Establishing Energy Efficiency—Drivers for Energy Efficiency in German Manufacturing Small- and Medium-Sized Enterprises

Abstract

:1. Introduction

2. Theoretical Background and Focus

2.1. The Concept of Culture in the Context of Energy Efficiency Research

2.2. Theoretical Perspective of the Study

- The Macro level encompasses the institutional issue field of which organizations and actors have emerged around the issue of energy efficiency. This field and its actors exert regulative (e.g., through policies, laws, and discourse), economic–financial (e.g., through prizes, grants, subsidies), normative (e.g., work roles, habits, professional, social, and scientific norms), and cognitive–cultural (e.g., constitutive schemes, values, beliefs, and assumptions) influences on the organization’s decisions.

- The Meso level encompasses the industrial organization with its material environment, energy efficiency climate, energy efficiency practices, and basic energy assumptions and beliefs. The material environment of industrial enterprises has been a focal point of empirical studies on barriers, such as energy intensity [52,53] or firm size [54,55,56], and must be considered as a crucial factor of decision making. Following Denison’s concept of organizational climate [57], the energy efficiency climate represents the interpretation of the situations related to energy efficiency within the organization. The energy efficiency practices are understood as the totality of all practices toward energy efficiency and energy conservation by an enterprise and represent outcomes as well as inputs to decisions on energy efficiency measures. Referring to Fiedler and Mircea [58], who view energy management as “the sum of all measures and activities which are planned or executed in order to minimize the energy consumption of a company”, the energy efficiency practices synonymously represent the energy management of an enterprise. Following Schein’s concept of organizational culture [51], the basic energy assumptions and beliefs within an industrial organization are mutually dependent from the organizational structures, practices, environment, and individual members.

- The Micro level incorporates the decision makers and members of the organization with their individual characteristics (e.g., attitudes, interests, competencies). These characteristics are mutually dependent of the positioning and socialization of individuals within the organization.

2.3. Research Focus and Research Questions

- Energy efficiency climate:

- What importance does energy efficiency have for the SMEs?

- What meanings and importance does energy efficiency have for and within the SMEs?

- How is energy efficiency perceived as being established within the enterprises and what aspects drive the establishment of energy efficiency within the SMEs?

- 2.

- Energy efficiency practices:

- What importance does energy efficiency have for corporate strategy of the SMEs?

- What importance do different energy efficiency practices have for the enterprises?

- What importance does energy management have for the SMEs?

- 3.

- Interface between the enterprise and its members:

- What importance does the everyday behavior of the employees have for energy conservation and energy efficiency?

- Who is perceived as responsible for energy efficiency and energy conservation within the enterprises?

- How do the SMEs and their leaders attempt to raise awareness among their workforce?

- 4.

- Interface between the enterprise and its environment:

- Regulative: How do the SMEs perceive external imperatives for energy efficiency?

- Economic–financial: To what extent is the financing of measures considered as an obstacle by the SMEs?

- Normative: What information sources do the SMEs use and how actively do they search for information?

- Cultural–cognitive: What importance does energy efficiency have for the environment of the SMEs and to what extent does it influence the decisions of the SMEs?

3. Materials and Methods

3.1. Qualitative Analysis: Case Studies

3.2. Quantitative Analysis: Survey

4. Results

4.1. Energy Efficiency Climate

4.1.1. What Importance Does Energy Efficiency Have for the SMEs?

4.1.2. What Meanings Does Energy Efficiency Have for the SMEs?

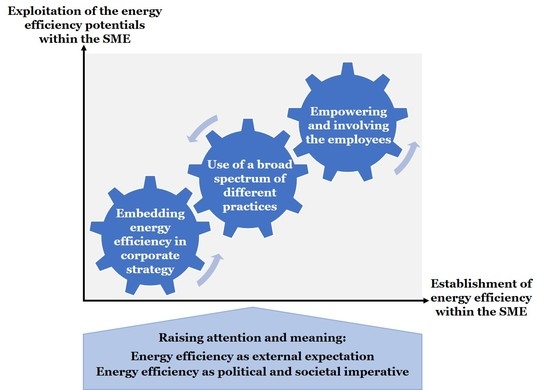

4.1.3. How Is Energy Efficiency Perceived as Being Established within the Enterprises and What Aspects Drive the Establishment of Energy Efficiency within the SMEs?

4.2. Energy Efficiency Practices

4.2.1. What Importance Does Energy Efficiency Have for Corporate Strategy of the SMEs?

4.2.2. What Importance Do Different Energy Efficiency Practices Have for the Enterprises?

4.2.3. What Importance Does Energy Management Have for the SMEs?

4.3. Interface between the Enterprise and Its Members

4.3.1. What Importance Does the Everyday Behavior of the Employees Have for Energy Conservation and Energy Efficiency?

4.3.2. Who Is Perceived as Responsible for Energy Efficiency and Energy Conservation within the SMEs?

4.3.3. How Do the SMEs and Their Leaders Attempt to Raise Awareness among Their Workforce?

4.4. Interface between the Enterprise and the Environment

4.4.1. Regulative: How Do the SMEs Perceive External Imperatives for Energy Efficiency?

4.4.2. Economic–Financial: To What Extent Is the Financing of Measures Considered as an Obstacle by the SMEs?

4.4.3. Normative: What Information Sources Do the SMEs Use and How Actively Do They Search for Information?

4.4.4. Cultural–Cognitive: What Importance Does Energy Efficiency Have for the Environment of the SMEs and to What Extent Does it Influence the Decisions of the SMEs?

5. Discussion

6. Conclusions and Future Research

Author Contributions

Funding

Conflicts of Interest

Appendix A

- What position do you have in the company? (if you have several positions please list the highest ranking, (Single selection)

- ☐

- Managing Director

- ☐

- Owner

- ☐

- Energy Manager or Energy Officer

- ☐

- Technical Manager

- ☐

- Production Manager

- ☐

- Controlling

- ☐

- Other

- 2.

- How many employees does your company have? (Single selection)

- ☐

- 1–9

- ☐

- 10–49

- ☐

- 50–249

- 3.

- What was the turnover in your company in the last financial year (million EUR)? If you are not sure, please estimate it.If you cannot estimate it, please try to indicate the turnover by selecting below. (Single selection)

- ☐

- under 250.000 Euros

- ☐

- 250.000 to less than 500.000 Euros

- ☐

- 500.000 to less than 1 million Euros

- ☐

- 1 million to less than 2 millions Euros

- ☐

- 2 million to less than 5 millions Euros

- ☐

- 5 millions to less than 10 millions Euros

- ☐

- 10 millions to less than 25 millions Euros

- ☐

- 25 millions to less than 50 millions Euros

- ☐

- 50 millions to less than 100 millions Euros

- ☐

- 100 millions to less than 500 millions Euros

- ☐

- 500 millions Euros and above

- 4.

- What was the energy demand (all energy sources such as electricity, gas, oil, etc.) in your company in the last 12 months in megawatt hours (MWh)? If you are not sure, you can estimate it or give the composition of your energy needs.________________________MWhIf you cannot estimate the energy demand, please try to specify the energy demand in the following categories. (Single selection)

- ☐

- under 10 MWh

- ☐

- 10 to less than 50 MWh

- ☐

- 50 to less than 100 MWh

- ☐

- 100 to less than 500 MWh

- ☐

- 500 to less than 1.000 MWh

- ☐

- Less than 2.500 MWh

- ☐

- 2.500 to less than 5.000 MWh

- ☐

- 5.000 to less than 10.000 MWh

- ☐

- 10.000 to less than 50.000 MWh

- ☐

- 50.000 MWh and above

or give the composition of your energy needs.- ☐

- Electricity approx.____________________(in MWh)

- ☐

- Coal approx.____________________(stating an unit________)

- ☐

- Oil approx.____________________(stating an unit________)

- ☐

- Gas approx.____________________(stating an unit________)

- ☐

- District heating approx.____________________(stating an unit________)

- ☐

- Biomass approx.____________________(stating an unit________)

- ☐

- Other approx.____________________(stating an unit)________)

- 5.

- In which year was your company founded?

- 6.

- What type of energy efficiency measures have you “implemented” (in the last 3 years), “is currently on focus”, “plan for the future”(in the next 3 years) and “do not plan to do so” (in the next 3 years? (please mark one answer per question)

| … “Have You Implemented ?” (Multiple Selection) | … “Is Currently on Focus ?” (Multiple Selection) | … “Plan for the Future ?” (Multiple Selection) | … “Do not Plan to Do so ?” (Multiple Selection) | |

| Technical investment (e.g. procurement of energy-efficient technology) | ☐ | ☐ | ☐ | ☐ |

| Technical and organizational (e.g. energetic optimized process control) | ☐ | ☐ | ☐ | ☐ |

| Organizational (e.g. energy audit, energy team) | ☐ | ☐ | ☐ | ☐ |

| Information-related (e.g. energy monitoring, energy consulting) | ☐ | ☐ | ☐ | ☐ |

| Competence-related (e.g. workshops, training courses) | ☐ | ☐ | ☐ | ☐ |

| Awareness and behavior related (e.g. employee sensibilities, rules of conduct) | ☐ | ☐ | ☐ | ☐ |

- 7.

- How do you see the subject of energy efficiency currently being established in your company? (Single selection)(1 = Very strong, 3 = moderate, 5 = not all)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 8.

- How do you estimate the importance of energy efficiency and energy saving in everyday work for the workforce in the company? (Single selection)(1 = Very high, 3 = moderate, 5 = very low)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 9.

- How important is energy efficiency currently for the general corporate strategy? (Single selection)(1 = Very high priority, 3=a moderate priority, 5=a very low priority)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 10.

- How important do you rate the behavior of employees in the company as a contribution to the achievement of energy savings? (Single selection)(1 = Very important, 3 = moderate, 5 = unimportant)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 11.

- Who (in your opinion) is responsible for energy saving and energy efficiency in your company? (Multiple selection)

- ☐

- Managing director or owner

- ☐

- Energy manager or energy officer

- ☐

- Technical management or single department

- ☐

- Everyone—Employees and directors

- ☐

- No one

- ☐

- Don’t know

- 12.

- Increasing energy efficiency in industry represents an increasing social and political demand. Which groups or actors do you attribute to these demands? (Multiple selection)

- ☐

- Global politics/world politics

- ☐

- National/German politics

- ☐

- Industry associations and stakeholders

- ☐

- Customers and sales market

- ☐

- Suppliers

- ☐

- End customers

- ☐

- Society

- ☐

- Don’t know

- 13.

- How is this demand for energy efficiency perceived in your company? (Single selection)(1 = Positive, 3 = indifferent, 5 = negative)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 14.

- Energy efficiency measures often require investment. Which economic possibilities of the realization of measures are suitable for your enterprise? (Multiple selection)

- ☐

- Equity capital

- ☐

- Bank credit

- ☐

- Sponsored loan and credit

- ☐

- Funding and subsidies

- ☐

- Contracting

- ☐

- Other

- ☐

- Don’t know

- 15.

- The financing of energy efficiency measures is an obstacle for my company. (Single selection)(1 = Strongly agree, 3 = partly agree, 5 = strongly disagree)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 16.

- How do you obtain information about energy efficiency measures? (Multiple selection)

- ☐

- Trade press

- ☐

- Industry associations, stakeholders

- ☐

- Ministries, offices and agencies

- ☐

- Commerce Chambers (IHK/HWK)

- ☐

- Service providers and trade

- ☐

- Consulting firms or consultants

- ☐

- Internal specialists

- ☐

- Other companies

- ☐

- Research institutes, universities, colleges

- ☐

- Other

- ☐

- Don’t know

- 17.

- How active is your company looking for information about energy efficiency measures? (Single selection)(1 = Very active, 3 = moderate, 5 = inactive)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 18.

- Importance of your environment: (1) “How do you rate the importance of energy efficiency for your x(see below)-environment?” (2) “Which influence does this setting have on your decision on energy efficiency measures in your company?” (Matrix question)

| (1) “How Do You Rate the Importance of Energy Efficiency for Your Environment? ” Energy Efficiency Is Very Important for Your (Multiple Selection) | (2) “Which Influence Does This Environment Have on Your Decision on Energy Efficiency Measures in Your Company?” (1 = A Very High Influence, 3 = a Moderate Influence, 5 = a Very Low Influence) (Selection Only for Those Mentioned in (1)) | ||||||

| Customers | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Suppliers or partners | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Industry or competitors | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Job/Profession | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Investor | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Owner | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Local environment (region, com- munity, municipality, city) | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Labor market (employees) | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Other | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

| Don’t know | ☐ | ☐1 | ☐2 | ☐3 | ☐4 | ☐5 | ☐Don’t know |

- 19.

- How important is energy saving to you personally? (Single selection)(1 = Very important, 3 = moderate, 5 = unimportant)☐1 ☐2 ☐3 ☐4 ☐5 ☐ Don’t know

- 20.

- To which extension does the topic of energy efficiency affect you in your everyday life in the company? (Multiple selection)

- ☐

- decide on measures and actions

- ☐

- am involved in decisions

- ☐

- am looking for information about energy efficiency

- ☐

- measure and monitor energy flows or consumption

- ☐

- try to save energy personally

- ☐

- I’m hardly or not affected by the topic

- ☐

- am affected in a different way

- ☐

- Don’t know

References

- Trianni, A.; Cagno, E.; Farne, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Destatis. Statista Dossier on Small and Medium-Sized Enterprises (SMEs) in Germany. 2019. Available online: https://de.statista.com/statistik/studie/id/46952/dokument/kleine-und-mittlere-unternehmen-kmu-in-deutschland (accessed on 28 February 2020).

- Thollander, P.; Backlund, S.; Trianni, A.; Cagno, E. Beyond barriers—A case study on driving forces for improved energy efficiency in the foundry industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 2013, 111, 636–643. [Google Scholar] [CrossRef] [Green Version]

- Jaffe, A.B.; Stavins, R.N. The energy-efficiency gab. What does it mean? Energy Policy 1994, 22, 804–810. [Google Scholar] [CrossRef]

- Gerarden, T.G.; Newell, R.G.; Stavins, R. Addressing the Energy-Efficiency Gap; Harvard Environmental Economics Program: Cambridge, MA, USA, 2015. [Google Scholar]

- DeCanio, S.; Dibble, C.; Amir-Atefi, K. The importance of organizational structures for the adoption of innovations. Manag. Sci. 1998, 46, 1285–1299. [Google Scholar] [CrossRef]

- Weber, L. Some reflections on barriers to the efficient use of energy. Energy Policy 1997, 25, 833–835. [Google Scholar] [CrossRef]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Sudhakara Reddy, B. Barriers and drivers to energy efficiency—A new taxonomical approach. Energy Convers. Manag. 2013, 74, 403–416. [Google Scholar] [CrossRef] [Green Version]

- Buettner, S.M.; Bottner, F.; Sauer, A.; Koenig, W.; Loebbe, S. Barriers to and decisions for energy efficiency: What do we know so far? A theoretical and empirical overview. In Proceedings of the 2018 Eceee Industrial Summer Study Proceedings, Berlin, Germany, 10–13 June 2018. [Google Scholar]

- Sorrell, S.; O’Malley, E.; Schleich, J.; Scott, S. The Economics of Energy Efficiency; Edward Elgar Publishing: Cheltenham, UK, 2004. [Google Scholar]

- Fleiter, T.; Worrell, E.; Eichhammer, W. Barriers to energy efficiency in industrial bottom-up energy demand models—A review. Renew. Sustain. Energy Rev. 2011, 15, 3099–3111. [Google Scholar] [CrossRef]

- Parker, C.M.; Redmond, J.; Simpson, M. A review of interventions to encourage SMEs to make environmental improvements. Environ. Plan. C Gov. Policy 2009, 27, 279–301. [Google Scholar] [CrossRef] [Green Version]

- Revell, A.; Stokes, D.; Chen, H. Small businesses and the environment: Turning over a new leaf? Bus. Strategy Environ. 2010, 19, 273–288. [Google Scholar] [CrossRef]

- Wilhite, H. Energy Consumptions as Cultural Practice: Implications for the Theory and Policy of Sustainable Energy Use. In Cultures of Energy: Power, Practices, Technologies; Strauss, S., Rupp, S., Love, T., Eds.; Routledge, Taylor & Francis Group: London, UK; New York, NY, USA, 2013; pp. 60–72. [Google Scholar]

- Trianni, A.; Cagno, E.; De Donatis, A. A framework to characterize energy efficiency measures. Appl. Energy 2014, 118, 207–220. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Zavanella, Z.E. Energy efficiency measures for refrigeration systems in the cold chain. In Proceedings of the XXIV Summer School “Francesco Turco”—Industrial Systems Engineering, Brescia, Italy, 11–13 September 2019. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies 2017, 10, 1618. [Google Scholar] [CrossRef] [Green Version]

- Perroni, M.G.; Gouvea da Costa, S.E.; Pinheiro de lima, E.; Vieira da Silva, W. The relationship between enterprise efficiency in resource use and energy efficiency practices adoption. Int. J. Prod. Econ. 2017, 190, 108–119. [Google Scholar] [CrossRef]

- McCardell, S. Energy Effectiveness: Strategic Objectives, Energy and Water at the Heart of the Enterprise; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar]

- Palm, J.; Thollander, P. An interdisciplinary perspective on industrial energy efficiency. Appl. Energy 2010, 87, 3255–3261. [Google Scholar] [CrossRef] [Green Version]

- Backlund, S.; Thollander, P.; Palm, J.; Ottosson, M. Extending the energy efficiency gap. Energy Policy 2012, 51, 392–396. [Google Scholar] [CrossRef] [Green Version]

- Brunke, J.-C.; Johannsson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef] [Green Version]

- Sa, A.; Paramonova, S.; Thollander, P.; Cagno, E. Classification of Industrial Energy Management Practices—A case study of a Swedish foundry. Energy Procedia 2015, 75, 2581–2588. [Google Scholar] [CrossRef] [Green Version]

- Banks, N.; Fawcett, T.; Redgrove, Z. What Are the Factors Influencing Energy Behaviours and Decision-Making in the Non-Domestic Sector? A Rapid Evidence Assessment; CSE: Bristol, UK, 2012. [Google Scholar]

- Cooremans, C. Investment in energy efficiency: Do the characteristics of investments matter? Energy Effic. 2012, 5, 497–518. [Google Scholar] [CrossRef] [Green Version]

- Perrow, C. Organizing for environmental destruction. Organ. Environ. 1997, 10, 66–72. [Google Scholar] [CrossRef]

- Palm, J. Placing barriers to industrial energy efficiency in a social context: A discussion of lifestyle categorization. Energy Effic. 2009, 2, 263–270. [Google Scholar] [CrossRef]

- Shwom, R. Strengthening Sociological Perspectives on Organizations and the Environment. Organ. Environ. 2009, 22, 271–292. [Google Scholar] [CrossRef]

- Shwom, R. A middle range theorization of energy politics: The struggle for energy efficient appliances. Environ. Politics 2011, 22, 705–726. [Google Scholar] [CrossRef]

- Zierler, R.; Wehrmayer, W.; Murphy, R. The energy efficiency behaviour of individuals in large organisations: A case study of a major UK infrastructure operator. Energy Policy 2017, 104, 38–49. [Google Scholar] [CrossRef] [Green Version]

- Williams, S.; Schaefer, A. Small and medium-sized enterprises and sustainability: Managers’ values and engagement with environmental and climate change issues. Bus. Strategy Environ. 2013, 22, 173–186. [Google Scholar] [CrossRef] [Green Version]

- Hampton, S. Making Sense of Energy Management Practice: Reflections on Providing Low Carbon Support to Three SMEs in the UK. Energy Effic. 2018. [Google Scholar] [CrossRef] [Green Version]

- Andrews, R.N.L.; Johnson, E. Energy use, behavioral change, and business organizations: Reviewing recent findings and proposing a future research agenda. Energy Res. Soc. Sci. 2016, 11, 195–208. [Google Scholar] [CrossRef]

- Fawcett, T.; Hampton, S. Why & how energy efficiency policy should address SMEs. Energy Policy 2020, 140, 111337. [Google Scholar] [CrossRef]

- König, W. Energy efficiency in industrial organizations—A cultural-institutional framework of decision-making. Energy Res. Soc. Sci. 2020, 60, 101314. [Google Scholar] [CrossRef]

- O’Malley, E.; Scott, S.; Sorrell, S. Barriers to Energy Efficiency: Evidence from Selected Sectors; Policy Research Series 47; The Economic and Social Research Institute: Dublin, Ireland, 2003. [Google Scholar]

- Trianni, A.; Cagno, E. Dealing with barriers to energy efficiency and SMEs: Some empirical evidences. Energy 2012, 37, 494–504. [Google Scholar] [CrossRef]

- Hatch, M.J. Organization Theory: Modern, Symbolic, and Postmodern Perspectives; Oxford University Press: Oxford, UK, 1997. [Google Scholar]

- Sorrell, S.; Schleich, J.; Scott, S.; O’Malley, E.; Trace, F.; Boede, U.; Ostertag, K.; Radgen, P. Reducing Barriers to Energy Efficiency in Public and Private Organizations; Final Report to the European Commission; University of Brighton: Brighton, UK, 2000. [Google Scholar]

- Stephenson, J.; Barton, B.; Carrington, G.; Gnoth, D.; Lawson, R.; Thorsnes, P. Energy cultures: A framework for understanding energy behaviours. Energy Policy 2010, 38, 6120–6129. [Google Scholar] [CrossRef] [Green Version]

- Bourdieu, P. Le Sens Pratique; Polity Press: Cambridge, UK, 1992. [Google Scholar]

- Giddens, A. Central Problems in Social Theory: Action, Structure and Contradiction in Social Analysis; University of California Press: Berkeley, CA, USA; Los Angeles, CA, USA, 1979. [Google Scholar]

- Stephenson, J.; Barton, B.; Carrington, G.; Doering, A.; Ford, R.; Hopkins, D.; Lawson, R.; MacCarthy, A.; Rees, D.; Scott, M.; et al. The energy cultures framework: Exploring the role of norms, practices and material culture in shaping energy behaviour in New Zealand. Energy Res. Soc. Sci. 2015, 7, 117–123. [Google Scholar] [CrossRef]

- Mirosa, M.; Lawson, R.; Gnoth, D. Linking personal values to energy-efficient behaviors in the home. Environ. Behav. 2011, 27, 1–21. [Google Scholar] [CrossRef]

- Bell, M.; Carrington, G.; Lawson, R.; Stephenson, J. Socio-technical barriers to the use of low-emission timber drying in New Zealand. Energy Policy 2014, 67, 747–755. [Google Scholar] [CrossRef]

- Scott, R.W. Institutions and Organizations: Ideas and Interests, 3rd ed.; SAGE Publ.: Thousand Oaks, CA, USA, 2008. [Google Scholar]

- Hoffman, A. Institutional evolution and change: Environmentalism and the US chemical industry. Acad. Manag. J. 1999, 42, 351–371. [Google Scholar] [CrossRef] [Green Version]

- Wæraas, A.; Nielsen, J.A. Translation Theory “Translated”: Three Perspectives on Translation in Organizational Research. Int. J. Manag. Rev. 2016, 18, 236–270. [Google Scholar] [CrossRef] [Green Version]

- Ocasio, W. Towards an attention-based view of the firm. Strateg. Manag. J. 1997, 18, 187–206. [Google Scholar] [CrossRef]

- Schein, E.H. Organizational Culture and Leadership, 3rd ed.; Jossey-Bass: San Francisco, CA, USA, 2004. [Google Scholar]

- Phylipsen, G.J.M.; Blok, K.; Worrell, E. International comparisons of energy efficiency—Methodologies for the manufacturing industry. Energy Policy 1997, 25, 715–725. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. An empirical investigation of barriers, drivers and practices for energy efficiency in primary metals manufacturing SMEs. Energy Procedia 2014, 61, 1252–1255. [Google Scholar] [CrossRef] [Green Version]

- Fleiter, T.; Hirzel, S.; Worrell, E. The characteristics of energy-efficiency measures–a neglected dimension. Energy Policy 2012, 51, 502–513. [Google Scholar] [CrossRef]

- Costa-Campi, M.T.; García-Quevedo, J.; Segerra, A. Energy efficiency determinants: An empirical analysis of Spanish innovative firms. Energy Policy 2015, 83, 229–239. [Google Scholar] [CrossRef] [Green Version]

- Cagno, E.; Trianni, A. Exploring drivers for energy efficiency within small- and medium-sized enterprises: First evidences from Italian manufacturing enterprises. Appl. Energy 2013, 104, 276–285. [Google Scholar] [CrossRef]

- Denison, D.R. What is the difference between organizational culture and organizational climate? A native’s point of view on a decade of paradigm wars. Acad. Manag. Rev. 1996, 21, 619–654. [Google Scholar] [CrossRef]

- Fiedler, T.; Mircea, P.M. Energy management systems according to the ISO 50001 standard—Challenges and benefits. In Proceedings of the International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 25–27 October 2012. [Google Scholar] [CrossRef]

- Federal Statistical Office Baden-Württemberg. Structural Data Industry by Employee Size Classes. 2019. Available online: https://www.statistik-bw.de/Industrie/Struktur/VG-GK-BBEU.jsp (accessed on 28 February 2020).

- European Commission. Industrial Revolution Brings Industry Back to Europe; Press Release Database; European Commission: Brussels, Belgium, 2012; Available online: http://europa.eu/rapid/press-release_IP-12-1085_en.htm?locale=en (accessed on 1 August 2020).

- Ministry of Economics and Finance Baden-Württemberg. Industry Perspective Baden-Württemberg 2025. Available online: http://www.kmu-digital.eu/de/publikationen/tags/fuehrung-management/15-gemeinsam-in-die-zukunft-industrieland-baden-wuerttemberg/file (accessed on 1 August 2020).

- Creswell, J.W. Research Design—Qualitative, Quantitative, and Mixed Methods Approaches, 3rd ed.; SAGE Publ.: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Ybema, S.; Yanow, D.; Wels, H.; Kamsteeg, F. Organizational Ethnography: Studying the Complexities of Everyday Life; SAGE Publications Ltd.: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- European Council. Commission recommendation of 6 May 2003 concerning the definition of micro, small and medium-sized enterprises. Off. J. Eur. Union 2003, 46, 36–41. [Google Scholar]

- Kühl, S.; Strodtholz, P.; Teffertshofer, A. Handbuch Methoden der Organisationsforschung; VS Verlag für Sozialwissenschaften: Wiesbaden, Germany, 2009. [Google Scholar]

- Glaser, B.G.; Strauss, A.L. Grounded Theory: Strategien Qualitativer Forschung; H. Huber: Göttingen, Germany, 1998; pp. 51–83. [Google Scholar]

- Mannheimer Company Panel. The Economical Importance of Family Businesses in Germany. 2019. Available online: https://www.familienunternehmen.de/media/public/pdf/publikationen-studien/studien/Die-volkswirtschaftliche-Bedeutung-der-Familienunternehmen-2019_Stiftung_Familienunternehmen.pdf (accessed on 20 February 2018).

- Froschauer, U.; Lueger, M. Das Qualitative Interview: Zur Praxis Interpretativer Analyse Sozialer Systeme; Facultas Verlags- und Buchhandels AG: Wien, Austria, 2003. [Google Scholar]

- Froschauer, U.; Lueger, M. Interpretative Sozialforschung: Der Prozess; Facultas Verlags- und Buchhandelshandels AG: Wien, Austria, 2009. [Google Scholar]

- Statista. Number of Companies in Germany by Company Size and Economic Sector in 2017. 2018. Available online: https://de.statista.com/statistik/daten/studie/731993/umfrage/unternehmen-in-deutschland-nach-unternehmensgroesse-und-wirtschaftszweigen/ (accessed on 10 August 2018).

- Czarniawska, B. Culture is the Medium of Life. In Reframing Organizational Culture; Frost, P.J., Ed.; SAGE Publ.: Thousand Oaks, CA, USA, 1992; pp. 285–297. [Google Scholar]

- FEA—Federal Environment Agency. Data on Environmental and Energy Management Systems in Germany. 2019. Available online: https://www.umweltbundesamt.de/daten/umwelt-wirtschaft/umwelt-energiemanagementsysteme (accessed on 22 March 2019).

- Weber, M. Gesammelte Aufsätze zur Wissenschaftslehre, 6th ed.; Winckelmann, J. (Hrsg.); Mohr Verlag: Tübingen, Germany, 1985. [Google Scholar]

- North, P. The business of the Anthropocene? Substantivist and diverse economies perspectives on SME engagement in local low carbon transitions. Prog. Hum. Geogr. 2016, 40, 437–454. [Google Scholar] [CrossRef]

- North, P.; Nurse, A. ‘War Stories’: Morality, curiosity, enthusiasm and commitment as facilitators of SME owners’ engagement in low carbon transitions. Geoforum 2014, 52, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Pye, M.; McKane, A. Making a stronger case for industrial energy efficiency by quantifying non-energy benefits. Resour. Conserv. Recycl. 2000, 28, 171–183. [Google Scholar] [CrossRef]

- Cagno, E.; Moschetta, D.; Trianni, A. Only non-energy benefits from the adoption of energy efficiency measures? A novel framework. J. Clean. Prod. 2019, 212, 1319–1333. [Google Scholar] [CrossRef]

- Finster, M.P.; Hernke, M.T. Benefits organizations pursue when seeking competitive advantage by improving environmental performance. J. Ind. Ecol. 2014, 18, 652–662. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Marchesani, F.; Spallina, G. Classification of drivers for industrial energy efficiency and their effect on the barriers affecting the investment decision –making process. Energy Effic. 2017, 10, 199–215. [Google Scholar] [CrossRef]

- Caffal, C. Learning from Experiences with Energy Management in Industry; Analysis Series 17; Centre for the Analysis and Dissemination of Demonstrated Energy Technologies: Sittard, The Netherlands, 1995. [Google Scholar]

- Thollander, P.; Palm, J.; Rohdin, P. Categorizing Barriers to Energy Efficiency—An Interdisciplinary Perspective. In Energy Efficiency; Palm, J., Ed.; InTechOpen: London, UK, 2010; Available online: https://www.intechopen.com/books/energy-efficiency/categorizing-barriers-to-energy-efficiency-an-interdisciplinary-perspective (accessed on 28 February 2020).

- Thollander, P.; Palm, J. Improving Energy Efficiency in Industrial Energy Systems: An Interdisciplinary Perspective on Barriers, Energy Audits, Energy Management, Policies, and Programs; Springer: London, UK, 2013. [Google Scholar]

- Thollander, P.; Ottosson, M. An energy efficient Swedish pulp and paper industry: Exploring barriers to and driving forces for cost-effective energy efficiency investments. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef] [Green Version]

- Thollander, P.; Solding, P.; Söderström, M. Energy management in industrial SMEs. In Proceedings of the 5th European Conference on Economics and Management of Energy in Industry (ECEMEI-5), Vilamoura, Portugal, 14–17 April 2009; pp. 1–9. [Google Scholar]

- Anderson, S.T.; Newell, R.G. Information programs for technology adoption: The case of energy efficiency audits. Resour. Energy Econ. 2004, 26, 27–50. [Google Scholar] [CrossRef] [Green Version]

- Sardianou, E. Barriers to industrial energy efficiency investments in Greece. J. Clean. Prod. 2008, 16, 1416–1423. [Google Scholar] [CrossRef]

- Sanstad, A.; Howarth, R. ‘Normal’ markets, market imperfections and energy efficiency. Energy Policy 1994, 10, 811–818. [Google Scholar] [CrossRef]

- Suchmann, M.C. Managing legitimacy: Strategic and institutional approaches. Acad. Manag. Rev. 1995, 20, 571–610. [Google Scholar] [CrossRef] [Green Version]

- Hwang, H.; Colyvas, J.A. Problematizing actors and institutions in Institutional Work. J. Manag. Inq. 2011, 20, 62–66. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A.; Worrell, E.; Miggiano, F. Barriers and drivers for energy efficiency: Different perspectives from an exploratory study in the Netherlands. Energy Procedia 2014, 61, 1256–1260. [Google Scholar] [CrossRef] [Green Version]

- Fresner, J.; Morea, F.; Krenn, C.; Uson, J.A.; Tomasi, F. Energy efficiency in small and medium enterprises: Lessons learned from 280 energy audits across Europe. J. Clean. Prod. 2017, 142, 1650–1660. [Google Scholar] [CrossRef]

| Case | Number of Employees | Sector | Energy Intensity * |

|---|---|---|---|

| Enterprise A | 110 | Surface engineering | Average |

| Enterprise B | 90 | Mechanical engineering | Low |

| Enterprise C | 70 | Foundry industry | Very high |

| Enterprise D | 135 | Manufacture of products of wood, synthetics, and metal | Average |

| Enterprise E | 115 | Mineral industry | Very high |

| Enterprise F | 240 | Pulp and paper industry | High |

| Enterprise G | 85 | Mechanical engineering and service | Average |

| Enterprise H | 45 | Surface engineering | High |

| Enterprise I | 20 | Mechanical engineering | Low |

| Enterprise J | 85 | Manufacture of chemical products | High |

| Director/ Owner | Energy Management | Controlling/Accounting | Production Workers | Engineering/Maintenance | Human Resource | Marketing | Trainees |

|---|---|---|---|---|---|---|---|

| 10 | 4 | 7 | 28 | 14 | 6 | 3 | 3 |

| Company Size | Number of Employees | Respondents | Percentage | Distribution of Manufacturing SMEs in Germany |

|---|---|---|---|---|

| micro | 0–9 | 282 | 56.7% | 62.8% |

| small | 10–49 | 135 | 27.2% | 27.8% |

| medium | 50–249 | 80 | 16.1% | 9.3% |

| Meanings of Energy Efficiency for the Enterprise | Meanings of Energy Efficiency within the Enterprise |

|---|---|

|

|

| Variables | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| 1. Establishment of energy efficiency | 1.000 | ||||||

| 2. Importance for corporate strategy | 0.475 ** | 1.000 | |||||

| 3. Variety past energy efficiency practices | 0.328 ** | 0.295 ** | 1.000 | ||||

| 4. Importance of employee behavior for energy savings | 0.226 ** | 0.338 ** | 0.124 ** | 1.000 | |||

| 5. Importance of energy efficiency for the environment | 0.204 ** | 0.223 ** | 0.290 ** | 0.216 ** | 1.000 | ||

| 6. Energy demand | 0.116 * | 0.119 ** | 0.218 ** | 0.071 | 0.161 ** | 1.000 | |

| 7. Firm size | 0.140 ** | 0.094 * | 0.137 ** | 0.232 | 0.116 | −0.140 ** | 1.000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

König, W.; Löbbe, S.; Büttner, S.; Schneider, C. Establishing Energy Efficiency—Drivers for Energy Efficiency in German Manufacturing Small- and Medium-Sized Enterprises. Energies 2020, 13, 5144. https://doi.org/10.3390/en13195144

König W, Löbbe S, Büttner S, Schneider C. Establishing Energy Efficiency—Drivers for Energy Efficiency in German Manufacturing Small- and Medium-Sized Enterprises. Energies. 2020; 13(19):5144. https://doi.org/10.3390/en13195144

Chicago/Turabian StyleKönig, Werner, Sabine Löbbe, Stefan Büttner, and Christian Schneider. 2020. "Establishing Energy Efficiency—Drivers for Energy Efficiency in German Manufacturing Small- and Medium-Sized Enterprises" Energies 13, no. 19: 5144. https://doi.org/10.3390/en13195144

APA StyleKönig, W., Löbbe, S., Büttner, S., & Schneider, C. (2020). Establishing Energy Efficiency—Drivers for Energy Efficiency in German Manufacturing Small- and Medium-Sized Enterprises. Energies, 13(19), 5144. https://doi.org/10.3390/en13195144