Configuration Investigation, Structure Design and Deployment Dynamics of Rigid-Reflector Spaceborne Antenna with Deviation-Angle Panel

Abstract

:1. Introduction

2. Feature Analysis of Existing RRSA Concepts

2.1. Description of RRSA

2.2. Sunflower

2.3. Solid Surface Deployable Antenna (SSDA)

2.4. Regular-Panel Antenna

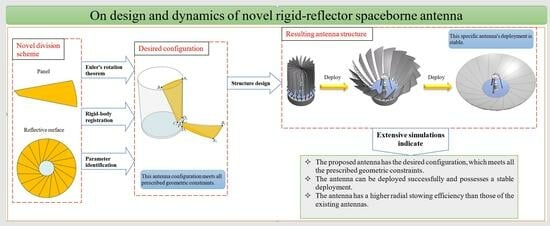

3. Deviation-Angle-Panel-Based Antenna Concept

3.1. Deviation-Angle Panel

3.2. Improving RSE by Pose Adjustment

3.3. Rotation Angle

4. Parameter-Identification-Based Configuration Design

4.1. Deployment Implementation and Theoretical RSE

- Point is on the envelope (GC 1), and it is conceivable that this constraint is easy to fulfill since line segment always intersects with the envelope at point after an appropriate rotation about P.

- Under the first constraint, locating point precisely on the envelope (GC 2) is difficult to realize because the two constraints are coupled.

- Point has a prespecified upward displacement h (GC 3) to avoid interference between the panel and central surface. This constraint should be fulfilled under the first two constraints.

- According to Figure 6c, the focal axis, i.e., coordinate axis , and plane are coplanar (GC 4). This constraint should be satisfied under the former three GCs. Thus, we lower the requirement first and simply guarantee that axis is coplanar with points and (weak GC 4). When points and are projected onto plane , their polar angles are the same, denoted as , which is a parameter to be determined, as shown in the top-left subfigure of Figure 7a. In addition, to avoid interference caused by the panel thickness, it is assumed that the distance between and is a prespecified parameter s, named an interference parameter.

4.2. Parametric Error Compensation Model

4.3. Parameter Identification of Configuration

4.4. Effectiveness in Algorithm

| Algorithm 1 Configuration parameter identification (CPI) |

Input: Focus/diameter ratio , number of panels n, fairing envelope diameter , deviation parameter , vertical displacement h, interference parameter s; Output: Maximum aperture diameter , transformation matrix , residual , compensation parameters and ;

|

4.5. Effectiveness in Stowing Efficiency

5. Structure Design Based on Universal Joint Coupling Mechanism

| (1) Composite panel |

| Although the reflective surface of the panel can be machined into an ideal paraboloid, its high accuracy cannot be guaranteed under harsh space environments without an elaborate panel design. In space, the environment temperature approximately ranges from to ; hence, the heat-resistant material is indispensable for fabricating the panel. Also, high-strength and high-stiffness materials are needed to avoid possible resonance during launch, deployment and altitude maneuver. To meet these two requirements, the carbon-fiber-reinforced plastic (CFRP) sandwich structure is adopted. As shown in Figure 10b, the two skins are made of M55J CFRP, and the honeycomb core is made of T300 CFRP. The related research has reported that this kind of sandwich structure is capable of sustaining a high surface accuracy under severe on-orbit thermal environments [64,65,66]. |

| (2) Supporting framework |

| To support the panels and further improve their strength and stiffness, a truss-type framework is also adopted, in which its constituent rods are made of T300 CFRP to reduce the weight, as shown in Figure 10c. In addition, diverse optimizations are performed with respect to the framework in terms of physical dimensions, position and topology to further lower its weight. Note that the fully deployed antenna is closely similar to the ground-based reflector antennas; thus, their topology optimization techniques [67,68,69] can be directly applied to this antenna by supplementing only one additional constraint. The constraint requires that the adjacent petals shall not interfere with each other during deployment, which was reported in Ref. [38]. (This optimization research will be presented in future studies.) |

| (3) Deployment mechanism |

| Typically, there are two ways to deploy the antenna: deploying all petals with one motor or deploying with the same number of motors as the petals. The first approach requires a synchronous device; however, its cost may not necessarily be lower than that of the second approach considering the expenditure. In addition, each petal is deployed by a single motor, which can reduce the position error of the petal to a large extent; therefore, the second approach is adopted. It is known that the universal joint coupling (UJC) is a compact structure capable of bearing high torque loading, which is appropriate to use for deploying the RRSAs due to their heavy weight and narrow space in placing deployment mechanisms. Figure 10a illustrates the deployment mechanism, from which it can be observed that each petal is mounted on the output rod of the UJC, and the input rod is connected through a hole with a reducer linked to the driving motor. The reducer is indispensable because of the extremely slow deployment process. According to the related reports, the deployment of Spektr-R takes one and a half hour, as shown in Figure 1. This operation can offer larger driving torque, which is of vital importance for large SSDAs due to their heavy petals. In this way, if all motors drive the input rods synchronously, the antenna deployment can be fulfilled without concerning the interference among petal deployment mechanisms. |

| (4) Supporting and axis-adjusting device |

| The EM performance of the antenna is influenced not only by the surface error caused by manufacturing but also by the position error largely induced by the rotation axis, which is equivalent to additional surface error. Therefore, strict rotation-axis accuracy must be guaranteed, to which a device capable of adjusting the axis position is introduced. A line in 3D space has five DOFs [70]; hence, the device must supply the output rod with at least five DOFs in order to precisely install the output rod. The ability of the input rod to move slightly on the hole plane provides two DOFs, and the telescopic function of the input rod provides an extra DOF, by which three translational DOFs are thus obtained. In addition, the universal joint provides the two other rotational DOFs, thereby verifying that adopting the UJC can guarantee the expected position of the output rod. |

| (5) Base |

| All the driving motors are anchored on the bottom plate of the base, and all axis-adjusting devices are mounted on the top plate, while the side of the base is hollowed out to realize the lightweight design. The bottom surface of the bottom plate base has bolt-fastening holes for mounting the antenna on the satellite platform, like Spektr-R shown in Figure 1. |

6. Trajectory-Planning-Based Deployment Dynamics

6.1. Trajectory Planning

6.2. Driving Torque

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Detailed Explanation of Completeness, Continuity and Minimality of PECM

Appendix B. Dynamic Equation of Deployment Mechanism

References

- Zhang, Y.; Ru, W.; Yang, G. Deployment analysis considering the cable-net tension effect for deployable antennas. Aerosp. Sci. Technol. 2016, 48, 193–202. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, N.; Yang, G. Dynamic analysis of the deployment for mesh reflector deployable antennas with the cable-net structure. Acta Astronaut. 2017, 131, 182–189. [Google Scholar] [CrossRef]

- Li, B.; Qi, X.; Huang, H. Modeling and analysis of deployment dynamics for a novel ring mechanism. Acta Astronaut. 2016, 120, 59–74. [Google Scholar] [CrossRef]

- Nie, R.; He, B.; Hodges, D. Integrated form finding method for mesh reflector antennas considering the flexible truss and hinges. Aerosp. Sci. Technol. 2019, 84, 926–937. [Google Scholar] [CrossRef]

- Han, B.; Xu, Y.; Yao, J. Design and analysis of a scissors double-ring truss deployable mechanism for space antennas. Aerosp. Sci. Technol. 2019, 93, 105357. [Google Scholar] [CrossRef]

- Yuan, P.; He, B.; Zhang, L. Pretension modeling and form-finding for cable-network antennas with varying topologies and parameters. Aerosp. Sci. Technol. 2021, 112, 106631. [Google Scholar] [CrossRef]

- Zhang, J.; He, B.; Zhang, L. High surface accuracy and pretension design for mesh antennas based on dynamic relaxation method. Int. J. Mech. Sci. 2021, 209, 106687. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, D.; Duan, B. Structural design, dynamic analysis, and verification test of a novel double-ring deployable truss for mesh antennas. Mech. Mach. Theory 2021, 165, 104416. [Google Scholar] [CrossRef]

- He, B.; Li, K.; Nie, R. Deployment modeling for soft cable networks from slack to tension. Int. J. Mech. Sci. 2022, 221, 107225. [Google Scholar] [CrossRef]

- Thomson, M. The Astromesh deployable reflector. In Proceedings of the IEEE Antennas and Propagation Society International Symposium. 1999 Digest. Held in Conjunction with: USNC/URSI National Radio Science Meeting (Cat. No. 99CH37010), Orlando, FL, USA, 11–16 July 1999; Volume 3, pp. 1516–1519. [Google Scholar]

- Wang, Z.; Li, T.; Cao, Y. Active shape adjustment of cable net structures with PZT actuators. Aerosp. Sci. Technol. 2013, 26, 160–168. [Google Scholar] [CrossRef]

- Du, J.; Zong, Y.; Bao, H. Shape adjustment of cable mesh antennas using sequential quadratic programming. Aerosp. Sci. Technol. 2013, 30, 26–32. [Google Scholar] [CrossRef]

- Du, J.; Bao, H.; Cui, C. Shape adjustment of cable mesh reflector antennas considering modeling uncertainties. Acta Astronaut. 2014, 97, 164–171. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, B.; Yang, G. Design technique for a shaped-reflector antenna with a three-layer cable net structure. IEEE Trans. Antennas Propag. 2020, 69, 109–121. [Google Scholar] [CrossRef]

- Du, J.; Zhang, Y.; Wang, C. Robust optimal design for surface accuracy of mesh reflectors considering cable length inaccuracy. J. Aerosp. Eng. 2021, 34, 04020090. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, Y.; Yang, D. Structural design, analysis, and experimental verification of an H-style deployable mechanism for large space-borne mesh antennas. Acta Astronaut. 2021, 178, 481–498. [Google Scholar] [CrossRef]

- Sauder, J.; Chahat, N.; Hodges, R. Designing, building, and testing a mesh Ka-band parabolic deployable antenna (KaPDA) for CubeSats. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 0694. [Google Scholar]

- Manohar, V.; Kovitz, J.; Rahmat-Samii, Y. Ka band umbrella reflectors for CubeSats: Revisiting optimal feed location and gain loss. In Proceedings of the 2016 International Conference on Electromagnetics in Advanced Applications (ICEAA), Cairns, QLD, Australia, 19–23 September 2016; pp. 800–803. [Google Scholar]

- Wang, P.; Wang, F.; Shi, T. Thermal distortion compensation of a high precision umbrella antenna. In Proceedings of the Journal of Physics: Conference Series, Taiyuan, China, 21–22 October 2017; IOP Publishing: Bristol, UK, 2017; Volume 916, p. 012051. [Google Scholar]

- Tang, Y.; Shi, Z.; Li, T. Double-layer cable-net structures for deployable umbrella reflectors. J. Aerosp. Eng. 2019, 32, 04019068. [Google Scholar] [CrossRef]

- Yang, D.; Liu, J.; Zhang, Y. Optimal surface profile design of deployable mesh reflectors via a force density strategy. Acta Astronaut. 2017, 130, 137–146. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, Y.; Li, P. Numerical form-finding method for large mesh reflectors with elastic rim trusses. Acta Astronaut. 2018, 147, 241–250. [Google Scholar] [CrossRef]

- Tang, Y.; Li, T.; Liu, Y. Minimization of cable-net reflector shape error by machine learning. J. Spacecr. Rocket. 2019, 56, 1757–1764. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; He, Y. Active adjustment of space-borne cable-net antenna via a two-way shape memory alloy spring. Smart Mater. Struct. 2023, 32, 035002. [Google Scholar] [CrossRef]

- Ruze, J. Antenna tolerance theory—A review. Proc. IEEE 1966, 54, 633–640. [Google Scholar] [CrossRef]

- Rudnitskiy, A.; Graauw, T.; Andrianov, A. Millimetron Space Observatory. In Proceedings of the 43rd COSPAR Scientific Assembly, Sydney, Australia, 28 January–4 February 2021; Volume 43, p. 1399. [Google Scholar]

- Astro Space Center of Lebedev Physical Institute, Russian Academy of Sciences. 15 September 2023. Available online: https://www.millimetron.ru/en/general/antenna (accessed on 11 December 2023).

- Archer, J. Advanced sunflower antenna concept development. Nasa Langley Res. Cent. Large Space Syst. Technol. 1979, 33–58. [Google Scholar]

- Guest, S.; Pellegrino, S. A new concept for solid surface deployable antennas. Acta Astronaut. 1996, 38, 103–113. [Google Scholar] [CrossRef]

- Zeng, X.; Zhou, Y.; Yuan, W. Optimal Design of Solid Surface Deployable Antennas Based on Twin-Bennett Linkage. China Mech. Eng. 2021, 32, 1361. [Google Scholar]

- Dornier. First Technology Study: Multisurface Control Mechanism for a Deployable Antenna; Final Report. Dornier Report RP-FA-D003; Dornier Corporation: Abu Dhabi, United Arab Emirates, 1987. [Google Scholar]

- Huang, H.; Guan, F.; Pan, L. Design and deploying study of a new petal-type deployable solid surface antenna. Acta Astronaut. 2018, 148, 99–110. [Google Scholar] [CrossRef]

- Specht, P. Dynamics of Large Reflectors: DAISY/MEA Reflector-Description. Dornier Technical Report; Dornier Corporation: Abu Dhabi, United Arab Emirates, 1990. [Google Scholar]

- Kardashev, N.; Khartov, V.; Abramov, V. “RadioAstron”—A telescope with a size of 300,000 km: Main parameters and first observational results. Astron. Rep. 2013, 57, 153–194. [Google Scholar] [CrossRef]

- Schwarz, S.; Barho, R. Deployment mechanisms for a 5 m unfurlable reflector. In Proceedings of the European Space Mechanisms and Tribology Symposium, Munich, Germany, 18–20 September 2019; pp. 18–20. [Google Scholar]

- Huang, H.; Cheng, Q.; Zheng, L. Development for petal-type deployable solid-surface reflector by uniaxial rotation mechanism. Acta Astronaut. 2021, 178, 511–521. [Google Scholar] [CrossRef]

- Tan, G.; Duan, X.; Yang, D. Parametric design optimization approach to petal-type solid surface deployable reflectors. Acta Astronaut. 2022, 197, 280–297. [Google Scholar] [CrossRef]

- Tan, G.; Duan, X.; Niu, D. Visual synthesis of uniaxial synchronous deployment mechanisms for solid-surface deployable antennas. Mech. Mach. Theory 2022, 178, 105073. [Google Scholar] [CrossRef]

- Sayapin, S.; Shkapov, P. Kinematics of deployment of petal-type large space antenna reflectors with axisymmetric petal packaging. J. Mach. Manuf. Reliab. 2016, 45, 387–397. [Google Scholar] [CrossRef]

- Chae, S.; Oh, Y.; Lee, S. Design and test of a deployment mechanism for the composite reflector antenna. J. Aerosp. Syst. Eng. 2018, 12, 58–65. [Google Scholar]

- Astro Space Center of Lebedev Physical Institute, Russian Academy of Sciences. 15 September 2023. Available online: http://www.asc.rssi.ru/radioastron/index.html (accessed on 11 December 2023).

- Kovalev, Y.; Kardashev, N.; Kellermann, K. The RadioAstron space VLBI project. In Proceedings of the 2014 XXXIth URSI General Assembly and Scientific Symposium (URSI GASS), Beijing, China, 16–23 August 2014; p. 1. [Google Scholar]

- Arkhipov, M.; Savel’ev, V.; Smirnov, A. Solving the problem of the deployment kinematics of a large petal reflector. J. Mach. Manuf. Reliab. 2020, 49, 796–801. [Google Scholar] [CrossRef]

- Elsayed, E. Reliability Engineering, 3rd ed.; Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Tan, G.; Duan, X.; Ma, J. Investigation of compact packing strategy for large rigid-panel deployable antennas. Mech. Mach. Theory 2022, 176, 104930. [Google Scholar] [CrossRef]

- Guang, C.; Yang, Y. An approach to designing deployable mechanisms based on rigid modified origami flashers. J. Mech. Des. 2018, 140, 082301. [Google Scholar] [CrossRef]

- The Xinhua News Agency, 15 September 2023. Available online: http://www.chinanews.com/gn/2020/05-06/9176071.shtml (accessed on 11 December 2023).

- Guo, H.; Li, Z.; Liu, R. Parametric analysis and optimization and structure design of deployable solid-surface antenna. In Proceedings of the Chinese Society of Space Research Symposium, Xi’an, China, 4–8 November 2013. [Google Scholar]

- Guo, H.; Li, Z.; Liu, R. Twin–Bennett Linkage and One Type of Its Mobile Assemblies. In Advances in Reconfigurable Mechanisms and Robots II; Springer: Berlin/Heidelberg, Germany, 2016; pp. 117–126. [Google Scholar]

- Chen, Y.; You, Z. An Extended Myard Linkage and its Derived 6R Linkage. J. Mech. Des. 2008, 130, 052301. [Google Scholar] [CrossRef]

- Wang, Z. Structure Design and Analysis of Solid Surface Antenna Based on Rigid Origami. Master’s Thesis, Xidian University, Xi’an, China, 2020. (In Chinese). [Google Scholar]

- Feng, H.; Peng, R.; Zang, S. Rigid foldability and mountain-valley crease assignments of square-twist origami pattern. Mech. Mach. Theory 2020, 152, 103947. [Google Scholar] [CrossRef]

- Luo, A.; Liu, H.; Li, Y. Structural Analysis of Flowerlike Deployable Antenna. China Mech. Eng. 2012, 23, 1656. [Google Scholar]

- Blitzer, R. Trigonometry; Pearson: London, UK, 2022. [Google Scholar]

- Kelley, C. Solving Nonlinear Equations with Newton’s Method; SIAM: Philadelphia, PA, USA, 2003. [Google Scholar]

- Palais, B.; Palais, R. Euler’s fixed point theorem: The axis of a rotation. J. Fixed Point Theory Appl. 2007, 2, 215–220. [Google Scholar] [CrossRef]

- Palais, B.; Palais, R.; Rodi, S. A Disorienting Look at Euler’s Theorem on the Axis of a Rotation. Am. Math. Mon. 2009, 116, 892–909. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; You, Z. An overview of dynamic parameter identification of robots. Robot. Comput.-Integr. Manuf. 2010, 26, 414–419. [Google Scholar] [CrossRef]

- Li, Z.; Li, S.; Luo, X. An overview of calibration technology of industrial robots. IEEE/CAA J. Autom. Sin. 2021, 8, 23–36. [Google Scholar] [CrossRef]

- Schröer, K.; Albright, S.; Grethlein, M. Complete, minimal and model-continuous kinematic models for robot calibration. Robot. Comput.-Integr. Manuf. 1997, 13, 73–85. [Google Scholar] [CrossRef]

- Gatti, G.; Danieli, G. A practical approach to compensate for geometric errors in measuring arms: Application to a six-degree-of-freedom kinematic structure. Meas. Sci. Technol. 2007, 19, 015107. [Google Scholar] [CrossRef]

- Arun, K.; Huang, T.; Blostein, S. Least-squares fitting of two 3-D point sets. IEEE Trans. Pattern Anal. Mach. Intell. 1987, PAMI-9, 698–700. [Google Scholar] [CrossRef] [PubMed]

- Besl, P.; McKay, N. Method for registration of 3-D shapes. In Proceedings of the Sensor fusion IV: Control Paradigms and Data Structures, Boston, MA, USA, 12–15 November 1991; SPIE: Bellingham, WA, USA, 1992; Volume 1611, pp. 586–606. [Google Scholar]

- Qian, Y.; Lou, Z.; Hao, X. Initial development of high-accuracy CFRP panel for DATE5 antenna. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation II, Edinburgh, UK, 22 July 2016; Volume 9912, pp. 475–482. [Google Scholar]

- Qian, Y.; Hao, X.; Shi, Y. Deformation behavior of high accuracy carbon fiber-reinforced plastics sandwiched panels at low temperature. J. Astron. Telesc. Instruments Syst. 2019, 5, 034003. [Google Scholar] [CrossRef]

- Wei, X.; Li, D.; Xiong, J. Fabrication and mechanical behaviors of an all-composite sandwich structure with a hexagon honeycomb core based on the tailor-folding approach. Compos. Sci. Technol. 2019, 184, 107878. [Google Scholar] [CrossRef]

- Leng, G.; Duan, B. Topology optimization of planar truss structures with continuous element intersection and node stability constraints. Proc. Inst. Mech. Eng. Part J. Mech. Eng. Sci. 2012, 226, 1821–1831. [Google Scholar] [CrossRef]

- Feng, S.; Duan, B.; Wang, C. Topology optimization of pretensioned reflector antennas with unified cable-bar model. Acta Astronaut. 2018, 152, 872–879. [Google Scholar] [CrossRef]

- Zhang, S.; Song, J. Surface segmentation design using a weighting level set topology optimization method for large radio telescope antennas. Struct. Multidiscip. Optim. 2021, 64, 905–918. [Google Scholar] [CrossRef]

- Saliklis, E. Structures: A Geometric Approach; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Li, T. Deployment analysis and control of deployable space antenna. Aerosp. Sci. Technol. 2012, 18, 42–47. [Google Scholar] [CrossRef]

- Goldstein, H. Classical Mechanics; Pearson Education India: London, UK, 2011. [Google Scholar]

- Wittenburg, J. Shaft Couplings. In Kinematics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 387–410. [Google Scholar]

- Krodkiewski, J. Mechanical Vibration; The University of Melbourne—Department of Mechanical and Manufacturing Engineering: Parkville, VIC, Australia, 2008. [Google Scholar]

- Craig, J. Introduction to Robotics: Mechanics and Control, 4th ed.; Pearson Educacion: London, UK, 2018. [Google Scholar]

| Antenna Concept | Specification | ||||||

|---|---|---|---|---|---|---|---|

| Number of Units | Panel Number of Each Unit | Supporting Structure | Deployment Mechanism | Surface Accuracy | Symmetry | Number of Molds | |

| Sunflower | 6 | 3 | No | Complex | Medium | Medium | 3 |

| SSDA | 6 | 3 | No | Complex | Medium | Medium | 4 |

| Regular panel | 18 | 1 | Yes | Simple | High | High | 2 |

| Deviation-angle panel | 18 | 1 | Yes | Simple | High | High | 2 |

| Structure | Solution | ||

|---|---|---|---|

| Parameter | Value | Parameter | Value |

| Initial aperture (mm) | 2000 | Theoretical and simulated maximum aperture (mm) | (2190.726, 2190.726) |

| Focus/diameter ratio | 0.5 | Transformation matrix | |

| Number of panels n | 18 | Compensation parameters | |

| Fairing diameter s (mm) | 5 | Compensation parameter (deg) | 37.413 |

| Vertical displacement h (mm) | 10 | Fixed point P | |

| Fairing diameter (mm) | 740 | Theoretical and simulated RSE | (2.960, 2.960) |

| Initial RSE | 2.703 | Deployment angle (deg) | 149.952 |

| Deviation parameter | 0.6 | Axial vector | |

| – | – | Residual | |

| Parameter | Antenna | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dornier FIRST [31] | Dornier MEA | RadioAstron | MilliMetron | NPSSDA [32] | Uniaxial Model [36] | CFRP Model [40] | Sunflower | Improved Sunflower | |

| Aperture | |||||||||

| diameter (m) | 8.0 | 4.7 | 10.0 | 10.0 | 1.2 | 1.2 | 1.0 | 4.42 | 1.5 |

| Focal length (m) | [2.4] | [1.41] | 4.30 | 3.00 | 0.48 | 0.48 | 0.37 | 1.77 | 1.25 |

| Panel number | 24 | 24 | 27 | 24 | 24 | 20 | 30 | 18 | 18 |

| RSE | 2.78 | 2.78 | 3.33 | 3.33 | 3.16 | 2.82 | 3.76 | 2.29 | 2.70 |

| Antenna | Deviation Parameter | Improvement Rate (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | |||||||||||||

| Dornier FIRST | 3.86 | 3.87 | 3.88 | 3.90 | 3.92 | 3.94 | 3.96 | 3.98 | 4.01 | 4.04 | 4.08 | 39.15 | 46.70 |

| Dornier MEA | 3.86 | 3.87 | 3.88 | 3.90 | 3.92 | 3.94 | 3.96 | 3.98 | 4.01 | 4.04 | 4.08 | 39.15 | 46.70 |

| RadioAstron | 4.33 | 4.34 | 4.36 | 4.37 | 4.39 | 4.41 | 4.43 | 4.46 | 4.48 | 4.51 | 4.55 | 30.45 | 36.50 |

| MilliMetron | 3.86 | 3.87 | 3.88 | 3.90 | 3.92 | 3.94 | 3.96 | 3.98 | 4.01 | 4.04 | 4.08 | 16.17 | 22.47 |

| NPSSDA | 3.86 | 3.87 | 3.89 | 3.90 | 3.92 | 3.94 | 3.97 | 4.00 | 4.03 | 4.06 | 4.09 | 22.51 | 29.54 |

| Uniaxial Model | 3.23 | 3.25 | 3.26 | 3.28 | 3.31 | 3.33 | 3.36 | 3.39 | 3.43 | 3.47 | 3.51 | 15.10 | 24.47 |

| CFRP Model | 4.81 | 4.82 | 4.83 | 4.84 | 4.86 | 4.87 | 4.89 | 4.91 | 4.94 | 4.96 | 4.99 | 28.11 | 32.78 |

| Sunflower | 2.92 | 2.93 | 2.95 | 2.98 | 3.00 | 3.03 | 3.06 | 3.10 | 3.14 | 3.18 | 3.23 | 28.10 | 40.86 |

| Improved Sunflower | 2.92 | 2.94 | 2.96 | 2.99 | 3.02 | 3.05 | 3.08 | 3.12 | 3.16 | 3.20 | 3.25 | 8.93 | 20.37 |

| Antenna | Deviation Parameter | Improvement Rate (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | |||||||||||||

| Dornier FIRST | 3.96 | 3.97 | 3.99 | 4.01 | 4.03 | 4.06 | 4.09 | 4.12 | 4.16 | 4.20 | 4.25 | 42.80 | 52.87 |

| Dornier MEA | 3.96 | 3.98 | 3.99 | 4.01 | 4.03 | 4.06 | 4.09 | 4.12 | 4.15 | 4.19 | 4.25 | 43.08 | 52.81 |

| RadioAstron | 4.41 | 4.42 | 4.44 | 4.46 | 4.48 | 4.51 | 4.52 | 4.56 | 4.58 | 4.62 | 4.66 | 32.82 | 39.87 |

| MilliMetron | 3.96 | 3.98 | 3.99 | 4.01 | 4.04 | 4.06 | 4.09 | 4.12 | 4.16 | 4.20 | 4.25 | 19.50 | 27.62 |

| NPSSDA | 3.94 | 3.95 | 3.97 | 4.00 | 4.02 | 4.05 | 4.07 | 4.11 | 4.14 | 4.18 | 4.23 | 25.13 | 33.92 |

| Uniaxial Model | 3.34 | 3.35 | 3.37 | 3.40 | 3.43 | 3.46 | 3.49 | 3.52 | 3.56 | 3.61 | 3.67 | 18.92 | 30.23 |

| CFRP Model | 4.87 | 4.86 | 4.88 | 4.90 | 4.92 | 4.95 | 4.97 | 5.00 | 5.03 | 5.06 | 5.10 | 29.29 | 35.62 |

| Sunflower | 3.04 | 3.06 | 3.08 | 3.10 | 3.13 | 3.17 | 3.20 | 3.23 | 3.28 | 3.33 | 3.40 | 33.46 | 48.33 |

| Improved Sunflower | 3.00 | 3.02 | 3.04 | 3.07 | 3.09 | 3.13 | 3.16 | 3.20 | 3.25 | 3.30 | 3.35 | 11.76 | 24.20 |

| No. | Semi-Period | ||

|---|---|---|---|

| 1 | 0.398 | 8.139 | 97.703 |

| 2 | 6.596 | 23.943 | 23.241 |

| 3 | 19.921 | 30.166 | 13.161 |

| 4 | 40.555 | 34.168 | 9.165 |

| 5 | 68.545 | 37.123 | 7.027 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, G.; Liu, K.; Duan, X.; Wang, Q.; Zhang, D.; Yang, D.; Niu, D. Configuration Investigation, Structure Design and Deployment Dynamics of Rigid-Reflector Spaceborne Antenna with Deviation-Angle Panel. Sensors 2024, 24, 385. https://doi.org/10.3390/s24020385

Tan G, Liu K, Duan X, Wang Q, Zhang D, Yang D, Niu D. Configuration Investigation, Structure Design and Deployment Dynamics of Rigid-Reflector Spaceborne Antenna with Deviation-Angle Panel. Sensors. 2024; 24(2):385. https://doi.org/10.3390/s24020385

Chicago/Turabian StyleTan, Guodong, Kaiqi Liu, Xuechao Duan, Qunbiao Wang, Dan Zhang, Dongwu Yang, and Dingchao Niu. 2024. "Configuration Investigation, Structure Design and Deployment Dynamics of Rigid-Reflector Spaceborne Antenna with Deviation-Angle Panel" Sensors 24, no. 2: 385. https://doi.org/10.3390/s24020385

APA StyleTan, G., Liu, K., Duan, X., Wang, Q., Zhang, D., Yang, D., & Niu, D. (2024). Configuration Investigation, Structure Design and Deployment Dynamics of Rigid-Reflector Spaceborne Antenna with Deviation-Angle Panel. Sensors, 24(2), 385. https://doi.org/10.3390/s24020385