Fuzzy Logic Energy Management Strategy of a Multiple Latent Heat Thermal Storage in a Small-Scale Concentrated Solar Power Plant †

Abstract

:1. Introduction

2. Methodology

2.1. The Micro Solar CHP Model

- OM1: the oil flow rate through the LFR is adjusted to maintain 210 °C as the outlet temperature when the collected solar power is greater than 15 kWth.

- OM3: if the solar power is below 15 kWth, the ORC does not operate, while the thermal storage (if not fully charged, TTES,av < 215 °C) is charged and the LFR outlet temperature set-point is kept 10 °C higher than the LHTES temperature to contrast the thermal losses.

- OM4: if the solar radiation is even higher than the power needed by the ORC, the thermal storage is also recharged and when it goes above the limit of 280 °C, defocus occurs to reduce the collected thermal power (OM1).

- OM5 and OM6: when the power produced by the solar field is low or zero but the average TES temperature is within a given operating range (hysteresis cycle between TORC,on = 217 °C and TORC,off = 215 °C), the thermal energy of the TES can be used to run the ORC unit together with energy from the LFR (OM6) or even with no sun (OM5) for a maximum of 4 h.

2.2. The Thermal Storage Model

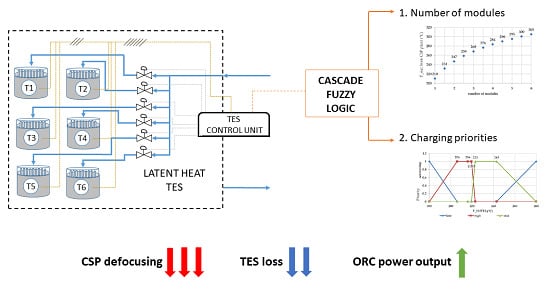

2.3. The Fuzzy Logic Controller

- (i)

- Charging the thermal storage at low temperature is not convenient, even if the corresponding thermal losses are negligible, and at the same time, the high difference in temperature between the PCM and the LFR outlet temperature facilitates the thermal exchange (preventing the defocusing). Indeed, rarely the received energy increases to the point that the sub-LHTES temperature is suitable for the ORC supply, and as consequence it is often lost. Thus, a low priority for this occurrence has been chosen. The low priority also occurs when the sub-LHTES is at high temperature, since the thermal losses are high, whilst the ORC unit does not benefit from this increase in temperature (there is a limit of the inlet temperature for preventing its damage). Moreover, the sub-LHTES is less prone to receive thermal energy at high temperatures, because of the low temperature difference between the PCM and the oil and, therefore, a serious risk of LFR defocusing exists.

- (ii)

- The highest priority occurs whenever the sub-LHTES module has a temperature close to the melting temperature range of the PCM. In this case, indeed, the thermal energy input can be exploited to run the ORC unit in OM5 and OM6.

- (iii)

- When the sub-LHTES is at mid-high temperature, although the storage is near the melting phase with good thermal exchange properties, thermal losses are significant and the temperature difference between the PCM and the outlet temperature of the diathermic oil from the LFR is quite low; then, it is not very convenient to charge the sub-LHTES. Therefore, a mid-priority is assigned to this condition.

3. Results and Discussion

4. Conclusions

- a significant increase in the storage efficiency during the winter season, allowing a longer duration of the discharging phase of the storage towards the ORC, while the two TES configuration behaves in a similar way in the other seasons (overall annual TES efficiency increase of 13%);

- an electric efficiency of the ORC unit, as well as the operating time, is higher in winter, which results in an increased yearly electric energy production (about 5%);

- 30% less thermal losses of the LFR solar field are due to defocus.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| CHP | Combined Heat and Power |

| CPC | Compound Parabolic Collectors |

| CSP | Concentrated Solar Power |

| DNI | Direct Normal Irradiance (W/m2) |

| EEORC,out | Electrical Energy output from the ORC unit (kJ) |

| LHTES | Latent Heat Thermal Energy Storage |

| LFR | Linear Fresnel Reflectors |

| LFRdef | energy dissipated by the LFR due to defocusing (kJ) |

| OM | Operation Mode |

| ORC | Organic Rankine Cycle |

| ORCeff | electrical efficiency of the ORC unit (%) |

| ORCin | inlet thermal energy to the ORC (kJ) |

| ORCout | outlet thermal energy from the ORC (kJ) |

| PLFRdiss | power dissipated by the LFR due to defocusing (kW) |

| PLFR,out | outlet thermal power from the LFR (kW) |

| PORC,in | inlet thermal power to the ORC (kW) |

| PTES,in | inlet thermal power to the TES (kW) |

| PTES,out | outlet thermal power from the TES (kW) |

| PTES | thermal power exchanged by the TES (kW) |

| PCM | Phase Change Material |

| PV | Photovoltaic |

| QTES | heat exchanged by the TES (kJ) |

| sub-LHTES | Subdivided LHTES |

| t | time (s) |

| T | Temperature (°C) |

| TES | Thermal Energy Storage |

| TTES | temperature of the TES (°C) |

| TTES,av | average temperature of the TES (°C) |

| TESloss | thermal losses of the TES (kJ) |

| TESin | inlet thermal energy to the TES (kJ) |

| TESout | outlet thermal energy to the TES (kJ) |

| TLFR,out | outlet temperature of the oil from the LFR (°C) |

| TORC,in | inlet temperature of the oil to the ORC (°C) |

| TORC,off | lower bound temperature set-point of the TES (°C) |

| TORC,on | upper bound temperature set-point of the TES (°C) |

| tubeloss | thermal losses of the tubes (kJ) |

| ΔTTES | temperature variation of the PCM (°C) |

| Δtint-timestep | time interval of the internal time step (s) |

| 1,2,3,4,5,6 | number of the module of the TES |

References

- Energy Performance of Buildings Directive|Energy. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_it (accessed on 21 May 2020).

- Energy Union|Energy. Available online: https://ec.europa.eu/energy/topics/energy-strategy/energy-union_it (accessed on 21 May 2020).

- Dentice d’Accadia, M.; Sasso, M.; Sibilio, S.; Vanoli, L. Micro-combined heat and power in residential and light commercial applications. Appl. Therm. Eng. 2003, 23, 1247–1259. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Mekhilef, S.; Mahian, O. Progress and latest developments of evacuated tube solar collectors. Renew. Sustain. Energy Rev. 2015, 51, 1038–1054. [Google Scholar] [CrossRef]

- Leveni, M.; Manfrida, G.; Cozzolino, R.; Mendecka, B. Energy and exergy analysis of cold and power production from the geothermal reservoir of Torre Alfina. Energy 2019, 180, 807–818. [Google Scholar] [CrossRef]

- Cioccolanti, L.; Tascioni, R.; Bocci, E.; Villarini, M. Parametric analysis of a solar Organic Rankine Cycle trigeneration system for residential applications. Energy Convers. Manag. 2018, 163, 407–419. [Google Scholar] [CrossRef]

- Villarini, M.; Tascioni, R.; Arteconi, A.; Cioccolanti, L. Influence of the incident radiation on the energy performance of two smallscale solar Organic Rankine Cycle trigenerative systems: A simulation analysis. Appl. Energy 2019, 242, 1176–1188. [Google Scholar] [CrossRef]

- Xu, G.; Song, G.; Zhu, X.; Gao, W.; Li, H.; Quan, Y. Performance evaluation of a direct vapor generation supercritical ORC system driven by linear Fresnel reflector solar concentrator. Appl. Therm. Eng. 2015, 80, 196–204. [Google Scholar] [CrossRef]

- Petrollese, M.; Cocco, D. Optimal design of a hybrid CSP-PV plant for achieving the full dispatchability of solar energy power plants. Sol. Energy 2016, 137, 477–489. [Google Scholar] [CrossRef]

- Comodi, G.; Cioccolanti, L.; Renzi, M. Modelling the Italian household sector at the municipal scale: Micro-CHP, renewables and energy efficiency. Energy 2014, 68, 92–103. [Google Scholar] [CrossRef]

- Arteconi, A.; Del Zotto, L.; Tascioni, R.; Mahkamov, K.; Underwood, C.; Cabeza, L.; Maldonado, J.; Manca, R.; Mintsa, A.; Bartolini, C.; et al. Multi-Country Analysis on Energy Savings in Buildings by Means of a Micro-Solar Organic Rankine Cycle System: A Simulation Study. Environments 2018, 5, 119. [Google Scholar] [CrossRef] [Green Version]

- Settino, J.; Sant, T.; Micallef, C.; Farrugia, M.; Spiteri Staines, C.; Licari, J.; Micallef, A. Overview of solar technologies for electricity, heating and cooling production. Renew. Sustain. Energy Rev. 2018, 90, 892–909. [Google Scholar] [CrossRef]

- Manfrida, G.; Secchi, R.; Stańczyk, K. Modelling and simulation of phase change material latent heat storages applied to a solar-powered Organic Rankine Cycle. Appl. Energy 2016, 179, 378–388. [Google Scholar]

- Sebastián, A.; Abbas, R.; Valdés, M.; Casanova, J. Innovative thermal storage strategies for Fresnel-based concentrating solar plants with East-West orientation. Appl. Energy 2018, 230, 983–995. [Google Scholar] [CrossRef]

- Michels, H.; Pitz-Paal, R. Cascaded latent heat storage for parabolic trough solar power plants. Sol. Energy 2007, 81, 829–837. [Google Scholar] [CrossRef]

- Cioccolanti, L.; Tascioni, R.; Arteconi, A. Mathematical modelling of operation modes and performance evaluation of an innovative small-scale concentrated solar organic Rankine cycle plant. Appl. Energy 2018, 221, 464–476. [Google Scholar]

- Majdi, L.; Ghaffari, A.; Fatehi, N. Control strategy in hybrid electric vehicle using fuzzy logic controller. In Proceedings of the 2009 IEEE International Conference on Robotics and Biomimetics, ROBIO 2009, Guilin, China, 19–23 December 2009; pp. 842–847. [Google Scholar]

- LeBreux, M.; Lacroix, M.; Lachiver, G. Fuzzy and feedforward control of an hybrid thermal energy storage system. Energy Build. 2006, 38, 1149–1155. [Google Scholar]

- Fossati, J.P.; Galarza, A.; Martín-Villate, A.; Echeverría, J.M.; Fontán, L. Optimal scheduling of a microgrid with a fuzzy logic controlled storage system. Int. J. Electr. Power Energy Syst. 2015, 68, 61–70. [Google Scholar] [CrossRef]

- Ren, J. Sustainability prioritization of energy storage technologies for promoting the development of renewable energy: A novel intuitionistic fuzzy combinative distance-based assessment approach. Renew. Energy 2018, 121, 666–676. [Google Scholar] [CrossRef]

- Suganthi, L.; Iniyan, S.; Samuel, A.A. Applications of fuzzy logic in renewable energy systems—A review. Renew. Sustain. Energy Rev. 2015, 48, 585–607. [Google Scholar] [CrossRef]

- Arteconi, A.; Del Zotto, L.; Tascioni, R.; Cioccolanti, L. Modelling system integration of a micro solar Organic Rankine Cycle plant into a residential building. Appl. Energy 2019, 251, 113408. [Google Scholar]

- Tascioni, R.; Cioccolanti, L.; Del Zotto, L.; Mahkamov, K.; Kenisarin, M.; Costa, C.; Cabeza, L.F.; de Gracia, A.; Maldonado, J.M.; Halimic, E.; et al. Numerical investigation of the smart energy management of modular latent heat thermal storage on the performance of a micro-solar power plant. In Proceedings of the ECOS 2019 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Wrocław, Poland, 23–28 June 2019. [Google Scholar]

- Mahkamov, K.; Pili, P.; Manca, R.; Leroux, A.; Mintsa, A.C.; Lynn, K.; Mullen, D.; Halimic, E.; Costa, S.C.; Bartolini, C.; et al. Development of a small solar thermal power plant for heat and power supply to domestic and small business buildings. In Proceedings of the American Society of Mechanical Engineers, Power Division (Publication) POWER, Lake Buena Vista, FL, USA, 24–28 June 2018. [Google Scholar]

- Innova-Microsolar. Available online: http://innova-microsolar.eu/ (accessed on 3 November 2017).

- Costa, S.C.; Mahkamov, K.; Kenisarin, M.; Lynn, K.; Halimic, E.; Mullen, D. Solar salt latent heat thermal storage for a small solar organic rankine cycle plant. In Proceedings of the ASME 2018 12th International Conference on Energy Sustainability Collocated with the ASME 2018 Power Conference and the ASME 2018 Nuclear Forum, Lake Buena Vista, FL, USA, 24–28 June 2018; Volume 142, pp. 1–9. [Google Scholar]

- Chacartegui, R.; Vigna, L.; Becerra, J.A.; Verda, V. Analysis of two heat storage integrations for an Organic Rankine Cycle Parabolic trough solar power plant. Energy Convers. Manag. 2016, 125, 353–367. [Google Scholar] [CrossRef]

- Simulink—Simulation and Model-Based Design—MATLAB & Simulink. Available online: https://www.mathworks.com/products/simulink.html (accessed on 27 February 2020).

- Tascioni, R.; Cioccolanti, L.; Del Zotto, L.; Habib, E. Numerical investigation of pipelines modeling in small-scale concentrated solar combined heat and power plants. Energies 2020, 13, 429. [Google Scholar] [CrossRef] [Green Version]

- Aavid, Thermal Division of Boyd Corporation. Available online: https://www.boydcorp.com/aavid.html (accessed on 21 May 2020).

- Maldonado, J.; Fullana-Puig, M.; Martín, M.; Solé, A.; Fernández, Á.; de Gracia, A.; Cabeza, L. Phase Change Material Selection for Thermal Energy Storage at High Temperature Range between 210 °C and 270 °C. Energies 2018, 11, 861. [Google Scholar]

- Serrano-López, R.; Fradera, J.; Cuesta-López, S. Molten salts database for energy applications. Chem. Eng. Process. 2013, 73, 87–102. [Google Scholar] [CrossRef] [Green Version]

- Streicher, W.; Bony, J.; Citherlet, S.; Heinz, A.; Puschnig, P.; Schranzhofer, H.; Schultz, J.M. Simulation Models of PCM Storage Units A Report of IEA Solar Heating and Cooling programme-Task 32 “Advanced Storage Concepts for Solar and Low Energy Buildings” Report C5 of Subtask C; International Energy Agency: Paris, France, 2008. [Google Scholar]

- TRNSYS: Transient System Simulation Tool. Available online: http://www.trnsys.com/ (accessed on 14 November 2017).

| Operation Mode | Description | Operating Conditions |

|---|---|---|

| OM1 | LFR supplies ORC | TLFR,out = 210 °C TLFR,out = 290 °C if TTES,av ≥ 280 °C (defocusing) |

| OM2 | System off | - |

| OM3 | LFR supplies TES | TLFR,out = TTES,av + 10 °C |

| OM4 | LFR supplies TES and ORC | TLFR,out = 210 °C if TTES,av < 200 °C or TLFR,out = TTES,av + 10 °C if 200 °C ≤ TTES,av ≤ 270 °C |

| OM5 | TES supplies ORC | 215 °C ≤ TTES,av ≤ 217 °C and oil flow rate 0.22 kg/s |

| OM6 | TES and LFR supply ORC | TLFR,out = 210 °C and oil flow rate 0.22 kg/s |

| Parameter | Single TES No Fuzzy Logic | Sub-LHTES with Fuzzy Logic | Variation, % |

|---|---|---|---|

| TES in, kJ | 1.42 × 108 | 1.37 × 108 | −3.67 |

| TES out, kJ | −1.15 × 108 | −1.14 × 108 | −0.38 |

| TES eff, % | 65.73 | 73.97 | 12.53 |

| ORC in, kJ | 3.38 × 108 | 3.52 × 108 | 4.13 |

| TES loss, kJ | 3.13 × 107 | 2.72 × 107 | −13.25 |

| Time ORC on, s | 1.36 × 107 | 1.41 × 107 | 3.74 |

| LFR def, kJ | 4.75 × 107 | 3.26 × 107 | −31.39 |

| T TES av, °C | 199.60 | 210.70 | 5.56 |

| T ORC in, °C | 228.24 | 235.80 | 3.32 |

| tube loss, kJ | −5.45 × 107 | −5.97 × 107 | 9.56 |

| ORC out, kJ | 2.45 × 108 | 2.55 × 108 | 4.09 |

| EE ORC out, kJ | 2.63 × 107 | 2.75 × 107 | 4.68 |

| ORC eff, % | 7.48 | 7.62 | 1.80 |

| Month | Single TES No Fuzzy Logic, % | Sub-LHTES with Fuzzy Logic, % | ||||||

|---|---|---|---|---|---|---|---|---|

| ORC in, kJ | Time ORC on, s | EE ORC Out, kJ | ORC eff, % | ORC in, kJ | Time ORC on, s | EE ORC Out, kJ | ORC eff, % | |

| January | 8.34 × 106 | 3.50 × 105 | 5.20 × 105 | 6.28 | 8.64 × 106 | 3.73 × 105 | 6.00 × 105 | 6.98 |

| February | 1.56 × 107 | 6.39 × 105 | 1.18 × 106 | 7.53 | 1.62 × 107 | 6.81 × 105 | 1.22 × 106 | 7.53 |

| March | 3.01 × 107 | 1.21 × 106 | 2.35 × 106 | 7.79 | 2.97 × 107 | 1.22 × 106 | 2.32 × 106 | 7.78 |

| April | 3.34 × 107 | 1.34 × 106 | 2.62 × 106 | 7.82 | 3.44 × 107 | 1.38 × 106 | 2.70 × 106 | 7.84 |

| May | 3.89 × 107 | 1.57 × 106 | 3.08 × 106 | 7.90 | 4.11 × 107 | 1.63 × 106 | 3.25 × 106 | 7.89 |

| June | 4.42 × 107 | 1.76 × 106 | 3.50 × 106 | 7.92 | 4.69 × 107 | 1.83 × 106 | 3.72 × 106 | 7.91 |

| July | 4.81 × 107 | 1.92 × 106 | 3.82 × 106 | 7.92 | 5.17 × 107 | 1.99 × 106 | 4.10 × 106 | 7.92 |

| August | 4.33 × 107 | 1.73 × 106 | 3.42 × 106 | 7.88 | 4.56 × 107 | 1.80 × 106 | 3.59 × 106 | 7.87 |

| September | 3.56 × 107 | 1.42 × 106 | 2.81 × 106 | 7.89 | 3.65 × 107 | 1.47 × 106 | 2.88 × 106 | 7.88 |

| October | 2.29 × 107 | 9.39 × 105 | 1.79 × 106 | 7.80 | 2.31 × 107 | 9.74 × 105 | 1.79 × 106 | 7.74 |

| November | 1.07 × 107 | 4.50 × 105 | 7.59 × 105 | 7.10 | 1.13 × 107 | 4.90 × 105 | 8.46 × 105 | 7.51 |

| December | 6.97 × 106 | 2.94 × 105 | 4.13 × 105 | 5.99 | 7.03 × 106 | 3.04 × 105 | 4.60 × 105 | 6.58 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tascioni, R.; Arteconi, A.; Del Zotto, L.; Cioccolanti, L. Fuzzy Logic Energy Management Strategy of a Multiple Latent Heat Thermal Storage in a Small-Scale Concentrated Solar Power Plant. Energies 2020, 13, 2733. https://doi.org/10.3390/en13112733

Tascioni R, Arteconi A, Del Zotto L, Cioccolanti L. Fuzzy Logic Energy Management Strategy of a Multiple Latent Heat Thermal Storage in a Small-Scale Concentrated Solar Power Plant. Energies. 2020; 13(11):2733. https://doi.org/10.3390/en13112733

Chicago/Turabian StyleTascioni, Roberto, Alessia Arteconi, Luca Del Zotto, and Luca Cioccolanti. 2020. "Fuzzy Logic Energy Management Strategy of a Multiple Latent Heat Thermal Storage in a Small-Scale Concentrated Solar Power Plant" Energies 13, no. 11: 2733. https://doi.org/10.3390/en13112733

APA StyleTascioni, R., Arteconi, A., Del Zotto, L., & Cioccolanti, L. (2020). Fuzzy Logic Energy Management Strategy of a Multiple Latent Heat Thermal Storage in a Small-Scale Concentrated Solar Power Plant. Energies, 13(11), 2733. https://doi.org/10.3390/en13112733