Previously, because of proper architectural design and natural environment, natural ventilation could be used to develop a healthy and comfortable living space. Nowadays, because of the excessive consumption of natural resources, energy crisis, considerable reduction in natural resources, and environmental degradation, we need to consider not only the impact and destruction of life because of damage to the ecological environment but also the importance and necessity of sustainable development. Previously, the ventilation of most residential buildings was dependent on the openings of the building for natural ventilation; however, when the natural ventilation conditions were insufficient to affect the comfort of indoor space, an air conditioner was used to decrease the discomfort for building users. Because of the awareness of environmental protection, we advocate using natural methods and replace the use of mechanical energy. Studies on natural ventilation and practical application methods have been conducted for several years; however, these methods are often difficult to operate because of differences in climatic conditions and microclimate environments in various regions [

1,

2,

3,

4,

5,

6]. The “hybrid ventilation system” is based on the natural ventilation and is supplemented by mechanical ventilation; moreover, it pursues the consumption of the least number of resources to achieve the best indoor environmental quality for sustainability, low energy consumption, and preservation of humanity. In addition to improving the quality of the environment, it also considers both health and sustainability. Several researchers have published various algorithms to optimize the ventilation efficiency and reduce engineering costs. For example, Petri et al. [

7] introduced the energy optimization of existing buildings using the building information modeling (BIM) software to obtain the building and electricity consumption data related to the equipment used in the buildings’ heating, ventilation, and air conditioning (HVAC) system in the building for a long term. They used a multiobjective genetic optimization algorithm (NSGAII) to optimize the electricity consumption of the HVAC equipment. Furthermore, based on the results, it was confirmed that the building energy model showed that the established NSGAII algorithm could be used to build the HVAC system and thus achieve a cost-effective economic benefit. Moreover, Ma et al. [

8] proposed a dual gradient search method for energy management based on temperature optimization, energy supply, and price for constructed buildings (HVAC). Furthermore, Sporr et al. [

9] used information from BIM to design control strategies such as integrity checks and enhancements to the dataset from the necessary information, as well as clarified how operational data from the energy system could be used to modify the existing buildings and HVAC controller. Ke et al. [

10] presented a cooling design for a tunnel’s machine room at the Zhonghe Xinlu Line Xinzhuang Huilong Section of the Taipei MRT, i.e., the side was installed with a vertical ventilation shaft. The results showed that the cross-sectional area of the vertical ventilation shaft affected both ventilation volume and temperature of the tunnel machine room. Moreover, the computational fluid dynamics (CFD) software was used to simulate the ventilation environment of the subway tunnel’s machine room to achieve the cooling system design’s benefits. Furthermore, on both sides of each station in the Xinzhuang Huilong section, tunnel ventilation and vertical wells were installed. This study is unique because the design of ventilation and electromechanical equipment in the substation was optimized before the construction. Ke et al. [

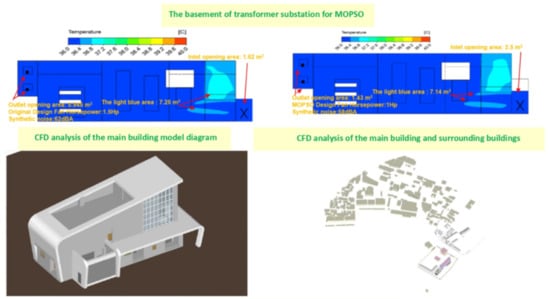

10] also indicated that the ventilation opening area is inversely related to the indoor temperature and air-exchange volume but that the ventilation opening area can be increased to enhance the cooling effect. However, the ventilation opening area cannot be infinitely increased to affect the civil structure. In future, the aim of the multiobjective particle swarm optimizer (MOPSO) optimization design for the substation ventilation system will be to determine a balance between the civil structure and electromechanical equipment design such that it reduces the cost of electricity and maintains the ventilation system subsequent to completing the construction. In consideration of the varying land sizes, climates, temperatures, and humidity in different countries, the voltage of transformer substations is also different to avoid energy attenuation owing to the distance of power transmission from the power plant to the transformer substation; consequently, the voltage grade, cable, and transformer size of the transformer substation are also different. Therefore, the equipment may have different spaces and heating values. As Taiwan’s voltage grade of a transformer substation is different from that of global transformer substations, we are unable to compare the improvement effects of the ventilation system in the same space, but we must compare the improvement methods for ventilation system in the equipment room with global transformer substations. According to the improvement of ventilation systems in transformer substations [

11,

12,

13,

14,

15] reported by studies from other countries in recent years, H. Liu et al. (2017) proposed a study on the application of COMSOL software in ventilation design and application of transformer substations; they concluded that power consumption and synthetic noise will be increased in the transformer substation if ventilation equipment is increased [

11]. In 2018, M. Kanaan et al. and FAS Bahri et al. reduced the temperature of the equipment room by changing the position of the inlet/outlet [

12,

13] and simulated indoor cooling effects via fluid mechanics, but they did not analyze the windward side of the building, power consumption of power equipment, and synthetic noise. In 2019, Yun Liu et al. investigated the mean lowest temperature in the equipment room using the variational method and adjusted the ventilation equipment; however, the sole objective of this study was to optimize the indoor temperature of equipment to the lowest mean performance value and re-plan the ventilation equipment, but no multiple-target optimization plan was prepared for the power consumption and synthetic noise of ventilation equipment [

14]. F Liu et al. studied the synthetic noise of the equipment room [

15]. However, all the above studies had no plans or designs on reducing the temperature of the equipment room by optimizing inlet/outlet size via machine learning, energy conservation design, or noise reduction of continuous cooling equipment. Besides, there are many reports on application of machine learning in power systems [

16,

17,

18,

19,

20], but they have not yet been applied in the ventilation system of a transformer substation. The remainder of this paper is organized as follows. In

Section 1, we review the ventilation and cooling effects of the ventilation system equipment used to prevent an increase in the temperature in the equipment room of the substation and the generation of undesirable gases. In

Section 2, we describe the materials and methods used in the system structure. In

Section 3, we report and analyze the simulation results. Finally, in

Section 4, we provide the conclusions and discussions of this study.

1.1. Establishing a Ventilation System to Prevent Increase in the Temperature in the Equipment Room of the Substation and Generation of Adverse Gases

The substation buildings need to be provided with a number of inlet/outlet openings for ventilation on both the inner and outer walls. Because ventilation facilities, such as ducts, need considerable space, the ventilation design should consider the space required for the installation, maintenance, and operation of the internal compartment configuration, ventilation facilities, and substation equipment. The design of the ventilation equipment is closely related to the appearance of the building, the firefighting equipment, the installation of the substation equipment, and the function of the substation. Therefore, the planning and design of the ventilation system should be carried out along with those of the building to minimize the revisions of the plan view and elevation view of the building as well as facilitate the acquisition of construction permits. For the firefighting function, both the air inlet and outlet ports in each fire and CO

2 protection zone compartment (including its buffer zone) shall be provided with an electric damper that can be automatically closed and shut off before the CO

2 fire-extinguishing agent is irradiated to ensure appropriate CO

2 concentration is obtained, which can be calculated using formulas (1)–(3) [

21]. Furthermore, the fan, damper, and other facilities can be manually turned on the total monitoring panel to discharge harmful gases such as CO

2 to the outside.

In addition, fans, dampers, and other facilities can manually turn on the total monitoring panel to discharge harmful gases, such as CO2, to the outside.

The concentration of CO2 should not be less than 34% and that of O2 should not be greater than 13.86%.

Based on relevant building regulations, [

22,

23] the distribution room, transformer room, and reactor room need to be equipped with a fire-venting damper that fulfills the requirement of firefighting timeliness for 2 h or more; however, the remaining CO

2 protection zone must be equipped with a fire-venting damper that fulfills the requirement of firefighting timeliness for 1 h or more.

The ventilation of an indoor substation should be designed as natural air inlet/mechanical outlet ventilation [

24,

25,

26,

27,

28,

29,

30,

31,

32]. When each room is independently ventilated, the required fan is generally placed outside the ventilation room or in space that does not affect the operation and maintenance of the equipment in the same room to directly discharge hot air, outlet gas, etc. If necessary, the fan can be located elsewhere and a separate duct or air duct can be set to guide the inlet/outlet. The ventilation fan should have a safe maintenance working space without the need for a shutdown of the substation equipment. The used cable processing room, transformer room, reactor room, GIS room, and system capacity (SC) room at all levels should be equipped with two and more units of fans according to the total air volume. The ventilation of the underground substation or semi-underground substation can be designed using the natural air inlet/mechanical outlet or mechanical air inlet/mechanical outlet, and a centralized air inlet duct and outlet duct shall be provided. The fans used in each room on each floor are installed in the fan room in a centralized manner, and facilities such as air ducts, air channels, and dampers are installed to guide the ventilation of each room. The inlet/outlet of each ventilation zone should be independent and unaffected by other ventilation zones. The indoor reference temperature (ti) is maintained at 40 °C DB (dry bulb temperature), while the outdoor reference temperature (to) is 36 °C DB.

The ventilation volume is calculated by considering the calorific value of the device and the air-exchange times and considering the relative maximum air volume value. Furthermore, the ventilation volume is calculated from the air-exchange times in the place specified in

Table 1 [

33], and the ventilation volume of respective rooms in

Table 2 and

Table 3 are calculated using the calorific value of the device. The calculation formula of each ventilation volume has been described below.

1.1.1. Air Change Rate Conversion Method

The calorific values of certain devices may not be considerable; however, they can produce harmful substances such as odor, moisture, and corrosive gas. Moreover, there must still be sufficient ventilation volume to be discharged to the outside to maintain the indoor air quality.

Qc: Ventilation volume (m3/min; CMM)

N: Air change rate (times/h). See

Table 1.

V: Indoor volume (m3)

1.1.2. Calorific Value Conversion Method

The conversion formula (5) for obtaining the ventilation volume through the calorific value of the device is as follows:

Qh: Ventilation volume (CMM)

Δt: Indoor and outdoor temperature difference, i.e., Δt = ti − to.

1.1.3. Calculation of Ventilation Openings

To reduce water intrusion, the ventilating inlet/outlet opening should be waterproof and splash-proof, and an appropriate silencing louver or the sound-reducing enclosure should be provided according to the noise calculation. If the building design can meet the requirements of waterproofing and noise reduction, these setups will be exempted. The opening size for mounting the louver, the silencing louver, or the sound-reducing enclosure can be calculated as follows:

A: Wall opening area (m2)

Q: Ventilation volume (CMM)

V: Louver conversion wind speed (m/s).

The speeds of the air inlet, outlet, and the roof exhaust fans should be <4 m/s, <6 m/s, <10 m/s, respectively. The level of air pressure is related to the density of air. When the air is compressed in a narrow space, the density increases, the weight of the air increases, the pressure per unit area rises, and a high air pressure is formed and vice versa. The relation between wind and air pressure: Air and water can flow similarly. Affected by gravity, the heavier will sink and the lighter will float. If the high and low air pressures are in an up and down relation, the air will move up and down; however, if the high and low air pressures are in the left and right relation, the air will move in parallel. Note that this air flow is the wind; therefore, the greater the difference in air pressure, the greater is the wind speed. The centrifugal fan uses the shaft power to rapidly rotate the fan blade, thus compressing the air to the outer edge of the fan blade and forming a positive air pressure difference:

V: Louver conversion wind speed (m/s)

P: Static pressure of the opening (mmAq)

r: Air specific gravity = 1.2 kg/m3

g: Gravity acceleration = 9.8 m/s2

For places not listed in

Table 1 and

Table 2, if mechanical ventilation is required the ventilation volume should be calculated based on six times of ventilation per hour (unless otherwise specified). The surrounding conditions of the air inlet or outlet port should be considered, and the appropriate mounting surface and height and set positions should be selected such that the ventilation short circuit will not occur and the indoor air distribution will be uniform without local retention. The opening height of the air inlet or outlet port should meet the following requirements: the top of the opening of the outlet port should be 10 cm below the beam, while the bottom of the opening of the air inlet should be 50 cm above the floor. When the air inlet is located on the wall adjacent to the road outside the substation, the height of the bottom of the opening should be >2 m above the ground. When the outlet port is located in a park or a square, the bottom height of the opening should be >3 m above the ground to prevent the hot air from being directly blown to the pedestrian. It should be installed at the bottom of the opening of the air inlet and outlet ports on the outer wall of the first floor and placed at >100 cm above the floor. Moreover, anti-theft measures should be adopted, and the top of the remaining outlet openings should be 10 cm below the beam, whereas the bottom of the air inlet opening should be 50 cm above the floor.

1.1.4. Fan Power Calculation

The power required by the fan is primarily increased or decreased according to the ventilation volume required by the ventilation system and the pressure loss of the system. The required ventilation volume can be obtained according to Equations (4)–(6), and the system pressure loss varies with different ventilation equipment and the speed of wind. The pressure loss of each ventilation device in the system must be listed in the calculation sheet for calculating the shaft power of the fan motor. Note that the calculation formula (8) is as follows:

BHP: Shaft power (kW)

Q: Ventilation volume (CMM)

TSP: System pressure loss (centimeter water column, mmAq or mmWG)

SF: Safety factor (1.2 or more)

ESP: Static fan efficiency (%)

Considering factors such as an increase in the system pressure loss, the fan motor power should have a margin of 10% or more. If a belt-driven fan is used, the fan motor must have another margin of 3% or more to supply the required power loss. In air-conditioned places such as the control room, communication room, and electrical relay room, CO2 automatic fire-extinguishing equipment is required. According to the “Fire-fighting Installation Standard”, a special fan equipment for removing the CO2 gas must be provided. The minimum ventilation volume should be calculated based on six or more times of ventilation per hour. In each machine room, the synthetic noise value of the fan should not exceed 82 dBA. The measurement height of the indoor noise should be 150 cm above the floor and the vicinity of the synthetic noise should be in higher places. The indoor noise of the fan-dedicated room may not be limited by the upper value of 82 dBA; however, the noise measured outside the fan’s wall or door at a distance of 150 cm from the wall should not exceed 70 dBA, and the measurement height should be 120 cm above the building floor. Except for the above outdoor areas, the noise in the other places (such as ladders and workrooms) should not exceed 60 dBA; moreover, the measurement height should be 150 cm above the floor, close to the point where the synthetic noise is the highest. The synthetic noise value generated by all fans should not exceed 70 dBA outside the building. This noise measurement should be near the center of the ventilation louver, and the point where the synthetic noise is higher and 150 cm away from the outer wall of the building. Moreover, the synthetic noise value of the fan on the roof should be <70 dBA. The noise measurement position should be closest to the noise source on the parapet wall or at the point where the synthetic noise is the highest. The measurement height should agree with the noise source height. The operations of the transformer, reactor, 161 kV GIS, and emergency generators can continuously generate larger noises; thus, silencers should be installed indoors or at the inlet/outlet openings or the building design should be used to achieve a sound-absorbing function that complies with the design guidelines and noise control standards. The fan types of models selected for use in the substation building listed below:

In-line fixed-load centrifugal fan: It is suitable for indoor use because it requires less space for configuration. It can be used as an exhaust fan or blower.

Rooftop louver-type fixed-load centrifugal fan: It is suitable for roof installation and can generally be used only as an exhaust fan.

Conventional vortex-type fixed-load centrifugal fan: It is suitable for indoor or outdoor use but requires a large space for configuration. It can be used as either an exhaust fan or a blower.

To control the operation or stop the ventilation, all fans and their associated equipment must be equipped with an electromagnetic switch on their power circuit, and the electromagnetic switch selected must have appropriate overload, undervoltage, or under-equal protection for the fan motor. Furthermore, the ventilation system should be equipped with the following control devices:

- (a)

Timed automatic control: Each ventilation zone must be equipped with a timed automatic control facility to control the operation of the ventilation system. The timed control method should be determined according to the characteristics of each site. In the electromechanical equipment location with high calorific value (

Table 2), in addition to the timed automatic control, the indoor ventilation facilities must be equipped with automatic temperature control such that the ventilation facilities can be automatically started and stopped according to the set temperature. (The temperature control switch should be separated, the controller should be placed in the room at a height of 1.5 m above the floor, the sensor should be placed 50 cm below the beam; however, the sensors in the transformer room, reactor room, and the 69 kV, 161 kV GIS room should be set at a height of 4.5 m above the floor.) The rest of the site may be exempted from such installations.

- (b)

On-site manual control: Each ventilation zone should be located next to its outdoor door. At least one place can be manually specified to manually start and stop the manual control switch of each area of the ventilation facilities; moreover, the area can be automatically ventilated for 5 h after the operation is manually started. If there is other automatic control, it should be restored to this automatic control state.

- (c)

Total monitoring panel: The ventilation system should be equipped with a total monitoring panel. The control panel of the ventilation equipment and the warning light number should be provided for monitoring on the panel and installed in the stairwell of the non-main entrance and exit on the first floor of the building.