Tensductor—Amorphous Alloy Based Magnetoelastic Tensile Force Sensor

Abstract

:1. Introduction

2. Materials and Methods

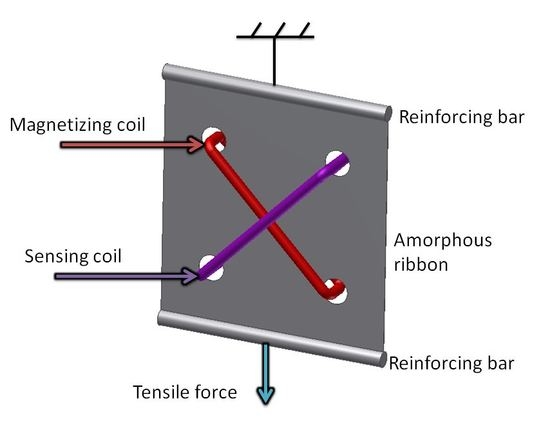

2.1. New Sensor Construction

2.2. Measurement Test Stand

3. Results

4. Conclusions

Funding

Conflicts of Interest

References

- Stefanescu, D.M. Handbook of Force Transducers: Principles and Components; Springer Science & Business Media: Berlin, Germany, 2011; ISBN 3642182968. [Google Scholar]

- Dahle, O. The pressductor and the torductor—Two heavy-duty transducers based on magnetic stress sensitivity. IEEE Trans. Commun. Electron. 1964, 83, 752–758. [Google Scholar] [CrossRef]

- Bieńkowski, A.; Szewczyk, R.; Salach, J. Industrial application of magnetoelastic force and torque sensors. Acta Phys. Pol. A 2010, 118, 1008–1009. [Google Scholar] [CrossRef]

- ABB Load Monitoring System Helps Extend Life of London’s Landmark Tower Bridge. Available online: https://new.abb.com/products/measurement-products/measurement-made-easy/load-monitoring-system-helps-extend-life-of-london-s-landmark-tower-bridge (accessed on 4 November 2018).

- Wang, M.L.; Chen, Z.L.; Koontz, S.S.; Lloyd, G.M. Magnetoelastic permeability measurement for stress monitoring in steel tendons and cables. In Proceedings of the SPIE Volume 3995, Nondestructive Evaluation of Highways, Utilities, and Pipelines IV, Newport Beach, CA, USA, 9 June 2000; SPIE: Bellingham, WA, USA, 2000; pp. 492–501. [Google Scholar]

- Guan, B.; Zang, Y.; Han, X.; Zheng, K. Cold-Rolled Strip Steel Stress Detection Technology Based on a Magnetoresistance Sensor and the Magnetoelastic Effect. Sensors 2018, 18. [Google Scholar] [CrossRef] [PubMed]

- Flynn, F.P. Pressductor. Stud. Q. J. 1966, 36, 125. [Google Scholar] [CrossRef]

- Bieńkowski, A.; Szewczyk, R. The possibility of utilizing the high permeability magnetic materials in construction of magnetoelastic stress and force sensors. Sens. Actuators A Phys. 2004, 113, 270–276. [Google Scholar] [CrossRef]

- Szewczyk, R.; Bieńkowski, A. Magnetoelastic Villari effect in high-permeability Mn–Zn ferrites and modeling of this effect. J. Magn. Magn. Mater. 2003, 254, 284–286. [Google Scholar] [CrossRef]

- Mihalca, I.; Ercuta, A.; Ionascu, C. The Villari effect in Fe–Cr–B amorphous ribbons. Sens. Actuators A Phys. 2003, 106, 61–64. [Google Scholar] [CrossRef]

- Szewczyk, R.; Bienkowski, A.; Kolano, R. Influence of nanocrystalization on magnetoelastic Villari effect in Fe73. 5Nb3Cu1Si13. 5B9 alloy. Cryst. Res. Technol. 2003, 38, 320–324. [Google Scholar] [CrossRef]

- Vacuumschmelze/Information Sheets/MSDS VITROPERM. Available online: https://www.vacuumschmelze.com/en/the-company/quality/information-sheets-msds/vitroperm.html (accessed on 4 November 2018).

- Frydrych, P.; Szewczyk, R.; Salach, J.; Trzcinka, K. Two-axis, miniature fluxgate sensors. IEEE Trans. Magn. 2012, 48, 1485–1488. [Google Scholar] [CrossRef]

- Protter, M.H.; Morrey, C.B., Jr. College Calculus with Analytic Geometry, 2nd ed.; Addison-Wesley: Boston, MA, USA, 1970. [Google Scholar]

- Kraus, L.; Švec, P. Magnetoelastic hysteresis of amorphous ribbons. J. Appl. Phys. 2003, 93, 7220–7222. [Google Scholar] [CrossRef]

- Jackiewicz, D.; Kachniarz, M.; Rożniatowski, K.; Dworecka, J.; Szewczyk, R.; Salach, J.; Bienkowski, A.; Winiarski, W. Temperature resistance of magnetoelastic characteristics of 13CrMo4-5 constructional steel. Acta Phys. Pol. A 2015, 127, 614–616. [Google Scholar] [CrossRef]

- Ferenc, J.; Kowalczyk, M.; Cieslak, G.; Kulik, T. Magnetostrictive iron-based bulk metallic glasses for force sensors. IEEE Trans. Magn. 2015, 50, 1–3. [Google Scholar] [CrossRef]

- Moran, T.J.; Ursetta, F. Magnetoelastic Sensor. U.S. Patent Application No. 14/586,017, 10 June 2015. [Google Scholar]

- Smith, R.C. Inverse compensation for hysteresis in magnetostrictive transducers. Math. Comput. Modell. 2001, 33, 285–298. [Google Scholar] [CrossRef]

- Davino, D.; Visone, C.; Ambrosino, C.; Campopiano, S.; Cusano, A.; Cutolo, A. Compensation of hysteresis in magnetic field sensors employing Fiber Bragg Grating and magneto-elastic materials. Sens. Actuators A Phys. 2008, 147, 127–136. [Google Scholar] [CrossRef]

- Oppermann, K.; Arminger, B.R.; Zagar, B.G. Smart hysteresis compensation of a magneto-elastic force sensor based on Terfenol-D. In Proceedings of the 2010 IEEE Instrumentation and Measurement Technology Conference (I2MTC), Austin, TX, USA, 3–6 May 2010; pp. 662–667. [Google Scholar]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowicki, M. Tensductor—Amorphous Alloy Based Magnetoelastic Tensile Force Sensor. Sensors 2018, 18, 4420. https://doi.org/10.3390/s18124420

Nowicki M. Tensductor—Amorphous Alloy Based Magnetoelastic Tensile Force Sensor. Sensors. 2018; 18(12):4420. https://doi.org/10.3390/s18124420

Chicago/Turabian StyleNowicki, Michał. 2018. "Tensductor—Amorphous Alloy Based Magnetoelastic Tensile Force Sensor" Sensors 18, no. 12: 4420. https://doi.org/10.3390/s18124420

APA StyleNowicki, M. (2018). Tensductor—Amorphous Alloy Based Magnetoelastic Tensile Force Sensor. Sensors, 18(12), 4420. https://doi.org/10.3390/s18124420