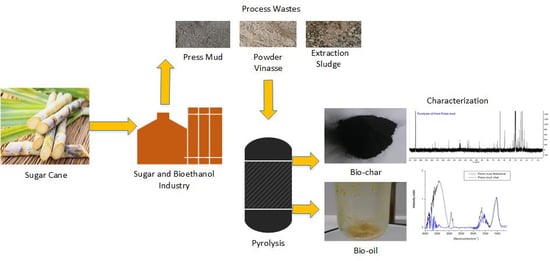

3.2.1. Influence of Biomass Type on Pyrolysis Product Distribution

Figure 8 presents the difference in pyrolysis products yield when each type of biomass waste—press mud, powder vinasse, and extraction sludge—was used as feedstock for slow pyrolysis. The liquid product was divided into heavy fraction and water (collected in the first two condensers of the pyrolysis unit) and light fraction (collected in the other two condensers). The gas yield was calculated as the mass difference between feedstock, liquid, and char yields.

The results obtained show significant differences between the three waste biomass samples subjected to pyrolysis. It was observed that powder vinasse led to the formation of the lowest content of bio-char (42.7%) and the highest production of volatiles. The results are confirmed by the proximate analysis of the raw biomass samples where powder vinasse showed the highest volatiles content (61.6 wt.%) and the lowest ash content (20.5 wt.%).

Meanwhile, the extraction sludge presented the highest liquid yield (32%) with the lowest gas formation (18.2 wt.%), which is likely owing to the high water content in the extraction sludge (7.5 wt.%). This is consistent with the extraction sludge high heavy fraction yield (6.8 wt.%), low content of volatiles (47.8 wt.%), and high ash content (40.1 wt.%).

The press mud presented the greatest char yield (60.1%) owing to its initial high ash content (53.8%). The elevated char yield of all biomass samples could suggest an incomplete decomposition of the organic phase at 450 °C.

Similar product distributions of biomass wastes through slow pyrolysis were presented by other studies [

38,

39,

40,

41,

42]. Agar et al. [

38] converted wastewater sludge and organic fines from municipal wastewater treatment plants (similar volatiles and ash content as our biomass feedstock) in carbon-rich char through pyrolysis in a laboratory fixed-bed reactor at 600 °C and 700 °C. The product distribution of sewage sludge at 600 °C was gas fraction 19%, liquid 33%, and char 48%, while for solid organic fines, the product yields at the same temperature were gas 33%, liquid 14%, and char 53%. Even at 700 °C, the char produced was 45% for the sewage sludge feedstock, while the gas yield increased to 29%. Williams and Besler [

39] studied the influence of temperature and heating rate on the slow pyrolysis of biomass wood. The pyrolysis experiments were performed for 2 h at temperatures ranging from 300 to 720 °C, and heating rates of 5–80 °C/min. The wood biomass presented a moisture of 7 wt.%, volatiles of 92.2 wt.%, and ash of 0.8 wt.%. At 420 °C and a heating rate of 5 °C/min (similar to our experimental conditions), the compositions were 29.7% for char, 12.4 % for oil, 35.9% for the aqueous fraction, and 21.5% for gas. At higher operating temperatures, the char proportion decreased to 23.2%, while the gas increased to 26.8%. Increasing the heating rate promoted the gas yield, but decreased the oil yield. Al Arni [

40] obtained a product distribution of 37.6% char, 26.1% liquid, and 25.1% gas from sugarcane bagasse (84 wt.% volatiles, 5.9 wt.% ash) by conventional pyrolysis at 480 °C, heating rates of 40–50 °C/min, and 1 h residence time.

3.2.2. Influence of Biomass Type on Bio-Char Composition

The bio-char obtained after each pyrolysis test was analyzed in terms of moisture, C, H, N, and S contents, as well as FTIR analysis. The compositions of the bio-char samples are shown in

Table 3.

After pyrolysis at 450 °C for 2 h, the moisture content in all char samples decreased to almost 0%. The results are also correlated with hydrogen content that decreased in all samples after pyrolysis. The sulfur content was not detected in any bio-char sample, suggesting that organic sulfur components were reduced to light fractions of the increase of gas yield bio-oil or gas. The char produced from powder vinasse was the richest in carbon (favorable as fuel and activated carbon). The increase of carbon content after pyrolysis was also observed by Parthasarathy and Sheeba [

41] and Lee et al. [

43]; these authors also associated the release of volatiles, such as hydrogen and oxygen by dehydrogenation and deoxygenation, to the relative increase of carbon content. In comparison, the pyrolysis of rubber wood at 550 °C showed a bio-char yield of 28.0% ± 0.35% and a moisture content of 7.5% [

44]

FTIR spectra of each waste biomass sample and their corresponding chars are presented in

Figure 9. Four regions were detected on FTIR spectra of all biomass feedstock samples: in the range of 3000–3800 cm

−1, between 2750 and 3000 cm

−1, a region between 1500 and 1800 cm

−1, and between 750 and 1250 cm

−1. The small peak that appears at 3750–3970 cm

−1 can be related to the presence of water in all biomass samples, while the broad peaks with maximum intensity around 3420 cm

−1 can be attributed to O–H stretching from aromatic and aliphatic alcohols, in particular, lignin [

45]. The small peak from 2920–2930 cm

−1 is characteristic of C–H stretching of methyl and methylene groups from cellulose, hemicellulose, and lignin.

The peaks in the region of 1500–1750 cm

−1 correspond to C=O stretching of ketones, aldehydes, esters from hemicellulose, and lignin [

45,

46]. Powder vinasse also shows an intense peak at 1417 cm

−1, which is characteristic of C–H deformation of the aromatic ring from lignin. The presence of this peak at higher intensity in the case of the powder vinasse could be the result of the higher content of lignin in this biomass sample. The peaks from 1033–1180 cm

−1 can be attributed to C–O stretching from cellulose and hemicellulose.

Significant changes of FTIR spectra appear in the case of all bio-char samples obtained after slow pyrolysis at 450 °C for 2 h. The OH stretching band from 3750–3970 cm

−1 decreased drastically in the case of all char samples, disappearing completely in the case of char from extraction sludge (with the lowest content of lignin of 12.7%). The absence of a peak at the 2920–2930 cm

−1 range suggests a significant decomposition of the biomass material during pyrolysis [

47]. While the bio-char produced from press mud still shows the peaks characteristic to C–O stretching at almost the same intensity as the feedstock, the other two char samples show a significant decrease of the peaks from this region, suggesting the higher degradation of the organic compounds for these two biomass samples.

3.2.3. Influence of Biomass Type on Bio-Oil Composition

The bio-oils produced from each biomass waste pyrolysis were analyzed in terms of chemical composition using the gas chromatography mass spectrometer (GC-MS) technique. For each test, the liquid phase was extracted separately from each condenser of the cooling unit and analyzed with GC-MS; the reason for analyzing separately was to observe the way the organic components condensed in the cooling unit, as well as to obtain a more precise identification of the organic components.

The oil collected from condenser 1 (heavy fraction and water collector) showed a wide variety of organic components in the case of the powder vinasse and the extraction sludge, and fewer components for the press mud (

Table 4).

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

Similar compounds were obtained from all three biomass waste samples, although with significant differences in terms of concentration. The powder vinasse and the extraction sludge showed a high concentration of nitrogen compounds, related to the higher N content observed in these two samples. The liquid obtained from the press mud showed a significant amount of 2.2-dimethoxypropane (DMP)—the compound is generally formed from acetone and methanol at room temperature in the presence of an acidic environment [

48]. Small amounts of 2-cyclopenten-1-one, phenolic compounds, as well as alkanes (C12–C18) were also observed.

In the case of the powder vinasse, oxazole and aziridine compounds (both with nitrogen in their structure) were in the highest concentration—50.8%, along with phenolic compounds (13.4%) and furanmethanol (5.4%). While the powder vinasse did not show any alkanes or alkenes, it contained a significantly higher concentration of aromatics than the liquid from the press mud. Similar results have been obtained by David et al. [

49] from pyrolysis of sugarcane bagasse.

The extraction sludge showed the highest concentration of phenols (16.1%), aziridines and pyrazines (22.1%), and furanmethanol (12.6%), as well as the most elevated content of alkanes and alkenes (11.6%). In the second condenser of the cooling unit, heavier organic compounds were observed in the composition of the pyrolysis liquids (

Table 5).

For all of the samples, the main components of the liquid collected from the second condenser were phenolic compounds that were produced by the degradation of lignin. Powder vinasse and extraction sludge showed 50% of phenolic compounds, which is a very similar result to those reported in the literature [

49,

50,

51]. The liquid fraction obtained from the press mud pyrolysis contained the highest proportion of alkanes (25.1%), although powder vinasse presented heavier alkenes, up to C32. A higher content of ketones (aliphatic and cyclic) was formed when the press mud (13.7%) and the extraction sludge (14.7%) were used for pyrolysis.

The liquid extracted from the last two condensers showed a variety of components, including heavy and volatile compounds. A significant amount of phenols was still observed in the liquid collected at the third condenser.

The liquid from the press mud collected in the third condenser (

Table 6) also showed a high content of alkanes, phenols, and ketones, similar to the compounds gathered in the previous condenser. For the powder vinasse, the main components observed were ketones (38%); phenols (16.1%); and organic compounds based on nitrogen (17.6%)—azirides, pyrroles, piperidines, and pyrazines. The extraction sludge showed a lower content of ketones (17.5%) and phenols (15.7%), but a higher content of organic nitrogen compounds (29.9%) and alkanes (6.5%). The liquids obtained from the pyrolysis of the press mud and the extraction sludge seemed to be, in general, heavier than that obtained from powder vinasse.

In the case of the press mud, it was observed that the pyrolysis liquid from the fourth condenser presented a significant amount of volatiles—acetic acid and toluene (32.9%). The proportion of furfural, benzene, and furan components was also significant (21%), evidencing the decomposition of hemicellulose (

Table 7).

The pyrolysis liquid from the powder vinasse still contained a significant amount of phenolic compounds (18.9%), in particular, phenol, phenol methoxy, phenol methyl, and ethyl.

Figure 10 shows the chromatogram of the pyrolysis liquid obtained from powder vinasse with the identification of the peaks characteristic to phenols. This sample contained a higher content of aliphatic and aromatic ketones (19.2%) compared with the other two pyrolysis oils generated from the press mud and the extraction sludge. Moreover, the sample also showed the presence of alkynes and sulfur organic compounds; the powder vinasse presented the highest content of sulfur—1.47%. The extraction sludge showed significant amounts of toluene, xylenes, and benzenes (37.3%), as well as aliphatic and aromatic ketones (6%), alkanes, and alkenes (13.7%).

After individual analysis of pyrolysis liquids samples collected at each condenser, the overall composition of the pyrolysis bio-oil for each biomass waste feedstock was calculated, based on the concentration of each component and the quantity of liquid collected from each condenser. The main components found in each pyrolysis bio-oil are shown in

Table 8. As a general observation, the powder vinasse produced a large variety of organic components owing to the thermal decomposition of the lignocellulosic compounds (with high volatiles content).

More than 200 components were identified in the liquid phases collected from each condenser; the separate GC-MS analysis eased the identification of all components. In the case of all three biomass samples, similar compounds were identified, in particular for the powder vinasse and the extraction sludge (high amount of organic components with nitrogen). The press mud produced important amounts of propane alkyloxy (propane, 2,2-diethoxy, 2-propanone, 1,1-dimethoxy, 2-propanone, 1-(acetyloxy)), carboxylic acids, furfural, toluene, and aliphatic and aromatic phenols, as well as alkanes and alkenes. The powder vinasse showed higher produced concentrations of phenolic, aliphatic, and aromatic ketones, as well as organic nitrogen compounds, compared with the bio-oil produced from the press mud. The bio-oil from the powder vinasse showed a high content of aromatics and a low content of hydrocarbons (alkanes, alkenes), which could have a positive impact on the physicochemical properties of the bio-oil.

Conversely, the main component of bio-oil from extraction sludge was toluene (more than 22%) as well as phenolic and organic nitrogen compounds—azirides, piperazines, piridines, and indolizines. The content of hydrocarbons was also high for the bio-oil produced from the extraction sludge.