensor and was capable of detecting a very low concentration (3 ppm) of ammonia. However, the recovery of PPy-rGO composite sensor is very difficult due to the presence of high energy binding sites.

A chemiresistor sensor for NO

2 gas molecules was fabricated by a porous conducting polymer PEDOT nanocomposite prepared on rGO film [

29]. The increase in charge carriers of composite was attributed to π-π interactions between PEDOT and rGO sheets which leads to a decrease in composite resistance. Adsorption of NO

2 gas molecules increases the number of charge carriers and tremendously decreases resistance of rGO-PEDOT composite.

A combination of an electrospinning method and GO wrapping on nylon-6 fibers through an electrostatic self-assembly, followed by a low-temperature chemical reduction, was utilized to produce a sensor for detecting NO

2 gas. A procedure to fabricate rGO/nylon-6 nanofiber mats (FRGO) based gas sensor has been illustrated in

Figure 1a and

Figure 1b. Nylon-6 nanofiber scaffold was produced by using electrospinning method directly onto SiO

2/Si substrate having platinum (Pt) interdigitated electrode (IDE) arrays [

30]. These nanofibers were functionalized using bovine serum albumin (BSA) molecules which induce a positive charges on nanofiber surface and improves GO adsorption onto electrospun nanofibers. The GO sheets are negatively charged and form a uniform coating on positively charged BSA functionalized nylon-6 nanofibers via electrostatic self-assembly. Finally, a low temperature chemical reduction method was utilized to reduce GO/nylon-6 nanofiber mats. SEM image of FRGO shows that porous interwoven structure of nylon-6 nanofibers wrapped completely with rGO sheets as shown in

Figure 1c. The FRGO based NO

2 gas sensor exhibited a sensor response of 7% to 0.25 ppm of NO

2 as shown in

Figure 1d. The excellent sensing performance of GO/nylon-6 nanofiber mat was attributed to the large surface area of nanofibers. This hybrid nanofiber has approximately π (~3.14) times’ higher surface area than flattened fiber, which leads to better adsorption and, finally, higher sensing performance of the sensor.

The GO was reduced to rGO during the formation of PPy nanofibers by utilizing a one-step redox reaction under UV illumination at room temperature [

31]. The rGO-PPy nanofiber composite is highly sensitive to NO

2 gas. The pyrrole monomer was absorbed by the GO surface by π-π stacking interactions. Polymerization of pyrrole to PPy and reduction of GO to rGO occur simultaneously under UV illumination. Graphene oxide (GO) was synthesized by acid dissolution method in which graphite powder is heated with sulfuric acid and phosphoric acid in the presence of potassium permanganate. Then, prepared GO was chemically reduced with ascorbic acid to synthesize rGO.

In another study, a paper-like nanocomposite of G/nylon-6 was fabricated by incorporating rGO onto a nylon-6 (N6) membrane via vacuum assisted self-assembly (VASA) method [

32]. The dispersion of rGO onto a nylon sheet creates a conducting network and resistance to polymer nanocomposite decreases with an increase in rGO dispersion. There is an abrupt increase in electrical resistance of graphene nanocomposite when exposed to trimethylamine (TMA) concentrations. The GO was prepared by modifying Hummers method in which graphite was oxidized with concentrated sulfuric acid [

33]. Then, CrGO was prepared by reducing GO with PPD. The synthesis of CrGO via GO reduction eliminates many of the oxygen-containing functional groups (restoring original properties of sheets) but it still contains oxygen-based moieties and structural defects. The p-type semiconducting behavior of resultant CrGO is attributed to the existing oxygen-based moieties and structural defects which are electron withdrawing and promote holes in the valence bond of CrGO which play a key role in sensing properties. The analyte dimethyl methylphosphonate (DMMP) is a strong electron donor which depletes holes from the valence bond of CrGO, resulting in an increase in resistance after being adsorbed on the CrGO surface.

Figure 1.

(

a) Schematic representation of fabricating a gas sensor based on rGO/nylon-6 nanofibers; (

b) Optical images of the bare device (i), GO/nylon-6 coated, formation of GO network based on interwoven fibers (FGO) (ii), and rGO/nylon-6 sensing device, rGO gas sensors fabricated on electrospun nanofibers (FRGO) (iii); (

c) SEM image of rGO nanofiber; (

d) Sensing response of the devices based on FRGO as synthesized (blue line) and thermally treated FRGO at 300 °C (red line). {Reprinted with permission from [

30], ©2014 Royal Society of Chemistry}.

Figure 1.

(

a) Schematic representation of fabricating a gas sensor based on rGO/nylon-6 nanofibers; (

b) Optical images of the bare device (i), GO/nylon-6 coated, formation of GO network based on interwoven fibers (FGO) (ii), and rGO/nylon-6 sensing device, rGO gas sensors fabricated on electrospun nanofibers (FRGO) (iii); (

c) SEM image of rGO nanofiber; (

d) Sensing response of the devices based on FRGO as synthesized (blue line) and thermally treated FRGO at 300 °C (red line). {Reprinted with permission from [

30], ©2014 Royal Society of Chemistry}.

4. Gas Sensors Based on Metal/Metal Oxide Graphene Hybrid

Hong

et al. deposited palladium nanoparticles (Pd NPs) on single-layer graphene (SLG) via galvanic displacement between graphene-buffered Cu and Pd ion followed by spin-coating with a PMMA membrane layer to fabricate a hydrogen gas sensor [

34]. This process involved four main steps: growth of SLG on Cu foil by CVD method, deposition of Pd NPs on SLG via a galvanic displacement reaction, transfer of Pd NP/SLG hybrid onto electrode-patterned glass substrate, spin coating of PMMA polymer to fabricate PMMA/Pd NPs/SLG hybrid sensor. The mechanism of H

2 detection can be explained by dissolution and dissociation of H

2 molecules into atomic hydrogen in the presence of Pd NPs deposited on graphene. Pd-hydrides (PdHx) were formed (as a function of Pd is diminished) when H

2 molecules dissolved into atomic hydrogen after being adsorbed on Pd NPs surfaces. The resistance of the sensor increases as the diminished function of PdHx results in increased electron transfer to graphene from PdHx. Increase in the density of Pd NPs on SLG increases PdHx formation due to the high surface area of Pd. This will change the conduction pathways from graphene to Pd film like structures, which decreases gas response sensitivity. Pak

et al. synthesized palladium-decorated graphene nanoribbons (Pd-GNRs) for detecting hydrogen gas sensor [

35]. Laser interference lithography was utilized to prepare polymer residue-free GNRs. These nanoribbons were further decorated with Pd NPs. The GNRs were used for enhancing electrically conductive pathways, and Pd NPs were utilized as catalysts for sensing hydrogen gas. The SLG was grown on Cu/Ni film coated on a SiO

2/silicon wafer by inductively coupled plasma chemical vapor deposition (ICP-CVD) technique. The CVD-grown graphene was transferred to desired substrate by following polymer PMMA transferring technique. A periodically aligned GNR array was synthesized by placing a chromium interlayer under photoresist via laser interference lithography and then, incorporating it into the Pd-decorated hydrogen sensors. The developed sensor exhibited excellent response towards H

2 gas with response/recovery time of 60 s/90 s.

Another hydrogen gas sensor has been fabricated by incorporating Pd-WO

3 (Palladium-tungsten trioxide) nanostructures in GO and partially reduced graphene oxide (PrGO) by utilizing a controlled hydrothermal process [

36]. The homogeneous and stable WO

3 sol was synthesized from sodium tungstate powder Na

2WO

4 and its ribbon like nanostructure was formed by adding K

2SO

4. The GO was synthesized by following Hummer’s method, whereas PrGO suspension was obtained through the hydrothermal method. Pd-WO

3/GO and Pd-WO

3/PrGO hybrid was produced by adding Pd-WO

3 drop by drop to GO and PrGO suspensions under vigorous stirring. In this hybrid structure, Pd NPs and adsorbed oxygen species (such as O

−, O

2−, O

2−) play a dominant role in sensing target gas molecules. These oxygen species capture electrons from conduction band of WO

3 (as an n-type semiconductor) which generate a depletion layer with low electrical conductivity. Hydrogen as a reducing gas remove oxygen charge after interacting with these oxygen species and the generation of electrons in this reaction results in conductivity increase. The rate of this reaction increases in Pd NPs’ presence due to molecular hydrogen dissociation into active atoms. PdHx hybrids are also formed due to hydrogen dissolution in Pd, which has diminished function. This effect also leads to donation of electrons to the conduction band of WO

3 and increases the electrical conductivity of Pd-WO

3/graphene hybrid.

Phan

et al. synthesized graphene-supported platinum/palladium (Pt/Pd) core-shells hybrid to fabricate a hydrogen sensor device [

37]. At first, Pt/Pd core-shells were prepared by using highly uniformed colloidal solution of Pd nanocubes as the core and, then, Pt was coated on Pd cubes as shells. In the second step, graphene was decorated with these Pt/Pd core-shells to synthesize a Pt/Pd core–shell graphene hybrid. The sensor response of graphene hybrid towards 10,000 ppm (1% H

2) is 36% at room temperature with an excellent response/recovery time of 3/1.2 min whereas the detectable range of Pt/Pd core-shell hybrid is 1–40,000 ppm. Another hydrogen sensor was fabricated by using Pt and platinum-iron alloy (Pt

3Fe) nanoparticles which were decorated on nitrogen doped graphene [

38]. GO was prepared from graphite powder and, then, converted to graphene by hydrogen exfoliation at high temperatures. PSS served as anionic electrolyte and pyrrole monomer as a nitrogen source for incorporating nitrogen functional groups in graphene. The defects introduced to graphene by incorporating nitrogen in the structure facilitate uniform dispersion of Pt and Pt

3Fe alloy nanoparticles. Then, ethylene glycol reduction technique was followed to decorate graphene with Pt and Pt

3Fe alloy nanoparticles. Chloroplatinic acid (H

2PtCl

6) solution was used for decorating graphene with Pt nanoparticles whereas a mixture of H

2PtCl

6 and FeCl

3 solutions was used for Pt

3Fe alloy decoration. The sensor sensitivities were measured through exposure to 1%–4% of H

2 which indicates that sensitivity decreases when alloying Pd with 3D transition metals.

Anand

et al. synthesized a nanocomposite of graphene and zinc oxide (ZnO) by

in situ reduction of zinc acetate and GO during refluxing whereas GO was prepared from graphite powder by following Hummer’s method [

39]. A paste of G-ZnO was prepared by mixing it with ethanol, then a thick film of this paste was coated on alumina substrate having gold electrodes to fabricate the H

2 sensor. A number of G-ZnO thick film sensors were fabricated by varying the graphene content (0.6, 0.9, 1.2 and 1.5 wt%) in G-ZnO composite. The G-ZnO composite having 1.2 wt% of graphene content is very sensitive in comparison to ZnO (optimum operating temperature 400 °C) and other composites, and gives a sensor response of 3.5 at an optimum operating temperature of 150 °C. The composites exhibited improved performance even at lower temperatures in comparison to bare ZnO. Mishra

et al. synthesized rGO decorated with tin oxide (SnO

2) quantum dots (QDs) by a surfactant assisted hydrothermal method [

40]. Graphite powder was used for synthesizing rGO and SnO

2 QDs were prepared from SnCl

4·5H

2O by a hydrothermal method. The rGO-SnO

2 QDs based sensor was used to detect H

2 and liquefied petroleum gas (LPG) in a concentration range of 100–500 ppm and it gives a response of 89.3% to H

2 (500 ppm) and 92.4% to LPG (500 ppm) at an operating temperature of 200 °C and 250 °C, respectively.

Multiple gas sensors based on Pt decorated rGO nanostructures were fabricated via DEP. Different parameters of the DEP technique such as applied voltage, frequency and processing time were optimized to assemble Pt-rGO nanocomposite into the electrodes [

41]. For this purpose, Pt nanoparticles solution was mixed with GO nanostructure solution and then dropped into the gaps of electrodes. An AC voltage was applied which pulled and bound nanohybrid structures to the substrate surface between electrodes under the influence of electric field gradient. A sensor device based on a DEP assembled rGO structure without Pt was also fabricated for comparison. The sensitivities of both these sensor devices were investigated through exposure to different concentrations (200–1000 ppm) of H

2, NH

3, and NO gases at room temperature. The Pt nanoparticles decorated rGO sensor device exhibited an improvement of 100%, 60% and 25% to H

2, NH

3, and NO gases in comparison to the sensor having an rGO structure without Pt.

A surface plasmon resonance based gas sensor was synthesized depositing graphene flakes over gold (Au) nanoparticles [

42]. These nanoparticles were chemically attached to a functionalized fused silica substrate. The sensing performance depends on the concentration of Au NPs in rGO coupled Au thin films. A higher concentration of Au NPs in rGO-Au thin films leads to the best sensing performance towards H

2, NO

2, and CO. The rGO coupled Au NPs’ thin film sensor was exposed to 1 ppm of NO

2, 10,000 ppm and 100 ppm of H

2 and 10,000 ppm of CO. A change in optical properties was observed while exposing the sensitive surface (graphene flakes-Au NPs) to different gases such as reducing and oxidizing gases. This shift in surface plasmon resonance is attributed to an electron transfer to Au NPs and sp

2-hybridized carbons atoms of graphene oxide.

A chemiresistive type of acetylene gas sensor was synthesized based on silver (Ag) loaded ZnO-rGO hybrid via a chemical route [

43]. A chemiresistive semiconductor sensor was based on the change in resistance of sensing material after interacting with adsorbed gas. The sensing mechanism can be described in terms of oxygen adsorption reaction on the sensing material surface, which depends on operating temperature, and stable oxygen species are O

2−, O

−, O

2− that operate below 100 °C, between 100 and 300 °C and above 300 °C, respectively. The oxygen adsorption reactions can be represented as follows:

Non-ZnO modified graphene exhibited p-type behavior, whereas, in case of ZnO modified graphene, an opposite sensitivity response was observed due to n-type sensitivity nature of ZnO. Ag has better oxygen dissociation ability than ZnO and activates molecular oxygen dissociation on hybrid surface and creates more acetylene sensing active sites on the surface. The oxygen species on sensing material becomes more active with acetylene molecules, which donate electrons to the sensing surface.

A room temperature acetone gas sensor based on SnO

2-rGO hybrid composite film was fabricated on a printed circuit board (PCB) substrate (having interdigitated electrodes) by utilizing a hydrothermal method [

44]. It was prepared by reacting SnCl

4 with rGO and, later on, autoclave at high temperature. Then, the sensor was fabricated on PCB by microfabrication and sensing film was casted by drop casting. The higher sensing performance of SnO

2-rGO hybrid composite can be attributed to three factors:

(i) Incorporation of SnO2 nanoparticles in rGO creates a porous nanostructure by reducing aggregation of rGO sheets. The porous structure has greater surface area and more active sites such as defects, vacancies, oxygen functional groups and sp2-bonded carbons which adsorb and diffuse acetone gas molecules.

(ii) The gas sensing performance is due to heterojunction formation at the interface between n-type SnO2 nanoparticles and p-type rGO nanosheets. The electron donor ability of acetone gas increases negative charge carriers in n-type thin film and reduces an overall sensor resistance.

(iii) The surface oxygen species such as O2− is also responsible for gas sensing. These chemisorbed oxygen molecules are ionized to oxygen species by capturing free electrons from SnO2 nanoparticles. The rGO exhibits p-type semiconducting behavior and contains dominantly positive charge carriers (holes). The adsorbed acetone gas is an electron donor which changes the concentration of holes in rGO, resulting in a change in rGO resistance. The SnO2-rGO hybrid composite shows a higher response to acetone gas, which is attributed to high surface area and porous nanostructure.

A thin film of zinc oxide was deposited on graphene film by Atomic Layer Deposition (ALD), whereas graphene film was grown by CVD [

45]. A ZnO/G hybrid sensor was evaluated by exposing formaldehyde vapors. ALD is better than CVD because its synthesized layer is uniform, conformal and atomically precise and it also does not damage the substrate due to its low temperature and chemisorptions processing. Non-ZnO modified graphene exhibited p-type behavior and shows an increase in resistance upon exposure to reducing gas formaldehyde, which donates its electrons to graphene. Whereas, in case of ZnO modified graphene, an opposite sensitivity response was observed due to the n-type sensitivity nature of ZnO. The oxygen molecules adsorbed on ZnO extract electron from the conduction band of ZnO and form O

−, O

2−, O

2− which leads to a formation of depletion layer and, finally, increases ZnO resistance. The adsorbed oxygen species interacts with formaldehyde and releases trapped electrons back to ZnO conduction band resulting in a decrease in sensor resistance. Thus, ZnO-G hybrid exhibits enhanced sensor response in comparison to ZnO or graphene alone as a sensing material.

A graphene-zinc ferrite (G-ZnFe

2O

4) composite was prepared by solvothermal method and utilized to fabricate acetone gas sensor [

46]. The graphene for this composite was prepared by reduction of graphene oxide with hydrazine hydrate whereas graphene oxide was synthesized by modified Hummer’s method. ZnFe

2O

4 was produced by using Zn(NO

3)

2·6H

2O and Fe(NO

3)

3·9H

2O reagents as precursors. Acetone molecules interact with oxygen species on sensor surface and oxidize them to carbon dioxide and water along with release of free electrons, which results in a decrease in sensor resistance. A gas sensor was fabricated composed of ZnO conductive bottom layer on a metal foil (vertically aligned ZnO nanorod channel) and a graphene based top conductive electrode [

47]. A conductive layer of ZnO nanorods was prepared on stainless steel foil by following a wet hydrothermal method. The graphene film was grown by CVD method. The change in conductance is based on the depletion of ZnO NR channels by oxygen ionosorption on their surface by either O

− or O

2− depending on operating temperature. The interaction of reducing gas ethanol with ZnO NR substitutes surface-bound oxygen which releases electrons back to ZnO crystals and leads to an increase in electrical conductivity. The higher sensitivity of this sensor is attributed to the existence of pores between monolithic nanorods which means more surface area and greater sensor response.

Khadem

et al. synthesized G-ZnO hybrid to fabricate a gas sensor [

48]. ZnO nanowires in this hybrid has two important roles: reduction of GO to obtain graphene as well as acting as an efficient electromechanical actuator due to their piezoelectric properties. GO was prepared by utilizing Hummer’s method in which graphite powder was oxidized to produce GO. Laterally grown ZnO nanowires (NWs) were formed on Si wafer as substrate. The synthesized GO sheets were dispersed on previously grown ZnO NWs by dip-coating. The ZnO NWs have been used to reduce GO sheets through exposure to UV illumination. The gas sensing behavior of ZnO-G was evaluated through expoosure to ethanol vapors. The conductivity of ZnO NWs increases upon ethanol (which behaves as donor) exposure because of ethanol interaction with oxygen vacancies in ZnO NWs. The enhanced sensitivity of the ZnO-G hybrid structure in comparison to ZnO was attributed to the greater surface area of graphene. Moreover, sp

2 orbitals of carbon in graphene act as active sites which interact with gas molecules and change their conductivity according to the electron affinity of gas molecules as well as number of adsorbed gas molecules.

In a comparison of G-mica and G-SiO

2 based ammonia gas sensors, graphene is supported on two different substrates. Mica substrate induces more p-doping in graphene which leads to enhanced sensitivity [

49]. Muscovite mica is a well-known, natural insulating material having the formula KAl

2(Si

3AlO

10)(FOH)

2 and possessing high dielectric strength and chemical and thermal stability. Monolayer graphene (MLG) was prepared by CVD on Cu foil and, subsequently, transferred to the desired substrate by a PMMA assisted transfer technique. NH

3 molecules have strong electron donating capability and donate electrons to p-type graphene when adsorbed. The effect will shift Fermi level to Dirac point and leads to an increase in resistance upon exposure to NH

3 gas. The higher sensitivity on mica substrate can be explained in terms of substrate dependant doping and hydrophilicity. The mica substrate shift graphene Fermi level to downward which leads to form additional states around Fermi level. Thus, graphene orbitals significantly overlap with highest occupied molecular orbitals (HOMO) of NH

3 and cause large charge transfer. A gas sensor has been fabricated by using SnO

2-G composite which was synthesized by one-pot method with GO and SnCl

2 as precursors [

50]. The SnO

2 was n-type semiconductor and its interaction with reducing/oxidizing gas molecules leads to an increase/decrease in conductivity, respectively. The SnO

2-G composite also exhibited increased conductivity while in contact with reducing gases such as hydrogen sulfide (H

2S) and NH

3.

Xiang

et al. synthesized a composite of PPy and graphene nanoplatelets (GNs) by chemical polymerization and decorated it with titanium dioxide nanoparticles (TiO

2 NPs) by sol-gel technique (TiO

2@PPy-GN) [

51]. The TiO

2 NPs were in the range of 10–30 nm which were well dispersed on the PPy-GN composite. NH

3 sensor was fabricated by drop-coating a suspension of TiO

2@PPy-GN in DMF on integrated indium-tin oxide (ITO) electrodes. The sensors of GN, PPy-GN thin films were also fabricated for comparison. TiO

2@PPy-GN sensor content showed higher sensitivity to NH

3 and faster response and recovery times in comparison to GN and PPy-GN thin films. The response of TiO

2@PPy-GN sensor is about 12 and 4.5 times higher in comparison to GN and PPy-GN composite sensors. In another study, a single step synthetic procedure was applied to fabricate a room temperature gas sensor for CO, NH

3 and NO gases based on photoluminescence (PL) properties of zinc oxide (ZnO) decorated graphene oxide sheets (GO) as sensitive coatings [

52]. GO was synthesized by following Hummer's method and lithium hydroxide was utilized for reducing GO to produce rGO. ZnO nanoparticles were produced by using zinc acetate as precursor. The ZnO based gas sensors have high sensitivity and moderate selectivity which can be further improved by doping but these sensors work at high temperature. Whereas, the sensors based on graphene or CNTs can work at room temperature but have poor selectivity.

A hybrid of rGO and cobalt hydroxide (Co(OH)

2) nanoflakes were prepared by one-pot reflux method to fabricate NOx gas sensors [

53]. The negative charges on graphene sheets (such as hydroxyl, carbonyl, and epoxy groups) interact strongly with positive ions such as Co

2+ in an aqueous solution through electrostatic interaction to form Co(OH)

2 nanoparticles on graphene sheets. The small nanocrystals with high energy recrystallize to form nanosheets and nanopetals, in a manner of energy minimization. The nanopetals arrange themselves to form nanoflowers. Some of the nano-nuclei form the shape of nanowires because of time and space constraints. Gas-sensing performance of this hybrid can be explained as: the chemisorbed oxygen present on Co(OH)

2-rGO hybrid interact with NO

x molecules which extract electrons from hybrid, leading to an increase of hole conductance, which finally decreases the resistance of p-type hybrid. The oxygen adsorption plays an important role in the gas sensing mechanism of the Co(OH)

2-rGO composite sensor which follows the surface charge model. The adsorption of NO

x and high electron affinity of NO

x molecules lead to electron transfer from the Co(OH)

2-rGO layer to NO

x. Thus, adsorption of NO

2 on graphene hybrid converts NO

2 to NO

2− and NO to NO

−. The target gas molecules NO or NO

2 also adsorbed onto graphene hybrid and reacted with O

- to generate NO

2− or NO

3−.

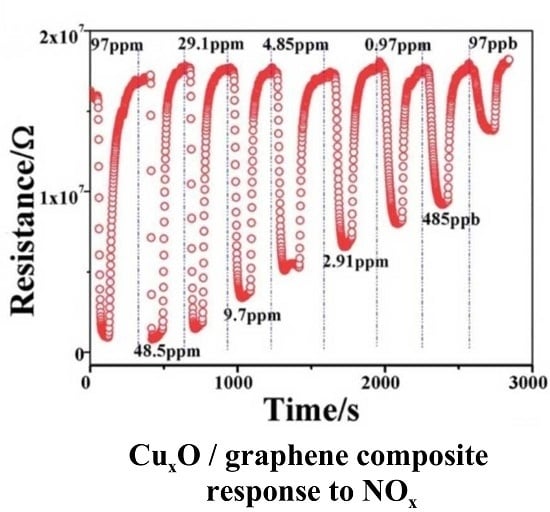

In another study, a 3D nanoflower-like Cu

xO/multilayer graphene composite was synthesized to measure NO

x gas molecules at room temperature [

54]. The thermally expanded graphite (EG) was prepared by heating expandable graphite using intermittent microwave heating (IMH) method and activated with KOH to generate many moderate functional groups. The activated EG is labeled as aEG. The Cu

xO/multilayer graphene composites (CuMGCs) were synthesized by vacuum assisted reflux method. Copper acetate and cetyltrimethylammonium bromide (CTAB) are incorporated into the layers of aEG by vacuum-assisted technique and, then, react with functional groups by exfoliation of aEG via reflux, which results in formation of 3D nanoflowers of Cu

xO homogeneously grown on aEG.

The schematic illustration of the synthesis of CuMGCs is shown in

Figure 2a. The sensitivity of CuMGCs sensor device was analyzed by exposing it to different concentrations of NO

x ranging from 97 ppm to 97 ppb at room temperature as shown in

Figure 2b. It is evident from the curves that sensor response is highly dependent on gas concentration. The gas response and response time of sensor device towards 97 ppm were 95.1% and 10 s. At the lower concentration of 97 ppb (NO

x), the sensor response was 27.1% with a response time of 59 s. The gas molecules extract electrons from CuMGCs when exposed to oxidizing gas NO

x, which leads to a decrease in electron density and increases hole carriers on p-type semiconductor surface. This effect results in decreasing resistance of sensor material when NO

x gas molecules directly adsorb onto CuMGCs. The adsorption of NO

2 on sensor material leads to NO

2− and adsorption of NO to NO

−.

Figure 2.

(

a) Schematic illustration of the formation of Cu

2O/MLG 3D nano-flowers; (

b) Dynamic response-recovery curves of sensor device towards 97 ppm to 97 ppb NO

x at room temperature. {Reprinted with permission from [

54], © 2014 Royal Society of Chemistry}.

Figure 2.

(

a) Schematic illustration of the formation of Cu

2O/MLG 3D nano-flowers; (

b) Dynamic response-recovery curves of sensor device towards 97 ppm to 97 ppb NO

x at room temperature. {Reprinted with permission from [

54], © 2014 Royal Society of Chemistry}.

Cu

2O NW-rGO composite mesocrystals were also synthesized by crystallizing copper (II) acetate in the presence of GO and o-anisidine under hydrothermal conditions [

55]. These nanowire mesocrystals possess distinct octahedral morphologies and triangular external faces as evident from their field emission scanning electron microscopy image shown in

Figure 3a. These octahedral mesocrystals are made of branched nanowires with diameters ranging from 80–110 nm. A small amount of GO (0.9 mg) is sufficient to initiate the formation of nanowire mesocrystals of Cu

2O. GO interacts with Cu

2+ ions during the

in situ crystal growth and was subsequently reduced to rGO (under hydrothermal conditions) to form Cu

2O mesocrystal interconnected via rGO network as shown in

Figure 3b. Sensors devices based on rGO, Cu

2O NW and Cu

2O-rGO composite were fabricated. These sensors were exposed to different concentrations of NO

2 ranging from 0.4–2 ppm as shown in

Figure 3c. The sensing ability of Cu

2O-rGO composite based sensor is greater in comparison to rGO and Cu

2O NW based sensors. The calculated LOD of Cu

2O-rGO based sensor is 64 ppb which is the best LOD in NO

2 sensing at room temperature. The sensing mechanism for rGO-Cu

2O composite can be explained as charge doping by adsorbing gas at sensor material which alters conductivity. The rGO prepared by chemical modification contains electron-withdrawing oxygen functionalities.

Figure 3.

(

a) FESEM image of Cu

2O mesocrystal with octahedron morphologies comprised of branched nanowires; (

b) FESEM image of Cu

2O-rGO mesocrystal; (

c) The response of rGO, Cu

2O NW, and Cu

2O-rGO sensor devices under increasing NO

2 exposure. {Reprinted with permission from [

55], © 2012 American Chemical Society}.

Figure 3.

(

a) FESEM image of Cu

2O mesocrystal with octahedron morphologies comprised of branched nanowires; (

b) FESEM image of Cu

2O-rGO mesocrystal; (

c) The response of rGO, Cu

2O NW, and Cu

2O-rGO sensor devices under increasing NO

2 exposure. {Reprinted with permission from [

55], © 2012 American Chemical Society}.

The rGO-Cu2O composite is a p-type semiconductor and releases its electrons to oxidizing gas NO2, which results in an increase in hole conductance. This composite is highly oriented and contains porous structure which gives a much larger surface accessibility in a 3D network. This effect results in increasing the sensor sensitivity towards adsorbed NO2 gas molecules.

Indium oxide (In

2O

3) was homogenously dispersed on rGO nanosheets by a hydrothermal method to synthesize a nanocomposite of In

2O

3-rGO [

56]. The graphite powder was oxidized to produce GO and, then, hydrothermally treated with In(NO

3)

3 in the presence of hydrazine hydrate to obtain In

2O

3-rGO. The NO

2 sensor was fabricated by coating a suspension of nanocomposite onto the IDEs. Different nanocomposite samples were prepared by varying rGO concentrations (0.72, 1.08, 2.16 and 4.32 wt%). The maximum sensor response of In

2O

3-rGO composite having 0.72 wt% of rGO was observed towards NO

2 at room temperature. Co

3O

4 intercalated rGO based sensor showed a much higher response to NO

2 at room temperature compared to rGO alone [

57]. The increase in rGO concentration of composite leads to a decrease in sensor response due to a lower resistance of rGO in composite. Moreover, recovery becomes very difficult due to much strong adsorption of NO

2 at defective sites of rGO. The enhanced sensor response can be explained by two possible mechanisms: increased surface area of rGO thick film by intercalation of Co

3O

4 and the Co

3+-carbon coupling effect for rapid response. The in-between cobalt oxide (Co

3O

4) nanocrystals behave like nanopillars which leads to an extra macroporous structure between rGO layers. This results in better diffusion of gas molecules driven by capillary force which leads to enhanced response. The other possible mechanism is related to the coupling effect between Co and graphene, leading to enhanced oxygen reduction ability. The coupling between oxygen ions on graphene and Co makes Co-O a more ionic bond and results in Co

3+ because extra interaction sites for NO

2 molecules and electrons would be extracted indirectly from the p-type graphene through bridging oxygen. However, this composite based sensor showed a fast response and full recovery when exposed to methanol gas due to the interaction of gas molecules with sp

2 carbon bonding sites. This interaction with gas molecules results in the release of electrons to graphene leading to a rise in resistance. The methanol gas molecules do not interact with oxygen containing defect sites because these species are negatively charged and reject electron donation from reducing species such as methanol.

Liu

et al. prepared rGO-CNT-SnO

2 hybrid from graphite powder, multiwalled carbon nanotubes (MWCNT) and tin chloride (SnCl

4) by the hydrothermal method [

58]. The aqueous dispersion of rGO-CNT-SnO

2 hybrid was dip coated on ceramic substrate (already printed with gold electrodes) to fabricate NO

2 sensor device. The incorporation of CNTs in rGO-SnO

2 hybrid not only improve surface area of rGO by preventing its restacking but also improving electron transfer rate during gas sensing. The presence of SnO

2 enhanced the recovery rate of hybrid sensor which was actually slow due to defects in the rGO structure. Thus, response and recovery time was greatly improved after incorporation of CNT and SnO

2 in the rGO structure. The sensor based on rGO-CNT-SnO

2 hybrid was used over a detection range of 1–100 ppm of NO

2 gas at room temperature. The sensor exhibited a sensitivity of 2.53 at 5 ppm of NO

2 gas with fast response/ recovery time of 8 s/77 s. The response and recovery time of rGO-CNT-SnO

2 hybrid based sensor is better than previously proposed NO

2 gas sensors [

59,

60,

61,

62,

63]. Zhang

et al. synthesized a nanocomposite based on SnO

2-rGO by reacting aqueous dispersion of GO with Sn salt hydrothermally [

60]. This nanocomposite was utilized to fabricate a sensor for detecting NO

2 gas at low operating temperatures. The nanocomposite exhibited higher sensor response of 3.31 at 5 ppm of NO

2 gas in comparison to response of 1.13 of rGO based sensor. A NO

2 gas sensor has been developed on interdigitated Pt electrodes by synthesizing caesium doped graphene oxide (GO-Cs) [

64]. The graphite was chemically oxidized to produce GO which was further doped with caesium by thermal solid-state reaction. The developed sensor based on GO-Cs exhibited higher sensor response to NO

2 gas in comparison to pristine GO based sensors with the detection limit of approximately 90 ppb. Li

et al. prepared three-dimensional (3D) SnO

2/rGO composite by hydrothermal and lyophilization method to measure NO

2 gas [

65]. The 3D porous composites were synthesized by using different metal salts as precursors such as Sn

2+ and Sn

4+ and it was found that NO

2 detection behavior of these composites was dependent on precursors. The Brunauer-Emmett-Teller method was used to analyze the surface area and porosity of 3D porous composite. It was found that surface area of porous composite prepared from Sn

4+ precursor is large which is beneficial for gas sensing applications. The extremely large surface area of 3D porous composite made it possible to detect as low as 2 ppm of NO

2 gas at low temperature.

A CO

2-assisted thermal method was followed to synthesize iron oxide-graphene (Fe

2O

3-G) hybrid. This hybrid was further converted into paper-like vertically arranged Fe

2O

3-G nanosheets by a controlled magnetic field [

66]. These paper-like materials were used to fabricate H

2S gas sensor. Both vertically and horizontally aligned nanosheets were synthesized and used as sensing material for H

2S, which showed that nanosheets with vertical arrangements are more beneficial than with horizontal arrangements in terms of sensitivity. In Fe

2O

3-G nanocomposite, the contents of both carbon and oxygen are decreased in comparison to that of GO. The decarboxylation reaction decreases carbon content, and dehydration is the cause for decreasing oxygen, which are the main reactions that occurred during formation of nanocomposite. The better sensitivity of vertically aligned Fe

2O

3/graphene is not only due to a large amount of uniformly distributed Fe

2O

3 on graphene sheets but also the special structure of vertically aligned nanosheets. This special structure provides a large contact area and less resistance which makes it very sensitive to H

2S gas. In another study, a 3D array structure was synthesized from 1D SnO

2 nanorods and 2D graphene sheets (SnO

2-G 3D array structure) via a straightforward nanocrystal-seeds-directing hydrothermal method [

67]. The growth of SnO

2 nanorods on graphene sheets can be controlled by changing seeding concentration and temperature. Graphene sheets were synthesized by CVD method. The 3D array structures were synthesized in two steps: at first nanocrystal seeds were arranged hydrolytically on graphene sheets and then grown into a 3D structure hydrothermally. The gas sensing behavior of SnO

2 is an adsorption-oxidation-desorption process which changes the electrical conductance of the sensing material. The electron depletion layer is generated on n-type SnO

2 semiconductor due to the presence of surface oxygen species (O

2−, O

−, O

2−) which increases surface potential barrier. These ions were consumed after exposure to reductive gas such as H

2S which generates additional electrons resulting in increased material conductance. The sensing performances of SnO

2-G 3D array structures are significantly better than SnO

2 flowers due to the following reasons: (1) The uniform distribution and highly aligned nanorods of moderate diameter offer a large surface area which facilitate molecular adsorption, gas diffusion and mass transport; (2) The outstanding electrical conductivity and chemical sensitivity of graphene as a sensing platform lead to better gas sensing behavior. MalekAlaie

et al. prepared molybdenum trioxide (MoO

3) nanoparticle decorated GO for the detection of H

2S [

68]. At first, GO was synthesized from natural graphite by following modified Hummer's method and, then, it was reduced to rGO by exposure to hydrazine. A metal precursor ammonium molybdate tetrahydrate ((NH

4)

6Mo

7O

24) was used to decorate rGO by calcination at 550 °C in N

2 environment to convert Mo to MoO

3. MoO

3-rGO composite was spin coated between Pt electrodes on alumina substrate to fabricate a sensor device. Sensor response was investigated by adding different wt% of metal precursor in different concentrations of graphene oxide suspensions. The composite of 3 wt% of MoO

3 and 5 mg/mL of GO suspension exhibits higher sensitivity at different concentrations (50–500 ppm) of H

2S at 160 °C. The operating temperature of MoO

3-rGO is lower in comparison to pristine rGO.