An Innovative System for Maize Cob and Wheat Chaff Harvesting: Simultaneous Grain and Residues Collection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. HarvestingSystem Harcob

2.3. Pre-harvesting Activities

- Ten sample areas (1 m2 each) randomly chosen, corresponding to 10 m2 in total, were hand harvested. The sample plot was chosen far from the edges to avoid the overestimation due to the “edge effect”. The plants from the sampling areas were collected as whole plants from the ground level.

- Plants of each sample area were weighed directly in field using a precision scale.

2.3.1. Harvesting System Productivity

2.3.2. Harvesting Lost Calculation and Statistical Analysis

2.4. Harvesting Cost Analysis

2.5. Avoided CO2 Emission From Fossil Fuel

3. Results

3.1. Maize Seeds and Cobs Harvesting Test

3.1.1. Combine Performance and Quality of the Work–Maize Seeds and Cob Harvesting

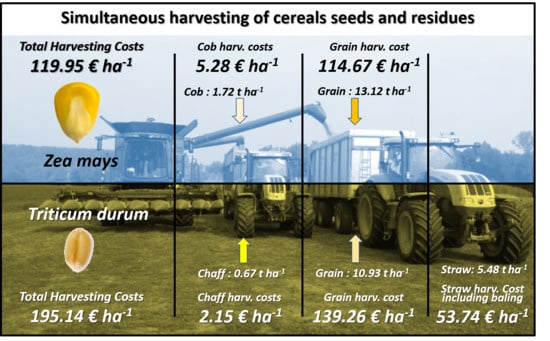

3.1.2. Cost Analysis of Maize Seeds and Cobs Harvesting

3.2. Wheat Seeds and Chaff Harvesting Test

3.2.1. Combine Performance and Quality of the Work–Wheat Seeds and Chaff Harvesting

3.2.2. Cost Analysis of Wheat Seeds and Residue Harvesting

3.3. Impact of Residuals on Cemissions

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and climate change mitigation: An assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef] [Green Version]

- Scarlat, N.; Martinov, M.; Dallemand, J.F. Assessment of the availability of agricultural crop residues in the European Union: Potential and limitations for bioenergy use. Waste Manag. 2010, 30, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Suardi, A.; Bergonzoli, S.; Alfano, V.; Scarfone, A.; Pari, L. Economic Distance to Gather Agricultural Residues from the Field to the Integrated Biomass Logistic Centre: A Spanish Case-Study. Energies 2019, 12, 3086. [Google Scholar] [CrossRef] [Green Version]

- Paul, S.; Dutta, A.; Defersha, F. Mechanical and Alkaline Hydrothermal Treated Corn Residue Conversion in to Bioenergy and Biofertilizer: A Resource Recovery Concept. Energies 2018, 11, 516. [Google Scholar] [CrossRef] [Green Version]

- Dyjakon, A.; Noszczyk, T.; Smędzik, M. The Influence of Torrefaction Temperature on Hydrophobic Properties of Waste Biomass from Food Processing. Energies 2019, 12, 4609. [Google Scholar] [CrossRef] [Green Version]

- Eurostat Main annual crops statistics. Cereal (excluding rise) for the production of grain (including seeds). Most recent data: Further Eurostat information, Main tables and Database 2017. Available online: https://ec.europa.eu/eurostat/tgm/refreshTableAction.do;jsessionid=9RtD-bVDHUXBA82cd_Gfy_FKm3Do4LUXaoihLaKC-TQKaI-ZSmfS!-755574875?tab=table&plugin=1&pcode=tag00047&language=en (accessed on 6 March 2020).

- Kiš, D.; Jovičić, N.; Matin, A.; Kalambura, S.; Vila, S.; Guberac, S. Energy value of agricultural spelt residue (Triticum spelta L.)—Forgotten cultures. Teh. Vjesn. Tech. Gaz. 2017, 24, 369–373. [Google Scholar]

- Weiser, C.; Zeller, V.; Reinicke, F.; Wagner, B.; Majer, S.; Vetter, A.; Thraen, D. Integrated assessment of sustainable cereal straw potential and different straw-based energy applications in Germany. Appl. Energy 2014, 114, 749–762. [Google Scholar] [CrossRef]

- Weiß, B.D.; Glasner, C. Evaluation of the process steps of pretreatment, pellet production and combustion for an energetic utilization of wheat chaff. Front. Environ. Sci. 2018, 6, 36. [Google Scholar] [CrossRef]

- Eurostat Grain Maize and Corn-Cob-Mix by Area, Production and Humidity. EU Dataset. Code: TAG00093 Last Update: 13/02/2020 23:00 2019. Available online: https://ec.europa.eu/eurostat/databrowser/view/tag00093/default/table?lang=en (accessed on 6 March 2020).

- Halvorson, A.D.; Johnson, J.M.F. Corn cob characteristics in irrigated central great plains studies. Agron. J. 2009, 101, 390–399. [Google Scholar] [CrossRef] [Green Version]

- Jansen, C.; Lübberstedt, T. Turning Maize Cobs into a Valuable Feedstock. Bioenergy Res. 2012, 5, 20–31. [Google Scholar] [CrossRef]

- Wilson, G.V.; Dabney, S.M.; McGregor, K.C.; Barkoll, B.D. Tillage and residue effects on runoff and erosion dynamics. Trans. Am. Soc. Agric. Eng. 2004, 47, 119–128. [Google Scholar] [CrossRef]

- Blanco-Canqui, H. Crop Residue Removal for Bioenergy Reduces Soil Carbon Pools: How Can We Offset Carbon Losses? Bioenergy Res. 2013, 6, 358–371. [Google Scholar] [CrossRef]

- Eleki, K. Soil management, crop rotations, and biomass removal effects on soil organic matter content. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2007. [Google Scholar] [CrossRef]

- Palmieri, N.; Forleo, M.B.; Giannoccaro, G.; Suardi, A. Environmental impact of cereal straw management: An on-farm assessment. J. Clean. Prod. 2017, 142, 2950–2964. [Google Scholar] [CrossRef]

- Shinners, K.J.; Binversie, B.N.; Muck, R.E.; Weimer, P.J. Comparison of wet and dry corn stover harvest and storage. Biomass Bioenergy 2007, 31, 211–221. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Wilhelm, W.W.; Karlen, D.L.; Archer, D.W.; Wienhold, B.; Lightle, D.T.; Laird, D.; Baker, J.; Ochsner, T.E.; Novak, J.M. Nutrient removal as a function of corn stover cutting height and cob harvest. BioEnergy Res. 2010, 3, 342–352. [Google Scholar] [CrossRef] [Green Version]

- Desai, B.B. Seeds Handbook: Processing and Storage; CRC Press: Boca Raton, FL, USA, 2004; ISBN 1482276429. [Google Scholar]

- Maung, T.A.; Gustafson, C.R. The Viability of Harvesting Corn Cobs and Stover for Biofuel Production in North Dakota. Agric. Appl. Econ. Assoc. 2011, 2011, 1–41. [Google Scholar]

- Pari, L.; Alfano, V.; Scarfone, A.; Bergonzoli, S.; Suardi, A. Best available technologies to harvest cereal chaff. In Proceedings of the 26th European Biomass Conference and Exhibition (EUBCE), Copenhagen, Denmark, 2018. [Google Scholar]

- NSAI. ISO 18134-2:2015, Solid Biofuels—Determination of Moisture content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; NSAI: Vernier, Geneva, Switzerland, September 2015. Available online: https://www.iso.org/standard/61539.html (accessed on 6 March 2020).

- NSAI. ISO 17828:2015, Solid Biofuels—Determination of Bulk Density; NSAI: Vernier, Geneva, Switzerland, December 2015. Available online: https://www.iso.org/standard/60687.html (accessed on 6 March 2020).

- Assirelli, A.; Croce, S.; Acampora, A.; Civitarese, V.; Suardi, A.; Santangelo, E.; Pari, L. An innovative system for conditioning biomass sorghum [Sorghum bicolor (L.) moench.]. Trans. ASABE 2013, 56, 829–837. [Google Scholar]

- Assirelli, A.; Pignedoli, S. Costo di esercizio delle macchine agricole. Cent. Ric. e Prod. Anim. 2005, 5, 1–10. (In Italian) [Google Scholar]

- American Society of Agricultural Engineers. Agricultural Machinery Management; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2000; pp. 344–349. [Google Scholar]

- Camera di Commercio di Modena (Chamber of Commerce of Modena) Listino dei prezzi all’ingrosso rilevati sul mercato di Modena nella settimana dal 16 luglio al 22 luglio 2019 (List of Wholesale Prices Recorded on the Modena Market in the Week from 16 July to 22 July 2019). 2019. Available online: https://www.mo.camcom.it/tutela-del-mercato/borsamerci/listini/listino-dei-prezzi-allingrosso-rilevati-sul-mercato-di-modena-nella-settimana-dal-16-al-22-luglio-2019 (accessed on 6 March 2020).

- Snow, K.T. Corn Picker. U.S. Patent No. 2,974,465, 14 March 1961. [Google Scholar]

- Stone, J.A. Corn Harvester and Husker. U.S. Patent US 786,239, 5 May 1905. [Google Scholar]

- Bargiel, D.A.; Liljedahl, B.; Richey, C.B. A combine cob saver. Am. Soc. Agric. Biol. Eng. 1982, 25, 544–548. [Google Scholar] [CrossRef]

- Johnson, J.K. Integration of a cob separation system into a biomass harvesting combine. Grad. Theses Diss. Iowa State Univ. 2010, 11241, 67. [Google Scholar]

- Shinners, K.J.; Bennett, R.G.; Hoffman, D.S. Single-and two-pass corn grain and stover harvesting. Trans. ASABE 2012, 55, 341–350. [Google Scholar] [CrossRef]

- Unger, J.S.; Glasner, C. Cost analysis of chaff harvesting concepts in Germany. Agronomy 2019, 9, 579. [Google Scholar] [CrossRef] [Green Version]

- Pari, L.; Alfano, V.; Scarfone, A.; Bergonzoli, S.; Suardi, A. Agricultural byproducts valorization in the circular economy: The case of chaff. In Proceedings of the Book of Abstracts, Olsztyn, Poland, 24–26 September 2019; Wydawnictwo Uniwersytetu Warmińsko-Mazurskiego: Olsztyn, Poland, 2019. [Google Scholar]

- Pari, L.; Scarfone, A.; Lundin, G.; Gunnarsson, C.; Bergonzoli, S.; Alfano, V.; Lazar, S.; Suardi, A. Combined harvesting of chaff and straw for bioethanol production: The first experience on wheat in Sweden. In Proceedings of the 26th European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–18 May 2018; pp. 289–293. [Google Scholar]

- C.A.I. (Confederazione Agromeccanici e Agricoltori Italiani) Price List Net of VAT (10%) of Agricultural Mechanic Work on Behalf of Third Parties Valid for the Province of Alessandria for the Year 2017; European Automobile Manufacturers Association: Roma, Italy, 2017, Sheet no. 2—Price Listof 22.06.2017. Available online: http://www.confagricolturalessandria.it/documenti/listprez_giugno2017_APTMA_ALESSANDRIA_AL.pdf (accessed on 6 March 2020).

| Crop | Wheat | Maize |

|---|---|---|

| Rotor Speed (rpm) | 750 | |

| Gap between Rotor and Separator (mm) | 15 | 20 |

| Cleaning Fan Speed (rpm) | 540 | |

| Spreader Speed (rpm) | 560 | |

| Openings of Upper Sieve (mm) | 17 | 12 |

| Openings of Lower Sieve (mm) | 14 | 9 |

| Parameters | Unit | Maize Cob Collection | Wheat Chaff Collection | Straw Baling | ||

|---|---|---|---|---|---|---|

| Machine | Combine Harvester CASE IH Axial Flow 7088 | Deutz-Fahr Agrotron M620 | ||||

| Power | kW | 269 | 115.6 | |||

| Operating Machine | Harcob | Baler-Deutz-Fahr Varimaster 690 | ||||

| Financial Cost | ||||||

| Investment | € | 226,380.00 | 75,000.00 | 85,000 | 32,000 | |

| Service Life | year | 10 | 10 | 12 | 8 | |

| Service Life | h | 3000 | 3000 | 14,000 | 2500 | |

| Resale | % | 19 | 18 | 28 | 23 | |

| Resale | € | 43,260.00 | 13,263.00 | 28,200 | 7225 | |

| Depreciation | € | 183,120.00 | 61,737.00 | 56,800 | 24,775 | |

| Annual Usage | h y−1 | 480 | 480 | 294 | 294 | |

| Interest Rate | % | 3 | 3 | 3 | 3 | |

| Labour Cost | € h−1 | 11.5 | - | 11.5 | - | |

| Workers | n° | 1 | - | 1 | - | |

| Fixed Costs | ||||||

| Ownership Costs | € y−1 | 18,312.00 | 6,173.69 | 7,080.99 | 3,096.86 | |

| Interest | € y−1 | 4,044.60 | 1,323.95 | 1,275.42 | 588.38 | |

| Machine Shelter | m−2 | 26.88 | 9.12 | 9.89 | ||

| Value of the Shelter | € m−2 | 100.00 | 100.00 | 100.00 | ||

| Value of the Shelter | € y−1 | 53.76 | 0.00 | 27.36 | 29.67 | |

| Insurance (0.25%) | € y−1 | 565.95 | 0.00 | 212.50 | 80.00 | |

| Variable Costs | ||||||

| Repair Factor | % | - | 45.00 | 80.00 | 90.00 | |

| Repairs and Maintenance | € h−1 | 48.29 | 18.00 | 1.22 | 10.83 | |

| Fuel Cost | € l−1 | 0.57 | - | 0.57 | - | |

| Fuel Consumption | l h−1 | 36.86 | 35.45 | - | 9.68 | - |

| Fuel Cost | € h−1 | 21.16 | 20.35 | - | 5.56 | - |

| Lubricant Cost | € l−1 | 3.03 | 3.03 | - | 3.03 | - |

| Lubricant Consumption | l h−1 | 0.18 | 0.18 | - | 0.09 | - |

| Lubricant Consumption | € h−1 | 0.55 | 0.55 | - | 0.27 | - |

| Salary | € h−1 | 11.50 | 11.50 | - | 11.50 | - |

| Cost of Baling String | € h−1 | - | - | - | - | 32.32 |

| Product | Market Price (€ t−1) | Yield (t ha−1) | Revenue (€ ha−1) | Economic Allocation for Combine Harvester (%) | Economic Allocation for Baling (%) |

| Wheat seed | 198.50 | 10.93 | 2169.60 | 88% | 0% |

| Straw | 50.00 | 5.48 | 274.00 | 11% | 100% |

| Chaff | 50.00 | 0.67 | 33.5 | 1% | 0% |

| Total | 17.08 | 2477.11 | 100% | 100% | |

| Product | Market price (€ t−1) | Yield (t ha−1) | Revenue (€ ha−1) | Economic Allocation for Combine Harvester (%) | |

| Maize seed | 185.00 | 13.12 | 2427.20 | 96% | |

| Cob | 65.00 | 1.72 | 111.80 | 4% | |

| Total | 14.84 | 2539.00 | 100% | ||

| Parameters | Mean | Dev. St. |

|---|---|---|

| Theoretical Field Capacity (ha h−1) | 1.89 | ±0.29 |

| Effective Field Capacity (ha h−1) | 1.36 | ±0.18 |

| Yield (t grain ha−1) | 13.12 | ±0.28 |

| Material Capacity (t grain h−1) | 18.58 | ±0.13 |

| Yield (tdw cobs ha−1) | 1.72 | ±0.23 |

| Material Capacity (t cobs h−1) | 2.31 | ±0.09 |

| Fuel Consumption (l ha−1) | 27.1 | ±4.02 |

| Cob Losses (t ha−1) | 0.58 | ±0.23 |

| Maize Seeds and Cob Harvesting Costs with Harcob Technology | ||||

| Unit | Corn | Cob | Total Harvesting Cost | |

| Market price | € t−1 | 185 | 65 | |

| Yield | t ha−1 | 13.12 | 1.72 | |

| Cost Allocation | % | 96% | 4% | 100% |

| Combine Harvester + Harcob | € h−1 | 155.95 | 7.18 | 163.13 |

| € ha−1 | 114.67 | 5.28 | 119.95 | |

| € t−1 | 8.74 | 3.07 | ||

| Traditional Maize Seeds Harvesting Costs Without Cob Collection | ||||

| Unit | Corn | |||

| Market Price | € t−1 | 185 | ||

| Yield | t ha−1 | 13.12 | ||

| Cost Allocation | % | 100% | ||

| Combine Harvester | € h−1 | 129.51 | ||

| € ha−1 | 95.23 | |||

| € t−1 | 7.26 | |||

| Parameters | Mean | Dev. St. |

|---|---|---|

| Theor. Field Capacity (ha h−1) | 1.42 | ±0.05 |

| Eff. Field Capacity (ha h−1) | 1.19 | ±0.01 |

| Yield (t seeds ha−1) | 10.93 | ±0.43 |

| Material Capacity (t seeds h−1) | 12.98 | ±0.66 |

| Yield (t chaff ha−1) | 0.67 | ±0.02 |

| Material Capacity (t chaff h−1) | 0.79 | ±0.02 |

| Fuel Consumption (l ha−1) | 29.86 | ±0.31 |

| Wheat Fractions | Potential Biomass * (tdw ha−1 ) | Harvested Products (tdw ha−1) | Biomass Losses (%) |

|---|---|---|---|

| Grain | 10.2 | 9.7 | 4.87 |

| Chaff | 2.2 | 0.6 | 47.06 |

| Straw | 5.2 | 3.3 | |

| Stubble | 2.1 | 2.1 | - |

| Total Residues | 9.5 | 6.0 | 47.06 |

| Wheat Harvesting Cost using Harcob Technology | |||||

| Unit | Grain | Straw | Chaff | Total Cost Per Phase | |

| Market Rice | € t−1 | 198.50 | 50.00 | 50.00 | |

| Yield | t ha−1 | 10.93 | 5.48 | 0.67 | |

| Cost Allocation | % | 88% | 11% | 1% | 100% |

| Combine Harvester + Harcob | € h−1 | 142.04 | 17.94 | 2.19 | 162.18 |

| € ha−1 | 139.26 | 17.59 | 2.15 | 159.00 | |

| € t−1 | 12.74 | 3.21 | 3.21 | ||

| Cost Allocation | % | - | 100% | - | 100% |

| Tractor + Baler | € h−1 | - | 112.71 | - | 112.71 |

| € ha−1 | - | 36.15 | - | 36.15 | |

| € t−1 | - | 6.60 | - | 6.60 | |

| Total Cost of the Harvesting System | € h−1 | 142.04 | 130.65 | 2.19 | 274.88 |

| € ha−1 | 139.26 | 53.74 | 2.15 | 195.14 | |

| € t−1 | 12.74 | 9.81 | 3.21 | ||

| Traditional Wheat Harvesting Cost Without Chaff Collection | |||||

| Unit | Grain | Straw | Chaff | Total Cost Per Phase | |

| Market Price | € t−1 | 198.50 | 50.00 | 0.00 | |

| Yield | t ha−1 | 10.93 | 5.48 | 0.00 | |

| Cost Allocation | % | 89% | 11% | 0% | 100% |

| Combine Harvester | € h−1 | 114.15 | 14.41 | 0.00 | 128.56 |

| € ha−1 | 111.91 | 14.13 | 0.00 | 126.04 | |

| € t−1 | 10.24 | 2.58 | 0.00 | ||

| Cost Allocation | % | - | 100% | - | 100% |

| Tractor + Baler | € h−1 | - | 112.71 | - | 112.71 |

| € ha−1 | - | 36.15 | - | 36.15 | |

| € t−1 | - | 6.60 | - | 6.60 | |

| Total Cost of the Harvesting System | € h−1 | 114.15 | 127.12 | 0.00 | 241.27 |

| € ha−1 | 111.91 | 50.28 | 0.00 | 162.19 | |

| € t−1 | 10.24 | 9.18 | 0.00 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bergonzoli, S.; Suardi, A.; Rezaie, N.; Alfano, V.; Pari, L. An Innovative System for Maize Cob and Wheat Chaff Harvesting: Simultaneous Grain and Residues Collection. Energies 2020, 13, 1265. https://doi.org/10.3390/en13051265

Bergonzoli S, Suardi A, Rezaie N, Alfano V, Pari L. An Innovative System for Maize Cob and Wheat Chaff Harvesting: Simultaneous Grain and Residues Collection. Energies. 2020; 13(5):1265. https://doi.org/10.3390/en13051265

Chicago/Turabian StyleBergonzoli, Simone, Alessandro Suardi, Negar Rezaie, Vincenzo Alfano, and Luigi Pari. 2020. "An Innovative System for Maize Cob and Wheat Chaff Harvesting: Simultaneous Grain and Residues Collection" Energies 13, no. 5: 1265. https://doi.org/10.3390/en13051265

APA StyleBergonzoli, S., Suardi, A., Rezaie, N., Alfano, V., & Pari, L. (2020). An Innovative System for Maize Cob and Wheat Chaff Harvesting: Simultaneous Grain and Residues Collection. Energies, 13(5), 1265. https://doi.org/10.3390/en13051265