1. Introduction

Materials and their development depend on their purpose, in order to find the ones with excellent properties that best serve the intended purpose. The development method is based on tests. In aviation, the use of composite materials is growing thanks to their practical advantages [

1] such as: building larger window openings; achieving a lower resistance of air flow, which contributes to a reduction in fuel consumption; and reduction in the total number of parts and components. On one hand, there are efforts to reduce the amount of material, used but on the other hand, it is vital to consider an increased risk of fire initiation of the given materials.

The organization laying down the general rules for the fire safety of the materials used in civil aviation is the FAA (Federal Aviation Administration). FAA regulations technically apply to the aircraft designed and manufactured in the USA, but they are applied in general in the whole aviation sector [

2]. FAA has drawn up fire test procedures, in regulation FAR 25.853 Flammability Requirements for Aircraft Seat Cushions [

3], to test flammability and fire resistance. FAR 25.853 [

3] sets out the major fire properties of materials, namely, the total heat release rate, heat release rate, smoke release, and temperature of surfaces [

2].

According to the regulations in civil aviation, fire, explosion, smoke, and toxic or harmful fumes, even after putting out a fire, are considered states of emergencies [

2,

4,

5,

6].

The FAA has also drawn up fire test procedures, outlined in regulation FAR 25.853 [

3], to test materials’ flammability and fire resistance. FAR 25.853 sets out the major fire properties of materials (

Table 1), such as the total heat release, heat release rate, and smoke release [

2].

The limit values presented in

Table 1 are specified to ensure that the material used in the aircraft does not contribute to the development and spread of fire during the first five minutes after landing [

7].

The Federal Aviation Administration (FAA) aimed to create a database of the materials tested that have been used or are in the development stage for their use in civil aviation. The database is to provide air safety authorities, engineers in the aviation industry, and aviation technology operators with information on flammability and fire characteristics of the tested materials [

2].

Fire-fighting properties in the FAA database determined using the cone calorimeter test are only provided for the heat flow of 50 kW/m

2, because most available data on fires of composite materials are designed for fire testing for the given heat flow (

Table 1). This heat flow creates the surface temperature of maximum 700 °C on the polymer composite, which is equivalent to a fire of medium intensity in the aircraft [

2].

The FAA database also offers additional fire properties of (composite) materials such as: time until ignition, limit oxygen index, maximum heat release rate, average heat release rate, total heat release, flame spread rate, and production of smoke and combustion products.

Upholstered seats represent a part of the interior equipment of an aircraft. There are separate tests relating to these materials [

8,

9].

Wang et al. [

10] simulated the conditions of fire in the cargo area of an aircraft. They studied behavior characteristics of the selected materials in a partially closed chamber and in an alpine laboratory for the same low atmospheric pressure. The authors observed the control effects of exhaust air and oxygen concentration. Experiments with fire using n-heptane were carried out separately in a low-pressure chamber Langfang (altitude 50 m) and in airport laboratories Kangding (altitude 4290 m) at the air pressure of 60 kPa according to ISO-9705 [

11]. The main characteristic parameters were burning rate, flame temperature, and radiation heat flow. Increased oxygen concentration caused the burning rate of the material to increase and burning time to decrease. A higher amount of air absorbed, or higher oxygen concentration, could increase the fire intensity in the cargo area and worsen the flame spread rate.

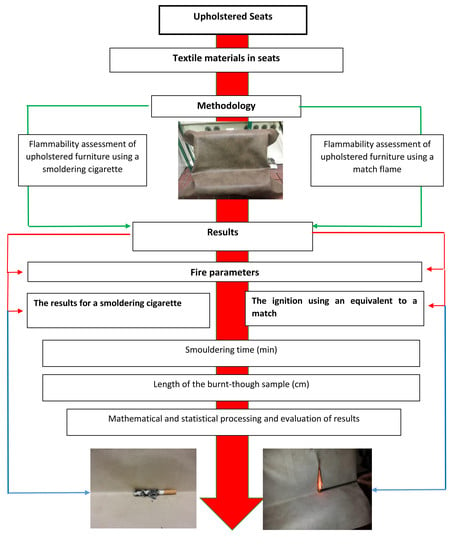

1.1. Textile Materials in Seats

Currently, upholstery forms an integral part of seat construction. In the industrial sector, upholstered material must meet safety measures such as the strength, sanitariness, and fire resistance. Upholstery fabrics, which belong to the category of combustible substances, are a part of the upholstered product. Therefore, it is necessary to implement measures to increase fire safety of these textiles. Seats are a part of an aircraft and are covered with upholstery material. Upholstery is the surface treatment of materials and walls using textile, leather, leatherette, netting, or other natural and synthetic materials [

8]. Upholstery is composed of external covering (outer cover), of inner liner (inner cover; coating thicker than 2 mm), and padding (filling).

Cushioning belongs to the category of materials that are easily flammable, such as latex foam, polyurethane foam, etc. These materials react dangerously in contact with fire, such that they melt, run, and release toxic residues.

Methods determining the ability of materials to ignite is based on the setting of boundary conditions in which we observe flare-up, i.e., ignition.

The basic parameters to be assessed when observing the behavior of the selected upholstery materials are: [

8] time of the flame exposure (flame application time) which is the time a test sample is exposed to ignition flame; and time of flame spread (flame spread time), which is the time the flame covers a certain distance onto the burning material under the specified test conditions.

1.2. Sources of Combustion Initistion

All aspects of a fire have to test in the field of fire protection. One of the basic conditions of combustion is the presence of an effective initiation source. To initiate burning, the initiation source must have a sufficient amount of energy. After initiating the burning process, to continue burning it needs sufficient heat output either from the combustion zone itself or in cooperation with other heat sources. A necessary condition of initiation, as well as of continuous burning, is the existence of combustible file, i.e., a suitable quantity ratio of flammable substances and oxygen [

7,

12,

13]. Based on the initiation source, we can identify three types of fire initiation processes [

14]: (1) spontaneous ignition caused by an external radiant heat source; (2) initiation caused by external source of ignition (open flame, spark); and (3) spontaneous ignition without any external heat source (self-ignition, chemical reaction). Conditions for burning initiation are limited in particular by the concentration of fuel and oxygen and the source of ignition (flame, radiant heat, spark, etc.) [

15,

16,

17,

18]. Initiation source always refers to a particular combustive or an explosive system [

19,

20,

21,

22].

Initiation energy is fed to the combustive material by an external initiation source. It is a so-called “external” initiation. However, there are substances that are able to self-activate as a result of their particular instability (either the chemical composition or physical properties).

Such substances are referred to as self-ignitive [

23]. Initiation sources are divided as follows [

24]: hot surfaces; flames and hot gases (including hot particles); mechanical sparks, electrical devices; stray voltage and cathodic protection against corrosion; static electricity; lightning; high-frequency (HF) electromagnetic waves ranging from 104 Hz to 31,012 Hz; electromagnetic waves from 31,011 Hz to 31,015 Hz; ionizing radiation; ultrasound; adiabatic compression, shock waves, and exothermic reactions; and including auto-ignition of dust.

The specific sources of ignition for the manufacture of upholstered sitting furniture are smoldering cigarette and equivalent of flame by matches. The energy released from the cigarettes proves itself as not very effective, with no flame initiation in most cases [

25]. The cigarette burning is, in the process of smoldering, accompanied by the release of harmful products. Their characteristics are presented in the works of [

26].

Stoliarov [

27] explains the processes as follows: “The pyrolysis region, dominated by anaerobic decomposition, provided gaseous fuel, the ignition of which resulted in the transition. The smoldering region, dominated by oxidation reactions at the solid–gas interface, generate the heat necessary to maintain the pyrolysis process and ignite the gaseous fuel” [

27].

We need to note that objections to the existing methods of the tests of upholstery material have been made. In 2012, Lloyd treated this issue [

28] while presenting the diversity of cigarette position and the time of application on wheelchair materials.

The aim of this article was to analyze and compare of the effect of initiation sources (cigarettes and matches) on the upholstery materials, namely surface materials of the upholstery set and impact assessment of the materials on the degradation processes.