The Role of Biorefinery Co-Products, Market Proximity and Feedstock Environmental Footprint in Meeting Biofuel Policy Goals for Winter Barley-to-Ethanol

Abstract

:1. Introduction

2. Materials and Methods

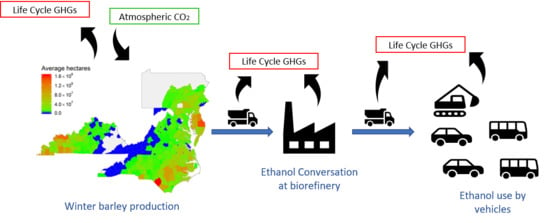

2.1. System Boundary Definition

2.2. Life Cycle Inventory Analysis

2.2.1. Feedstock Production

2.2.2. Winter Barley Soil GHG Emissions

2.3. Barley Transport and Ethanol Conversion

2.4. Ethanol Transport, Distribution and Use

2.5. LCA Model Uncertainty and Indirect Land Use Change Effects

3. Results and Discussion

3.1. Greenhouse Gas Emissions for Winter Barley-to-Ethanol

3.2. Implications of Stochastic Life Cycle Greenhouse Gas Emissions of Winter Barley and Other Starch Pathways for Renewable Fuel Policy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, S.; Sperling, D. Low carbon fuel policy and analysis. Energy Policy 2013, 56, 1–4. [Google Scholar] [CrossRef]

- McKechnie, J.; Pourbafrani, M.; Saville, B.A.; MacLean, H.L. Exploring impacts of process technology development and regional factors on life cycle greenhouse gas emissions of corn stover ethanol. Renew. Energy 2015, 76, 726–734. [Google Scholar] [CrossRef]

- Ahlgren, S.; Björklund, A.; Ekman, A.; Karlsson, H.; Berlin, J.; Börjesson, P.; Ekvall, T.; Finnveden, G.; Janssen, M.; Strid, I. Review of methodological choices in LCA of biorefinery systems-key issues and recommendations. Biofuels Bioprod. Biorefin. 2015, 9, 606–619. [Google Scholar] [CrossRef] [Green Version]

- Cai, H.; Han, J.; Wang, M.; Davis, R.; Biddy, M.; Tan, E. Life-cycle analysis of integrated biorefineries with co-production of biofuels and bio-based chemicals: Co-product handling methods and implications. Biofuels Bioprod. Biorefin. 2018, 12, 815–833. [Google Scholar] [CrossRef]

- Riazi, B.; Zhang, J.; Yee, W.; Ngo, H.; Spatari, S. Life Cycle Environmental and Cost Implications of Isostearic Acid Production for Pharmaceutical and Personal Care Products. ACS Sustain. Chem. Eng. 2019, 7, 15247–15258. [Google Scholar] [CrossRef]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.-H. Use of U.S. Croplands for Biofuels Increases Greenhouse Gases Through Emissions from Land Use Change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and climate change mitigation: An assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef] [Green Version]

- Taheripour, F.; Tyner, W.E. US biofuel production and policy: Implications for land use changes in Malaysia and Indonesia. Biotechnol. Biofuels 2020, 13, 11. [Google Scholar] [CrossRef] [Green Version]

- Bryant, R.B.; Veith, T.L.; Kleinman, P.J.A.; Gburek, W.J. Cannonsville Reservoir and Town Brook watersheds: Documenting conservation efforts to protect New York City’s drinking water. J. Soil Water Conserv. 2008, 63, 339–344. [Google Scholar] [CrossRef] [Green Version]

- Dzombak, D. Nutirent Control in Large-Scale U.S. Watersheds: The Chesapeake Bay and Northern Gulf of Mexico. Bridge 2011, 41, 13–22. [Google Scholar]

- Jayasundara, S.; Wagner-Riddle, C.; Parkin, G.; Bertoldi, P.; Warland, J.; Kay, B.; Voroney, P. Minimizing nitrogen losses from a corn–soybean–winter wheat rotation with best management practices. Nutr. Cycl. Agroecosyst. 2007, 79, 141–159. [Google Scholar] [CrossRef]

- U.S. Congress. Energy Independence and Security Act; 12 December 2007; U.S. Congress: Washington, DC, USA, 2017.

- USEPA. Notice of Data Availability Concerning Renewable Fuels Produced from Barley under the RFS Program; EPA-HQ-OAR-2013-0178; 23 July 2013; U.S. Environmental Protection Agency: Washington, DC, USA, 2013; pp. 44075–44089.

- USEPA. Supplemental Determination for Renewable Fuels Produced Under the Final RFS2 Program From Grain Sorghum; EPA-HQ-OAR-2011-0542; FRL-9760-2; 17 December 2012; Federal Register: Washington, DC, USA, 2012; pp. 74592–74607.

- Sindelar, A.J.; Schmer, M.R.; Gesch, R.W.; Forcella, F.; Eberle, C.A.; Thom, M.D.; Archer, D.W. Winter oilseed production for biofuel in the US Corn Belt: Opportunities and limitations. GCB Bioenergy 2017, 9, 508–524. [Google Scholar] [CrossRef]

- Krohn, B.J.; Fripp, M. A life cycle assessment of biodiesel derived from the “niche filling” energy crop camelina in the USA. Appl. Energy 2012, 92, 92–98. [Google Scholar] [CrossRef]

- Tabatabaie, S.M.H.; Tahami, H.; Murthy, G.S. A regional life cycle assessment and economic analysis of camelina biodiesel production in the Pacific Northwestern US. J. Clean. Prod. 2018, 172, 2389–2400. [Google Scholar] [CrossRef]

- Nghiem, N.P.; Ramírez, E.C.; McAloon, A.J.; Yee, W.; Johnston, D.B.; Hicks, K.B. Economic analysis of fuel ethanol production from winter hulled barley by the EDGE (Enhanced Dry Grind Enzymatic) process. Bioresour. Technol. 2011, 102, 6696–6701. [Google Scholar] [CrossRef] [PubMed]

- Joelsson, E.; Erdei, B.; Galbe, M.; Wallberg, O. Techno-economic evaluation of integrated first- and second-generation ethanol production from grain and straw. Biotechnol. Biofuels 2016, 9, 1. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nghiem, N.P.; Montanti, J.J.D.B. Sorghum as a renewable feedstock for production of fuels and industrial chemicals. AIMS Bioeng. 2016, 3, 75–91. [Google Scholar] [CrossRef]

- Fallahpour, F.; Aminghafouri, A.; Ghalegolab Behbahani, A.; Bannayan, M. The environmental impact assessment of wheat and barley production by using life cycle assessment (LCA) methodology. Environ. Dev. Sustain. 2012, 14, 979–992. [Google Scholar] [CrossRef]

- Garcia-Garcia, G.; Rahimifard, S. Life-cycle environmental impacts of barley straw valorisation. Resour. Conserv. Recycl. 2019, 149, 1–11. [Google Scholar] [CrossRef]

- Adler, P.R.; Spatari, S.; D’Ottone, F.; Vazquez, D.; Peterson, L.; Del Grosso, S.J.; Baethgen, W.E.; Parton, W.J. Legacy effects of individual crops affect N2O emissions accounting within crop rotations. GCB Bioenergy 2018, 10, 123–136. [Google Scholar] [CrossRef] [Green Version]

- Malça, J.; Freire, F. Addressing land use change and uncertainty in the life-cycle assessment of wheat-based bioethanol. Energy 2012, 45, 519–527. [Google Scholar] [CrossRef]

- Fertitta-Roberts, C.; Spatari, S.; Grantz, D.A.; Jenerette, G.D. Trade-offs across productivity, GHG intensity, and pollutant loads from second-generation sorghum bioenergy. GCB Bioenergy 2017, 9, 1764–1779. [Google Scholar] [CrossRef] [Green Version]

- Adler, P.R.; Mitchell, J.G.; Pourhashem, G.; Spatari, S.; Del Grosso, S.J.; Parton, W.J. Integrating biorefinery and farm biogeochemical cycles offsets fossil energy and mitigates soil carbon losses. Ecol. Appl. 2015, 25, 1142–1156. [Google Scholar] [CrossRef] [PubMed]

- Adler, P.R.; Del Grosso, S.J.; Parton, W.J. Life-cycle Assessment of Net Greenhouse Gas Flux for Bioenergy Cropping Systems. Ecol. Appl. 2007, 13, 675–691. [Google Scholar] [CrossRef] [PubMed]

- Adler, P.R.; Del Grosso, S.J.; Inman, D.; Jenkins, R.E.; Spatari, S.; Zhang, Y.M. Mitigation Opportunities for Life-Cycle Greenhouse Gas Emissions during Feedstock Production across Heterogeneous Landscapes. Manag. Agric. Greenh. Gases Coord. Agric. Res. Through Gracenet Address Our Chang. Clim. 2012, 203–219. [Google Scholar] [CrossRef]

- Gao, S.; Gurian, P.L.; Adler, P.R.; Spatari, S.; Gurung, R.; Kar, S.; Ogle, S.M.; Parton, W.J.; Del Grosso, S.J. Framework for improved confidence in modeled nitrous oxide estimates for biofuel regulatory standards. Mitig. Adapt. Strateg. Glob. Chang. 2018, 23, 1281–1301. [Google Scholar] [CrossRef]

- Springborn, M.; Yeo, B.-L.; Lee, J.; Six, J. Crediting uncertain ecosystem services in a market. J. Environ. Econ. Manag. 2013, 66, 554–572. [Google Scholar] [CrossRef]

- Hsu, D.D.; Inman, D.; Heath, G.A.; Wolfram, E.J.; Mann, M.K.; Aden, A. Life cycle environmental impacts of selected U.S. ethanol production and use pathways in 2022. Environ. Sci. Technol. 2010, 44, 5289–5297. [Google Scholar] [CrossRef]

- Spatari, S.; Bagley, D.; MacLean, H. Life cycle evaluation of emerging lignocellulosic ethanol conversion technologies. Bioresour. Technol. 2010, 101, 654–667. [Google Scholar] [CrossRef]

- Kylili, A.; Christoforou, E.; Fokaides, P.A. Environmental evaluation of biomass pelleting using life cycle assessment. Biomass Bioenergy 2016, 84, 107–117. [Google Scholar] [CrossRef]

- Liu, W.; Wang, J.; Richard, T.L.; Hartley, D.S.; Spatari, S.; Volk, T.A. Economic and life cycle assessments of biomass utilization for bioenergy products. Biofuels Bioprod. Biorefin. 2017, 11, 633–647. [Google Scholar] [CrossRef]

- Sorunmu, Y.; Billen, P.; Elangovan, S.E.; Santosa, D.; Spatari, S. Life-Cycle Assessment of Alternative Pyrolysis-Based Transport Fuels: Implications of Upgrading Technology, Scale, and Hydrogen Requirement. ACS Sustain. Chem. Eng. 2018, 6, 10001–10010. [Google Scholar] [CrossRef]

- Longato, D.; Gaglio, M.; Boschetti, M.; Gissi, E. Bioenergy and ecosystem services trade-offs and synergies in marginal agricultural lands: A remote-sensing-based assessment method. J. Clean. Prod. 2019, 237, 117672. [Google Scholar] [CrossRef]

- Nguyen, L.; Cafferty, K.; Searcy, E.; Spatari, S. Uncertainties in Life Cycle Greenhouse Gas Emissions from Advanced Biomass Feedstock Logistics Supply Chains in Kansas. Energies 2014, 7, 7125–7146. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO 14044:2006(E); International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Gaglio, M.; Tamburini, E.; Lucchesi, F.; Aschonitis, V.; Atti, A.; Castaldelli, G.; Fano, E.A. Life Cycle Assessment of Maize-Germ Oil Production and the Use of Bioenergy to Mitigate Environmental Impacts: A Gate-To-Gate Case Study. Resources 2019, 8, 60. [Google Scholar] [CrossRef] [Green Version]

- Pourhashem, G.; Spatari, S.; Boateng, A.A.; McAloon, A.J.; Mullen, C.A. Life Cycle Environmental and Economic Tradeoffs of Using Fast Pyrolysis Products for Power Generation. Energy Fuels 2013, 27, 2578–2587. [Google Scholar] [CrossRef]

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Chapter 2. Changes in Atmospheric Constituents and in Radiative Forcing in Climate Change 2007—The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Marquis, M., Averyt, K., Tignor, M.M.B., Miller, H.L., Eds.; Cambridge University Press: New York, NY, USA, 2007. [Google Scholar]

- CBC. Biofuels and the Bay: Getting it Right to Benefit Farms, Forests, and the Chesapeake; A Report of the Chesapeake Bay Commission; Chesapeake Bay Commission: Annapolis, MD, USA, 2007; p. 34. [Google Scholar]

- Kwiatkowski, J.R.; McAloon, A.J.; Taylor, F.; Johnston, D.B. Modeling the process and costs of fuel ethanol production by the corn dry-grind process. Ind. Crops Prod. 2006, 23, 288–296. [Google Scholar] [CrossRef]

- MacLean, H.L.; Spatari, S. The contribution of enzymes and process chemicals to the life cycle of ethanol. Environ. Res. Lett. 2009, 4, 014001. [Google Scholar] [CrossRef]

- SimaPro, version 8.4; PRé Consultants: Amersfoort, The Netherlands, 2018.

- Thomason, W. Barley for Grain (Intensive Management); Virginia Cooperative Extension: Blacksburg, VA, USA, 2007. [Google Scholar]

- Parton, W.J.; Hartman, M.; Ojima, D.S.; Schimel, D.S. DAYCENT and its land surface submodel: Description and testing. Glob. Planet. Chang. 1998, 19, 35–48. [Google Scholar] [CrossRef]

- Wang, M.Q. GREET1; Argonne National Laboratory: DuPage County, IL, USA, 2019; p. 49. [Google Scholar]

- US Department of Agriculture NASS Quick Statistics Database. Available online: http://www.nass.usda.gov/QuickStats/ (accessed on 17 November 2011).

- Kim, S.; Dale, B.; Jenkins, R. Life cycle assessment of corn grain and corn stover in the United States. Int. J. Life Cycle Assess. 2009, 14, 160–174. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Environmental aspects of ethanol derived from no-tilled corn grain: Nonrenewable Energy consumption and greenhouse gas emissions. Biomass Bioenergy 2005, 28, 475–489. [Google Scholar] [CrossRef]

- Wang, M.; Han, J.; Dunn, J.B.; Cai, H.; Elgowainy, A. Well-to-wheels energy use and greenhouse gas emissions of ethanol from corn, sugarcane and cellulosic biomass for US use. Environ. Res. Lett. 2012, 7, 045905. [Google Scholar] [CrossRef] [Green Version]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 4: Agriculture, Forestry and Other Land Use; 4-88788-032-4; Institute for Global Environmental Strategies (IGES), Hayama, Japan on behalf of the IPCC: Hayama, Japan, 2006. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Wakeley, H.L.; Hendrickson, C.T.; Griffin, W.M.; Matthews, H.S. Economic and Environmental Transportation Effects of Large-Scale Ethanol Production and Distribution in the United States. Environ. Sci. Technol. 2009, 43, 2228–2233. [Google Scholar] [CrossRef] [Green Version]

- Pourhashem, G.; Adler, P.R.; McAloon, A.J.; Spatari, S. Cost and greenhouse gas emission tradeoffs of alternative uses of lignin for second generation ethanol. Environ. Res. Lett. 2013, 8, 025021. [Google Scholar] [CrossRef] [Green Version]

- Adams, D.; Alig, R.; McCarl, B.; Murray, B. FASOMGHG Conceptual Structure, and Specification: Documentation; Texas A&M University: College Station, TX, USA, 2005; p. 447. [Google Scholar]

- Beach, R.H.; Zhang, Y.W.; McCarl, B.A. Modeling Bioenergy, Land Use, and GHG Emissions with FASOMGHG: Model Overview and Analysis of Storage Cost Implications. Clim. Chang. Econ. 2012, 3, 1250012. [Google Scholar] [CrossRef]

- Devadoss, S.W.; Patrick, C.; Helmar, M.D.; Grundmeier, E.; Skold, K.D.; Meyers, W.H.; Johnson Stanley, R. The FAPRI Modeling System at CARD: A Documentation Summary; Iowa State University: Ames, IA, USA, 1989. [Google Scholar]

- U.S. Office of Management and Budgets (OMB). Circular A-4, Regulatory Analysis; Last modified 17 September 2003 ed.; U.S. Office of Management and Budgets (OMB): Washington, DC, USA, 2003.

- Spatari, S.; MacLean, H.L. Characterizing Model Uncertainties in the Life Cycle of Lignocellulose-Based Ethanol Fuels. Environ. Sci. Technol. 2010, 44, 8773–8780. [Google Scholar] [CrossRef]

- Pourbafrani, M.; McKechnie, J.; Shen, T.; Saville, B.A.; MacLean, H.L. Impacts of pre-treatment technologies and co-products on greenhouse gas emissions and energy use of lignocellulosic ethanol production. J. Clean. Prod. 2014, 78, 104–111. [Google Scholar] [CrossRef]

| Scenario | Major Assumptions |

|---|---|

| WBE1 | Biorefinery includes co-product crediting for: |

| fermentative CO2 capture for the beverage industry; | |

| barley protein meal; | |

| onsite steam production; | |

| barley hull waste pelleting for cofiring with coal for power generation. | |

| WBE2 | Biorefinery includes co-product crediting for: |

| barley protein meal; | |

| onsite steam production; | |

| barley hull waste pelleting for cofiring with coal for power generation. | |

| WBE3 | Biorefinery includes the production of co-products (barley protein meal, onsite steam production, and barley hull waste pelleting for coal cofiring). A co-product credit is only assigned to the barley protein meal. |

| WBE4 | Biorefinery includes the production of three co-products (barley protein meal, onsite steam production, and barley hull waste pelleting for coal cofiring). No credits are applied for the avoided co-products. |

| Input | Quantity | Unit |

|---|---|---|

| Barley (feedstock) | 59 | kg |

| Enzymes | 126 | g |

| Liquid ammonia | 65 | g |

| Urea | 65 | g |

| Hydrous ammonia | 122 | g |

| Sulfuric acid | 35 | g |

| Inorganic chemicals | 2.1 | g |

| Lime | 72.2 | g |

| Yeast | 0.71 | g |

| Make-up water | 167 | L |

| Electrical utilities | 7 | kWh |

| Electricity for CO2 capture (WBE1 Scenario only) | 3 | kWh |

| Externally sourced steam | 11 | kg |

| Onsite steam | 40 | kg |

| Natural gas (drying) | 112 | MJ |

| Natural gas (onsite steam) | 121 | MJ |

| Co-products: | ||

| Barley hulls (coal and onsite steam displacement) | 75 | MJ |

| Barley protein meal (dry basis) | 19 | kg |

| CO2 | 14 | kg |

| (WBE1) | (WBE2) | (WBE3) | (WBE4) | |

|---|---|---|---|---|

| Feedstock Production, Collection, and Transport: | ||||

| Fertilizer (N) | 11.6 | 11.6 | 11.6 | 11.6 |

| Nitrous Oxide | 7.0 | 7.0 | 7.0 | 7.0 |

| SOC change | −5.9 | −5.9 | −5.9 | −5.9 |

| Farm operations (diesel) | 2.2 | 2.2 | 2.2 | 2.2 |

| Fertilizer (P) | 2.1 | 2.1 | 2.1 | 2.1 |

| Feedstock transport | 2.1 | 2.1 | 2.1 | 2.1 |

| Fertilizer (K2O) | 0.8 | 0.8 | 0.8 | 0.8 |

| Lime | 0.1 | 0.1 | 0.1 | 0.1 |

| Ethanol Production and Distribution: | ||||

| Natural Gas | 32.3 | 32.3 | 32.3 | 32.3 |

| Electricity | 12.3 | 9.3 | 9.3 | 9.3 |

| Chemicals and enzymes | 2.3 | 2.3 | 2.3 | 2.3 |

| Co-product transport | 1.7 | 1.6 | 1.6 | 1.6 |

| Barley protein meal credit | −13.2 | −13.2 | −13.2 | 0 |

| Barley hull coal substitution credit | −19.9 | −19.9 | 0 | 0 |

| Onsite steam credit | −5.9 | −5.9 | 0 | 0 |

| Liquid CO2 recovery credit | −21.8 | 0 | 0 | 0 |

| Fuel transport and distribution | 0.4 | 0.4 | 0.4 | 0.4 |

| Vehicle operation | 2.0 | 2.0 | 2.0 | 2.0 |

| Total | 10 | 29 | 55 | 68 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spatari, S.; Stadel, A.; Adler, P.R.; Kar, S.; Parton, W.J.; Hicks, K.B.; McAloon, A.J.; Gurian, P.L. The Role of Biorefinery Co-Products, Market Proximity and Feedstock Environmental Footprint in Meeting Biofuel Policy Goals for Winter Barley-to-Ethanol. Energies 2020, 13, 2236. https://doi.org/10.3390/en13092236

Spatari S, Stadel A, Adler PR, Kar S, Parton WJ, Hicks KB, McAloon AJ, Gurian PL. The Role of Biorefinery Co-Products, Market Proximity and Feedstock Environmental Footprint in Meeting Biofuel Policy Goals for Winter Barley-to-Ethanol. Energies. 2020; 13(9):2236. https://doi.org/10.3390/en13092236

Chicago/Turabian StyleSpatari, Sabrina, Alexander Stadel, Paul R. Adler, Saurajyoti Kar, William J. Parton, Kevin B. Hicks, Andrew J. McAloon, and Patrick L. Gurian. 2020. "The Role of Biorefinery Co-Products, Market Proximity and Feedstock Environmental Footprint in Meeting Biofuel Policy Goals for Winter Barley-to-Ethanol" Energies 13, no. 9: 2236. https://doi.org/10.3390/en13092236

APA StyleSpatari, S., Stadel, A., Adler, P. R., Kar, S., Parton, W. J., Hicks, K. B., McAloon, A. J., & Gurian, P. L. (2020). The Role of Biorefinery Co-Products, Market Proximity and Feedstock Environmental Footprint in Meeting Biofuel Policy Goals for Winter Barley-to-Ethanol. Energies, 13(9), 2236. https://doi.org/10.3390/en13092236