Bio-inspired Flexible Lateral Line Sensor Based on P(VDF-TrFE)/BTO Nanofiber Mat for Hydrodynamic Perception

Abstract

:1. Introduction

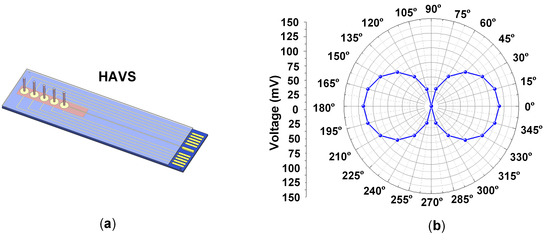

2. Design of the HAVS

2.1. Sensor Structure and Sensing Principle

2.2. Directivity of the HAVS

3. Fabrication of the HAVS

3.1. Fabrication Process

3.2. Fabrication Results

4. Characterization of the HAVS

4.1. Velocity Response of the HAVS

4.2. Directivity Measurement of the HAVS

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, K.; Zhang, J.; Song, H.; Fang, Y.; Wang, X.; Chen, D.; Liu, L.; Niu, S.; Yao, Z.; Han, Z.; et al. Highly Efficient Mechanoelectrical Energy Conversion Based on the Near-Tip Stress Field of an Antifracture Slit Observed in Scorpions. Adv. Funct. Mater. 2019, 29, 1–11. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.; Kim, T.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Casas, J.; Steinmann, T.; Krijnen, G. Why do insects have such a high density of flow-sensing hairs? Insights from the hydromechanics of biomimetic MEMS sensors. J. R. Soc. Interface 2010, 7, 1487–1495. [Google Scholar] [CrossRef] [PubMed]

- Takei, K.; Yu, Z.; Zheng, M.; Ota, H.; Takahashi, T.; Javey, A. Highly sensitive electronic whiskers based on patterned carbon nanotube and silver nanoparticle composite films. Proc. Natl. Acad. Sci. USA 2014, 111, 1703–1707. [Google Scholar] [CrossRef] [Green Version]

- Dehnhardt, G.; Mauck, B.; Hanke, W.; Bleckmann, H. Hydrodynamic trail-following in harbor seals (Phoca vitulina). Science 2001, 293, 102–104. [Google Scholar] [CrossRef] [PubMed]

- Kottapalli, A.G.P.; Asadnia, M.; Miao, J.; Triantafyllou, M.S. Biomimetic Microsensors Inspired by Marine Life; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Tao, J.; Yu, X. Hair flow sensors: From bio-inspiration to bio-mimicking-A review. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

- Han, Z.; Liu, L.; Wang, K.; Song, H.; Chen, D.; Wang, Z.; Niu, S.; Zhang, J.; Ren, L. Artificial Hair-Like Sensors Inspired from Nature: A Review. J. Bionic. Eng. 2018, 15, 409–434. [Google Scholar] [CrossRef]

- Brown, J.; Chambers, L.D.; Akanyeti, O.; Venturelli, R.; Jez, J.; Kruusmaa, M.; Fiorini, P.; Megill, W.M.; Venturelli, R. A fish perspective: detecting flow features while moving using an artificial lateral line in steady and unsteady flow. J. R. Soc. Interface 2014, 11. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Ma, Z.; Zhang, D. Flow field perception based on the fish lateral line system. Bioinspir. Biomim. 2019, 14. [Google Scholar] [CrossRef]

- Goulet, J.; Engelmann, J.; Chagnaud, B.P.; Franosch, J.M.P.; Suttner, M.D.; Van Hemmen, J.L. Object localization through the lateral line system of fish: Theory and experiment. J. Comp. Physiol. A Neuroethol. Sens. Neural Behav. Physiol. 2008, 194, 1–17. [Google Scholar] [CrossRef]

- Kasumyan, A.O. The lateral line in fish: structure, function, and role in behavior. J. Ichthyol. Orig. Russ. Text 2003, 43, 175–213. [Google Scholar]

- Chagnaud, B.P.; Coombs, S. Information Encoding and Processing by the Peripheral Lateral Line System. Springer Handb. Audit. Res. 2013, 48, 151–194. [Google Scholar]

- Ma, Z.; Jiang, Y.; Wu, P.; Xu, Y.; Hu, X.; Gong, Z.; Zhang, D. Constriction canal assisted artificial lateral line system for enhanced hydrodynamic pressure sensing. Bioinspir. Biomim. 2019, 14. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Ma, Z.; Fu, J.; Zhang, D. Development of a Flexible Artificial Lateral Line Canal System for Hydrodynamic Pressure Detection. Sensors 2017, 17, 1220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, G.; Wang, A.; Wang, X.; Liu, P. A Review of Artificial Lateral Line in Sensor Fabrication and Bionic Applications for Robot Fish. Appl. Bionics Biomech. 2016, 2016. [Google Scholar] [CrossRef] [PubMed]

- Kottapalli, A.G.P.; Bora, M.; Asadnia, M.; Miao, J.; Venkatraman, S.S.; Triantafyllou, M. Nanofibril scaffold assisted MEMS artificial hydrogel neuromasts for enhanced sensitivity flow sensing. Sci. Rep. 2016, 6, 19336. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dusek, J.E.; Triantafyllou, M.S.; Lang, J.H. Sensors and Actuators A: Physical Piezoresistive foam sensor arrays for marine applications. Sens. Actuators A Phys. 2016, 248, 173–183. [Google Scholar] [CrossRef]

- Anderson, K.D.; Lu, D.; McConney, M.E.; Han, T.; Reneker, D.H.; Tsukruk, V.V. Hydrogel microstructures combined with electrospun fibers and photopatterning for shape and modulus control. Polymer 2008, 49, 5284–5293. [Google Scholar] [CrossRef]

- Zhang, G.; Ding, J.; Xu, W.; Liu, Y.; Wang, R.; Han, J.; Bai, B.; Xue, C.; Liu, J.; Zhang, W. Design and optimization of stress centralized MEMS vector hydrophone with high sensitivity at low frequency. Mech. Syst. Signal Process. 2018, 104, 607–618. [Google Scholar] [CrossRef]

- Yang, Y.; Nguyen, N.; Chen, N.; Lockwood, M.; Tucker, C.; Hu, H.; Bleckmann, H.; Liu, C.; Jones, D.L. Artificial lateral line with biomimetic neuromasts to emulate fish sensing. Bioinspir. Biomim. 2010, 5. [Google Scholar] [CrossRef] [Green Version]

- Dagamseh, A.M.K.; Wiegerink, R.J.; Lammerink, T.S.J.; Krijnen, G.J.M. Towards a high-resolution flow camera using artificial hair sensor arrays for flow pattern observations. Bioinspir. Biomim. 2012, 7. [Google Scholar] [CrossRef] [PubMed]

- Herzog, H.; Steltenkamp, S.; Klein, A.; Tätzner, S.; Schulze, E.; Bleckmann, H. Micro-machined flow sensors mimicking lateral line canal neuromasts. Micromachines 2015, 6, 1189–1212. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Fan, Z.; Zou, J.; Engel, J.; Liu, C. Two-Dimensional Micromachined Flow Sensor Array for Fluid Mechanics Studies. J. Aerosp. Eng. 2003, 16, 85–97. [Google Scholar] [CrossRef] [Green Version]

- Asadnia, M.; Kottapalli, A.G.P.; Miao, J.; Warkiani, M.E.; Triantafyllou, M.S. Artificial fish skin of self-powered micro-electromechanical systems hair cells for sensing hydrodynamic flow phenomena. J. R. Soc. Interface 2015, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Asadnia, M.; Kottapalli, A.G.P.; Karavitaki, K.D.; Warkiani, M.E.; Miao, J.; Corey, D.P.; Triantafyllou, M. From Biological Cilia to Artificial Flow Sensors: Biomimetic Soft Polymer Nanosensors with High Sensing Performance. Sci. Rep. 2016, 6, 1–13. [Google Scholar] [CrossRef]

- Sharma, T.; Naik, S.; Langevine, J.; Gill, B.; Zhang, J.X.J. Aligned PVDF-TrFE nanofibers with high-density PVDF nanofibers and PVDF core-shell structures for endovascular pressure sensing. IEEE Trans. Biomed. Eng. 2015, 62, 188–195. [Google Scholar] [CrossRef]

- Bora, M.; Kottapalli, A.G.P.; Miao, J.; Triantafyllou, M.S. Biomimetic hydrogel-CNT network induced enhancement of fluid-structure interactions for ultrasensitive nanosensors. NPG Asia Mater. 2017, 9, e440. [Google Scholar] [CrossRef]

- Tseng, H.J.; Tian, W.C.; Wu, W.J. P(VDF-TrFE) polymer-based thin films deposited on stainless steel substrates treated using water dissociation for flexible tactile sensor development. Sensors 2013, 13, 14777–14796. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Sun, F.; Yin, G.; Wang, Y.; Liu, B.; Dong, M. Tactile-sensing based on flexible PVDF nanofibers via electrospinning: A review. Sensors 2018, 18. [Google Scholar] [CrossRef] [Green Version]

- Zno, C.P.; Based, N.; Deng, W.; Yang, T.; Jin, L.; Yan, C.; Tian, G.; Gao, Y.; Zhang, H.; Yang, W. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy 2018, 10, 049. [Google Scholar]

- Yun, J.S.; Park, C.K.; Jeong, Y.H.; Cho, J.H.; Paik, J.-H.; Yoon, S.H.; Hwang, K.-R. The Fabrication and Characterization of Piezoelectric PZT/PVDF Electrospun Nanofiber Composites. Nanomater. Nanotechnol. 2016, 6, 20. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Yan, X.; Gong, L.; Wang, F.; Xu, Y.; Feng, L.; Zhang, D.; Jiang, Y. Improved Piezoelectric Sensing Performance of P(VDF-TrFE) Nanofibers by Utilizing BTO Nanoparticles and Penetrated Electrodes. ACS Appl. Mater. Interfaces 2019, 11, 7379–7386. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Dong, Y.; Hossain, M.M.; Gorman, S.; Towfeeq, I.; Gajula, D.; Childress, A.; Rao, A.M.; Koley, G. Piezoresistive Graphene/P(VDF-TrFE) Heterostructure Based Highly Sensitive and Flexible Pressure Sensor. ACS Appl. Mater. Interfaces 2019, 11, 16006–16017. [Google Scholar] [CrossRef]

- Motamedi, A.S.; Mirzadeh, H.; Hajiesmaeilbaigi, F.; Bagheri-Khoulenjani, S.; Shokrgozar, M.A. Piezoelectric electrospun nanocomposite comprising Au NPs/PVDF for nerve tissue engineering. J. Biomed. Mater. Res. Part A 2017, 105A, 1984–1993. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Gong, L.; Hu, X.; Zhao, Y.; Chen, H.; Feng, L.; Zhang, D. Aligned P(VDF-TrFE) nanofibers for enhanced piezoelectric directional strain sensing. Polymers 2018, 10, 364. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McConney, M.E.; Chen, N.; Lu, D.; Hu, H.A.; Coombs, S.; Liu, C.; Tsukruk, V.V. Biologically inspired design of hydrogel-capped hair sensors for enhanced underwater flow detection. Soft Matter 2009, 5, 292–295. [Google Scholar] [CrossRef]

- Zhao, Y.; Liao, Q.; Zhang, G.; Zhang, Z.; Liang, Q.; Liao, X.; Zhang, Y. High output piezoelectric nanocomposite generators composed of oriented BaTiO 3 NPs @ PVDF. Nano Energy 2015, 11, 719–727. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Jiang, Y.; Ma, Z.; Xu, Y.; Zhang, D. Bio-inspired Flexible Lateral Line Sensor Based on P(VDF-TrFE)/BTO Nanofiber Mat for Hydrodynamic Perception. Sensors 2019, 19, 5384. https://doi.org/10.3390/s19245384

Hu X, Jiang Y, Ma Z, Xu Y, Zhang D. Bio-inspired Flexible Lateral Line Sensor Based on P(VDF-TrFE)/BTO Nanofiber Mat for Hydrodynamic Perception. Sensors. 2019; 19(24):5384. https://doi.org/10.3390/s19245384

Chicago/Turabian StyleHu, Xiaohe, Yonggang Jiang, Zhiqiang Ma, Yuanhang Xu, and Deyuan Zhang. 2019. "Bio-inspired Flexible Lateral Line Sensor Based on P(VDF-TrFE)/BTO Nanofiber Mat for Hydrodynamic Perception" Sensors 19, no. 24: 5384. https://doi.org/10.3390/s19245384

APA StyleHu, X., Jiang, Y., Ma, Z., Xu, Y., & Zhang, D. (2019). Bio-inspired Flexible Lateral Line Sensor Based on P(VDF-TrFE)/BTO Nanofiber Mat for Hydrodynamic Perception. Sensors, 19(24), 5384. https://doi.org/10.3390/s19245384