Evaluation of Hydrogen Sulfide Scrubbing Systems for Anaerobic Digesters on Two U.S. Dairy Farms

Abstract

:1. Introduction:

2. Methods

2.1. Farm and H2S Scrubber Information

2.2. Performance Monitoring and Cost Information

2.3. H2S Removal Calculations

2.4. Statistical Analysis

3. Results and Discussion

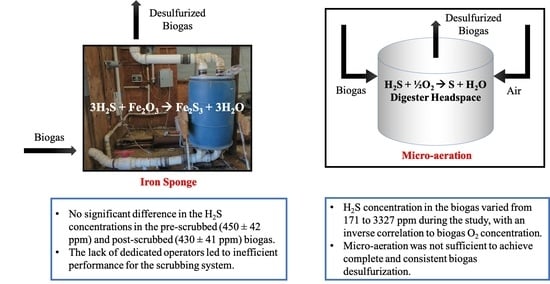

3.1. Iron Oxide Scrubber (SIOS)

3.2. In-Vessel Biological Desulfurization System Using Air Injection (SBDS)

3.3. Economic Analysis

3.4. Scrubber Management

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Occupational Safety and Health Administration. OSHA safety and health standards. 29 CFR 1910.1000. Occup. Saf. Health Adm. Revis. 1997, 1, 444. [Google Scholar]

- Steven, M. Zicari Removal of Hydrogen Sulfide from Biogas Using Cow Manure Compost; Cornell University: Ithaca, NY, USA, 2003. [Google Scholar]

- Krich, K.; Augenstein, D.; Batmale, J.P.; Benemann, J.; Rutledge, B.; Salour, D. Biomethane from Dairy Waste; Western United Dairymen: Modesto, CA, USA, 2005. [Google Scholar]

- Shelford, T.J.; Gooch, C.A.; Lansing, S.A. Performance and Economic Results for Two Full-Scale Biotrickling filters to remove H2S from Dairy Manure-derived Biogas. Appl. Eng. Agric. 2019, 35, 283–291. [Google Scholar] [CrossRef]

- Gooch, C.A.; Hogan, J.S.; Glazier, N.; Noble, R. Use of Post-Digested Separated Manure Solids as Freestall Bedding: A Case Study; Cornell University: Ithaca, NY, USA, 2006. [Google Scholar]

- Key, N.; Sneeringer, S. Climate Change Policy and the Adoption of Methane Digesters on Livestock Operations; U.S. Department of Agriculture: Washington, DC, USA, 2012.

- Allegue, L.B.; Hinge, J. Biogas Upgrading Evaluation of Methods for H2S Removal; Danish Technology Institute: Taastrup, Denmark, 2014; p. 31. [Google Scholar]

- Petersson, A.; Wellinger, A. Biogas Upgrading Technologies–Developments and Innovations; IEA Bioenergy: Paris, France, 2009. [Google Scholar]

- Oliver, J.P.; Gooch, C.A. Microbial Underpinnings of H2S Biological Filtration; Cornell University: Ithaca, NY, USA, 2016. [Google Scholar]

- Schieder, D.; Quicker, P.; Schneider, R.; Winter, H.; Prechtl, S.; Faulstich, M. Microbiological removal of hydrogen sulfide from biogas by means of a separate biofilter system: Experience with technical operation. Water Sci. Technol. 2003, 48, 209–212. [Google Scholar] [CrossRef] [PubMed]

- Shelford, T.; Gooch, C. Hydrogen Sulfide Removal from Biogas: Iron Sponge Basics; Cornell University: Ithaca, NY, USA, 2017. [Google Scholar]

- Abatzoglou, N.; Boivin, S. A review of biogas purification processes. Biofuels Bioprod. Biorefin. 2009. [Google Scholar] [CrossRef]

- Weather Underground. Available online: https://www.wunderground.com/history/daily/us/md/rising-sun/KILG (accessed on 17 October 2019).

- Cord-Ruwisch, R.; Kleinitz, W.; Widdel, F. Sulfate-reducing Bacteria and Their Activities in Oil Production. J. Pet. Technol. 1987, 39, 97–106. [Google Scholar] [CrossRef]

- Kohl, A.L.; Nielsen, R.B. Gas Purification; Elsevier: Amsterdam, The Netherlands, 1997; Volume 10, ISBN 978-0-88-415220-0. [Google Scholar]

- Mehta, A. The Economics and Feasibility of Electricity Generation Using Manure Digesters on Small and Mid-Size Dairy Farms. 2002. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=2638078 (accessed on 23 August 2019).

- Ramos, I.; Pérez, R.; Fdz-Polanco, M. Microaerobic desulphurisation unit: A new biological system for the removal of H2S from biogas. Bioresour. Technol. 2013, 142, 633–640. [Google Scholar] [CrossRef] [PubMed]

- Mulbry, W.; Selmer, K.; Lansing, S. Effect of liquid surface area on hydrogen sulfide oxidation during micro-aeration in dairy manure digesters. PLoS ONE 2017, 12, e0185738. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krayzelova, L.; Bartacek, J.; Díaz, I.; Jeison, D.; Volcke, E.I.P.; Jenicek, P. Microaeration for hydrogen sulfide removal during anaerobic treatment: A review. Rev. Environ. Sci. Biotechnol. 2015, 14, 703–725. [Google Scholar] [CrossRef]

- Ramos, I.; Fdz-Polanco, M. Microaerobic control of biogas sulphide content during sewage sludge digestion by using biogas production and hydrogen sulphide concentration. Chem. Eng. J. 2014, 250, 303–311. [Google Scholar] [CrossRef]

- Khanal, S.K.; Huang, J.-C. Online Oxygen Control for Sulfide Oxidation in Anaerobic Treatment of High-Sulfate Wastewater. Water Environ. Res. 2006, 78, 397–408. [Google Scholar] [CrossRef] [PubMed]

- Khanal, S.K.; Huang, J.C. ORP-based oxygenation for sulfide control in anaerobic treatment of high-sulfate wastewater. Water Res. 2003, 37, 2053–2062. [Google Scholar] [CrossRef]

- Speece, R.E. Anaerobic Biotechnology and Odor/Corrosion Control for Municipalities and Industries; Nashville (Ten.); Archae Press: Nashville, TN, USA, 2008; ISBN 9781578430529. [Google Scholar]

- Greer, D. Biogas conditioning and upgrading in action. Biocycle 2010, 51, 53–56. [Google Scholar]

- Lusk, P. Methane Recovery from Animal Manures: A Current Opportunities Casebook, 3rd ed.; NREL/SR-25145; National Renewable Energy Laboratory: Golden, CO, USA, 1998. [Google Scholar]

- Libarle, D.L. Barriers to Adoption of Methane Digester Technology on California Dairies; California Polytechnic State University: San Luis Obispo, CA, USA, 2014. [Google Scholar]

| Technology | H2S Limit (ppmv) |

|---|---|

| Gas Heating Boilers | <1000 |

| Combined Heat and Power (CHP) | <1000 |

| Fuel Cells | <1 |

| Natural Gas Upgrade | <4 (variations among countries) |

| Scrubber Type | Iron Oxide Scrubber (SIOS) | In-Vessel Biological Desulfurization (SBDS) | Bio-Trickling Filter 1 * | Bio-Trickling Filter 2 * |

|---|---|---|---|---|

| Farm Size | 750 cows | 650 cows | 4200 cows | 1500 cows |

| Generator Capacity | 110 kW | 140 kW | 1000 kW | 500 kW |

| Scrubber System Capital Cost | $525 | $450 | $342,000 | $185,000 |

| Annual Labor, Cleanout Costs | N/A | $0 | $10,323 | $4340 |

| Annual Generator Maintenance Costs | $450 | $28,708 | N/A | N/A |

| Annual Scrubber Maintenance Costs | $960 # | $120 | $8900 | $9400 |

| Scrubber Type | Iron Oxide Scrubber (SIOS) | In-Vessel Biological Desulfurization (SBDS) | Bio-Trickling Filter 1 * | Bio-Trickling Filter 2 * |

|---|---|---|---|---|

| Average Untreated H2S (ppm) | 450 ± 42 | N/A | 2640 ± 5.85 | 2350 ± 5.67 |

| Average Treated H2S (ppm) | 430 ± 41 | 1938 ± 65 | 150 ± 1.84 | 450 ± 3.42 |

| Overall removal Efficiency (%) | 3.0 | N/A | 94.5 | 80.1 |

| Avg. Mass of H2S removed (kg/h) | 0.0009 | N/A | 2.37 | 0.35 |

| Engine-Generator Set Capacity Factor | N/A | 0.76 | 0.93 | 0.68 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choudhury, A.; Shelford, T.; Felton, G.; Gooch, C.; Lansing, S. Evaluation of Hydrogen Sulfide Scrubbing Systems for Anaerobic Digesters on Two U.S. Dairy Farms. Energies 2019, 12, 4605. https://doi.org/10.3390/en12244605

Choudhury A, Shelford T, Felton G, Gooch C, Lansing S. Evaluation of Hydrogen Sulfide Scrubbing Systems for Anaerobic Digesters on Two U.S. Dairy Farms. Energies. 2019; 12(24):4605. https://doi.org/10.3390/en12244605

Chicago/Turabian StyleChoudhury, Abhinav, Timothy Shelford, Gary Felton, Curt Gooch, and Stephanie Lansing. 2019. "Evaluation of Hydrogen Sulfide Scrubbing Systems for Anaerobic Digesters on Two U.S. Dairy Farms" Energies 12, no. 24: 4605. https://doi.org/10.3390/en12244605

APA StyleChoudhury, A., Shelford, T., Felton, G., Gooch, C., & Lansing, S. (2019). Evaluation of Hydrogen Sulfide Scrubbing Systems for Anaerobic Digesters on Two U.S. Dairy Farms. Energies, 12(24), 4605. https://doi.org/10.3390/en12244605