Design of Piezoelectric Acoustic Transducers for Underwater Applications

Abstract

:1. Introduction

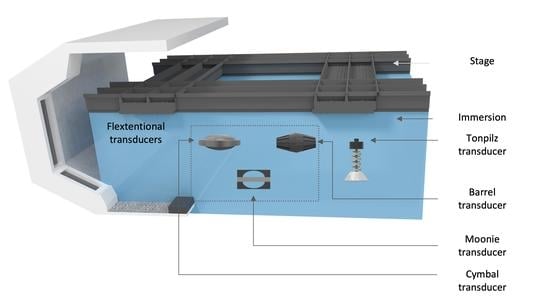

2. Underwater Transducer

3. Flextensional Transducer

3.1. Moonie Transducer

3.2. Cymbal Transducer

4. Tonpilz Transducer

5. Conclusions

6. Future Direction

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Diamant, R.; Lampe, L. Low Probability of Detection for Underwater Acoustic Communication: A Review. IEEE Access 2018, 6, 19099–19112. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, J.; Zhang, A.; Yang, L.; Shu, Y. Marine Vehicle Sensor Network Architecture and Protocol Designs for Ocean Observation. Sensors 2012, 12, 373–390. [Google Scholar] [CrossRef] [PubMed]

- Viana, S.S.; Vieira, L.F.M.; Vieira, M.A.M.; Nacif, J.A.M.; Vieira, A.B. Survey on the Design of Underwater Sensor Nodes. Des. Autom. Embed. Syst. 2016, 20, 171–190. [Google Scholar] [CrossRef]

- Akyildiz, I.F.; Pompili, D.; Melodia, T. Underwater Acoustic Sensor Networks—Research Challenges. Ad Hoc Netw. 2005, 3, 257–279. [Google Scholar] [CrossRef]

- Lloret, J. Underwater Sensor Nodes and Networks. Sensors 2013, 13, 11782–11796. [Google Scholar] [CrossRef]

- Sherman, C.H.; Butler, J.L. Transducers and Arrays for Underwater Sound; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–632. [Google Scholar]

- Billon, K.; Montcoudiol, N.; Aubry, A.; Pascual, R.; Mosca, F. Shunted Piezoelectrical Flextensionnal Suspension for Vibration Insulation. Hal Open Sci. 2019, 1, 2–5. [Google Scholar]

- Andrade, M.A.B.; Alvarez, N.P.; Buiochi, F.; Negreira, C.; Adamowski, J.C. Analysis of 1–3 Piezocomposite and Homogeneous Piezoelectric Rings for Power Ultrasonic Transducers. J. Braz. Soc. Mech. Sci. Eng. 2009, 4, 312–318. [Google Scholar] [CrossRef]

- Gururaja, T.R.; Cross, L.E.; Newnham, R.E.; Auld, B.A.; Wang, Y.J.; Schulze, W.A. Piezoelectric Composite Materials for Ultrasonic Transducer Applications. Part I: Resonant Modes of Vibration of PZT Rod-Polymer Composites. IEEE Trans. Sonics Ultrason. 1985, 32, 481–498. [Google Scholar] [CrossRef]

- Akdogan, E.K.; Allahverdi, M.; Safari, A. Piezoelectric Composites for Sensor and Actuator Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 746–775. [Google Scholar] [CrossRef]

- Martins, M.; Faria, C.; Matos, T.; Goncalves, L.; Cabral, J.; Silva, A.; Jesus, S. Wideband and Wide Beam Polyvinylidene Difluoride (PVDF) Acoustic Transducer for Broadband Underwater Communications. Sensors 2019, 19, 3991. [Google Scholar] [CrossRef]

- Zhang, Q.; Lewin, P.A.; Bloomfield, P.E. PVDF transducers-a performance comparison of single-layer and multilayer structures. IEEE Trans Ultrason. Ferroelectr. Freq. Control 1997, 44, 1148–1156. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Yu, F.; Jiang, X.; Lee, H.-Y.; Luo, J.; Shrout, T.R. Recent Developments in Piezoelectric Crystals. J. Korean Ceram. Soc. 2018, 55, 419–439. [Google Scholar] [CrossRef]

- Mudiyala, J.; Shim, H.; Kim, D.; Roh, Y. Development of a Dual-Layer Structure for Cymbal Transducer Arrays to Achieve a Wider Bandwidth. Sensors 2022, 22, 6614. [Google Scholar] [CrossRef]

- Kim, D.; Shim, H.; Oh, C.; Kim, K.; Seo, H.; Roh, Y. Design of a Broadband Array Pattern of Underwater Cymbal Transducers. Sensors 2021, 21, 6119. [Google Scholar] [CrossRef]

- Corsaro, R.D.; Klunder, J.D.; Jarzynski, J. Filled Rubber Materials System: Application to Echo Absorption in Waterfilled Tanks. J. Acoust. Soc. Am. 1980, 68, 655–664. [Google Scholar] [CrossRef]

- Jayakumari, V.G.; Shamsudeen, R.K.; Ramesh, R.; Mukundan, T. Modeling and Validation of Polyurethane based Passive Underwater Acoustic Absorber. J. Acoust. Soc. Am. 2011, 130, 724–730. [Google Scholar] [CrossRef]

- Jayakumari, V.G.; Shamsudeen, R.K.; Rajeswari, R.; Mukundan, T. Viscoelastic and Acoustic Characterization of Polyurethane-based Acoustic Absorber Panels for Underwater Applications. J. Appl. Polym. Sci. 2019, 136, 47165. [Google Scholar] [CrossRef]

- Martins, M.; Correia, V.; Cabral, J.M.; Lanceros-Mendez, S.; Rocha, J.G. Optimization of piezoelectric ultrasound emitter transducers for underwater communications. Sens. Actuators A Phys. 2012, 184, 141–148. [Google Scholar] [CrossRef]

- Steinem, C.; Janshoff, A. Piezoelectric Sensors; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; Volume 5. [Google Scholar]

- Tressler, J.F.; Alkoy, S.; Newnham, R.E. Piezoelectric sensors and sensor materials. J. Electroceramics 1998, 2, 257–272. [Google Scholar] [CrossRef]

- Zhang, K. Broadband 1-3 piezocomposite transducers for underwater ultrasound. In Proceedings of the 2014 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications, Beijing, China, 30 October–2 November 2014; pp. 437–440. [Google Scholar] [CrossRef]

- Rupitsch, S.J. Piezoelectric sensors and actuators. In Topics in Mining, Metallurgy and Materials Engineering; Springer: Cham, Switzerland, 2019; pp. 83–126. Available online: https://link.springer.com/book/10.1007/978-3-662-57534-5 (accessed on 1 February 2023).

- Wevers, M.; Lafaut, J.P.; Baert, L.; Chilibon, I. Low-frequency ultrasonic piezoceramic sandwich transducer. Sens. Actuators A Phys. 2005, 122, 284–289. [Google Scholar] [CrossRef]

- Turner, R.C.; Fuierer, P.A.; Newnham, R.E.; Shrout, T.R. Materials for high temperature acoustic and vibration sensors: A review. Appl. Acoust. 1994, 41, 299–324. [Google Scholar] [CrossRef]

- Holmes-Siedle, A.G.; Wilson, P.D.; Verrall, A.P. PVdF: An electronically-active polymer for industry. Mater. Des. 1983, 4, 910–918. [Google Scholar] [CrossRef]

- Hurmila, S.; Stubb, H.; Pitkänen, J.; Lahdenperä, K.; Penttinen, A.; Suorsa, V.; Tauriainen, A. Ultrasonic transducers using PVDF. Ferroelectrics 1991, 115, 267–278. [Google Scholar] [CrossRef]

- Platte, M. PVDF ultrasonic transducers. Ferroelectrics 1987, 75, 327–337. [Google Scholar] [CrossRef]

- Royster, L.H. The Flextensional Concept: A New Approach to the Design of Underwater Acoustic Transducers. Appl. Acoust. 1970, 3, 117–126. [Google Scholar] [CrossRef]

- Hladky-Hennion, A.C.; Uzgur, A.E.; Markley, D.C.; Safari, A.; Cochran, J.K.; Newnham, R.E. Miniature multimode monolithic flextensional transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 1992–2000. [Google Scholar] [CrossRef]

- Brigham, G.A.; Royster, L.H. Present status in the design of flextensional underwater acoustic transducers. J. Acoust. Soc. Am. 1969, 46, 92. [Google Scholar] [CrossRef]

- Brigham, G.; McTaggart, B. Low frequency acoustic modeling of small monopole transducers. In UDT Conference Proceedings; Microwave Exhibitions & Publish: Tunbridge Wells, UK, 1990; pp. 747–755. [Google Scholar]

- Teng, D.; Liu, X.; Gao, F. Effect of Concave Stave on Class I Barrel-Stave Flextensional Transducer. Micromachines. 2021, 12, 1258. [Google Scholar] [CrossRef]

- Zhang, J. Miniaturized Flextensional Transducers and Arrays; The Pennsylvania State University: State College, PA, USA, 2000; pp. 1–185. [Google Scholar]

- Jones, D.F.; Christopher, D.A. A Broadband Omnidirectional Barrel-Stave Flextensional Transducer. J. Acoust. Soc. Am. 1999, 106, L13–L17. [Google Scholar] [CrossRef]

- Zhou, T.; Lan, Y.; Zhang, Q.; Yuan, J.; Li, S.; Wei, L. A Conformal Driving Class IV Flextensional Transducer. Sensors 2018, 18, 2102. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Hughes, W.J.; Bouchilloux, P.; Meyer, R.J.; Uchino, K.; Newnham, R.E. Class V Flextensional Transducer: The Cymbal. Ultrasonics 1999, 37, 387–393. [Google Scholar] [CrossRef]

- Moosad, K.P.B.; Abraham, P. Design Optimization of a Class VII Flextensional Transducer. Appl. Acoust. 2015, 100, 3–9. [Google Scholar] [CrossRef]

- Somayajula, N.; Nemana, S.; Ng, H. Design, Assembly and Performance of a 1.6 KHz Class I Barrel Stave Projector. In Proceedings of the OCEANS 2018 MTS/IEEE, Charleston, SC, USA, 22–25 October 2018; pp. 1–4. [Google Scholar]

- Mosca, F.; Matte, G.; Mignard, V.; Rioblanc, M. Low-Frequency Source for Very Long-Range Underwater Communication. J. Acoust. Soc. Am. 2013, 133, 61–67. [Google Scholar] [CrossRef]

- Moosad, K.P.B.; Krishnakumar, P.; Chandrashekar, G.; Vishnubhatla, R.M.R. Frequency Fine-Tuning in Class IV Flextensional Transducers. Appl. Acoust. 2007, 68, 1280–1285. [Google Scholar] [CrossRef]

- Feeney, A.; Tweedie, A.; Mathieson, A.; Lucas, M. A Miniaturized Class IV Flextensional Ultrasonic Transducer. Phys. Procedia 2016, 87, 10–15. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y. Finite Element Analysis of Flextensional Transducer with Slotted Shell. Appl. Mech. Mater. 2012, 187, 151–154. [Google Scholar] [CrossRef]

- Mathieson, A.; Feeney, A.; Tweedie, A.; Lucas, M. Ultrasonic Biopsy Needle Based on the Class IV Flextensional Configuration. In Proceedings of the 2015 IEEE International Ultrasonics Symposium (IUS), Taipei, Taiwan, 21–24 October 2015; pp. 5–8. [Google Scholar]

- Chen, S.; Lan, Y. The Study of Broadband Flextensional Transducer. In Proceedings of the International Conference on Graphic and Image Processing (ICGIP 2012), Singapore, 5–7 October 2012; Volume 8768, p. 87685L. [Google Scholar]

- Butler, S.C.; Butler, J.L.; Butler, A.L.; Cavanagh, G.H. A Low-Frequency Directional Flextensional Transducer and Line Array. J. Acoust. Soc. Am. 1997, 102, 308–314. [Google Scholar] [CrossRef]

- Guo, R.; Li, S.; An, D.; Han, T.; Chen, J.; Cao, W. Comprehensive Analysis of Mn:PIN-PMN-PT Single Crystals for Class IV Flextensional Transducer. Ceram. Int. 2018, 44, 2864–2868. [Google Scholar] [CrossRef]

- Hladky-Hennion, A.C.; Uzgur, A.E.; Newnham, R.E. Monolithic Class IV Type Flextensional Transducers. J. Electroceramics 2008, 20, 139–144. [Google Scholar] [CrossRef]

- Hu, J.; Hong, L.; Yin, L.; Lan, Y.; Sun, H.; Guo, R. Research and Fabrication of Broadband Ring Flextensional Underwater Transducer. Sensors 2021, 21, 1548. [Google Scholar] [CrossRef]

- Shankar, N.; Hom, C.L. An Acoustic/Thermal Model for Self-Heating in PMN Sonar Projectors. J. Acoust. Soc. Am. 2000, 108, 2151–2158. [Google Scholar] [CrossRef] [PubMed]

- Chilibon, I. Low Frequency Underwater Piezoceramic Transducer. Sens. Actuators A Phys. 2000, 85, 292–295. [Google Scholar] [CrossRef]

- Moffett, M.B.; Clay, W.L. Demonstration of the power-handling capability of Terfenol-D. J. Acoust. Soc. Am. 1993, 93, 1653–1654. [Google Scholar] [CrossRef]

- Zheng, J.; Li, S.; Wang, B. Design and Analysis of a Broadband Class VII Flextensional Transducer with the Third-Generation Crystal, Mn:PIN-PMN-PT. Sens. Actuators A Phys. 2022, 345, 113777. [Google Scholar] [CrossRef]

- Liu, J.J.; Qin, L.; Wang, L.K.; Zhong, C.; Zhang, B.; Gup, C.X.; Long, D. A Flextensional Transducer Prototype with PVDF Piezoelectric Film. Appl. Mech. Mater. 2014, 670–671, 1153–1158. [Google Scholar] [CrossRef]

- Chilibon, I. Underwater Flextensional Piezoceramic Sandwich Transducer. Sens. Actuators A Phys. 2002, 100, 287–292. [Google Scholar] [CrossRef]

- Kim, H.; Roh, Y. Optimal Design of a Barrel Stave Flextensional Transducer. Jpn. J. Appl. Phys. 2009, 48, 07GL07. [Google Scholar] [CrossRef]

- Pan, Y.; Mo, X.; Chai, Y.; Liu, Y.; Cui, Z. A New Design on Broadband Flextensional Transducer. Appl. Acoust. 2011, 72, 836–840. [Google Scholar] [CrossRef]

- Moosad, K.P.B.; Chandrashekar, G.; Joseph, M.J.; John, R. Class IV Flextensional Transducer with a Reflector. Appl. Acoust. 2011, 72, 127–131. [Google Scholar] [CrossRef]

- Fleming, R.A.G.; Jones, D.F.; Reithmeier, C.G. Broadband Cluster Transducer for Underwater Acoustics Applications. J. Acoust. Soc. Am. 2009, 126, 2285–2293. [Google Scholar] [CrossRef]

- Butler, S.C. A Directional Dogbone Flextensional Transducer. Proc. Meet. Acoust. 2011, 11, 030001. [Google Scholar]

- Xu, Q.C.; Yoshikawa, S.; Belsick, J.R.; Newnham, R.E. Piezoelectric Composites with High Sensitivity and High Capacitance for Use at High Pressures. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1991, 38, 634–639. [Google Scholar] [CrossRef]

- Dogan, A.; Yoshikawa, S.; Uchino, K.; Newnham, R.E. Effect of Geometry on the Characteristics of the Moonie Transducer and Reliability Issue. In Proceedings of the IEEE Ultrasonics Symposium, Cannes, France, 31 October–3 November 1994; Volume 2, pp. 935–939. [Google Scholar]

- Dogan, A.; Uchino, K.; Newnham, R.E. Flextensional Composite Transducers: Designing, Fabrication and Application. Piezoelectric. Mater. Adv. Sci. Technol. Appl. 2000, 76, 357–374. [Google Scholar]

- Erhart, J.; Panos, S. Piezoelectric Composite Shear Moonie Transducer. Ann. Chim. Sci. Mat. 2001, 26, 173–176. [Google Scholar]

- Param Naidu, B.; Bhujanga Rao, A.; Prasad, N.S.; Trinath, K. Modal Analysis of Class V Flextensional Transducer. In Proceedings of the 2009 International Symposium on Ocean Electronics (SYMPOL 2009), Cochin, India, 18–20 November 2009; pp. 122–127. [Google Scholar]

- Dogan, A.; Newnham, E. Composite Piezoelectric Transducer with Truncated Conical Endcaps “Cymbal”. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 597–605. [Google Scholar] [CrossRef]

- Zhang, J.; Hughes, W.J.; Hladky-Hennion, A.C.; Newnham, R.E. Concave Cymbal Transducers. Mater. Res. Innov. 1999, 2, 252–255. [Google Scholar] [CrossRef]

- Sun, C.L.; Guo, S.S.; Li, W.P.; Xing, Z.B.; Liu, G.C.; Zhao, X.Z. Displacement Amplification and Resonance Characteristics of the Cymbal Transducers. Sens. Actuators A Phys. 2005, 121, 213–220. [Google Scholar] [CrossRef]

- Dogan, A.; Uzgur, E. Size and Material Effects on Cymbal Transducer for Actuator Applications. Ferroelectrics 2006, 331, 53–63. [Google Scholar] [CrossRef]

- Newnham, R.E.; Dogan, A.; Markley, D.C.; Tressler, J.F.; Zhang, J.; Uzgur, E.; Meyer, R.J.; Hladky-Hennion, A.C.; Hughes, W.J. Size Effects in Capped Ceramic Underwater Sound Projectors. Ocean. Conf. Rec. 2002, 4, 2315–2321. [Google Scholar]

- Narayanan, M.; Schwartz, R.W. Finite Element Modeling of a Donut Flextensional Transducer. J. Am. Ceram. Soc. 2007, 90, 850–857. [Google Scholar] [CrossRef]

- Ochoa, P.; Villegas, M.; Pons, J.L.; Leidinger, P.; Fernández, J.F. Tunability of Cymbals as Piezocomposite Transducers. J. Electroceramics 2005, 14, 221–229. [Google Scholar] [CrossRef]

- Ochoa, P.; Pons, J.L.; Villegas, M.; Fernandez, J.F. Advantages and Limitations of Cymbals for Sensor and Actuator Applications. Sens. Actuators A Phys. 2006, 132, 63–69. [Google Scholar] [CrossRef]

- Ochoa, P.; Pons, J.L.; Villegas, M.; Fernandez, J.F. Effect of Bonding Layer on the Electromechanical Response of the Cymbal Metal-Ceramic Piezocomposite. J. Eur. Ceram. Soc. 2007, 27, 1143–1149. [Google Scholar] [CrossRef]

- Meyer, R.J.; Hughes, W.J.; Montgomery, T.C.; Markley, D.C.; Newnham, R.E. Design of and Fabrication Improvements to the Cymbal Transducer Aided by Finite Element Analysis. J. Electroceramics 2002, 8, 163–174. [Google Scholar] [CrossRef]

- Bejarano, F.; Feeney, A.; Lucas, M. A Cymbal Transducer for Power Ultrasonics Applications. Sens. Actuators A Phys. 2014, 210, 182–189. [Google Scholar] [CrossRef]

- Naidu, B.P.; Rao, A.B.; Prasad, N.S.; Trinath, K. Low Frequency Acoustic Projectors for Underwater Applications. Integr. Ferroelectr. 2010, 118, 86–94. [Google Scholar] [CrossRef]

- Newnham, R.E.; Zhang, J.D.; Meyer, R. Cymbal Transducers: A review. In Proceedings of the ISAF 2000, Honolulu, HI, USA, 21 July–2 August 2000; pp. 29–32. [Google Scholar]

- Feeney, A.; Lucas, M. Smart Cymbal Transducers with Nitinol End Caps Tunable to Multiple Operating Frequencies. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1709–1719. [Google Scholar] [CrossRef]

- Feeney, A.; Lucas, M. A Comparison of Two Configurations for a Dual-Resonance Cymbal Transducer. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2018, 65, 489–496. [Google Scholar] [CrossRef]

- Newnhnm, R.E. Doubly Resonant Cymbal Type Transducer. IEEE Trans. Ultrason. Ferroelectr. Freq Control 1997, 44, 11–13. [Google Scholar]

- Zhang, J.; Hladky-Hennion, A.C.; Hughes, W.J.; Newnham, R.E. Modeling and Underwater Characterization of Cymbal Transducers and Arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2001, 48, 560–568. [Google Scholar] [CrossRef]

- Tressler, J.F.; Newnham, R.E.; Hughes, W.J. Capped Ceramic Underwater Sound Projector: The “Cymbal” Transducer. J. Acoust. Soc. Am. 1999, 105, 591–600. [Google Scholar] [CrossRef]

- Zhang, J.; Hladky-Hennion, A.C.; Jack Hughes, W.; Newnham, R.E. Miniature Class V Flextensional Cymbal Transducer with Directional Beam Patterns: The Double-Driver. Ultrasonics 2001, 39, 91–95. [Google Scholar] [CrossRef]

- Howarth, T.R.; Tressler, J.F. Thin Lightweight Low-Frequency Acoustic Projectors for Shallow-Water Environments. Detect. Remediat. Technol. Mines Minelike Targets V 2000, 4038, 1510. [Google Scholar]

- Rajapan, D.; Rajeshwari, P.M.; Sankar, M.; Trinath, K.; Prasad, N.S. Miniaturized Underwater Sensors for the Realization of Conformal Arrays. In Proceedings of the OCEANS 2006-Asia Pacific, Singapore, 16–19 May 2006; pp. 2–8. [Google Scholar]

- Kannan, C.; Rajeshwari, P.M.; Jacob, S.; Malarkkodi, A.; Dhilsha, R.; Atmanand, M.A. Effect of Manufacturing Procedure on the Miniaturized Flextensional Transducers (Cymbals) and Hydrophone Array Performance. In Proceedings of the OCEANS 2011 IEEE, Santander, Spain, 6–9 June 2011; pp. 1–5. [Google Scholar]

- Lonkar, C.M.; Kharat, D.K.; Kumar, H.H.; Prasad, S.; Balasubramanian, K.; Prasad, N.S. Pb(Ni1/3Sb2/3)O3-PbZrTiO3 Ceramic Sensors for Underwater Transducer Application. Def. Sci. J. 2012, 62, 269–273. [Google Scholar] [CrossRef]

- Kannan, C. Performance Evaluation of Cymbal Hydrophones for Underwater Applications. Int. J. Mech. Eng. Appl. 2013, 1, 43. [Google Scholar] [CrossRef]

- Tressler, J.F.; Howarth, T.R. Thin, Low Frequency, High Displacement Actuator Panels. Mater. Res. Innov. 1999, 2, 270–277. [Google Scholar] [CrossRef]

- Zhang, J.; Hughes, W.J.; Meyer, R.J.; Uchino, K.; Newnham, R.E. Cymbal Array: A Broad Band Sound Projector. Ultrasonics 2000, 37, 523–529. [Google Scholar] [CrossRef]

- Jun, T. Low Frequency Broadband Submarine Acoustic Actuator Based on Cymbal Transducer. Mater. Res. Innov. 2014, 18, S2412–S2418. [Google Scholar] [CrossRef]

- Newnham, R.E.; Alkoy, S.; Hladky, A.C.; Hughes, W.J.; Markley, D.C.; Meyer, R.J.; Zhang, J. Underwater Flat-Panel Transducer Arrays. In Proceedings of the MTS/IEEE Oceans 2001, Honolulu, HI, USA, 5–8 November 2001; pp. 1529–1535. [Google Scholar]

- Lee, K., II; Suk Won, J.; Ji, Y.J.; Hyun Park, J.; Seo, Y.G.; Shin, K.S.; Hong, S.M. Miniature Flextensional Acoustic Transducers for Long Range Location Tracking. In Proceedings of the OCEANS 2019, Marseille, France, 17–20 June 2019; pp. 7–10. [Google Scholar]

- Palosaari, J.; Leinonen, M.; Hannu, J.; Juuti, J.; Jantunen, H. Energy Harvesting with a Cymbal Type Piezoelectric Transducer from Low Frequency Compression. J. Electroceramics 2012, 28, 214–219. [Google Scholar] [CrossRef]

- Luis, J.; Park, E.J.; Meyer, R.J.; Smith, N.B. Rectangular Cymbal Arrays for Improved Ultrasonic Transdermal Insulin Delivery. J. Acoust. Soc. Am. 2007, 122, 2022–2030. [Google Scholar] [CrossRef]

- Narayanan, M.; Schwartz, R.W. Design, Fabrication and Finite Element Modeling of a New Wagon Wheel Flextensional Transducer. J. Electroceramics 2010, 24, 205–213. [Google Scholar] [CrossRef]

- Moffett, M.B.; Powers, J.M.; Jevnager, M.D. A Tonpilz Projector for Use in an Underwater Horn. J. Acoust. Soc. Am. 1997, 102, 3353–3361. [Google Scholar] [CrossRef]

- Hawkins, D.W.; Gough, P.T. Multiresonance design of a Tonpilz transducer using the finite element method. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1996, 43, 782–790. [Google Scholar] [CrossRef]

- Yao, Q.; Bjgrng, L. Broadband Tonpilz Underwater Acoustic Multimode Optimization. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 1060–1066. [Google Scholar]

- Xiping, H.; Jing, H. Study on the Broadband Tonpilz Transducer with a Single Hole. Ultrasonics 2009, 49, 419–423. [Google Scholar] [CrossRef]

- Chhith, S.; Roh, Y. Wideband Tonpilz Transducer with a Cavity inside a Head Mass. Jpn. J. Appl. Phys. 2010, 49, 07HG08. [Google Scholar] [CrossRef]

- Choe, M.S.; Kim, Y.M.; U, H.C.; Choe, J.G. Influence of a Radial Gap between Clamped Bolt and Transducer’s Component Elements on the Wide-Band Characteristic of Multi-Resonant Tonpilz Longitudinal Vibrating Piezoelectric Transducers. Appl. Acoust. 2021, 172, 107658. [Google Scholar] [CrossRef]

- Lin, S.; Xu, L.; Wenxu, H. A New Type of High-Power Composite Ultrasonic Transducer. J. Sound Vib. 2011, 330, 1419–1431. [Google Scholar] [CrossRef]

- Rehrig, P.W.; Hackenberger, W.S.; Jiang, X.; Meyer, R.J.; Geng, X. Naval Device Applications of Relaxor Piezoelectric Single Crystals. In Proceedings of the 2002 IEEE Ultrasonics Symposium, Munich, Germany, 8–11 October 2002; Volume 1, pp. 733–737. [Google Scholar]

- Snook, K.A.; Rehrig, P.W.; Xiaoning, J.; Hackenberger, W.S.; Meyer, R.J.; Markley, D. Advanced Piezoelectric Single Crystal Based Transducers for Naval Sonar Applications. In Proceedings of the IEEE Ultrasonics Symposium, Rotterdam, The Netherlands, 18–21 September 2006; pp. 1065–1068. [Google Scholar]

- Roh, Y.; Lu, X. Design of an Underwater Tonpilz Transducer with 2-2 Mode Piezocomposite Materials. J. Acoust. Soc. Am. 2006, 119, 3734–3740. [Google Scholar] [CrossRef]

- Pei, D.L.; Roh, Y. Design of an Underwater Tonpilz Transducer with 1-3 Piezocomposite Materials. Jpn. J. Appl. Phys. 2008, 47, 4003–4006. [Google Scholar] [CrossRef]

- Indue, T.; Yamamotq, M.; Sasaki, T.; Miyama, T. An Investigation for Miniaturized, Light-Weight and High-Power Tonpilz Piezoelectric Transducers. IEICE Trans. Electron. 2000, 83, 502–511. [Google Scholar]

- Kvarnsjö, L. Underwater Acoustic Transducers Based on Terfenol-D. J. Alloys Compd. 1997, 258, 123–125. [Google Scholar] [CrossRef]

- Goldi, J.H.; Gervera, M.J.; Oleksy, J.; Carmanb, G.P.; Duenasb, T.A. Composite Terfenol-D Sonar Transducers. Smart Struct. Mater. 1999, 3675, 223–234. [Google Scholar]

- Basumatary, H.; Palit, M.; Chelvane, J.A.; Pandian, S.; Abraham, R.M.; Kumar, R.K.; Moosad, K.P.B.; Ebenezer, D.D. Design and Fabrication of Tonpilz Type Acoustic Transducer Using Grain Oriented Tb-Dy-Fe Magnetostrictive Material. In Proceedings of the 2013 Ocean Electronics, Kochi, India, 23–25 October 2013; pp. 323–330. [Google Scholar]

- Wei, Y.; Yang, X.; Chen, Y.; Zhang, Z.; Zheng, H. Modeling of High-Power Tonpilz Terfenol-D Transducer Using Complex Material Parameters. Sensors 2022, 22, 3781. [Google Scholar] [CrossRef]

- Butler, S.C. A 2.5 KHz Magnetostrictive Tonpilz Sonar Transducer Design. J. Acoust. Soc. Am. 2001, 4699, 510–521. [Google Scholar] [CrossRef]

- Weisensel, G.N.; Hansen, T.T.; Hrbek, W.D.; Alaterial, S. High Power Ultrasonic Terfenol-D Transducers Enable Commercial Applications. Smart Struct. Mater. 2017, 3326, 450–458. [Google Scholar]

- Kurt, P.; Şansal, M.; Tatar, İ.; Duran, C.; Orhan, S. Vibro-Acoustic Design, Manufacturing and Characterization of a Tonpilz-Type Transducer. Appl. Acoust. 2019, 150, 27–35. [Google Scholar] [CrossRef]

- Rajapan, D.; Rajeshwari, P.M.; Zacharia, S. Development of Wide Band Underwater Acoustic Transducers. Curr. Sci. 2020, 118, 1702–1706. [Google Scholar] [CrossRef]

- Zhang, K.; Huang, D.; Chen, B.R.; Tang, Y.Z. Wideband Single Crystal Longitudinal Transducer for Underwater Sound. In Proceedings of the 2019 14th Symposium on Piezoelectrcity, Acoustic Waves and Device Applications (SPAWDA), Shijiazhuang, China, 1–4 November 2019; pp. 25–27. [Google Scholar]

- Roh, Y.; Afzal, M.S.; Kwon, S.R. Analysis of the Effect of Radiating Surface Geometry on the Beam Pattern of Underwater Acoustic Transducers. Sens. Actuators A Phys. 2021, 330, 112843. [Google Scholar] [CrossRef]

- Abdullah, Z.; Naz, S.; Raja, M.A.Z.; Zameer, A. Design of Wideband Tonpilz Transducers for Underwater SONAR Applications with Finite Element Model. Appl. Acoust. 2021, 183, 108293. [Google Scholar] [CrossRef]

- Tang, J.; Bai, Y.; Yan, L.; Wang, W. GMA Phased Array for Active Echo Control of Underwater Target. Appl. Acoust. 2022, 190, 108646. [Google Scholar] [CrossRef]

| Ref. | Type | Mass | Active Shape | Active Material | Material Type | TVR | RVS | Array | Size |

|---|---|---|---|---|---|---|---|---|---|

| (mm) | |||||||||

| [29] | Flextensional | Plate | Ceramic | PZT | Single | 123.9 | |||

| [30] | Flextensional | Steel | Ceramic | PZT 5H | 150 * | Single | 400 | ||

| [33] | Flextensional | Aluminum | Disk | Ceramic | PZT-4 | 129 | Single | 141 | |

| [35] | Flextensional | Aluminum | Ring | Ceramic | Navy type I | 140 * | Single | 200 | |

| [36] | Flextensional | Aluminum | Arc | Ceramic | PZT-4 | 135.4 | Single | 300 | |

| [38] | Flextensional | Aluminum | Plate | Ceramic | PZT-8 | 126.1 | Single | 64 | |

| [39] | Flextensional | Disk | Ceramic | BM400 | 126.4 | Single | |||

| BM532 | |||||||||

| [40] | Flextensional | Aluminum | Disk | Ceramic | Navy type 3 | 200 | Single | 550 | |

| [41] | Flextensional | Stainless steel | Plate | Ceramic | PZT-8 | 147 * | Single | 300 | |

| [42] | Flextensional | Stainless steel | Plate | Ceramic | PZ26 | Single | 52 | ||

| [43] | Flextensional | Aluminum | Plate | Ceramic | PZT-4 | 131 | Single | 200 | |

| 590 | |||||||||

| [44] | Flextensional | Brass | Plate | Ceramic | PZT-8 | Single | 44.9 | ||

| [45] | Flextensional | Aluminum | Plate | Ceramic | PZT-4 | 131.5 | Single | 170 | |

| [46] | Flextensional | Aluminum | Plate | Ceramic | Navy type 3 | 141.4 | Array | 205.7 | |

| 154.4 | 508 | ||||||||

| [47] | Flextensional | Aluminum | Disk | Ceramic | PMNPT | 140 * | Single | 72 | |

| Stainless steel | PZT-4 | ||||||||

| [48] | Flextensional | Metal | Plate | Ceramic | PZT | 150 * | Single | 8.75 | |

| [49] | Flextensional | Aluminum | Ring | Ceramic | PZT-4 | 147.2 | Single | 400 | |

| [50] | Flextensional | Aluminum | Plate | Ceramic | PMN-PT | Single | 40.1 | ||

| [51] | Flextensional | Aluminum | Disk | Ceramic | PZT | Single | 86 | ||

| +Nickel | |||||||||

| Bismuth | |||||||||

| Manganese | |||||||||

| [52] | Flextensional | Aluminum | Ring | Magnetostrictive | Terfenol | 206 | Single | 190.5 | |

| Ceramic | PZT-8 | ||||||||

| [53] | Flextensional | Aluminum | Plate | Ceramic | Mn:PIN-PMN-PT | 130 * | Single | 54.6 | |

| PZT-4 | |||||||||

| [54] | Flextensional | Plate | Polymer | PVDF | 104.7 | 30 | |||

| [55] | Flextensional | Steel | Ring | Ceramic | PZT | Single | 49 | ||

| Duralumin | |||||||||

| [56] | Flextensional | Metallic | Plate | Ceramic | PZT-4 | Single | 74 | ||

| [57] | Flextensional | Aluminum | Ring | Ceramic | PZT-4 | 132.5 | Single | 206 | |

| [58] | Flextensional | Aluminum | Plate | Ceramic | PZT-4 | 137 * | Single | 400 | |

| [59] | Flextensional | Aluminum | Ring | Ceramic | Navy type 3 | 127 | Single | 740 | |

| 154 | Array | ||||||||

| [60] | Flextensional | Stainless steel | Plate | Ceramic | PZT-8 | 127.98 | Single | 57 |

| Ref. | Type | Mass | Active Shape | Active Material | Material Type | TVR | RVS | Array | Size |

|---|---|---|---|---|---|---|---|---|---|

| (mm) | |||||||||

| [61] | Moonie | Brass | Disk | Ceramic | PZT-5A | Array | 11 | ||

| Plastic | |||||||||

| [62] | Moonie | Brass | Disk | Ceramic | PZT-5A | Single | 12.7 | ||

| [63] | Moonie | Brass | Disk | Ceramic | PZT-5H | Single | 12.7 | ||

| PZT-5A | |||||||||

| PZT-8D | |||||||||

| [64] | Moonie | Metallic | Ring | Ceramic | PZT | Single |

| Ref. | Type | Mass | Active Shape | Active Material | Material Type | TVR | RVS | Array | Size |

|---|---|---|---|---|---|---|---|---|---|

| (mm) | |||||||||

| [14] | Cymbal | Brass | Disk | Ceramic | PZT-5A | 140.7, 149.7 | Array | 20 | |

| [15] | Cymbal | Brass | Disk | Ceramic | PZT-5A | 133.7 | Array | 20 | |

| [37] | Cymbal | Titanium | Disk | Ceramic | PZT-5H | 125 * | Single | 12.7 | |

| PZT-4 | 135 * | Array | |||||||

| [65] | Cymbal | Brass | Disk | Ceramic | PZT-4 | Single | 40 | ||

| Stainless steel | PZT-5A | ||||||||

| Titanium | PZT-8A | ||||||||

| Aluminum | |||||||||

| Tungsten | PZT-5H | ||||||||

| [66] | Cymbal | Brass | Disk | Ceramic | PZT-5A | Array | 12.7 | ||

| [67] | Cymbal | Metal | Ring | Ceramic | PKI 552 | 125 | Single | 12.7 | |

| [68] | Cymbal | Brass | Disk | Ceramic | TSMn-PZT | Single | 12.7 | ||

| [69] | Cymbal | Brass | Disk | Ceramic | PZT-5H | Single | 3.2–35 | ||

| [70] | Cymbal | Tungsten | Disk | Ceramic | PZT-5H | Single | 3.2–35 | ||

| Molybdenum | |||||||||

| Brass | |||||||||

| Steel | |||||||||

| Titanium | |||||||||

| [71] | Cymbal | Brass | Disk | Ceramic | PZT 5A | Single | 25 | ||

| Titanium | PZT-4 | ||||||||

| Steel | PZT-8 | ||||||||

| Aluminum | PKI 552 | ||||||||

| Tungsten | |||||||||

| [72] | Cymbal | Kovar | Disk | Ceramic | PZT-5A | Single | 12.7 | ||

| [73] | Cymbal | Kovar | Disk | Ceramic | PZT-5A | Single | 12.7 | ||

| [74] | Cymbal | Kovar | Disk | Ceramic | PZT-5A | Single | 12.7 | ||

| [75] | Cymbal | Titanium | Disk | Ceramic | PZT-5H | 124 | Array | 12.7 | |

| PZT-4 | 15.9 | ||||||||

| [76] | Cymbal | Brass | Disk | Ceramic | PZT 402 | Single | 16.7 | ||

| [77] | Cymbal | Brass | Disk | Ceramic | PZT-4 | 140 * | Single | 120 | |

| 130 * | 600 | ||||||||

| Al | PZT-5H | 128 * | 1200 | ||||||

| Stainless steel | 6000 | ||||||||

| [78] | Cymbal | Brass | Disk | Ceramic | PZT | 124 * | Single | 12.7 | |

| 146 * | Array | ||||||||

| [79] | Cymbal | Nitinol | Disk | Ceramic | Sonox P4 | Single | 12.72 | ||

| [80] | Cymbal | Silver steel | Disk | Ceramic | Sonox P4 | Single | 12.71 | ||

| Titanium | 12.72 | ||||||||

| Nitinol | |||||||||

| [81] | Cymbal | Brass | Disk | Ceramic | PZT-5A | Single | 12.7 | ||

| Steel | |||||||||

| [82] | Cymbal | Metal | Disk | Ceramic | PKI 402 | 122 * | Array | 12.7 | |

| [83] | Cymbal | Brass | Disk | Ceramic | PZT-5H | 130 | Single | 12.7 | |

| Titanium | PZT-5A | 153 | Array | ||||||

| Molybdenum | PZT-4 | ||||||||

| PZT-8 | |||||||||

| [84] | Cymbal | Titanium | Disk | Ceramic | PKI 552 | Array | 12.7 | ||

| [85] | Cymbal | Brass | Disk | Ceramic | Navy type VI | 119 | Array | 12.7 | |

| 130 | |||||||||

| Titanium | 131 | ||||||||

| [86] | Cymbal | Brass | Disk | Ceramic | PZT-4 | 120 | −205 | Array | 12.7 |

| 12.9 | |||||||||

| PZT-5A | 19 | ||||||||

| [87] | Cymbal | Brass | Disk | Ceramic | PZT-5A | −203 | Array | 13 | |

| [88] | Cymbal | Brass | Disk | Ceramic | PZT-5A | −183.2 | Single | 25 | |

| PNS-PZT | −191.2 | ||||||||

| [89] | Cymbal | Brass | Disk | Ceramic | PZT-5A | −203 | Array | 13 | |

| [90] | Cymbal | Brass | Disk | Ceramic | PZT-5H | Single | 12.7 | ||

| Array | 25.4 | ||||||||

| [91] | Cymbal | Titanium | Disk | Ceramic | PKI 402 | 134 | Array | 12.7 | |

| [92] | Cymbal | Brass | Disk | Ceramic | PZT-4 | 130 | Array | 20 | |

| 25 | |||||||||

| [93] | Cymbal | Titanium | Disk | Ceramic | PKI402 | 134 | Array | 12.7 | |

| [94] | Cymbal | Steel | Disk | Ceramic | PZT-5H | Single | 35 | ||

| Plate | |||||||||

| [96] | Cymbal | Titanium | Disk | Ceramic | Navy type I 402 | 134 * | Array | 50.8 | |

| Rectangle |

| Ref. | Type | Mass | Active Shape | Active Material | Material Type | TVR | RVS | Array | Size |

|---|---|---|---|---|---|---|---|---|---|

| (mm) | |||||||||

| [99] | Tonpilz | Aluminum | Ring | Ceramic | PZT-4 | 130 | Single | 25 | |

| Steel | 27 | ||||||||

| [100] | Tonpilz | Aluminum | Ring | Ceramic | PZT-4 | 146.8 | Single | 60 | |

| Brass | |||||||||

| [101] | Tonpilz | Aluminum | Ring | Ceramic | PZT | Single | 30 | ||

| Steel | |||||||||

| [102] | Tonpilz | Aluminum | Ring | Ceramic | PZT-4 | 140 * | Single | ||

| Brass | |||||||||

| [103] | Tonpilz | Aluminum | Ring | Ceramic | PZT-4 | 136 * | Single | 35 | |

| Steel | 135 * | ||||||||

| [104] | Transducer | Stainless steel | Ring | Ceramic | PZT-4 | Single | 25.5 | ||

| [105] | Tonpilz | Ring | Ceramic | PZT-8 | 143 * | Single | 16 | ||

| PMN-PT | 147 * | ||||||||

| [106] | Tonpilz | Ring | Ceramic | PMN-PT | Single | ||||

| PZT-8 | |||||||||

| [107] | Tonpilz | Aluminum | Ring | Composite | PZT-5H | Single | 9–17.4 | ||

| Steel | Polymer | ||||||||

| [108] | Tonpilz | Aluminum | Ring | Composite | PZT-5H | Single | 13.2 | ||

| Steel | Polymer | ||||||||

| [109] | Tonpilz | Aluminum | Ring | Ceramic | NEPEC-6 | Single | 250 | ||

| Steel | |||||||||

| [110] | Tonpilz | Magnetostrictive | Terfenol | Single | |||||

| [111] | Tonpilz | Beryllium | Ring | Magnetostrictive | Terfenol | Single | 28 | ||

| [112] | Tonpilz | Aluminum | Ring | Magnetostrictive | Terfenol | Single | 168 | ||

| Stainless steel | |||||||||

| [113] | Tonpilz | Aluminum | Rod | Magnetostrictive | Terfenol | Single | 160 | ||

| Stainless steel | |||||||||

| [114] | Tonpilz | Stainless steel | Rod | Magnetostrictive | Terfenol | Single | 280 | ||

| Magnesium | |||||||||

| [115] | Tonpilz | Metallic | Rod | Magnetostrictive | Terfenol | Single | |||

| [116] | Tonpilz | Aluminum | Ring | Ceramic | PZT-4 | 136.5 | −153.8 | Single | 96 |

| 138.5 | −154.9 | ||||||||

| [117] | Tonpilz | Aluminum | Ring | Ceramic | Piezo crystal | 151 | −163 | Array | |

| Brass | |||||||||

| [118] | Tonpilz | Beryllium | Ring | Ceramic | Single crystal | 146.3 * | Single | ||

| Tungsten | 162.6 * | Array | |||||||

| [119] | Tonpilz | Aluminum | Ring | Ceramic | PZT-4 | 146.6 | Single | 50 | |

| Brass | |||||||||

| [120] | Tonpilz | Aluminum | Ring | Ceramic | PZT-4 | 132.6 | Single | 25 | |

| 133 | |||||||||

| 133.5 | |||||||||

| Stainless steel | PMNPT | 133.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pyun, J.Y.; Kim, Y.H.; Park, K.K. Design of Piezoelectric Acoustic Transducers for Underwater Applications. Sensors 2023, 23, 1821. https://doi.org/10.3390/s23041821

Pyun JY, Kim YH, Park KK. Design of Piezoelectric Acoustic Transducers for Underwater Applications. Sensors. 2023; 23(4):1821. https://doi.org/10.3390/s23041821

Chicago/Turabian StylePyun, Joo Young, Young Hun Kim, and Kwan Kyu Park. 2023. "Design of Piezoelectric Acoustic Transducers for Underwater Applications" Sensors 23, no. 4: 1821. https://doi.org/10.3390/s23041821

APA StylePyun, J. Y., Kim, Y. H., & Park, K. K. (2023). Design of Piezoelectric Acoustic Transducers for Underwater Applications. Sensors, 23(4), 1821. https://doi.org/10.3390/s23041821