Influence of Raw Material Drying Temperature on the Scots Pine (Pinus sylvestris L.) Biomass Agglomeration Process—A Preliminary Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Densification

2.3. Pellets Quality Parameters Analysis

3. Results

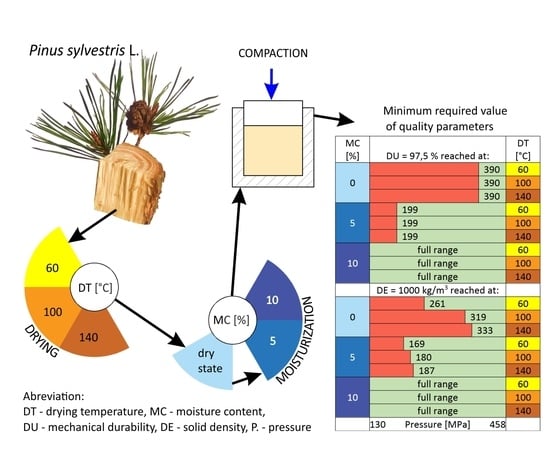

- The drying temperature of the raw material significantly affects the DE and DU values of the pellets obtained at the tested levels of pressure and raw material moisture content;

- The increase in the raw material moisture content compensated the influence of the drying temperature on the quality parameters (DE and DU) for the tested pressure levels.

4. Discussion

5. Conclusions

- The drying temperature significantly affects the specific density of the compacts over the entire pressure range when the compacted material is in the dry state;

- For DU, the influence of the drying temperature is significant in the pressure range of 130.8–261.6 MPa for the materials in the dry state;

- An increase in the drying temperature leads to a decrease in the DE and DU values (dry material);

- Significant differences are observed between the material dried at 60 °C and the materials dried at 100 and 140 °C, while the differences between the materials treated at the drying temperatures of 100 and 140 °C are not significant;

- An increase in the moisture content of the raw material to 5% eliminates the influence of the drying temperature on the obtained values of DE and DU and increases the obtained DE and DU values relative to those of the dry material;

- An increase in the moisture content to 10% results in a further increase in DE and DU;

- Assumed threshold values of specific density and mechanical durability were obtained for each drying temperature and moisture content level. As the moisture content of the raw material increases, the pressure necessary to obtain the threshold DE and DU decreases.

Supplementary Materials

Supplementary File 1Author Contributions

Funding

Conflicts of Interest

References

- Popper, Z.A.; Michel, G.; Hervé, C.; Domozych, D.S.; Willats, W.G.T.; Tuohy, M.G.; Kloareg, B.; Stengel, D.B. Evolution and Diversity of Plant Cell Walls: From Algae to Flowering Plants. Annu. Rev. Plant Biol. 2011, 62, 567–590. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Knox, J.P. Revealing the structural and functional diversity of plant cell walls. Curr. Opin. Plant Biol. 2008, 11, 308–313. [Google Scholar] [CrossRef] [PubMed]

- Wróbel, M. Zagęszczalność i Kompaktowalność Biomasy Lignocelulozowej; PTIR: Kraków, Poland, 2019; ISBN 978-83-64377-35-8. [Google Scholar]

- Welker, C.; Balasubramanian, V.; Petti, C.; Rai, K.; DeBolt, S.; Mendu, V.; Welker, C.M.; Balasubramanian, V.K.; Petti, C.; Rai, K.M.; et al. Engineering Plant Biomass Lignin Content and Composition for Biofuels and Bioproducts. Energies 2015, 8, 7654–7676. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for Pretreatment of Lignocellulosic Biomass for Efficient Hydrolysis and Biofuel Production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Zethrӕus, B. The Bioenergy System Planners Handbook—BISYPLAN Chapter 04. Available online: http://bisyplan.bioenarea.eu/html-files-en/02-02.html (accessed on 12 December 2018).

- Demirbaş, A. Estimating of structural composition of wood and non-wood biomass samples. Energy Sour. 2005, 27, 761–767. [Google Scholar] [CrossRef]

- Lamlom, S.H.; Savidge, R.A. A reassessment of carbon content in wood: Variation within and between 41 North American species. Biomass Bioenergy 2003, 25, 381–388. [Google Scholar] [CrossRef]

- Fajín, J.L.C.; Cordeiro, M.N.D.S. Probing the efficiency of platinum nanotubes for the H2 production by water gas shift reaction: A DFT study. Appl. Catal. B Environ. 2020, 263, 118301. [Google Scholar]

- García-Moncada, N.; González-Castaño, M.; Ivanova, S.; Centeno, M.Á.; Romero-Sarria, F.; Odriozola, J.A. New concept for old reaction: Novel WGS catalyst design. Appl. Catal. B Environ. 2018, 238, 1–5. [Google Scholar] [CrossRef]

- Chianese, S.; Fail, S.; Binder, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Blasi, A.; Musmarra, D. Experimental investigations of hydrogen production from CO catalytic conversion of tar rich syngas by biomass gasification. Catal. Today 2016, 277, 182–191. [Google Scholar] [CrossRef]

- Li, W.; Li, Q.; Chen, R.; Wu, Y.; Zhang, Y. Investigation of hydrogen production using wood pellets gasification with steam at high temperature over 800 °C to 1435 °C. Int. J. Hydrogen Energy 2014, 39, 5580–5588. [Google Scholar] [CrossRef]

- Demirbas, A. Higher heating values of lignin types from wood and non-wood lignocellulosic biomasses. Energy Sources Part A Recover. Util. Environ. Eff. 2017, 39, 592–598. [Google Scholar] [CrossRef]

- Dziurzyński, A. Zależności Między Wybranymi Właściwościami Fizycznymi Drewna Sosny i Buka a Zawartością jego Strukturalnych Składników Chemicznych; Wydawnictwo Akademii Rolniczej im. Augusta Cieszkowskiego: Poznań, Poland, 2003. [Google Scholar]

- Kaliyan, N.; Vance Morey, R. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Li, W.; Amos, K.; Li, M.; Pu, Y.; Debolt, S.; Ragauskas, A.J.; Shi, J. Fractionation and characterization of lignin streams from unique high-lignin content endocarp feedstocks. Biotechnol. Biofuels 2018, 11, 304. [Google Scholar] [CrossRef] [PubMed]

- Demirbaş, A. Relationships between heating value and lignin, fixed carbon, and volatile material contents of shells from biomass products. Energy Sources 2003, 25, 629–635. [Google Scholar] [CrossRef]

- White, R.H. Effect of lignin content and extractives on the higher heating value of wood. Wood Fiber Sci. 1987, 19, 446–452. [Google Scholar]

- Križan, P. The Densification Process of Wood Waste; De Gruyter Open Ltd.: Warsaw, Poland; Berlin, Germany, 2015; ISBN 978-3-11-044001-0. [Google Scholar]

- Robbins, M.P.; Evans, G.; Valentine, J.; Donnison, I.S.; Allison, G.G. New opportunities for the exploitation of energy crops by thermochemical conversion in northern Europe and the UK. Prog. Energy Combust. Sci. 2012, 38, 138–155. [Google Scholar] [CrossRef]

- Bajpai, P. Pretreatment of Lignocellulosic Biomass for Biofuel Production; Springer: Singapore, 2016; ISBN 978-981-10-0686-9. [Google Scholar]

- Mendu, V.; Harman-Ware, A.E.; Crocker, M.; Jae, J.; Stork, J.; Morton, S.; Placido, A.; Huber, G.; Debolt, S. Identification and thermochemical analysis of high-lignin feedstocks for biofuel and biochemical production. Biotechnol. Biofuels 2011, 4, 43. [Google Scholar] [CrossRef] [Green Version]

- van Dam, J.E.G.; van den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for production of high density/high performance binderless boards from whole coconut husk: Part 1: Lignin as intrinsic thermosetting binder resin. Ind. Crops Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Niemczyk, M.; Kaliszewski, A.; Jewiarz, M.; Wróbel, M.; Mudryk, K. Productivity and biomass characteristics of selected poplar ( Populus spp.) cultivars under the climatic conditions of northern Poland. Biomass Bioenergy 2018, 111, 46–51. [Google Scholar] [CrossRef]

- Bryś, A.; Bryś, J.; Głowacki, S.; Tulej, W.; Zajkowski, P.; Sojak, M. Analysis of Potential Related to Grass-Derived Biomass for Energetic Purposes; Springer: Cham, Switzerland, 2018; pp. 443–449. [Google Scholar]

- Knapczyk, A.; Francik, S.; Wójcik, A.; Bednarz, G. Influence of Storing Miscanthus x Gigantheus on Its Mechanical and Energetic Properties. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2018; pp. 651–660. [Google Scholar]

- Wróbel, M.; Mudryk, K.; Jewiarz, M.; Głowacki, S.; Tulej, W. Characterization of Selected Plant Species in Terms of Energetic Use. In Proceedings of the Renewable Energy Sources: Engineering, Technology, Innovation. Springer Proceedings in Energy ICORES 2017; Mudryk, K., Werle, S., Eds.; Springer Proceedings in Energy: Cham, Switzerland, 2018; pp. 671–681. [Google Scholar]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar]

- Bilbao, R.; Lezaun, J.; Abanades, J.C. Fluidization velocities of sand/straw binary mixtures. Powder Technol. 1987, 52, 1–6. [Google Scholar] [CrossRef]

- EN ISO 17225-1:2014. Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Brzychczyk, B.; Hebda, T.; Giełżecki, J. Physical and Chemical Properties of Pellets Produced from the Stabilized Fraction of Municipal Sewage Sludge. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2018; pp. 613–622. [Google Scholar]

- Brzychczyk, B.; Hebda, T.; Giełżecki, J. Energy Characteristics of Compacted Biofuel with Stabilized Fraction of Municipal Waste. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2018; pp. 451–462. [Google Scholar]

- Hebda, T.; Brzychczyk, B.; Francik, S.; Pedryc, N. Evaluation of suitability of hazelnut shell energy for production of biofuels. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; Volume 17, pp. 1860–1865. [Google Scholar]

- Knapczyk, A.; Francik, S.; Fraczek, J.; Slipek, Z. Analysis of research trends in production of solid biofuels. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 22–24 May 2019; Volume 18, pp. 1503–1509. [Google Scholar]

- Karbowniczak, A.; Hamerska, J.; Wróbel, M.; Jewiarz, M.; Nęcka, K. Evaluation of Selected Species of Woody Plants in Terms of Suitability for Energy Production. In Renewable Energy Sources: Engineering, Technology, Innovation. Springer Proceedings in Energy ICORES 2017; Mudryk, K., Werle, S., Eds.; Springer Proceedings in Energy: Cham, Switzerland, 2018; pp. 735–742. [Google Scholar]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Viana, H.; Vega-Nieva, D.J.; Ortiz Torres, L.; Lousada, J.; Aranha, J. Fuel characterization and biomass combustion properties of selected native woody shrub species from central Portugal and NW Spain. Fuel 2012, 102, 737–745. [Google Scholar] [CrossRef]

- Luca, C.; Pilu, R.; Tambone, F.; Scaglia, B.; Adani, F. New energy crop giant cane (Arundo donax L.) can substitute traditional energy crops increasing biogas yield and reducing costs. Bioresour. Technol. 2015, 191, 197–204. [Google Scholar] [PubMed]

- Zegada-Lizarazu, W.; Monti, A. Energy crops in rotation. A review. Biomass Bioenergy 2011, 35, 12–25. [Google Scholar] [CrossRef]

- EN ISO 17225-2:2014. Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Sitzmann, W.; Buschhart, A. Pelleting as Prerequisite for the Energetic Utilization of Byproducts of the Wood-Processing Industry; Amandus Kahl GmBH & Co.: Oslo, Norway, 2009. [Google Scholar]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Dyjakon, A.; Noszczyk, T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies 2019, 12, 2627. [Google Scholar] [CrossRef] [Green Version]

- Wójcik, A.; Frączek, J.; Wota, A.K. The methodical aspects of the friction modeling of plant granular materials. Powder Technol. 2019, 344, 504–513. [Google Scholar] [CrossRef]

- Wójcik, A.; Frączek, J.; Niemczewska-Wójcik, M. The relationship between static and kinetic friction for plant granular materials. Powder Technol. 2019, 361, 739–747. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.A.; Lestander, T. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Amos, W.A. Report on Biomass Drying Technology; National Renewable Energy Laboratory: Golden, CO, USA, 1999. [Google Scholar]

- Fagernäs, L.; Brammer, J.; Wilén, C.; Lauer, M.; Verhoeff, F. Drying of biomass for second generation synfuel production. Biomass Bioenergy 2010, 34, 1267–1277. [Google Scholar] [CrossRef]

- Gebreegziabher, T.; Oyedun, A.O.; Hui, C.W. Optimum biomass drying for combustion—A modeling approach. Energy 2013, 53, 67–73. [Google Scholar] [CrossRef]

- Ståhl, M.; Granström, K.; Berghel, J.; Renström, R. Industrial processes for biomass drying and their effects on the quality properties of wood pellets. Biomass Bioenergy 2004, 27, 621–628. [Google Scholar] [CrossRef]

- Francik, S.; Łapczyńska-Kordon, B.; Francik, R.; Wójcik, A. Modeling and Simulation of Biomass Drying Using Artificial Neural Networks. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2018; pp. 571–581. [Google Scholar]

- Głowacki, S.; Tulej, W.; Jaros, M.; Sojak, M.; Bryś, A.; Kędziora, R. Kinetics of Drying Silver Birch (Betula pendula Roth) as an Alternative Source of Energy. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2018; pp. 433–442. [Google Scholar]

- Kumar, A.; Jones, D.; Hanna, M. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef] [Green Version]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels production through biomass pyrolysis—A technological review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, X.T.; Sokhansanj, S.; Lim, C.J. Torrefaction and densification of different species of softwood residues. Fuel 2013, 111, 411–421. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Jim Lim, C.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Wróbel, M.; Hamerska, J.; Jewiarz, M.; Mudryk, K.; Niemczyk, M. Influence of Parameters of the Torrefaction Process on the Selected Parameters of Torrefied Woody Biomass. In Renewable Energy Sources: Engineering, Technology, Innovation. Springer Proceedings in Energy ICORES 2017; Mudryk, K., Werle, S., Eds.; Springer Proceedings in Energy: Cham, Switzerland, 2018; pp. 691–700. [Google Scholar]

- Chandler, C.; Cheney, P.; Thomas, P.; Traband, L.D.W. Fire in Forestry—Vol.I. Forest Fire Behavior and Effects; John Wiley & Sons: New York, NY, USA, 1983. [Google Scholar]

- Chen, D.; Gao, A.; Cen, K.; Zhang, J.; Cao, X.; Ma, Z. Investigation of biomass torrefaction based on three major components: Hemicellulose, cellulose, and lignin. Energy Convers. Manag. 2018, 169, 228–237. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. Torrefaction and co-torrefaction characterization of hemicellulose, cellulose and lignin as well as torrefaction of some basic constituents in biomass. Energy 2011, 36, 803–811. [Google Scholar] [CrossRef]

- Mierzwa-Hersztek, M.; Gondek, K.; Jewiarz, M.; Dziedzic, K. Assessment of energy parameters of biomass and biochars, leachability of heavy metals and phytotoxicity of their ashes. J. Mater. Cycles Waste Manag. 2019, 21, 786–800. [Google Scholar] [CrossRef]

- Jankowska, A.; Kozakiewicz, P. Determination of fibre saturation point of selected tropical wood species using different methods. Drewno 2016, 59, 89–97. [Google Scholar]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Effect of process parameters on pelletisation of herbaceous crops. Fuel 2009, 88, 1491–1497. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Melin, S. Energy input and quality of pellets made from steam-exploded douglas fir (Pseudotsuga menziesii). Energy Fuels 2011, 25, 1521–1528. [Google Scholar] [CrossRef]

- Shaw, M.D.; Karunakaran, C.; Tabil, L.G. Physicochemical characteristics of densified untreated and steam exploded poplar wood and wheat straw grinds. Biosyst. Eng. 2009, 103, 198–207. [Google Scholar] [CrossRef]

- Anglès, M.N.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of steam exploded residual softwood for the production of binderless panels. Effect of the pre-treatment severity and lignin addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Biswas, A.K.; Yang, W.; Blasiak, W. Steam pretreatment of Salix to upgrade biomass fuel for wood pellet production. Fuel Process. Technol. 2011, 92, 1711–1717. [Google Scholar] [CrossRef]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Kirsten, C.; Lenz, V.; Schröder, H.W.; Repke, J.U. Hay pellets—The influence of particle size reduction on their physical-mechanical quality and energy demand during production. Fuel Process. Technol. 2016, 148, 163–174. [Google Scholar] [CrossRef]

- Tumuluru, J. Effect of Moisture Content and Hammer Mill Screen Size on the Briquetting Characteristics of Woody and Herbaceous Biomass. KONA Powder Part. 2019. [Google Scholar] [CrossRef] [Green Version]

- Payne, J.D. Troubleshooting the Pelleting Process. In Feed Technology Technical Report Series; American Soybean Association: Singapore, 2006. [Google Scholar]

- Muramatsu, K.; Massuquetto, A.; Dahlke, F.; Maiorka, A. Factors that Affect Pellet Quality: A Review. J. Agric. Sci. Technol. A 2015, 5, 717–722. [Google Scholar] [CrossRef]

- EN ISO 18125:2017. Solid Biofuels—Determination of Calorific Value; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- EN ISO 18122:2015. Solid Biofuels—Determination of Ash Content; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- EN ISO 18123:2015. Solid Biofuels—Determination of the Content of Volatile Matter; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef] [Green Version]

- Wróbel, M. Assessment of Agglomeration Properties of Biomass—Preliminary Study. In Renewable Energy Sources: Engineering, Technology, Innovation. Springer Proceedings in Energy ICORES 2018; Wróbel, M., Jewiarz, M., Szlęk, A., Eds.; Springer Proceedings in Energy: Cham, Switzerland, 2020; pp. 411–418. [Google Scholar]

- EN ISO 18847:2016. Solid Biofuels—Determination of Particle Density of Pellets and Briquettes; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- EN ISO 17831-1:2015. Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- EN ISO 17225-6:2014. Solid Biofuels—Fuel Specifications and Classes—Part 6: Graded Non-Woody Pellets; International Organization for Standardization: Geneva, Switzerland.

- Filbakk, T.; Skjevrak, G.; Høibø, O.; Dibdiakova, J.; Jirjis, R. The influence of storage and drying methods for Scots pine raw material on mechanical pellet properties and production parameters. Fuel Process. Technol. 2011, 92, 871–878. [Google Scholar] [CrossRef]

- Ståhl, M.; Berghel, J. Energy efficient pilot-scale production of wood fuel pellets made from a raw material mix including sawdust and rapeseed cake. Biomass Bioenergy 2011, 35, 4849–4854. [Google Scholar] [CrossRef]

- Englund, F.; Nussbaum, R.M. Monoterpenes in Scots pine and Norway spruce and their emission during kiln drying. Holzforschung 2000, 54, 449–456. [Google Scholar] [CrossRef]

- Pietsch, W. Agglomeration Processes. Phenomena, Technologies, Equipment; Wiley-VCH Verlag GmBH.: Weinheim, Germany, 2002; ISBN 3-527-30369-3. [Google Scholar]

| Sieve Classes (mm) | C1: 0.1 | C2: 0.25 | C3: 0.5 | C4: 1 |

|---|---|---|---|---|

| Share [%] | 8.2 | 16.1 | 38.2 | 37.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wróbel, M.; Jewiarz, M.; Mudryk, K.; Knapczyk, A. Influence of Raw Material Drying Temperature on the Scots Pine (Pinus sylvestris L.) Biomass Agglomeration Process—A Preliminary Study. Energies 2020, 13, 1809. https://doi.org/10.3390/en13071809

Wróbel M, Jewiarz M, Mudryk K, Knapczyk A. Influence of Raw Material Drying Temperature on the Scots Pine (Pinus sylvestris L.) Biomass Agglomeration Process—A Preliminary Study. Energies. 2020; 13(7):1809. https://doi.org/10.3390/en13071809

Chicago/Turabian StyleWróbel, Marek, Marcin Jewiarz, Krzysztof Mudryk, and Adrian Knapczyk. 2020. "Influence of Raw Material Drying Temperature on the Scots Pine (Pinus sylvestris L.) Biomass Agglomeration Process—A Preliminary Study" Energies 13, no. 7: 1809. https://doi.org/10.3390/en13071809

APA StyleWróbel, M., Jewiarz, M., Mudryk, K., & Knapczyk, A. (2020). Influence of Raw Material Drying Temperature on the Scots Pine (Pinus sylvestris L.) Biomass Agglomeration Process—A Preliminary Study. Energies, 13(7), 1809. https://doi.org/10.3390/en13071809