1. Introduction

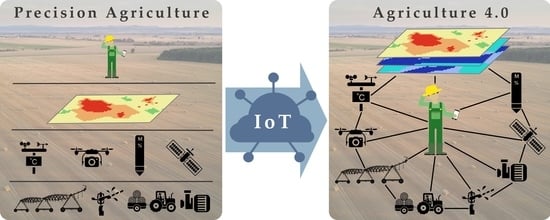

Agriculture is changing in recent years and, in the same way as the industry, is forced to modernize its work methodologies and to take advantage of opportunities offered by the Internet of things (IoT) [

1]. Despite this progress, it still cannot be claimed that precision agriculture (PA) has been widely established [

2]. There is a perception that the adoption of PA is occurring at a slower pace than expected [

3]. A confirmation of this perception can be found in the abundant literature that addresses the analysis of the factors affecting the adoption of PA, such as the recent studies of [

3,

4,

5,

6].

IoT plays a key role in agriculture since the sensors can measure several quantities continuously, and by using the cloud processing power [

7], it is possible to create models to evaluate the crop development and soil resources and water availability to support the decision-making process or even agriculture automation. Such models can evaluate evapotranspiration [

8] or soil properties and their dynamics or even evaluate water demands in paddy areas. Data from crop obtained by IoT sensors and meshed up with data gathered by additional IoT devices, such as drones and remote sensing devices, make it possible to correlate a multitude of parameters that helps in a broader crop understanding and to better approach the crop growth dynamics. The IoT sensing technologies make room for innovative ways to better use natural resources like water in irrigation [

9,

10].

IoT is also one of the key technologies for Agriculture 4.0 [

11]. This concept appeared at the beginning of the 21st century, as an evolution of the PA concept through the diffusion of IoT [

12]. Little research has been carried out about Agriculture 4.0 and, in particular, on operations management in this context [

13,

14]. Agriculture 4.0 is still restricted and put off in theory and limited to some pioneering companies [

15]. This means that a more in-depth analysis is needed to understand what Agriculture 4.0 is [

16].

Several studies highlight the potential of Agriculture 4.0, such as improvements in planning and control [

17], intelligent use of data collected by using advanced technologies mounted on board tractors, mobile ground robots, unmanned aerial vehicles (UAVs) and satellites [

18] and sustainable growth [

11]. Others highlight the challenges to be solved. For example, data by its nature in a scenario of Agriculture 4.0 becomes complex to manage both in terms of size and complexity of the analysis to be carried out [

18]. A few mention some factors related to operation management, like the mobility of production facilities and coverage of agricultural fields [

1,

17]. However, these studies do not investigate the relationship between factors and the adoption of PA in the context of Agriculture 4.0. Some researchers have suggested potential areas of investigation for studying the PA in the 4.0 era. [

12], to broaden the understanding of determinant factors in the adoption recommends studying farmer behavior, the field which has as its reference to the theory of planned behavior (TPB) [

19]. TPB has been applied in agriculture by some researchers, like [

20], but not yet in the Agriculture 4.0 context. Ref. [

21] suggests carrying out an analysis regarding whether the inspiration for the concept of Industry 4.0 can facilitate the establishment of operational solutions to explain the unexplored potential of PA in agricultural operations.

Therefore, this research seeks to contribute to filling these gaps by answering the following question: What drives the adoption of precision agriculture in the context of Agriculture 4.0, focusing on farmer behavior and operations management? To answer this question, this research aims to achieve the following objectives: exploring the factors that can affect the adoption of precision agriculture in the context of Agriculture 4.0; proposing a model to understand and formalize agricultural operations management based on identified factors; performing simulation scenarios, to study the relationships among the identified factors that allow the design of the model of agricultural operations management. This model and the simulation results support the development of theory on the adoption of PA in the context of Agriculture 4.0.

Considering the general lack of theory on Agriculture 4.0, this research adopts a multimethod approach consisting of interviews with experts, case studies, modeling techniques and simulations. Semi-structured interviews with experts [

22] and case studies [

23] are carried out to explore the factors that can affect the adoption investigated. Empirical findings are used to ground the model of agricultural operations management and the simulation scenarios [

24,

25,

26], which guide in supporting the development of theory on the adoption of PA in the context of Agriculture 4.0. The simulation allows the elaboration of theories and the accomplishment of exploratory works [

27]. Still, in an era where more data are available, it is possible to create simulation models based on real data, using IoT and sensors [

28]. The operations investigated are those relating to irrigation, in line with the international project SWAMP (smart water management platform), of which this work is part. This project involves pilots in Brazil, Italy and Spain, focusing on different crop types and irrigation techniques. SWAMP project intends to bring the concept of IoT for precision irrigation [

7]. Aligned to disseminate the results of the SWAMP project, this work includes the irrigation of the açaí palm, a plant native from the Amazon region, whose cultivation is expanding in upland areas. Açaí palm fruit has been showing increasing importance in exports to European, Asian and North American countries [

29,

30].

To model the agricultural operations management related to irrigation, the integration definition for function modeling (IDEF0) methodology is used. Farm enterprises are complex systems that need to be modeled to facilitate knowledge capitalization and information system design. [

31]. IDEF0 is used to identify the system components, data requirements, the flow of information and objects among the components [

32]. The modeling of operations management, in particular, planning, scheduling and control, through IDEF0, has been applied by several researchers in the industrial sector [

33,

34]. However, IDEF0 has rarely been used in the agricultural sector. Examples of applications are the studies of [

31] and [

35].

Since IDEF0 models attempt to capture the functional components of an enterprise or a system, rather than temporal constraints and flow [

25], IDEF0 methodology, as a static model, can be used to create simulations for dynamic analysis [

36]. Examples of applications combining the IDEF0 methodology and simulation are the works of [

37] and of [

32]. The simulation was applied to study the technology adoption for agriculture by some researchers, such as [

38].

To perform the simulation scenarios, irrigation planning is chosen since it involves the definitions of water requirements and of irrigation time, which are two priority decisions in irrigation water management. These decisions also have a direct effect on the efficiency of water use [

39,

40]. Another important parameter in the study of irrigation planning is the reference evapotranspiration that can be used with different crop characteristics to produce proper crop water requirements [

8,

41]. The crop water requirements are necessary for water resources planning and irrigation water management [

42,

43,

44]. There are several methods to estimate the reference evapotranspiration, despite the widespread of the FOAM model due to its consistency in different climatic regions [

41,

43,

45].

This study is ambitious since, in contrast to previous research on Agriculture 4.0, focused mainly on automation, robotics, food and sustainability, explores farmer behavior and operations management. As a result of empirical research, this work extends the current knowledge on Agriculture 4.0, proposing a list of categories and factors that can explain the adoption of PA in the context of Agriculture 4.0. In contrast to previous research on agriculture, the proposed model of irrigation operations management differentiates between irrigation planning and irrigation scheduling, highlighting the role of irrigation resources. The simulation results allow studying the relationships among some parameters involved in irrigation planning, contributing to a better understanding of what Agriculture 4.0 is. This work also contributes to the Agriculture 4.0 discussion. The access to data and irrigation planning can be improved through the possibility the farmer must adopt several IoT sensing technologies. This highlights the key role of IoT in the evolution of PA.

The purpose of this work is significant due to a multidisciplinary approach. By combining the competencies of PA, IoT and operations management, this work allows us to progress in the knowledge of Agriculture 4.0, bringing together different perspectives. These perspectives lead to propose a definition of what Agriculture 4.0 is as a result of empirical findings and based on the definitions of Agriculture 4.0, PA and IoT. Moreover, this work leads to expand the possibilities of the IoT in the domain of PA, also concerning the irrigation operations management.

In the remainder of this paper,

Section 2 introduces the related work.

Section 3 introduces the multimethod approach, while

Section 4 presents the results of this study.

Section 5 discusses these findings and presents the limitations and further research. Finally,

Section 6 draws conclusions.

4. Results

This section presents the results of the coding process used for identifying the factors that can affect the adoption of PA in the context of Agriculture 4.0. The factors resulting from interviews with experts are described first, to continue with the factors resulting from case studies and with the proposition of a model of irrigation operations management using IDEF0. The section ends up with the presentation of simulation findings.

Findings from expert interviews and case studies, combined with concepts of TPB, Agriculture 4.0, PA, operations management and irrigation, are used for identifying the factors that can affect the adoption of PA in the context of Agriculture 4.0. These findings are arranged to answer the research question and coded based on the TPB predictors (attitude and perceived behavioral control), categories and factors resulting from the related work [

19,

23,

95]. This approach is similar to the three-level codebook used by [

96] to analyze the data collected through interviews, in which the three coding levels are equivalent to the three levels identified in this work: TPB predictors, categories and factors. Interview responses and case study data were classified by TPB predictors for identifying categories (e.g., “performance measures”, “access to data”, “operations planning and control”) and factors. An example of a coding process for identifying the category “performance measures” and the factors “water use” and “energy use” is shown in

Table 5.

During the coding process, it was checked whether the interviewee had used the same category or factor in other answers, considering that the questions asked were semi-structured. The answers were analyzed to identify the factors to be assigned to each category (e.g., in the case of “performance measures”, the factors “water use efficiency”, “energy cost” and “water cost”) [

98]. The categories and factors identified were then applied to the data collected in the case studies to carry out within-case analysis and cross-case pattern search [

23]. Findings from interviews with experts and case studies were triangulated in order to allow a surplus of knowledge [

22].

4.1. Factors That Can Affect the Adoption Resulting from Interviews with Experts

The factors resulting from expert interviews are shown in

Table A3 in

Appendix C, classified according to the TPB predictors and associated with the categories resulting from the related work.

Table A3 presents a selection of quotes from expert interviews. The answers to the additional questions were associated with the most appropriate category, according to the three-level coding process described above. Factors not related to operations management and factors related to external actors to the farm are considered outside the scope of this work.

Performance measures, access to data, operations planning and control are the advantages of the adoption of PA in the context of Agriculture 4.0 indicated by most of the experts. Regarding performance measures, expert D stated: “In the case of precision agriculture for irrigation, the topic of cost reduction is essential, because you will work with minimizing resources and optimizing inputs”. Expert H relates water-saving to energy cost: “If you are using less water, you are also using less energy”. Expert I highlighted the fundamental role of water variable rate management to achieve irrigation efficiency. Experts H and G said that the use of sensors leads to access to much more data, such as evapotranspiration, soil characteristics, crop characteristics and rainfall. Expert H added that all this information could be used to calculate the irrigation water requirement.

Regarding operations planning and control, experts A, E and F suggested adopting the industrial model, which consists of the components: planning, scheduling and control. Expert A recommended scheduling tools and Gantt chart, while expert E and F highlighted the challenges of factor “weather”. Most interviewees indicated the following factors as critical: irrigation planning, weather forecast, harvest time, irrigation window, irrigation execution, irrigation control, performance indicators and farm size. Expert F mentioned the farm resources (raw material, equipment and people) involved in the operations. Experts A and E added sensors, which provide data to apply variable rate irrigation, as stated by expert I. Expert H highlighted the advantage of automation in activating the resources of the irrigation system. However, expert I stated that the factors “mobility degree of production facilities” and “coverage of agricultural field” pose challenges for operations planning and control related to farm size and connectivity infrastructure.

The main change in the adoption of PA in the context of Agriculture 4.0 entails for the farmer is the management of the rural property and agricultural operations, as declared by the experts D, G and F.

4.2. Factors That Can Affect the Adoption Resulting from Case Studies

The factors that can affect the adoption of PA in the context of Agriculture 4.0 resulting from case studies of açaí palm farms and pilots in Italy and Brazil are classified and presented according to the categories and factors resulting from the related work. These factors, shown in

Table 6, were triangulated with findings from interviews with experts.

The farm area of the MATOPIBA pilot is 105 hectares. The source of water for irrigation is a river. The irrigation technique is the central pivot. Two pivots are supplied by electrical pumps, including the pilot pivot; the other pivots are supplied through a reservoir located in the middle of the farm. The reservoir, with a capacity of 150,000 m3, allows reducing evaporation (around 20%) during water distribution. Regarding the CBEC pilot, the experimental area is 1.2 hectares. Access to water occurs through Consorzio di Bonifica Centrale, which distributes water to farms through a complex infrastructure of canals and pump stations. The irrigation technique is drip irrigation. The first açaí palm farm has not yet been irrigated. A well, located about 500 m away from the cultivated area, is available for irrigation. In the second açaí palm, access to water occurs through three springs. The farmer does not currently irrigate açaí palm cultivation as it rains enough.

In the MATOPIBA pilot, the expectation of the farm manager is to optimize water use and to reduce the irrigation cost, which is mainly the electricity cost. If he can use the necessary amount of water according to the type of soil and the water holding capacity of each pivot zone, he will be able to optimize both financial and water resources. For the farmer of the CBEC pilot, the advantages are related to the possibility of achieving water savings and experimenting with new approaches based on scientific methods. The two açaí palm farmers stated that the advantages of adoption are mainly related to the possibility of reducing both the use of water and electricity. Regarding the information the farmer considers necessary to adopt sensors and drones, farmer B cited especially the daily water requirement since there are no available scientific studies to be used as guidance. It is important to know the equipment and electricity costs, according to farmer C.

Regarding irrigation planning, in the MATOPIBA pilot, the water requirement is estimated based on the weather forecast, soil moisture and field capacity, evapotranspiration (obtained through a weather station located on the farm), crop demand according to the crop stage and a manual check. The irrigation time is estimated based on the electricity cost, which defines the turning-on time (around 9:00 pm) and the turning-off time (around 6:00 am) of the pivots. In the CBEC pilot, the water requirement for irrigation is defined through the CRITERIA model, based on water balance, provided by the ARPAE regional agency, since tools for the collection of these data are not available in farms [

99,

100]. The irrigation time is decided by the farmer based on his experience. Regarding açaí palm farms, a scientific reference study is not available for the estimation of the irrigation requirement. All producers known to the farmers B and C adopt a requirement equal to 120 liters per day per açaí plant. Such practices came from native people from the north of Brazil and have no scientific support or further studies. When açaí crops are irrigated, farmer B and C will consider this requirement as a reference.

As for irrigation control, the farm manager of the MATOPIBA pilot manually analyzes the soil moisture. He tries to perform night irrigation, which is cheaper (at night, irrigation costs are 10 times lower than during the day). He stated: “Night irrigation is what makes the business feasible”. The pivot control system generates reports and indicators to evaluate the efficiency of irrigation. The Italian farmer controls the irrigation exclusively by his own experience. Both farmers B and C use the experience and information shared with other farmers to control visually and manually the irrigation.

For the farm manager from MATOPIBA pilot, the main changes are managerial, in terms of training to learn about the new tools and to know how to read the data correctly, to support the decision-making process. In this pilot, the main challenge is the decision about where to irrigate, based on IoT sensing technology of soil probe and therefore implement variable rate irrigation. This allows zone management, which must be described in the geographic information system, in order to obtain the water requirement in the form of an irrigation prescription map. The key challenge of the CBEC pilot is to calculate the irrigation requirement through the use of the CRITERIA model considering the real requests from the field, according to a water balance approach. The adoption of UAV is being tested to check the model estimation and to refine the plant parameters. The use of a multispectral camera allows collecting data fundamental to calculate the NDVI and the LAI [

39,

54,

55]. Therefore, the LAI estimation, currently based on literature data, will be improved, thanks to the data collected through the UAV. As for the two açaí palm farms, both farmers B and C are involved in an ongoing irrigation project for açaí cultivation and are interested in experimenting with innovative technologies for irrigation.

4.3. Modelling of Irrigation Operations Management

As a result of the factors identified whit the related work, expert interviews and case studies, a model of irrigation operations management through IDEF0 is proposed, combining concepts of IoT, PA, Agriculture 4.0, TPB, irrigation and operations management. This model, built using the approach proposed by [

87], supports the formulation of the simulation scenarios and the development of theory on the adoption of PA in the context of Agriculture 4.0. The context diagram of irrigation operations management, shown in

Figure 4, depicts the top-level function being modeled and its inputs, controls, outputs and mechanisms.

The context diagram is decomposed into four functions, as shown in

Figure 5: irrigation planning, irrigation scheduling, irrigation execution and irrigation control. This model differentiates planning and scheduling in line with the literature on IDEF0 [

32,

33,

34] and the suggestion by experts A, E and F.

The irrigation planning produces the irrigation water requirements [

39,

41,

55,

91], the irrigation time [

101] and the fields to irrigate [

102]. Farm planning involves several seasonal decisions that the farmer must make, such as determining the crops to be grown, the area to be used for each crop, the irrigation policy [

103], including irrigation strategies [

92]. The seasonal nature of the operations is one of the main characteristics that differentiate agriculture from industry, as highlighted by the expert B: “

We work in the agricultural cycle, you have the right time to plant and if you make a mistake, you have committed a whole harvest. Agriculture is a window, so this must be done before, based on this window”. The inputs transformed by irrigation planning are crop characteristics, weather data and soil characteristics [

9,

39,

41,

91,

104,

105]. The resources which perform the irrigation planning are farmer or farm manager (depending on farm organization), farm characteristics and IoT sensing technologies [

9,

39,

52]. The farmer or farm manager supervises all operations. The fundamental role of resources is highlighted by the expert F: “

For the planning of agricultural operations, the following information is required: the necessary resources at the level of inputs (i.e., raw materials), the hardware (i.e., what equipment you need), the resources of people (i.e., how many people are involved in this process)”.

The irrigation scheduling defines which farm resources must be allocated. Farm resources to be allocated are men and machinery [

106] and irrigation system resources, which depend on farm characteristics and crop type, such as valves and pumps [

101,

102,

107], central pivots [

102], river, well, spring, canals, reservoir, drip irrigation system). As an example, the farm manager of the MATOPIBA pilot explained: “

In the farm, there is a river, which is the water source for the farm irrigation. The two nearest pivots are supplied by electrical pumps, including the pilot pivot. The other pivots are supplied through a reservoir located in the middle of the farm. The water is taken by electrical pumps to this reservoir, which distributes the water to the other more distant pivots”. The irrigation scheduling also produces a reservation in the tuple <

operation,

time window,

resources > and a sequence of the operations to be performed [

68]. An example can be illustrated with the MATOPIBA pilot, in which the operation “irrigation execution”, using the resource “central pivot 8”, is carried out in the time window “beginning at 21:00 h on day 1 and ending at 6:00 h on day 2”. Irrigation scheduling procedures can include which crop should receive priority when allocating water during the next irrigation turn [

108], priority rules based on management objectives [

34]. An example of a priority rule is the minimization of the energy cost compared to water use. In the case of the MATOPIBA pilot, this rule determines the nightly execution of the irrigation. Another example is the possibility of a switch on/off a pump/valve when the water level applied to the field reaches some predefined threshold value [

101].

The irrigation execution concerns the realization of scheduled operations [

68,

109]. Activating the scheduled resources in the context of Agriculture 4.0 is automatic, according to the expert H: “

The entire process is done automatically, which reduces labor work. You don’t have to turn on the pivot, you don’t have to turn on the irrigation system under the surface of the soil”. Water for irrigation can be considered unlimited and limited, depending on the amount of water available for irrigation or the capacity of the water distribution system [

110]. The irrigation execution outputs are the final irrigation status and the following performance measures: water use, water use efficiency, water cost and energy cost. The water use efficiency, which can be defined and measured in different ways [

111], is influenced by several factors, such as the timing and the quantity of water applied during irrigation, the losses along with the water distribution and the type of irrigation technique [

40].

Irrigation control receives, as inputs, the outputs from the other functions and the control commands from resources allocated [

10,

107,

112,

113]. Irrigation control monitors the irrigation system and resources allocated, through their identification, operation, location and status [

10], based on irrigation control procedures. This possibility of controlling irrigation operations through IoT sensing technologies, like soil probes, can affect Agriculture 4.0 adoption, as stated by expert F: “

The control would be much easier thanks to the use of sensors, in the context of IoT for irrigation, for example checking if that plant needs water, nutrients”. This will improve the visual inspection based on experience carried out by farmers A, B and C. Moreover, expert B added that the adoption of PA in the context of Agriculture 4.0 would allow monitoring exactly how much water, where, in which way, at what time, in what location. This control will overcome the risks of under and over-irrigation, as reported by [

9]. Irrigation control monitors irrigation status, based on information received from planning, scheduling and execution operations, to provide feedback to the other functions [

34,

87,

114]. Irrigation control also allows calculating performance measures, in addition to results directly related to the use of water and energy provided by the irrigation execution. Like in the manufacturing sector, agricultural farms should initiate key performance indicators for monitoring and reviewing the performance [

97]. This is highlighted by the expert F: “

Traditional industrial indicators, such as efficiency, productivity, capacity, availability, can be calculated and used, as in factory operations”. Expert G added: “

I believe that in the future the movement 4.0 will bring some close developments, for example, greater reliability, greater precision, greater productivity and, an issue that is very present in the industry, greater traceability”. Irrigation control procedures concern control information for carrying out irrigation operations. An example of the procedure concerns the irrigation water requirement and irrigation time. In line with the industrial model, if the actual values of these planned outputs deviate from the expected value, feedback is sent to the function irrigation planning [

32,

115] for reevaluating the existing irrigation programs [

110]. Another example involves the information for maintaining the soil moisture content between the field capacity and the permanent wilting point, in the case of IoT sensing technology of soil probe [

104].

4.4. Simulations: Application of the Model of Irrigation Operations Management

The proposed model of irrigation operations management provides an initial framework to study the identified factors, the relationships among them and, consequently, the adoption of PA in the context of Agriculture 4.0. The first application of this framework aimed to evaluate the cause–effect relationships among some factors involved in irrigation planning, is presented in this section, which illustrates the results of the simulations performed with MATOPIBA pilot, considering the crop type soybean and the “central pivot 8”. These simulations use the IDEF0 modeling shown in

Figure 6.

Using the methods proposed by [

8,

41,

91], the irrigation planning can be decomposed into three operations: reference evapotranspiration determination, crop water requirements estimation and irrigation water requirements estimation been represented by the respective IDEF0 functions.

The reference evapotranspiration determination produces the parameter. On the MATOBIBA pilot, this parameter is obtained from the local weather station. In addition, two new reference evapotranspiration estimations are studied: the derived from local weather station weather data as input and the FAOPM model; the derived from IoT sensing technology of satellite estimated weather data as input and the FAOPM model.

The crop water requirements estimation transforms the inputs of reference evapotranspiration, days after planting, length of growth stages and tabulated coefficients from the local 132 days soybeans crop, using the crop coefficient curve, provided by [

41], to produce the crop water requirements along the growth stages.

The third operation produces irrigation requirements (IR), based on the USDA soil conservation service method and the water balance equation. The operation took as inputs the

, weather data of rainfall and the soil saturation water (SAT). As highlighted by the farm manager: “the saturation parameter is used to reach the field capacity, which makes available water for seedlings on the initial growth stage”.

Figure 7 and

Table 7 show the results of the simulation scenarios.

4.4.1. Simulations of Scenarios S1.1 and S1.2

The first simulation (S1.1) performed uses the reference evapotranspiration provided by the weather station as well as the crop coefficients of soybeans to produce the crop water requirements (using Equation (2)). The effective rainfall from the weather station is used to produce irrigation water needs (using Equation (3)).

In the charts in

Figure 7a, irrigation water requirements follow the variability of rainfall and crop water requirements on each growth stage. Despite this, the irrigation recommended in the first and last stages was 0 mm. The results on these stages can be explained by the low crop water requirements, which is supplied by the high amount of effective rainfall.

The simulation considering the SAT parameter (S1.2), shown in the chart in

Figure 7b, had an increase of 6.81% in the total amount of water used on the initial growth stage. The chart in

Figure 7b shows that the crop water requirements chart represents the soil evaporation in the stage before sowing and has a decrease when the curve embodies the crop water requirements at the beginning of the first stage in the first month of growing.

4.4.2. Simulations of Scenarios S2.1 and S2.2

On the simulations S2.1 and S2.2, the reference evapotranspiration is determined using the weather data from the local water station (using Equation (1)) and the crop coefficients of soybeans to produce the crop water requirements (using Equation (2)). The irrigation water requirements are obtained through effective rainfall and crop water requirements (using Equation (3)).

The results shown in the chart in

Figure 7c reveal an increase of 119.93% of the total amount of water used in irrigation, compared with the S1.1 simulation, where no irrigation water is used in the initial and final stages. This is explained with the reference evapotranspiration parameter, which had its values increased by 61.51%, compared with the simulation S1.1. The rising of the reference evapotranspiration leads to an increment in crop water requirements. Once the precipitation does not supply the increase in crop water requirements, it will lead to more irrigation water.

The simulation S2.2, which uses the SAT parameter, increased 3.10% compared with the S2.1 simulation in the total amount of irrigation water. The following stages had the same behavior variability of S2.1 simulation.

4.4.3. Simulations of Scenarios S3.1 and S3.2

The simulation S3.1 uses the climatic parameters obtained from the satellite estimated weather data to determine the reference evapotranspiration (using Equation (1)) and the crop water requirements (using Equation (2)). Using the effective rainfall from the same IoT sensing technology, the irrigation water requirements are determined (using Equation (3)).

The results of the S3.1 simulation is close to those of the S1.1, as shown in

Table 7, in which a difference of 0.96 mm of the total amount of irrigation water was found. The chart in

Figure 7e shows that the variation of the parameters measured and IoT sensing technologies adopted contributes to the variability of the chart variability of reference evapotranspiration and crop water requirements, in which a difference of 180.05 mm and 256.08 mm, respectively, was found.

The results of simulations 3.1 and 3.2, shown in charts (e) and (f) of

Figure 7, also highlight that the rainfall is overestimated when compared with the precipitation obtained from the weather station on simulations S1.1, S1.2, S2.1 and S2.2. The simulation S3.2 uses 7.33% more water than the simulation S3.1. Water used in the stage before sowing presents a result slightly higher than simulations S1.2 and S2.2, due to the overestimation of precipitation in that period. However, the simulations S3.1 and S3.2 have the same variability along the crop growth stages.

5. Discussion

Within this section, the results and their contributions are discussed, starting with relevant factors for the adoption of PA in the context of Agriculture 4.0. Afterward, the proposed model of irrigation operations management based on IDEF0 and the results of simulations are discussed. Finally, limitations of the study and future research are presented.

5.1. Relevant Factors for the Adoption of PA in the Context of Agriculture 4.0 and the Key Role of IoT

This work contributes to current knowledge on Agriculture 4.0, proposing a list of categories and factors that can affect the adoption of PA in the context of Agriculture 4.0 through empirical research. The main categories that drive the adoption of PA in the context of Agriculture 4.0, focusing on farmer behavior and operations management are performance measurement, access to data, operations planning and control, farm characteristics. These categories and related factors, such as water use, energy cost, irrigation water requirement, irrigation planning, irrigation control, can influence the perception of the farmer in the evaluation of the investigated behavior and therefore impact his intention to adopt it. In line with [

19], the domain-specific factors are important to gain a complete understanding of the behavior under consideration. In this study, these factors are: farm size, methods to estimate the reference evapotranspiration, methods to crop water requirement estimation, crop characteristics, weather data, soil characteristics, farm resources, crop growth stages, farm planning, crop yield, water use efficiency, irrigation planning, irrigation control, in the agriculture domain; scheduling, resources to be allocated, farm resources allocated, reservation, the sequence of operations, performance measures, in the operations management domain; IoT sensing technologies and parameters measured through these technologies, in the IoT domain.

The greater the perception of the farmer regarding the benefits he can obtain (such as reduction of water use, reduction of energy costs, improvement of decision-making process relating to irrigation planning, scheduling and control), the more favorable the attitude of the farmer and consequently stronger his intention to adopt the PA in the context of Agriculture 4.0. Furthermore, the lower the perception of the farmer concerning obstacles, such as competency in managing the agricultural operations as reported by many experts, and the more resources the farmer believes he possesses, like IoT sensing technologies, the greater is his perceived control and consequently stronger his intention to adopt the PA in the context of Agriculture 4.0.

This work contributes to the progress of knowledge on Agriculture 4.0, proposing a list of factors related to farmer behavior and operations management, as a result of empirical research in four farms with different size, organization and irrigation technique, and overcoming the limit that Agriculture 4.0 is still restricted and put off in theory [

15]. The empirical findings contribute to answering the suggestion of [

16] regarding a more in-depth analysis needed to understand what Agriculture 4.0 is and also to include the perspective of operations management in the Agriculture 4.0 definition. In line with the definition of precision agriculture [

48], the definition of IoT of [

116], the definition of Agriculture 4.0 formulated by [

16], shown in

Table 8, and the IoT sensing technologies presented in

Table 1, the Agriculture 4.0 in this work is:

“a management strategy, evolution of precision agriculture, realized through the automated collection, integration and analysis of temporal, spatial and individual data, collected by IoT sensing technologies and farm resources, making in this way possible the generation of knowledge, to support the design of applications for the farmer decision-making process in irrigation operations management”.

The interconnection of IoT sensing technologies (such as satellite databases, weather station, soil probes, UAV) and farm resources (such as pumps, central pivots and valves) supports the design of applications, like an estimation of crop water requirement, allocation of farm resources, the definition of irrigation operations sequence, control of irrigation status and calculation of performance measures. These applications allow the farmer to make decisions concerning planning, scheduling, execution and control of irrigation. This definition highlights the key role of IoT in the evolution of precision agriculture towards Agriculture 4.0.

5.2. Proposed Model of Irrigation Operations Management

The identified factors allow to understand the management of irrigation operations and formalize it in a model, using the IDEF0 methodology. Considering the lack of theory on Agriculture 4.0 [

15,

16], this model contributes to the current level of knowledge on Agriculture 4.0, proposing relationships among those factors in order to explain the adoption of precision agriculture in the context of Agriculture 4.0. These relationships were identified during the construction of the model, decomposed into four functions illustrated in

Figure 5: irrigation planning, irrigation scheduling, irrigation execution and irrigation control.

In contrast to previous research on agriculture, the proposed model distinguishes between planning and scheduling. Considering terminological aspects [

33], planning and scheduling can have a different meaning in the literature. Some authors use irrigation scheduling to indicate how much irrigation water has to be given to the crop and how often or when this water is given [

91], to meet a specified management objective [

112] and based on different approaches (e.g., soil water measurement, soil water balance calculations, plant stress sensing) [

117]. Some authors use irrigation planning for referring to the planning horizon. According to [

110], irrigation planning refers to seasonal irrigation, with irrigation execution in terms of days since planting time. [

118] refer to short-term planning (7–14 days) for the estimation of irrigation water demand and rainfall in the irrigation season. [

119] differentiate between irrigation planning over a time horizon that is usually long and a water distribution schedule that is usually daily. Recently [

68] introduced a differentiation in agricultural operations management about planning and scheduling. The planning determines which operations to execute and with what resources, while the scheduling determines the times for executing the selected operations.

In contrast, in a manufacturing system, the planning involves the determination of the type and amount of products to be produced in a future time frame, while the scheduling involves the allocation of operations to the resources along with the specific start and finish times in each period [

32]. The allocation decisions for the production resources are the primary focus of the production scheduling [

120]. Therefore, the proposed model distinguishes between irrigation planning and irrigation scheduling in line with the literature on IDEF0 [

32,

33,

34] and the quotes of experts A, E and F. This model complements the recent work of [

68] who do not concentrate their study on irrigation operations management. The framework of the four-function model highlights the resources involved in each function, their role in performing the operations, the interfaces between the functions in terms of inputs and outputs, the rules governing the execution of operations. An example to illustrate this difference is the MATOPIBA pilot. As a result of the simulation illustrated in the chart of

Figure 7a, the farm manager receives the information that the irrigation time, relative to the “central pivot 8” studied, is equal to November and December of 2019 and January of 2020. Regarding the irrigation scheduling, the function depicted in

Figure 5, on the first day of November 2019, informs the farm manager that the “central pivot 8” will be activated in the time window “beginning at 21:00 on the first day of November 2019 and ending at 6:00 on the second day of November 2019, based on irrigation scheduling procedures. This scheduling is replicated for all the days in the irrigation time.

The model of irrigation operations management also answers to the suggestion of [

21], as the analysis carried out can facilitate the establishment of operational solutions to explain the unexplored potential of PA in agricultural operations. The inspiration for Industry 4.0 led to consider some advantages that can be introduced in agriculture, such as improvements in planning and control, which is related to one of the key categories (operations planning and control) of the proposed model. In addition, the formulation of the model includes the factors associated with the challenges analyzed in

Section 2.3. Regarding the interaction between agricultural field operations and biologically active systems [

21], the sensing technologies allow monitoring the development of the crop along the growth stages, thus mitigating the risk and uncertainty relating to operating in a biologically active environment. In this way, the farmer will be able to make decisions, also considering this challenging factor. Data collected by IoT sensing technologies of weather station and satellite can be used to support the farmer decision-making process challenged by uncertainty and risk relating to operating in a biologically active environment, as shown during simulations carried out. As for the mobility degree of production facilities [

17], this factor seems to be not challenging in irrigation planning, but its influence on irrigation execution and irrigation control should be investigated in future research, as well as the availability and bandwidth of wireless connections.

The exploration of the adoption of PA in the context of Agriculture 4.0 of this work leads to expand the possibilities of the IoT in the domain of PA since the IoT can also be studied concerning the operation’s management. The availability and adoption of different IoT sensing technologies allow managing irrigation operations in terms of access to data, planning and control of operations, performance measures, compared with the current management in the farms studied. Furthermore, the focus on farmer behavior and on his perceptions, related to the advantages and disadvantages of adopting these IoT sensing technologies, allows developing these possibilities according to farmer needs.

5.3. Relationships Among Identified Factors in the Proposed Model

The simulation results evidence the relationships among some factors involved in irrigation planning and, therefore, to study the parameters related to these factors. These findings contribute to the development of the theory on Agriculture 4.0 and to a better understanding of what Agriculture 4.0 is [

15,

16].

The simulation investigates the relationship among some factors, shown in

Figure 5, encoded in the categories “access to data” (crop characteristics, weather data and soil characteristics), “operations planning and control” (irrigation planning, irrigation time, irrigation water requirement, farm resources, IoT sensing technologies). The simulation findings explain the cause–effect relationships among the parameters related to these factors and the irrigation planning outputs.

In line with the literature [

39,

42,

44], reference evapotranspiration plays an essential role in irrigation planning. The simulations results suggest that IoT sensing technologies of the weather station and satellite with different measured parameters, as shown in

Table 7, affect the results of the FAOPM model in the same geolocation, changing both the crop water requirements and irrigation water needs variations.

As stated by authors as [

42,

44,

121,

122], the application of the FAOPM model using more measured parameters can lead to best performances in the determination of reference evapotranspiration compared with calculation with estimated parameters. This has an impact on the benefits perceived by the farmer in the use of these models [

75] and consequently has an impact on his intention to adopt Agriculture 4.0. However, the FAOPM model, using more measured parameters, can lead to the challenge highlighted by the expert L: “

The planning of operations is a complex process and the more data the farmer has, the more he needs to set up a process with less error”. This challenge is reported by [

18], who states that data by its nature in an Agriculture 4.0 scenario become complex to manage both in terms of size and complexity of the analysis to be carried out. This challenge, however, requires future research to study in greater depth the relationships between the factors involved. Notwithstanding, researchers as [

121,

122] elaborate that temperature and radiation are promising parameters to estimate de reference evapotranspiration. However, new models must be studied to perform a better or equal precision of the FAOPM and to investigate the relative impact on the adoption of precision agriculture in the context of Agriculture 4.0.

The sensibility of satellite-based solutions have to cloud levels [

55,

123,

124], and the questionable results of the use of air humidity, wind speed, and precipitation retrieved from the NASA/POWER gridded weather dataset [

56] suggest some disadvantages of satellite-based solutions. However, gridded weather databases provide applicable temperature and radiation parameters [

56], making room for future research of models that combine IoT sensing technologies shown in

Table 1 and the proposed model of irrigation planning. Another advantage related to IoT sensing technology of satellite is its applicability to irrigation planning applications [

125] and its high spatial resolution compared with the weather stations [

39] been suitable to small farmers, such as the two açaí palm producers. Thus, future research is needed to investigate the adoption of IoT sensing technology of satellite in regions with high cloudiness like Pará in Brazil.

This work also contributes to Agriculture 4.0 discussion, since the possibility the farmer must use different methods to estimate the reference evapotranspiration and the crop water requirement and to adopt IoT sensing technologies that improve access to data and the operations planning, in line with literature on Agriculture 4.0 [

17]. Consequently, Agriculture 4.0 enables the farmer to strengthen the decision-making process transforming the traditional operating model, often experience-based, to a digital data-intensive one [

69]. Decision-making mechanism is expected to be a complex mix of human and computer factors in the future [

126], mitigating the challenge posed by Agriculture 4.0 to farmers which lies in the interaction with ICT without necessarily being experts in the digital domain, but used to “understand” the crop behavior by experience and simple tools [

127].

5.4. Limitations and Further Research

The simulation findings represent the first application of the proposed list of factors and model of irrigation operations management, depicted in this work. However, some limitations should be considered and addressed in future studies, considering the exploratory nature of this study.

This work, carried out as part of the SWAMP project, involved the MATOPIBA pilot in Brazil and one of the three farms of the CBEC pilot. Moreover, interviews with experts were conducted in Brazil. To increase the external validity of the results obtained, the multimethod approach of this study will be applied to the other farms involved in the SWAMP project, and interviews will also be conducted with experts in Italy.

Regarding the relevant factors for the adoption of precision agriculture in the context of Agriculture 4.0, the TPB predictor “subjective norm” was considered out of scope. Future research is necessary to include this predictor in the exploration and to investigate the relationship between the actors operating in the farm ecosystem (for example, the Consorzio di Bonifica Centrale in the Italian pilot) and the farmer. Future research will also focus on studying the factors identified through semi-structured interviews and considered out of scope (such as access to the market of technologies, access to the market of financial resources and access to the market of education) and their impact on the adoption. To a holistic insight, the system dynamics simulation technique will also be applied.

The model of irrigation operations management is proposed as a framework for directing future studies aimed at investigating the cause–effect relationships among the parameters relative to the identified factors involved in the adoption of PA in the context of Agriculture 4.0. Therefore, a research topic will be promoted to develop a theory on Agriculture 4.0, which in the future will be extended to other agricultural operations in addition to irrigation. Since the IDEF0 methodology is also used for the design of new systems, the proposed model will guide the design of a support system for irrigation planning, scheduling and control.

Regarding the relationships among the identified factors in the proposed model, simulations were carried out to compare the IoT sensing technologies of weather station and satellite. To choose which is the best method for estimating the irrigation water requirement, it is necessary to study the relationship also with crop yield, as well as with the water use. Therefore, future research will be carried out through field experiments, considering IoT sensing technologies, such as soil probes and UAV and other crop types, also in order to evaluate the impact of temporal and spatial variability on the adoption.

6. Conclusions

The aims of this work were to explore the factors that can affect the adoption of precision agriculture in the context of Agriculture 4.0, proposing a model to understand and formalize agricultural operations management based on identified factors and performing simulation scenarios to study the relationships among the identified factors. Some research gaps were identified following the related work. To address these gaps, a multimethod approach consisting of interviews with experts, case studies, modeling techniques and simulation was adopted. Findings from empirical research supported the identification of a list of categories and factors that can affect the adoption of PA in the context of Agriculture 4.0, the formalization of these categories and factors in a model of irrigation operations management, the execution of the simulation scenarios to study the relationships among some factors involved in irrigation planning.

Considering the current development of Agriculture 4.0 concepts, this work makes a theoretical contribution, proposing a list of factors related to farmer behavior and operations management that drive the adoption of PA in the context of Agriculture 4.0. Furthermore, this multidisciplinary research, bringing together the different perspectives of precision agriculture, IoT and operations management, complements the extant literature on Agriculture 4.0, mainly focused on automation, robotics and sustainability.

This research also makes a contribution to Agriculture 4.0 discussion since the possibility the farmer must use different methods to estimate the reference evapotranspiration and the crop water requirement and to adopt several IoT sensing technologies allows to improve access to data and the irrigation planning, highlighting the key role of IoT in the evolution of the precision agriculture towards the Agriculture 4.0.

The model of irrigation operations management is proposed as a framework for directing future studies, involving the other farms of the SWAMP project, the factors considered out of scope, other agricultural operations in addition to irrigation, other crop types and the design of a support system for irrigation planning, scheduling, execution and control.