1. Introduction

Unexpected detonation of granular solid propellants is a key safety issue. Gun tubes experience pressure build-up during unstable burning in the chamber leading to high mechanical stresses which act on the grains leading to an increase of the chamber pressure, causing the explosion of the gun tube [

1]. Moreover, ignition and subsequent combustion of granular solid propellants are also complex mechanisms of high importance in the manufacturing process of many energetic materials, not only because of already mentioned safety issues, but also due to the design of propulsion systems. The penetration of the hot gases into the voids promotes the convective heating of the granules as well as the granule compaction and the rapid pressurization of the system. In case the ignition is not correctly controlled, the process can generate compressive waves which compact the un-reacting region of the grain bed. Under strong pressure waves, the propellant bed might rapidly collapse, leading to a compressive reaction and an explosion. Therefore, it is of major importance to properly understand and model this problem.

The theoretical modeling of this problem has focused on the interests of many studies in the last decades and different approaches can be found in the literature. Some of the first researchers facing the theoretical modeling of this kind of problem were Kuo et al. [

2] who developed in their work a fixed-bed model, usually referred to as the KVS (Kuo, Vichenevetsky, Summerfield) model, to describe the transient problem of flame propagation in a packed fixed-bed of granular energetic materials. They used a combination of an explicit finite difference scheme and the method of characteristics to numerically solve the problems. Koo and Kuo [

3] compared the model predictions with experimental firing tests with satisfactory results.

On the other hand, Markatos [

4] proposed a different approach based on the previous work of Spalding [

5]. In that case, the description of the problem considered the governing equations on the basis that mass, momentum, and energy fluxes are balanced over control volumes occupied by space-sharing interspersed continua. According to that concept, distinct phases are present within the same space, their shares of space being measured by their volume fractions. The approach was used to simulate the accelerating flame front for beds of granulated solid energetic materials fixed in a rigid enclosure with satisfactory results [

4].

Another type of approach is that developed by Gough [

6] and adopted by Oton-Martinez et al. [

7] among others, which is based on the formal averaging of the solid propellant and the surrounding gas in the spatial domain considered. This approach relies on the conservation equations of the solid and gas phases where the phases are considered to be a homogeneous continuum. This means that both the gas and the propellant grains are defined to have a uniform value of density and porosity within each fundamental volume cell. Thus, the heterogeneous flow composed of two interacting continua can be described by appropriately defined averages of flow properties.

Regarding the experimental data to feed numerical models, Sandusky [

8] provided constitutive relations of compaction obtained from quasi-static compaction experiments with bed diameters approaching that of gun breeches performed on five cannon propellants. The granular materials tested were single-base, double-base, triple-base propellants as well as a nitramine-composite propellant. They found that the dominant compaction mechanism was plastic deformation with the virtual absence of fracture. Kooker et al. [

9] experimentally studied the convective ignition process of granular solid propellant beds with the help of a previously built apparatus that transformed a confined bed to a planar hot gas ignition wave. The investigation examined convective ignition behavior of five different granular solid propellants with the same flow conditions: single-base, double-base, triple-base, and nitramine composites.

As for the numerical methods used in the modeling of detonation of granular solid energetic materials, most of the authors used finite-difference schemes [

10] although with distinct approaches. Hoffman and Krier [

11] and Krier and Kezerle [

12] used the MacCormack method [

13] with a predictor-corrector scheme. Sheu et al. [

14,

15,

16] and Krier et al. [

17] also used a finite-different scheme with the Lax–Wendroff approach [

18] whereas Baer and Nunziato [

19] and Butler [

20] applied the method of lines [

21,

22]. Markatos [

4] used an implicit finite difference algorithm called IPSA (interphase slip algorithm) which anticipates the effects of a change in the local property of one phase on the properties of the other phase at the same location.

To the author’s knowledge, finite-volume approximate Riemann solvers [

23] or Total Variation Diminishing (TVD) schemes [

24] have not been previously applied to the resolution of problems describing the detonation process of the granular solid energetic materials or explosives. Notwithstanding, these numerical methods are widely used in other types of fluid mechanic problems with good results. Among others, approximate Riemann solvers are heavily used in transient transonic or supersonic problems as well as in the case of transient contact discontinuity problems [

25,

26], whereas TVD schemes have shown good results in incompressible fluid flow problems [

27].

In this work, a predictive model is developed as a tool for the characterization of the detonation process of granular solid energetic materials under shock tube conditions. The tool relies on a two-phase model, which considers a set of equations of continuity, momentum, and energy for the solid and the gas phase, to describe the transient behavior of this combustion process. Regarding the numerical methods, the tool considers the use of approximate Riemann solvers and TVD schemes to face the resolution of the system of partial differential equations of the model. The article is structured as follows: firstly, the physical model and the considered constitutive relations are presented. In the next section, the numerical schemes used for the integration of the model are described. Afterwards, the results provided by the model are compared with data available in the literature and the validation of the model is discussed. The effectiveness of different numerical schemes when facing the description of the early stages of the detonation of granular solid energetic materials is also discussed. Finally, some conclusions are drawn, and future research lines are outlined.

2. Physical Model Description

The approach proposed in this work relies on the conservation equations of mass, energy, and momentum of both gas phase and solid phase to model the physical problem of combustion of granulated solid energetic materials. In this case, the solid phase is considered as incompressible. In the present work, the model is generalized in order to be applied to different solid granulated energetic materials. The basic guidelines proposed by Hoffman and Krier [

11] together with the considerations described by Gidaspow [

28] are included in this model. Gidaspow [

28] suggests including the time derivative of the porosity into the energy equation in order to satisfy the inequality of Clausius-Duhem. However, all space and time derivatives of the porosity, which are present in the momentum and energy equations, respectively, are non-conservative terms that cannot be solved with an explicit numerical method for hyperbolic systems. Thus, in the present work, an alternative model is presented where some constitutive laws are modified, and a re-organization of the conservation equations is performed to obtain a conservative form of the system of equations. That allows the use of numerical schemes for conservative fluxes with a finite-volume approach. This way, updated numerical methods for compressible flow can be applied for the numerical resolution [

7]. Moreover, an extension of approximated Riemann solvers to the solid phase was considered for the numerical integration of the problem. Another key aspect in these models is the inclusion of a pressure into the solid, which is defined as the addition of the gas pressure and the inter-granular stress, which introduces an important stiffness from the numerical point of view. All in all, the differential equation system considered in this work can be expressed as:

where

is the density,

is the gas porosity,

is the velocity vector,

is the identity vector,

is the mass generation,

is the pressure,

is the intergranular stress,

is the drag force, and

is the interfacial heat transfer. The chemical energy of the gas phase is defined as,

where

and

stand for the gas and the particle, respectively.

According to Hoffman and Krier [

11], intergranular stress formulation does not prevent particle compaction below minimum compaction. To consider that limitation, they proposed a modification of the momentum equation of particles, so they cannot be accelerated once they have reached that porosity value. If that limitation is imposed, the Equation (5) can be rewritten to:

The term

is defined as,

where

is a constant value that considers the properties of the particle’s framework,

and

are the minimum and critical porosity respectively.

Several correlations were chosen to close the proposed model. Among them, drag force, used in momentum and energy conservation equations of gas and solid phases, is defined as:

where

is the particle diameter,

is the drag coefficient presented by Butler et al. [

29] in their study,

This correlation (Equation (11)) is a function of the Reynolds number

and gas viscosity

:

where

is the temperature,

is the value of viscosity at 2000 K, and

is 2000 K [

12].

As for the interfacial heat transfer coefficient, the heat expression form, in the case of having spherical particles

, is:

The convective heat transfer coefficient

depends on the Nusselt number (

) with the following expression:

The convective heat transfer coefficient is a function of the Prandtl Number,

, and the gas conductivity

defined as:

where

is the specific heat of the gas at constant volume,

is the universal constant of gases, and

is the molecular weight of the gas phase.

The correlation of the Nusselt number proposed by Hoffman and Krier [

11], Butler et al. [

29], and Butler and Krier [

20] has the following form:

The gas mass generation equation assuming that particles are spheres is related to the combustion velocity and has the following form:

The combustion law is given by:

where

and

are vales that depend on the propellant.

As for the gas equation of state, the equation of Noble-Abel is considered,

As previously said, in this model the solid is considered incompressible. However, as presented in Equation (7), there is a solid pressure defined as the addition of gas pressure and the intergranular stress (

), understood as the resistance of the particles to be compacted under the critical porosity. In this study, the authors consider the expressions proposed in several works, such as the ones from Krier and Kezerle [

12], Hoffman and Krier [

11], and Gokhale and Krier [

30]:

where

K is the bulk modulus.

3. Numerical Method

The physical model includes non-conservative terms. In order to handle this issue, a reconversion of the system was performed in order to have a conservative form of the system of partial differential equations. In particular, the momentum and energy equations for both gas and solid phase are re-organized so that the terms containing partial derivatives of

are resolved separately by including them in the source terms. The final system of equations in a homogenous form (without source terms) could be presented in the conservative form and remains hyperbolic. This way, a finite volume approach with an approximate Riemann solver can be used to numerically solve the problem. In this case, an extension of approximated Riemann solvers to the solid phase was considered for the numerical integration of the problem. Therefore, the multi-dimensional Euler equations used in this work for modeling and describing the physical problem of combustion of energetic materials can be written with the following general conservative form,

where

is the conserved variables vector,

is the tensor of fluxes and

is the vector that includes the non-conservative terms and the source terms, which may or not include non-conservative terms and can be defined as:

In our case, the conserved variables vector U, the flux tensor and the source terms vector are

The integration of the homogeneous part of the equation system (Equation (22)) in a control volume

yields

where

A is the boundary of Ω and

is the normal vector to surface

A. Considering the first integral as a time-rate of change of the averaging of the conserved variables

and the boundary

A formed by N surfaces so that

, Equation (25) can be written as,

The time derivative of the conserved variables is defined as

. Therefore, making use of the Rotational property

and considering that the surface integral of the flux is approached by

, a finite volume scheme for multiple dimensions in unstructured grids is obtained. Considering the source terms of the nonhomogeneous system,

where

is the rotation matrix,

its inverse, and

is the area of the

surface bounding volume

Ω.

The time step to solve the equation system is calculated as,

where

stands for a Courant–Friedichs–Lewy-like constant,

is the speed of sound of the gas phase,

and

is the speed of sound of the solid phase,

where

is the initial bulk modulus, whose value was taken from Hoffman and Krier [

11], and

is the density of the propellant.

In order to evaluate the fluxes, several approximations such as the first-order upwind method of Godunov, Lax–Friedrichs scheme, and Lax–Wendroff scheme can be found in the existing literature.

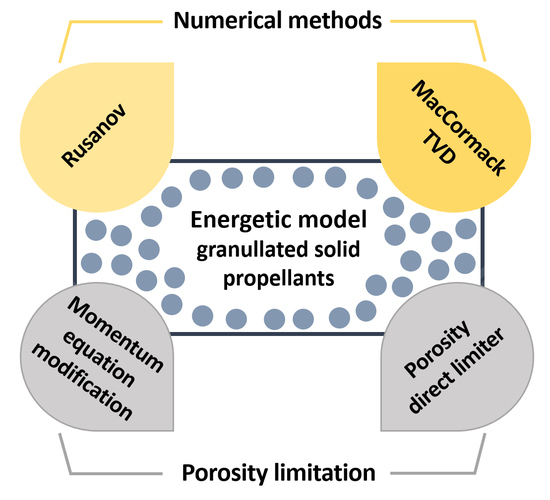

These methods require the solution of the Riemann problem which can be highly demanding. Therefore, approximate Riemann solvers are used in this work. Among the numerical schemes found in literature, Rusanov and MacCormack numerical schemes were chosen to solve the problem of energetic material combustion.

3.1. Rusanov Scheme

Rusanov scheme [

31] is a particular case of HLL (Harten Lax and van Leer) Riemann solver [

23]. In this approach, an approximation for the intercell numerical flux is obtained directly. The approximation consists of finding, for each interface between two cells, the approximate numerical flow that will be an average value of the numerical flows computed for each cell in the previous step time, corrected with a factor. This factor is proportional to the difference of conservative variables of each cell in the previous step time and a positive speed value

, so the numerical flux at each interface is computed as:

being

the flux at the interface,

the convective flow in the left cell in the previous time step,

,

the convective flow in the right cell,

and

a positive value of speed calculated by,

where

R and

L stand for right and left respectively.

3.2. MacCormack-TVD Scheme

The MacCormack numerical method of second-order in both time and space is presented to solve Navier–Stokes equations developed by Robert MacCormack [

13]. According to Lee and Kim [

32], the scheme can be written as a variation of the two steps Lax–Wendroff scheme [

18], one predictor and one corrector. According to Liang et al. [

27], the use of a total variation diminishing (TVD) of the MacCormack scheme will accurately reproduce all flow regimes. Thus, the solution of the system of Equation (22) is obtained by solving three 1-D problems in sequence as proposed in [

21],

The TVD-MacCormack scheme is used to solve consecutively the three 1D hyperbolic equations in each time step. Following [

21] and taking Equation (33) as an example the discretization scheme is given by

where the superscripts

p and

c denote the predictor and corrector steps respectively, ∆

x and ∆

t are the spatial and time steps, and

is a function defined as,

with

a flow-limiting function such as,

and

a variable defined as,

Vectors

and

are defined as,

and the values of

and

,

In this work, this numerical scheme was also extended to the solid phase.

5. Conclusions

A model was developed to study the early stages of the detonation process of granular energetic materials. To solve the system of differential equations for both gas and solid phases, Rusanov and MacCormack-TVD numerical schemes were used. Besides, the first-order Euler method was used to solve the source terms. Two different models were used to calculate pressure, temperature, and porosity distributions. The first model studied considered the modification of the particle momentum governing equation done by Hoffman and Krier [

11]. According to the authors, this modification prevents the porosity from reaching values below the minimum value of compaction that packed beds of spherical particles can reach. However, when this model is applied, the temperature of the particle phase increases and reaches values up to 8000 K and the porosity takes values below the minimum. In order to control the particle temperature, the limitation of the porosity is performed directly in the code by preventing the porosity reaching values below the possible minimum. The magnitude of the values obtained for the main variables of interest when applying this model is similar to those found in the literature. Moreover, the results obtained using Rusanov scheme agree well with those resulting from applying MacCormack-TVD numerical scheme. However, in some cases, the distributions of the variables are displaced in the x-direction with respect to those from the literature. This behavior can be seen by observing the x-coordinate position of the peak values obtained for pressure, temperature, and porosity variables. These differences could be due to the initial values of the parameters chosen as initial conditions, which highly determine the x-location of the peak values for all variables or, on the other hand, to the inconsistency of input data spread in many different sources from the literature.

All in all, the results show that MacCormack-TVD is an appropriate numerical scheme to be used when integrating the solid phase of this kind of physical problem. The extension of the numerical scheme will permit to apply this strategy to different solid propellant problems in future work. Finally, it can be concluded that the last model considered represents, with reasonable accuracy, the physical behavior of the propellant combustion for all variables of interest becoming a predictive tool for the characterization of the early stages of the detonation process of granular solid propellants.

Finally, it is worth commenting on the limitations found in the physical model considered in this work. These limitations can be improved in future work. On one hand, the model adopts the Equation of State (EOS) of Nobel-Abel for the gas phase. It would be advisable to use more complex real gas EOS to improve model accuracy. Moreover, the use of the Jones–Wilkins–Lee (JWL) EOS for both the solid and products could be also considered. However, there is an important limitation to obtain the coefficients for this kind of EOS for the reaction products of HMX and other explosives and/or propellants. On the other hand, turbulence is not considered in the present work. This is an improvement the authors plan to undertake in future work as turbulence can enhance the transport processes between phases.