Design of a Microwave Power Detection System in the 5G-Communication Frequency Band

Abstract

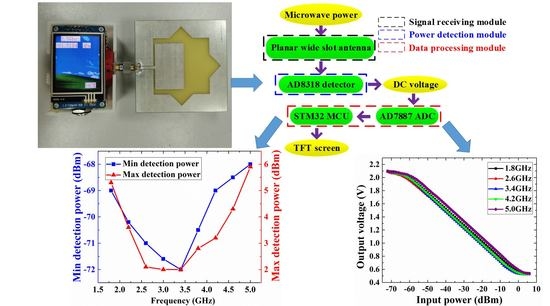

:1. Introduction

2. Principle and Theory

2.1. The Signal Receiving Module

2.2. The Power Detection Module

2.3. The Data Processing Module

3. Measurements and Discussions

3.1. Measurement of S11 Parameter

3.2. Measurement of Directivity and Gain

3.3. Measurement of Error and Dynamic Range

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Su, R.F.; Zhang, Y.D.; Tu, X.C.; Jia, X.Q.; Zhang, C.H.; Kang, L.; Jin, B.-B.; Xu, W.W.; Wang, H.B.; Chen, J.; et al. Microwave probing of relaxation oscillations related to terahertz power detection in superconducting hot electron bolometers. Supercond. Sci. Technol. 2019, 32, 105002. [Google Scholar] [CrossRef]

- Zhuang, Q.-H.; Yan, J.-K.; Liu, X.-L.; Hao, W.-X.; Yang, M.; Yan, F. Design and Implementation of the Microwave Detection System Based on DFB Laser Diode. In Proceedings of the 2018 International Applied Computational Electromagnetics Society Symposium–China (ACES), Beijing, China, 29 July–1 August 2018; IEEE: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Inoue, T.; Ikeda, K.; Kakubari, Y.; Yonemoto, N.; Shibagaki, N.; Toda, H.; Murata, H. Millimeter-wave wireless signal generation and detection using photonic technique for mobile communication systems. In Proceedings of the 2016 IEEE International Topical Meeting on Microwave Photonics (MWP), Long Beach, CA, USA, 31 October–3 November 2016. [Google Scholar]

- Dehe, A.; Krozer, V.; Chen, B.; Hartnagel, H.L. High-sensitivity microwave power sensor for GaAs-MMIC implementation. Electron. Lett. 1996, 32, 2149–2150. [Google Scholar] [CrossRef]

- Dehe, A.; Klingbeil, H.; Krozer, V.; Fricke, K.; Beilenhoff, K.; Hartnagel, H.L. GaAs monolithic integrated microwave power sensor in coplanar waveguide technology. In Proceedings of the 1996 IEEE MTT-S International Microwave Symposium Digest, San Fran-cisco, CA, USA, 17–21 June 1996. [Google Scholar]

- Liu, T.; Liao, X.P. Simulation of Characteristic of a Thermoelectric Power Sensor Based on MEMS Technology. Key Eng. Mater. 2012, 503, 91–96. [Google Scholar] [CrossRef]

- Yi, Z.; Liao, X.; Wu, H. Modeling of the terminating-type power sensors fabricated by GaAs MMIC process. J. Micromechanics Microengineering 2013, 23, 085003. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, X.P.; Wang, X. Research on Thermocouple Distribution for Microwave Power Sensors Based on GaAs MMIC Process. IEEE Sens. J. 2015, 15, 4178–4179. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, X. Suspended Thermopile for Microwave Power Sensors Based on Bulk MEMS and GaAs MMIC Technology. IEEE Sens. J. 2014, 15, 2019–2020. [Google Scholar] [CrossRef]

- Fernandez, L.J.; Visser, E.; Sese, J.; Wiegerink, R.; Flokstra, J.; Jansen, H.; Elwenspoek, M. Radio frequency power sensor based on MEMS technology. In Proceedings of the 2nd IEEE International Conference on Sensors, Toronto, ON, Canada, 22–24 October 2003. [Google Scholar]

- Fernández, L.J.; Wiegerink, R.J.; Flokstra, J.; Sesé, J.; Jansen, H.V.; Elwenspoek, M. A capacitive RF power sensor based on MEMS technology. J. Micromechanics Microengineering 2006, 16, 1099–1107. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Liao, X. A 0.1–40 GHz broadband MEMS clamped–clamped beam capacitive power sensor based on GaAs technology. J. Micromechanics Microengineering 2014, 24, 065024. [Google Scholar] [CrossRef]

- Yan, H.; Liao, X.; Chen, C.; Li, C. High-Power Handling Analysis of a Capacitive MEMS Power Sensor at X-Band. IEEE Sens. J. 2018, 18, 5272–5277. [Google Scholar] [CrossRef]

- Chu, C.L.; Liao, X.P. Bent cantilever radio frequency microelectromechanical system power detector with improved linearity up to 1 W. IET Microw. Antennas Propag. 2019, 13, 1732–1736. [Google Scholar]

- Han, L.; Huang, Q.-A.; Liao, X.-P.; Su, S. A Micromachined Inline-Type Wideband Microwave Power Sensor Based on GaAs MMIC Technology. J. Microelectromechanical Syst. 2009, 18, 705–714. [Google Scholar] [CrossRef]

- Han, L.; Huang, Q.-A.; Liao, X.-P. A microwave power sensor based on GaAs MMIC technology. J. Micromechanics Microengineering 2007, 17, 2132–2137. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, X. An Inline RF Power Sensor Based on Fixed Capacitive Coupling for GaAs MMIC Applications. IEEE Sens. J. 2014, 15, 665–666. [Google Scholar] [CrossRef]

- Yi, Z.; Liao, X. A Cascaded Terminating-Type and Capacitive-Type Power Sensor for −10- to 22-dBm Application. IEEE Electron. Device Lett. 2016, 37, 489–491. [Google Scholar] [CrossRef]

- Yi, Z.; Liao, X.; Zhang, Z. A cascade RF power sensor based on GaAs MMIC for improved dynamic range application. In Proceedings of the 2014 IEEE Radio Frequency Integrated Circuits Symposium, Tampa, FL, USA, 1–3 June 2014; pp. 201–204. [Google Scholar]

- Wang, D.; Gu, X.; Zhao, J.; Jin, L.; Ji, X. An In-Line Microwave Power Detection System Based on Double MEMS Cantilever Beams. IEEE Sens. J. 2020, 20, 10476–10484. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, J.; Li, L.; Xin, J.; Wang, D. Design of LTE-Band Microwave Power Detection System Based on Schottky Diode. IEEE Sens. J. 2019, 19, 3425–3430. [Google Scholar] [CrossRef]

- Ali, A.; Pirzada, N.; Jawaid, M.M.; Memon, S.A. Design and Simulation of a Rectangular E-Shaped Microstrip Patch Antenna for RFID based Intelligent Transportation. Int. J. Adv. Comput. Sci. Appl. 2018, 9, 165–169. [Google Scholar]

- Bhoot, A.A.; Memon, S.A.; Ahmed, A.; Hussain, S. Comparative Study of Microstrip Patch Antenna with Different Shapes and its Application. In Proceedings of the 2019 2nd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Prague, Czech Republic, 8–10 July 2019; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2019; pp. 1–8. [Google Scholar]

- Wang, X.W.; Li, Y.P.; Li, P. Microwave Technology and Antennas, 4th ed.; House of Electronics Industry: Beijing, China, 2016; p. 14. [Google Scholar]

- Elavarasi, C.; Shanmuganantham, T. Multiband SRR loaded Koch star fractal antenna. Alex. Eng. J. 2018, 57, 1549–1555. [Google Scholar]

- Devices, Analog. 1 MHz to 8 GHz 70 dB Logarithmic Detector, AD8318 Datasheet. 2004. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/AD8318.pdf (accessed on 19 February 2021).

| Feature | Symbol | Value |

|---|---|---|

| Width of the ground | G | 72 mm |

| Length of slot | L | 44 mm |

| Distance between patch and ground | S | 2.9 mm |

| Width of microstrip patch | w | 19.02 mm |

| Length of microstrip patch | l | 14.88 mm |

| Distance between feeder and ground | g | 0.3 mm |

| Width of feeder | wf | 2.18 mm |

| Frequency | 1.8 GHz | 2.6 GHz | 3.4 GHz | 4.2 GHz | 5 GHz |

|---|---|---|---|---|---|

| a1 | 22,070.09 | 16,075.62 | 239,434.56 | 181,312.14 | 98,472.62 |

| b1 | −33,803.43 | −24,962.33 | −352,678.4 | −271,412.7 | −147,548.6 |

| c1 | 17,228.35 | 12,892.29 | 173,143.09 | 135,401.76 | 73,677.41 |

| d1 | −2929.58 | −2222.78 | −28,338.75 | −22,519.33 | −12,267.88 |

| a2 | 21.124 | 17.403 | 18.087 | 18.581 | 21.747 |

| b2 | −39.911 | −37.091 | −39.33 | −38.594 | −37.55 |

| c2 | −0.184 | −1.134 | −0.016 | −0.293 | −0.911 |

| a3 | 14,284.09 | 2352.94 | 5254.66 | 1332.58 | 2944.75 |

| b3 | −74,069.41 | −11,750.83 | −27,328.92 | −6520.78 | −14,659.35 |

| c3 | 128,105.33 | 19,594.62 | 47,427.82 | 10,697.02 | 24,387.03 |

| d3 | −73,903.14 | −10,930.86 | −27,483.61 | −5871.38 | −13,558.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Q.; Zuo, W.; Xu, J.; Jin, L.; Li, W.; Wang, D. Design of a Microwave Power Detection System in the 5G-Communication Frequency Band. Sensors 2021, 21, 2674. https://doi.org/10.3390/s21082674

Ren Q, Zuo W, Xu J, Jin L, Li W, Wang D. Design of a Microwave Power Detection System in the 5G-Communication Frequency Band. Sensors. 2021; 21(8):2674. https://doi.org/10.3390/s21082674

Chicago/Turabian StyleRen, Qingying, Wen Zuo, Jie Xu, Leisheng Jin, Wei Li, and Debo Wang. 2021. "Design of a Microwave Power Detection System in the 5G-Communication Frequency Band" Sensors 21, no. 8: 2674. https://doi.org/10.3390/s21082674

APA StyleRen, Q., Zuo, W., Xu, J., Jin, L., Li, W., & Wang, D. (2021). Design of a Microwave Power Detection System in the 5G-Communication Frequency Band. Sensors, 21(8), 2674. https://doi.org/10.3390/s21082674