Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses

Abstract

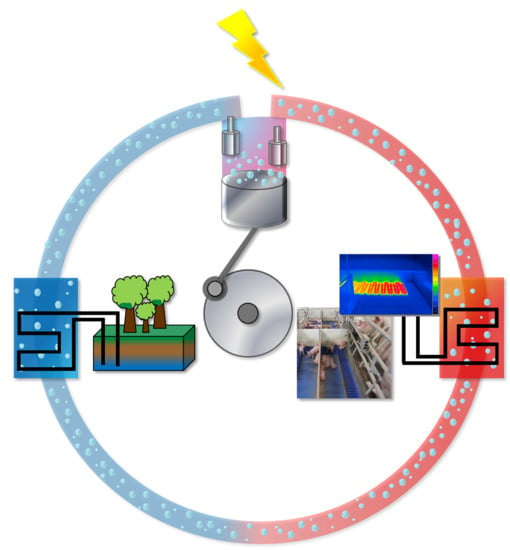

:1. Introduction

- COPT: the thermal output was set in relation to the total amount of electricity used for pumping medium (ground water pump), heat pump itself (compressors), circulation pumps of the heat pump, and distribution system (circulation pumps for hot water distribution in the house).

- COPP: the thermal output was set in relation to the amount of electricity used for pumping medium (groundwater pump) and the heat pump itself (compressors).

- COPZ: the thermal output was set in relation to the amount of electricity used for the heat pump itself (compressors), circulation pumps of heat pump, and distribution system (circulation pumps for hot water distribution in the barn).

2. Materials and Methods

2.1. Description of the Experimental Setup

2.2. Experiment Instrumentations

2.3. Assessment Limits and COP Calculation

- COPT: coefficient of performance of the total heating circuit;

- QHP: thermal heating energy in kWh;

- PGFP: electrical expenditure of the groundwater feeding pump in kWh;

- PCO,A+B: electrical expenditure of compressors A + B (in piglet rearing for both heat pumps) in kWh;

- PCI,A+B: electrical expenditure of circulation pumps A + B of the heat pump in kWh;

- PCI,FB or CI,RB: electrical expenditure of the circulation pump for the farrowing or piglet-rearing barns in kWh.

- COPP: coefficient of performance of the groundwater feeding pump and the electrical expenditure of compressors A + B (in piglet rearing for both heat pumps);

- QHP: thermal heating energy in kWh;

- PGFP: electrical expenditure of the groundwater feeding pump in kWh;

- PCO,A+B: electrical expenditure of compressors A + B (in piglet rearing for both heat pumps) in kWh;

- COPZ: coefficient of performance of the total heating circuit without the electrical expenditure of groundwater feeding pump;

- QHP: thermal heating energy in kWh;

- PCO,A+B: electrical expenditure of compressors A + B (in piglet rearing for both heat pumps) in kWh;

- PCI,A+B: electrical expenditure of circulation pumps A + B of the heat pump in kWh;

- PCI,FB or CI,RB: electrical expenditure of the circulation pump for the farrowing or piglet-rearing barns in kWh.

2.4. Data Analysis

3. Results

3.1. Climatic Conditions during the Experimental Periods

3.2. Utilization of Groundwater Heat Pumps

3.3. Coefficient of Performance (COP) of the Groundwater Heating Pumps

3.4. Heat Quantity and Produced Heating Capacity

3.5. Groundwater Flow Rates

4. Discussion

4.1. Climatic Conditions during the Experimental Periods

4.2. Groundwater Heat Pumps

4.3. Comparison with Other Heat Pumps Systems

4.4. Substitution Potential Power of Fossil Energy and a Contribution to CO2 Savings

4.5. Groundwater Heat Pump Compared to Oil or Gas Heating

5. Conclusions

- The warm-water piglet heater is preferable to the space heating variants due to the lower flow temperature.

- Hot water pipes of the heating circuit should be thermally insulated. As a result, the transport heat losses remain low and the flow temperatures can be selected lower, correspondingly.

- In addition, the warm-water piglet heater should be routed in a parallel proceeding to ensure a homogeneous heat distribution in the common area of the animals.

- The radiating surface of the heating elements in the animal house must be sufficiently large.

- The lying area should be provided with a heat protection cover. As a result, the animals can be provided with an optimal microclimate even at low heating circuit flow temperatures.

- The permanently constant ground water temperature has a positive effect on the performance of a heat pump.

- However, pumping groundwater requires a considerable amount of electrical power by the groundwater feeding pump.

- The heat pump was oversized for the stable complex under investigation. (Background: the barn should be doubled at a later date. However, the heat pumps were dimensioned directly for the entire building.)

- The application of the three different assessment limits could help to identify factors influencing the coefficient of performance.

- The high supply temperature of 50 °C in the piglet rearing barn has a negative effect on the COP. It is recommended that the radiating area in the house is increased (up to now only steel tubes have been installed here), so that the required heat output in the house can still be ensured at low supply temperature.

- The data collected refer to the winter.

- Against the background of the sharp drop in feed-in tariffs for electricity from photovoltaic systems in Germany, it should be examined whether it makes sense to install a photovoltaic system on the roof surfaces to generate electricity. On the one hand, the use of self-generated electricity could lead to becoming somewhat more independent of the energy market. On the other hand, the operation of the heat pump could become more economical if the kilowatt hour of electrical power generated on the own farm is cheaper than the kilowatt hour purchased from the network provider.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations and Indices

| COP | coefficient of performance |

| GFP | groundwater feeding pump |

| GWHP | groundwater heat pump |

| P | electric power consumption |

| Q | thermal energy in kWh |

| heating performance in kW | |

| CI,A+B | circulation pump A and B |

| CO,A+B | compressor A and B |

| el | electrical |

| FB | farrowing barn |

| HP | heat pump |

| RB | piglet-rearing barn |

| T | total electric power consumption of all compressors and circulation pumps of the heating system |

| th | thermal |

| Z | the electric power consumption of the circulation pumps A + B of the heat pump (in piglet rearing with both heat pumps) and the electric power consumption of the circulation pumps for the farrowing and piglet-rearing barns |

References

- German Environment Agency. Climate Footprint 2018: 4.5 Percent Decrease in Greenhouse Gas Emissions. German Environment Agency Produces Initial Detailed Estimate. 2019. Available online: https://www.umweltbundesamt.de/en/press/pressinformation/climate-footprint-2018-45-percent-decrease-in (accessed on 15 January 2020).

- Corré, W.; Schröder, J.; Verhagen, J. Energy use in conventional and organic farming systems. In Proceedings of the Open Meeting of the International Fertiliser Society, London, UK, 3 April 2003; London International Fertiliser Society: York, UK, 2003. ISBN 0-85310-147-7. ISSN 1466-1314. [Google Scholar]

- Krommweh, M.S.; Rösmann, P.; Büscher, W. Investigation of heating and cooling potential of a modular housing system for fattening pigs with integrated geothermal heat exchanger. Biosyst. Eng. 2014, 121, 118–129. [Google Scholar] [CrossRef]

- Büscher, W. Energiebedarf und Leistungsbereitstellung in der Schweinehaltung. In Baubriefe Landwirtschaft e. V. 47; Landwirtschaftsverlag GmbH: Münster-Hiltrup, Germany, 2009; pp. 10–15. [Google Scholar]

- Heinritzi, K.; Gindele, H.R.; Reiner, G.; Schnurrbusch, U. Allgemeiner Untersuchungsgang. In Schweinekrankheiten, UTB 8325; Verlag Eugen Ulmer KG: Stuttgart, Germany, 2006; pp. 18–22. [Google Scholar]

- European Commission. Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs, Industrial Emissions Directive 2010/75/EU Integrated Pollution Prevention and Control; EU 28674 EN; Publication Office of the European Union: Luxemburg, 2017. [Google Scholar] [CrossRef]

- Meyer, E.; Vogel, M.; Wähner, M. Investigations on acceptance and size of piglet nests. Landtechnik 2012, 67, 362–365. [Google Scholar]

- DIN 18910:2017-08. Thermal Insulation for Closed Livestock Buildings—Thermal Insulation and Ventilation—Principles for Planning and Design for Closed Ventilated Livestock Buildings; DIN Deutsches Institut für Normung e. V., Ed.; Beuth Verlag GmbH: Berlin, Germany, 2017. [Google Scholar]

- Büscher, W.; Cremer, P.; Feller, B.; Fritzsche, S. Lüftung und Wärmedämmung geschlossener Ställe—Bemessung nach DIN 18910:2017-08; Sonderveröffentlichung, Ed.; Kuratorium für Technik und Bauwesen in der Landwirtschaft e. V. (KTBL): Darmstadt, Germany, 2018; ISBN 978-3-945088-61-6. [Google Scholar]

- Lindley, J.A.; Whitaker, J.H. Agricultural Buildings and Structures; ASAE (The Society for Engineering in Agricultural, Food, and Biological Systems): St. Joseph, MI, USA, 1996; pp. 249–270, 347–356. ISBN 978-0-929355-73-3. [Google Scholar]

- Spengler, R.W.; Stombaugh, D.P. Optimization of earth-tube heat exchangers for winter ventilation of swine housing. Trans. ASAE 1983, 26, 1186–1193. [Google Scholar] [CrossRef]

- Van Caenegem, L. Energieeffizienz in Abferkelställen Durch Erdwärmenutzung, Energieeffiziente Landwirtschaft; KTBL-Schrift 463; Kuratorium für Technik und Bauwesen in der Landwirtschaft e. V. (KTBL): Darmstadt, Germany, 2008; pp. 162–172. ISBN 978-3-939371-59-5. [Google Scholar]

- Rösmann, P.; Büscher, W. Rating of an air-to-air heat exchanger in practice. Landtechnik 2010, 65, 418–420. [Google Scholar] [CrossRef]

- Allen, W.H.; Payne, F.A. Designing animal ventilation schedules with counterflow heat exchangers. Trans. ASAE 1987, 30, 782–788. [Google Scholar] [CrossRef]

- VDI 3803-5. VDI-Richtlinie 3803-5: Air-Conditioning, System Requirements. Part 5: Heat Recovery Systems; Verein Deutscher Ingenieure e. V. (VDI), Ed.; Beuth Verlag GmbH: Berlin, Germany, 2013. [Google Scholar]

- Recknagel, H.; Sprenger, E.; Albers, K.J. Taschenbuch für Heizung und Klimatechnik, Band 1; Deutscher Industrieverlag GmbH (DIV): München, Germany, 2015; p. 1035. ISBN 978-38356-7136-2. [Google Scholar]

- Matthias, J. Wärmepumpen zur Stallbeheizung. In Baubriefe Landwirtschaft e. V. 47; Landwirtschaftsverlag GmbH: Münster-Hiltrup, Germany, 2009; pp. 70–72. ISBN 978-3-7843-3410-3. [Google Scholar]

- Baumann, M.; Laue, H.-J.; Müller, P. Wärmepumpen—Heizen mit Umweltenergie, 4. Erweiterte und Vollständig Überarbeitete Auflage, BINE Informationsdienst; Verlag Solarpraxis AG: Berlin, Germany, 2007; ISBN 978-3-934595-60-6. [Google Scholar]

- Lucia, U.; Simonetti, M.; Chiesa, G.; Grisolia, G. Ground-source pump system for heating and cooling: Review and thermodynamic approach. Renew. Sustain. Energy Rev. 2017, 70, 867–874. [Google Scholar] [CrossRef]

- VDI 4645:2018-03. VDI-Guideline 4645: Heating Plants with Heat Pumps In Single-Family and Multi-Family Houses, Planning, Construction, Operation; Verein Deutscher Ingenieure e. V. (VDI), Ed.; Beuth Verlag GmbH: Berlin, Germany, 2018. [Google Scholar]

- Omer, A.M. Ground-source heat pumps systems and applications. Renew. Sustain. Energy Rev. 2008, 12, 344–371. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.A.; Sadaghiani, M.S.; Ghazvini, M.; Shahriar, S.; Nazari, M.A. Ground source heat pump carbon emissions and ground-source heat pump systems for heating and cooling of buildings: A review. Environ. Progress Sustain. Energy 2017, 37, 1241–1265. [Google Scholar] [CrossRef]

- Tissen, C.; Menberg, K.; Bayer, P.; Blum, P. Meeting the demand: Geothermal heat supply rates for an urban quarter in Germany. Geother. Energy 2019, 7, 9. [Google Scholar] [CrossRef] [Green Version]

- Zurmühlen, S.; Wolisz, H.; Angenendt, G.; Magnor, D.; Streblow, R.; Müller, D.; Sauer, D.U. Potential and Optimal Sizing of Combined Heat and Electrical Storage in Private Households. Energy Procedia 2016, 99, 174–181. [Google Scholar] [CrossRef] [Green Version]

- Meng, B.; Vienken, T.; Kolditz, O.; Shao, H. Modeling the groundwater temperature response to extensive operation of ground source heat pump systems: A case study in Germany. Energy Procedia 2018, 152, 971–977. [Google Scholar] [CrossRef]

- Ziegler, T.; Teodorov, T.; Mellmann, J. Fixed bed drying of medicinal plants using dehumidification of air. Landtechnik 2011, 66, 167–169. [Google Scholar] [CrossRef]

- Benli, H.; Durmus, A. Evaluation of ground-source heat pump combined latent heat storage system performance in greenhouse heating. Energy Build. 2009, 41, 220–228. [Google Scholar] [CrossRef]

- Tong, Y.; Kozai, T.; Nishioka, N.; Ohyama, K. Greenhouse heating using heat pumps with a high coefficient of performance (COP). Biosyst. Eng. 2010, 106, 405–411. [Google Scholar] [CrossRef]

- Cremer, P. Wärmepumpeneinsatz in Landwirtschaftlichen Betrieben—Hinweise und Beispiele; Förderkreis Stallklima: Dummerstorf, Germany, 2011. [Google Scholar]

- Lücke, W.; Hörsten, D. Utilising Heat in Roofs for Energy Generation in Agricultural Buildings. Landtechnik 2006, 61, 208–209. [Google Scholar] [CrossRef]

- Riva, G.; Pedretti, E.F.; Fabbri, C. Utilization of a Heat Pump in Pig Breeding for Energy Saving and Climate and Ammonia Control. J. Eng. Res. 2000, 77, 449–455. [Google Scholar] [CrossRef]

- Manolakos, D.; Panagakis, P.; Bartzanas, T.; Bouzianas, K. Use of heat pumps in HVAC systems for precise environment control in broiler houses: System´s modeling and calculation of the basic design. Comput. Electron. Agric. 2019, 163, 104876. [Google Scholar] [CrossRef]

- Islam, M.M.; Mun, H.-S.; Rubayet Bostami, A.B.M.; Ahmed, S.T.; Park, K.-J.; Yang, C.-J. Evaluation of a ground source geothermal heat pump to save energy and reduce CO2 and noxious gas emissions in a pig house. Energy Build. 2016, 111, 446–454. [Google Scholar] [CrossRef]

- Alberti, L.; Antelmi, M.; Angelotti, A.; Formentin, G. Geothermal heat pumps for sustainable farm climatization and field irrigation. Agric. Water Manag. 2018, 195, 187–200. [Google Scholar] [CrossRef]

- Wang, M.Z.; Wu, Z.H.; Chen, Z.H.; Tian, J.H.; Liu, J.J. Economic Performance Study on the Application of Ground Source Pump System in Swine Farms in Beijing China. AASRI Procedia 2012, 2, 8–13. [Google Scholar] [CrossRef]

- Rösmann, P. Einsatz von Regenerativen Energiequellen zum Heizen und Kühlen von Zwangsbelüfteten Tierställen. Ph.D. Thesis, Rheinische Friedrich-Wilhelms-Universität Bonn, Bonn, Germany, 2012. [Google Scholar]

- Costantino, A.; Fabrizio, E.; Ghiggini, A.; Bariani, M. Climate control in broiler houses: A thermal model for the calculation of the energy use and indoor environmental conditions. Energy Build. 2018, 169, 110–126. [Google Scholar] [CrossRef]

| Heat Pump System | GWHP [cf. 36] | GWHP [cf. 36] | Brine heat Pump with Area Collectors [29] | Brine Heat Pump with Area Collectors [29] |

|---|---|---|---|---|

| Source | Groundwater | Groundwater | Ground | Ground |

| Types of livestock housing | Piglet-rearing barn | Farrowing barn | Piglet-rearing barn | Farrowing barn |

| Experimental period in d | 70 | 70 | 146 | 364 |

| Electricity consumption in kWhel | ||||

| - HP with circulation pumps | 13,823 | 12,196 | 6725 | 8000 |

| - HP with GFP or brine pump | 17,636 | 14,201 | 8732 | - |

| - HP with circulation pumps and GFP or brine pump | 18,427 | 14,470 | 9961 | - |

| Σ Heat output in kWhth | 47,160 | 36,500 | 25,467 | 32,000 |

| COPZ | 3.4 | 3 | 3.8 | 4 |

| COPP | 2.7 | 2.6 | 2.6 | - |

| COPT | 2.6 | 2.5 | 2.6 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Licharz, H.; Rösmann, P.; Krommweh, M.S.; Mostafa, E.; Büscher, W. Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses. Energies 2020, 13, 662. https://doi.org/10.3390/en13030662

Licharz H, Rösmann P, Krommweh MS, Mostafa E, Büscher W. Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses. Energies. 2020; 13(3):662. https://doi.org/10.3390/en13030662

Chicago/Turabian StyleLicharz, Hannah, Peter Rösmann, Manuel S. Krommweh, Ehab Mostafa, and Wolfgang Büscher. 2020. "Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses" Energies 13, no. 3: 662. https://doi.org/10.3390/en13030662

APA StyleLicharz, H., Rösmann, P., Krommweh, M. S., Mostafa, E., & Büscher, W. (2020). Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses. Energies, 13(3), 662. https://doi.org/10.3390/en13030662