Sensitive and Flexible Polymeric Strain Sensor for Accurate Human Motion Monitoring

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Piezoelectric Characterization of a Single PVDF Nanofiber

3.2. Strain Sensor Fabrication and Characterization

3.3. Dynamic Pressure Testing Using Dipole Stimulus

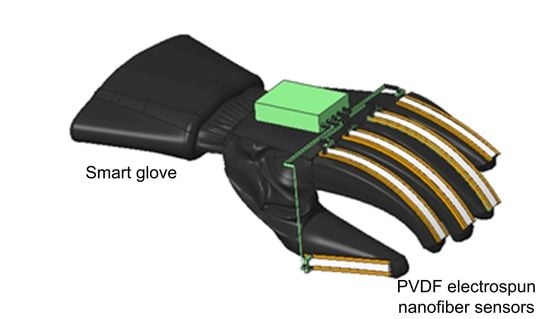

3.4. Finger Bending Experiment

4. Conclusions

Supplementary Materials

Author Contributions

Conflicts of Interest

References

- Bandodkar, A.J.; Wang, J. Non-invasive wearable electrochemical sensors: A review. Trends Biotechnol. 2014, 32, 363–371. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Wang, X.W.; Gu, Y.; Xiong, Z.P.; Cui, Z.; Zhang, T. Silk-Molded Flexible, Ultrasensitive, and Highly Stable Electronic Skin for Monitoring Human Physiological Signals. Adv. Mater. 2014, 26, 1336–1342. [Google Scholar] [CrossRef] [PubMed]

- Kang, I.; Schulz, M.J.; Kim, J.H.; Shanov, V.; Shi, D. A carbon nanotube strain sensor for structural health monitoring. Smart Mater. Struct. 2006, 15, 737–748. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Zhuang, R.; Maeder, E.; Heinrich, G.; Gao, S. Single MWNT-Glass Fiber as Strain Sensor and Switch. Adv. Mater. 2011, 23, 3392–3397. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire–elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Asadnia, M.; Kottapalli, A.; Miao, J.; Randles, A.; Sabbagh, A.; Kropelnicki, P.; Tsai, J. High temperature characterization of PZT (0.52/0.48) thin-film pressure sensors. J. Micromech. Microeng. 2013, 24, 015017. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, H.; Hu, L.; Yu, D.; Qiao, S.; Sun, J.; Bian, J.; Chen, X.; Zhang, L.; Fu, Q. Growth of ultralong ZnO microwire and its application in isolatable and flexible piezoelectric strain sensor. Phys. Status Solidi A 2010, 207, 488–492. [Google Scholar] [CrossRef]

- Yan, C.Y.; Wang, J.X.; Kang, W.B.; Cui, M.Q.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Highly Stretchable Piezoresistive Graphene-Nanocellulose Nanopaper for Strain Sensors. Adv. Mater. 2014, 26, 2022–2027. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.S.; Lu, C.; Yang, S.X.; Rogers, J. Highly Sensitive Skin-Mountable Strain Gauges Based Entirely on Elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050. [Google Scholar] [CrossRef]

- Cai, L.; Song, L.; Luan, P.S.; Zhang, Q.; Zhang, N.; Gao, Q.Q.; Zhao, D.; Zhang, X.; Tu, M.; Yang, F.; et al. Super-stretchable, Transparent Carbon Nanotube-Based Capacitive Strain Sensors for Human Motion Detection. Sci. Rep. 2013, 3, 8. [Google Scholar] [CrossRef] [PubMed]

- Asadnia, M.; Kottapalli, A.G.P.; Shen, Z.; Miao, J.; Triantafyllou, M. Flexible and surface-mountable piezoelectric sensor arrays for underwater sensing in marine vehicles. IEEE Sens. J. 2013, 13, 3918–3925. [Google Scholar] [CrossRef]

- Asadnia, M.; Kottapalli, A.G.P.; Karavitaki, K.D.; Warkiani, M.E.; Miao, J.M.; Corey, D.P.; Triantafyllou, M. From Biological Cilia to Artificial Flow Sensors: Biomimetic Soft Polymer Nanosensors with High Sensing Performance. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed]

- Sirohi, J.; Chopra, I. Fundamental understanding of piezoelectric strain sensors. J. Intell. Mater. Syst. Struct. 2000, 11, 246–257. [Google Scholar] [CrossRef]

- Shirinov, A.; Schomburg, W. Pressure sensor from a PVDF film. Sens. Actuators A Phys. 2008, 142, 48–55. [Google Scholar] [CrossRef]

- Edmondson, D.; Jana, S.; Wood, D.; Fang, C.; Zhang, M.Q. Uniaxially-aligned PVDF nanofibers as a sensor and transmitter for biotelemetry. Analyst 2013, 138, 7135–7139. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Rivera, D.; Rodriguez-Roldan, G.; Mora-Martinez, R.; Suaste-Gomez, E. A Capacitive Humidity Sensor Based on an Electrospun PVDF/Graphene Membrane. Sensors 2017, 17, 1009. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.Y.; Kim, K.J. Flexible Nanogenerator and Nano-Pressure Sensor Based on Nanofiber Web of PVDF and Its Copolymers. Soft Fibrillar Mater. Fabric. Appl. 2013, 235–264. [Google Scholar] [CrossRef]

- Asadnia, M.; Ehteshami, S.M.M.; Chan, S.H.; Warkiani, M.E. Development of a fiber-based membraneless hydrogen peroxide fuel cell. RSC Adv. 2017, 7, 40755–40760. [Google Scholar] [CrossRef]

- Sengupta, D.; Kottapalli, A.; Chen, S.; Miao, J.; Kwok, C.; Triantafyllou, M.; Warkiani, M.; Asadnia, M. Characterization of single polyvinylidene fluoride (PVDF) nanofiber for flow sensing applications. AIP Adv. 2017, 7, 105205. [Google Scholar] [CrossRef]

- Kottapalli, A.G.P.; Bora, M.; Asadnia, M.; Miao, J.; Venkatraman, S.S.; Triantafyllou, M. Nanofibril scaffold assisted MEMS artificial hydrogel neuromasts for enhanced sensitivity flow sensing. Sci. Rep. 2016, 6, 6. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, H.; Razmjou, A.; Ebrahimi Warkiani, M.; Kottapalli, A.; Asadnia, M. Sensitive and Flexible Polymeric Strain Sensor for Accurate Human Motion Monitoring. Sensors 2018, 18, 418. https://doi.org/10.3390/s18020418

Khan H, Razmjou A, Ebrahimi Warkiani M, Kottapalli A, Asadnia M. Sensitive and Flexible Polymeric Strain Sensor for Accurate Human Motion Monitoring. Sensors. 2018; 18(2):418. https://doi.org/10.3390/s18020418

Chicago/Turabian StyleKhan, Hassan, Amir Razmjou, Majid Ebrahimi Warkiani, Ajay Kottapalli, and Mohsen Asadnia. 2018. "Sensitive and Flexible Polymeric Strain Sensor for Accurate Human Motion Monitoring" Sensors 18, no. 2: 418. https://doi.org/10.3390/s18020418

APA StyleKhan, H., Razmjou, A., Ebrahimi Warkiani, M., Kottapalli, A., & Asadnia, M. (2018). Sensitive and Flexible Polymeric Strain Sensor for Accurate Human Motion Monitoring. Sensors, 18(2), 418. https://doi.org/10.3390/s18020418