Optimal Preventive Maintenance of Wind Turbine Components with Imperfect Continuous Condition Monitoring

Abstract

:1. Introduction

2. Quantification of the Uncertainty of Continuous Condition Monitoring

3. Maintenance Model with Imperfect Continuous Condition Monitoring

4. Example: Preventive Maintenance of Wind Turbine Blades

4.1. Methods of Condition Monitoring of Wind Turbine Blades

4.2. Crack Degradation Model

4.3. Model Parameters

5. Results and Discussion

5.1. Investigation of Probabilities of Correct and Incorrect Decisions of Online Condition Monitoring

- All probabilities depend on the length of the monitoring interval τ;

- The probability of an FP begins to go up remarkably at months and gets to 3.8% at months, and then slowly decreases to 1.6 % at months;

- The probability of TP decreases slowly, reaching 98.5% at months, and then begins to decrease rapidly, reaching 22.4% at months;

- The probability of FN begins to increase remarkably at months reaching the maximum value of 3.4% in the vicinity of the maximum of PDF of time to failure when months, and then decreases reaching 1.8% at months;

- The probability of TN begins to increase significantly at months when its value is 0.7%, and then increases sharply reaching 74.2% at months.

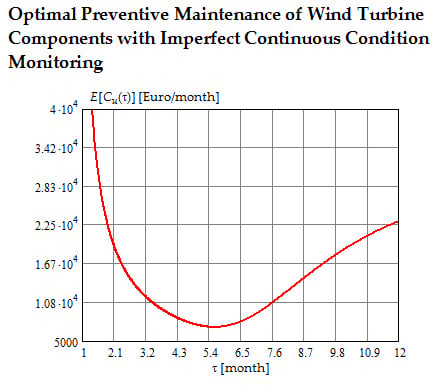

5.2. Investigation of the Expected Cost of Preventive Maintenance with Online Condition Monitoring

- The average lifetime maintenance cost is a convex function of the periodicity of predetermined preventive maintenance;

- The optimal periodicity of predetermined preventive maintenance decreases from 11 months to 8 months, when the crack initiation rate increases from 0.05 [1/year] to 0.2 [1/year];

- The minimal value of the average lifetime maintenance cost increases with an increase in the crack initiation rate. Indeed, when θ = 0.05 [1/year], then ; when θ = 0.2 [1/year], then .

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CBM | Condition-based maintenance |

| FN | False negative |

| FP | False positive |

| GW | Gigawatt |

| kwh | Kilowatt hour |

| MW | Megawatt |

| MWh | Megawatt hour |

| O&M | Operation and maintenance |

| Probability density function | |

| TN | True negative |

| TP | True positive |

| WT | Wind turbine |

Nomenclature

| H | random time to failure of a WT component |

| ω(η) | probability density function of time to failure |

| Q(η) | probability of failure |

| τ | periodicity of preventive maintenance |

| X(t) | stochastic process of a WT component degradation |

| e(t) | stochastic process of noise |

| Y(t) | sum of stochastic processes X(t) and Y(t) |

| FT | degradation failure threshold |

| H* | random time until stochastic process Y(t) crosses failure threshold FT |

| Δ | random error in evaluation of time to failure |

| joint probability density function of random variables H and H* | |

| P(τ) | probability of failure-free operation of the WT component in the interval (0, τ) |

| FP(0, τ) | a false positive event in the interval (0, τ) |

| TP(0, τ) | a true positive event in the interval (0, τ) |

| FN(0, τ) | a false negative event in the interval (0, τ) |

| TN(0, τ) | a true negative event in the interval (0, τ) |

| probability of a false positive in the interval (0, τ) | |

| probability of a true positive in the interval (0, τ) | |

| probability of a false negative in the interval (0, τ) | |

| probability of a true negative in the interval (0, τ) | |

| conditional probability density function of random variable | |

| conditional probability density function of the random error in evaluation of time to failure | |

| average maintenance cost for the time between renewals | |

| average duration of the time between renewals (regeneration cycle) | |

| expected cost of maintenance per unit of time | |

| optimal periodicity of preventive maintenance | |

| cost of corrective maintenance due to degradation failure | |

| cost of corrective maintenance due to catastrophic failure | |

| loss cost per unit of time due to unrevealed failure | |

| cost of preventive maintenance due to false positive | |

| cost of preventive maintenance due to true positive | |

| Ω(e) | probability density function of the sensor random measurement error |

| standard deviation of the measurement noise | |

| mathematical expectation of the random degradation rate of crack | |

| standard deviation of the random degradation rate of crack | |

| A | random degradation rate of crack |

| γ | exponent of time |

| Gaussian probability density function of the random degradation rate of crack | |

| θ | crack initiation rate |

| lifetime of a WT | |

| cost of ordering an offshore boat and inspection |

Appendix A

References

- Wind Power Capacity Worldwide Reaches 597 GW, 50.1 GW Added in 2018. Available online: https://wwindea.org/blog/2019/02/25/wind-power-capacity-worldwide-reaches-600-gw-539-gw-added-in-2018/ (accessed on 25 February 2019).

- Renewable Power Generation Costs in 2017. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2018/Jan/IRENA_2017_Power_Costs_2018.pdf (accessed on 8 January 2018).

- Wind Turbine Maintenance Costs to Almost Double by 2020. Available online: https://www.edie.net/news/6/Win-turbine-maintenance-costs-to-nearly-doubl/ (accessed on 19 March 2015).

- Byon, E.; Ntaimo, L.; Ding, Y. Optimal maintenance strategies for wind turbine systems under stochastic weather conditions. IEEE Trans. Reliab. 2010, 59, 393–404. [Google Scholar] [CrossRef]

- Wind Farms: Preventive to Predictive Maintenance with Remote Monitoring. Available online: https://innovate.ieee.org/innovation-spotlight/wind-farm-preventive-maintenance-local-control-unit/ (accessed on 30 March 2017).

- Yildirim, M.; Gebraeel, N.Z.; Sun, X.A. Integrated predictive analytics and optimization for opportunistic maintenance and operations in wind farms. IEEE Trans. Power Syst. 2017, 32, 4319–4328. [Google Scholar] [CrossRef]

- Ouyang, T.; Yusen He, Y.; Huang, H. Monitoring wind turbines’ unhealthy status: A data-driven approach. IEEE Trans. Emerg. Top. Comput. Intell. 2019, 3, 163–172. [Google Scholar] [CrossRef]

- Huang, L.L.; Fu, Y.; Mi, Y.; Cao, J.L.; Wang, P. A Markov-chain-based availability model of offshore wind turbine considering accessibility problems. IEEE Trans. Sustain. Energy 2017, 8, 1592–1600. [Google Scholar] [CrossRef]

- Leonardi, F.; Messina, F.; Santoro, C. A risk-based approach to automate preventive maintenance tasks generation by exploiting autonomous robot inspections in wind farms. IEEE Access 2019, 7, 49568–49579. [Google Scholar] [CrossRef]

- Besnard, F.; Fischer, K.; Tjernberg, L.B. A model for the optimization of the maintenance support organization for offshore wind farms. IEEE Trans. Sustain. Energy 2013, 4, 443–450. [Google Scholar] [CrossRef]

- BS EN 13306: 2017. Maintenance—Maintenance Terminology. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030324472 (accessed on 1 December 2017).

- Artigao, E.; Martín-Martíneza, S.; Honrubia-Escribano, A.; Gómez-Lázaro, E. Wind turbine reliability: A comprehensive review towards effective condition monitoring development. Appl. Energy 2018, 228, 1569–1583. [Google Scholar] [CrossRef]

- Yang, B.; Dongbai, S. Testing, inspecting and monitoring technologies for wind turbine blades: A survey. Renew. Sustain. Energy Rev. 2013, 22, 515–526. [Google Scholar] [CrossRef]

- Stetco, A.; Dinmohammadi, F.; Zhao, X.; Robu, V.; Flynn, D.; Barnes, M.; Keane, J.; Nenadic, G. Machine learning methods for wind turbine condition monitoring: A review. Renew. Energy 2019, 133, 620–635. [Google Scholar] [CrossRef]

- Kang, J.; Jose Sobral, J.; Soares, C.G. Review of Condition-Based Maintenance Strategies for Offshore Wind Energy. J. Mar. Sci. Appl. 2019, 18, 1–16. [Google Scholar] [CrossRef]

- Sensor Solutions for Predictive Maintenance of Wind Turbines and Generators. Available online: https://www.micro-epsilon.co.uk/news/2019/2019-04-09-ME334-Sensor-solutions-for-predictive-maintenance-of-wind-turbines-and-generators/ (accessed on 9 May 2019).

- Canizo, M.; Onieva, E.; Conde, A.; Charramendieta, S.; Trujillo, S. Real-time predictive maintenance for wind turbines using big data frameworks. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; pp. 1–8. [Google Scholar]

- Fu, Z.; Luo, Y.; Gu, C.; Li, F.; Yue, Y. Reliability analysis of condition monitoring network of wind turbine blade based on wireless sensor networks. IEEE Trans. Sustain. Energy 2019, 10, 549–557. [Google Scholar] [CrossRef]

- Krishna, D.G. Preventive maintenance of wind turbines using remote instrument monitoring system. In Proceedings of the 2012 IEEE Fifth Power India Conference, Murthal, India, 19–22 December 2012; pp. 1–5. [Google Scholar]

- Nilsson, J.; Bertling, L. Maintenance management of wind power systems using condition monitoring systems-life cycle cost analysis for two case studies. IEEE Trans. Energy Convers. 2007, 22, 223–229. [Google Scholar] [CrossRef]

- Kerres, B.; Fischer, K.; Madlener, R. Economic Evaluation of maintenance strategies for wind turbines: A stochastic analysis. IET Renew. Power Gener. 2015, 9, 766–774. [Google Scholar] [CrossRef]

- Van Horenbeek, A.; Van Ostaeyen, J.; Duflou, J.R.; Pintelon, L. Quantifying the added value of an imperfectly performing condition monitoring system—application to a wind turbine gearbox. Reliab. Eng. Syst. Saf. 2013, 111, 45–57. [Google Scholar] [CrossRef]

- Kaiser, K.A.; Gebraeel, N.Z. Predictive maintenance management using sensor-based degradation models. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2009, 39, 840–849. [Google Scholar] [CrossRef]

- Bryant, L.; John, A. Modelling wind turbine degradation and maintenance. Wind Energy 2016, 19, 571–591. [Google Scholar]

- Besnard, F.; Bertling, L. An approach for condition-based maintenance optimization applied to wind turbine blades. IEEE Trans. Sustain. Energy 2010, 1, 77–83. [Google Scholar] [CrossRef]

- Pattison, D.; Segovia Garcia, M.; Xie, W.; Quail, F.; Revie, M.; Whitfield, R.I.; Irvine, I. Intelligent integrated maintenance for wind power generation. Wind Energy 2016, 19, 547–562. [Google Scholar] [CrossRef]

- Ghamlouch, H.; Fouladirad, M.; Grall, A. The use of real option in condition-based maintenance scheduling for wind turbines with production and deterioration uncertainties. Reliab. Eng. Syst. Saf. 2019, 188, 614–623. [Google Scholar] [CrossRef]

- Shafiee, M.; Finkelstein, M. A proactive group maintenance policy for continuously monitored deteriorating systems: Application to offshore wind turbines. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2015, 229, 373–384. [Google Scholar] [CrossRef]

- Shafiee, M.; Finkelstein, M.; Bérenguer, C. An opportunistic condition-based maintenance policy for offshore wind turbine blades subjected to degradation and environmental shocks. Reliab. Eng. Syst. Saf. 2015, 142, 463–471. [Google Scholar] [CrossRef]

- Wang, J.; Liang, Y.; Zheng, Y.; Gao, R.X.; Zhang, F. An integrated fault diagnosis and prognosis approach for predictive maintenance of wind turbine bearing with limited samples. Renew. Energy 2019, 142, 642–650. [Google Scholar] [CrossRef]

- Marugán, A.P.; Chacon, A.M.; Marquez, F.P. Reliability analysis of detecting false alarms that employ neural networks: A real case study on wind turbines. Reliab. Eng. Syst. Saf. 2019, 191, 106574. [Google Scholar] [CrossRef] [Green Version]

- Gertsbakh, I. Reliability Theory: With Applications to Preventive Maintenance; Springer: New York, NY, USA, 2001; pp. 84–89. [Google Scholar]

- Nakagawa, T. Replacement and preventive maintenance models. In Handbook of Performability Engineering; Misra, K.B., Ed.; Springer: London, UK, 2008; pp. 807–823. [Google Scholar]

- Nakagawa, T. Maintenance Theory of Reliability; Springer: London, UK, 2005; pp. 220–224. [Google Scholar]

- Kavaz, A.G.; Barutcu, B. Fault detection of wind turbine sensors using artificial neural networks. J. Sens. 2018, 2018, 5628429. [Google Scholar] [CrossRef]

- McGugan, M.; Pereira, G.; Sørensen, B.F.; Toftegaard, H.; Branner, K. Damage tolerance and structural monitoring for wind turbine blades. Philos. Trans. Royal Soc. A. Math. Phys. Eng. Sci. 2015, 373, 1–16. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Rafiee, R. Simulation of fatigue failure in a full composite wind turbine blade. Compos. Struct. 2006, 74, 332–342. [Google Scholar] [CrossRef]

- Cian, C.C.; Lee, J.R.; Bang, H.J. Structural health monitoring for a wind turbine system: A review of damage detection method. Meas. Sci. Technol. 2008, 19, 1–20. [Google Scholar]

- Wedel-Heinen, J.; Hayman, B.; Bronsted, P. Materials challenges in present and future wind energy. Mater. Res. Soc. Bull. 2008, 33, 343–354. [Google Scholar]

- Li, D.; Ho SC, M.; Song, G.; Ren, L.; Li, H. A review of damage detection methods for wind turbine blades. Smart Mater. Struct. 2015, 24, 1–24. [Google Scholar] [CrossRef]

- Hameed, Z.; Hong, Y.S.; Cho, Y.M.; Ahn, S.H.; Song, C.K. Condition monitoring and fault detection of wind turbines and related algorithms: A review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Hyers, R.W.; McGowan, J.G.; Sullivan, K.L.; Manwell, J.F.; Syrett, B.C. Condition monitoring and prognosis of utility scale wind turbines. Energy Mater. 2006, 1, 187–203. [Google Scholar] [CrossRef]

- García, F.P.; Tobias, A.M.; Pinar, J.M.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Lu, B.; Li, Y.; Xin Wu, X. A Review of Recent Advances in Wind Turbine Condition Monitoring and Fault Diagnosis. In Proceedings of the 2009 IEEE Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Wang, K.; Sharma, V.S.; Zhang, Z.Y. SCADA data based condition monitoring of wind turbines. Adv. Manuf. 2014, 2, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Lopez-Higuera, J.M.; Rodriguez, L.; Quintela, A.; Cobo, A.; Madruga, F.J.; Conde, O.M.; Lomer, M.; Quintela, M.A.; Mirapeix, J. Fiber optics in structural health monitoring. In Advanced Sensor Systems and Applications IV; Brian, G., Ed.; Curran Associates, Inc.: Red Hook, NY, USA, 2010. [Google Scholar]

- Güemes, A.; Fernández-López, A.; Díaz-Maroto, P.F. Structural health monitoring in composite structures by fiber-optic sensors. Sensors 2018, 18, 1094. [Google Scholar] [CrossRef] [PubMed]

- Murayama, H.; Wada, D.; Igawa, H. Structural health monitoring by using fiber-optic distributed strain sensors with high spatial resolution. Photonic Sens. 2013, 3, 355–376. [Google Scholar] [CrossRef] [Green Version]

- Jaaskelainen, M. Fiber Optic Distributed Sensing Applications in Defense, Security, and Energy; Udd, E., Du, H.H., Wang, A., Eds.; SPIE: Orlando, FL, USA, 2009; p. 731606. [Google Scholar]

- Mishnaevsky, L.; Branner, K.; Petersen, H.; Beauson, J.; McGugan, M.; Sørensen, B. Materials for wind turbine blades: An overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef]

- Oh, K.Y.; Park, J.Y.; Lee, J.S.; Epureanu, B.I.; Lee, J.K. A novel method and its field tests for monitoring and diagnosing blade health for wind turbines. IEEE Trans. Instrum. Meas. 2015, 64, 1726–1733. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Y.; Yang, Z.; Zhang, L. Investigation of wind turbine blade monitoring based on optical fiber Brillouin sensor. In Proceedings of the 2009 International Conference on Sustainable Power Generation and Supply, Nanjing, China, 6–7 April 2009; pp. 1–4. [Google Scholar]

- Raza, A.; Ulansky, V. Modelling of predictive maintenance for a periodically inspected system. Procedia CIRP 2017, 59, 95–101. [Google Scholar] [CrossRef]

- Ignatov, V.A.; Ulansky, V.V.; Taisir, T. Prediction of Optimal Maintenance of Technical Systems; Znanie: Kiev, Ukraine, 1981; pp. 9–10. (In Russian) [Google Scholar]

- Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Electricity_price_statistics (accessed on 21 May 2019).

- Berrade, M.; Cavalcante, A.; Scarf, P. Maintenance scheduling of a protection system subject to imperfect inspection and replacement. Eur. J. Oper. Res. 2012, 218, 716–725. [Google Scholar] [CrossRef]

- Berrade, M.D.; Scarf, P.A.; Cavalcante, C.A.V.; Dwight, R.A. Imperfect inspection and replacement of a system with a defective state. A cost and reliability analysis. Reliab. Eng. Syst. Saf. 2013, 120, 80–87. [Google Scholar] [CrossRef]

- Zequeira, R.I.; Bérenguer, C. Optimal scheduling of non-perfect inspections. IMA J. Manag. Math. 2006, 17, 187–207. [Google Scholar] [CrossRef]

- He, K.; Maillart, L.M.; Prokopyev, O.A. Scheduling preventive maintenance as a function of an imperfect inspection interval. IEEE Trans. Reliab. 2015, 64, 983–997. [Google Scholar] [CrossRef]

- Nachimuthu, S.; Zuo, M.J.; Ding, Y. A decision-making model for corrective maintenance of offshore wind turbines considering uncertainties. Energies 2019, 12, 1408. [Google Scholar] [CrossRef]

- Van Noortwijk, J.M.; Pandey, M.D. A stochastic deterioration process for time-dependent reliability analysis. In Proceedings of the Eleventh IFIP WG 7.5 Working Conference on Reliability and Optimization of Structural Systems, Banff, AB, Canada, 2–5 November 2003; pp. 259–265. [Google Scholar]

- Van Noortwijk, J.M.; Cooke, R.; Kok, M. A Bayesian failure model based on isotropic deterioration. Eur. J. Oper. Res. 1995, 82, 270–282. [Google Scholar] [CrossRef]

- Abdel-Hameed, M. Inspection and maintenance policies of devices subject to deterioration. Adv. Appl. Probab. 1987, 19, 917–931. [Google Scholar] [CrossRef]

- Abdel-Hameed, M. Optimal predictive maintenance policies for a deteriorating system: The total discounted cost and the long-run average cost cases. Commun. Stat. Theory Methods 2004, 33, 735–745. [Google Scholar] [CrossRef]

| Type of Maintenance | Continuous Condition Monitoring | Studies |

|---|---|---|

| Corrective | perfect | [4,6,18,20,21] |

| imperfect | - | |

| Preventive | perfect | [4,6,19,20,21,24,25,26,27,32,33,34] |

| imperfect | [22] | |

| Condition-based | perfect | [28,29] |

| imperfect | - | |

| Predictive | perfect | [17,23] |

| imperfect | - |

| Parameter | Symbol | Value |

|---|---|---|

| Cost of corrective maintenance due to degradation failure | 100,000 | |

| Cost of corrective maintenance due to catastrophic failure | 440,000 | |

| Cost of preventive maintenance due to false positive | 20,000 | |

| Cost of preventive maintenance due to true positive | 20,000 | |

| Loss cost per unit of time due to unrevealed failure | 72,000 | |

| Cost of ordering an offshore boat and inspection | 12,500 | |

| Crack initiative rate | 0.05–0.2 | |

| WT lifetime | 25 |

| Crack Initiation Rate, θ [1/year] | Average Lifetime Maintenance Cost [€/blade] | |||

|---|---|---|---|---|

| Preventive Maintenance with Online Condition Monitoring | Corrective Maintenance | Predetermined Preventive Maintenance | ||

| 0.05 | 46,700 | 550,000 | 687,200 | 196,700 |

| 0.2 | 187,500 | 2,200,000 | 878,500 | 486,800 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raza, A.; Ulansky, V. Optimal Preventive Maintenance of Wind Turbine Components with Imperfect Continuous Condition Monitoring. Energies 2019, 12, 3801. https://doi.org/10.3390/en12193801

Raza A, Ulansky V. Optimal Preventive Maintenance of Wind Turbine Components with Imperfect Continuous Condition Monitoring. Energies. 2019; 12(19):3801. https://doi.org/10.3390/en12193801

Chicago/Turabian StyleRaza, Ahmed, and Vladimir Ulansky. 2019. "Optimal Preventive Maintenance of Wind Turbine Components with Imperfect Continuous Condition Monitoring" Energies 12, no. 19: 3801. https://doi.org/10.3390/en12193801

APA StyleRaza, A., & Ulansky, V. (2019). Optimal Preventive Maintenance of Wind Turbine Components with Imperfect Continuous Condition Monitoring. Energies, 12(19), 3801. https://doi.org/10.3390/en12193801