The Optimum Wood Procurement Scenario and Its Dynamic Management for Integrated Energy and Material Production in Carbon-Neutral Forest Industry

Abstract

:1. Introduction

1.1. Background

1.2. Management of Wood-Procurement Process

1.3. Strategic Planning of Wood Procurement on a Scenario Basis

1.4. Aims of the Study

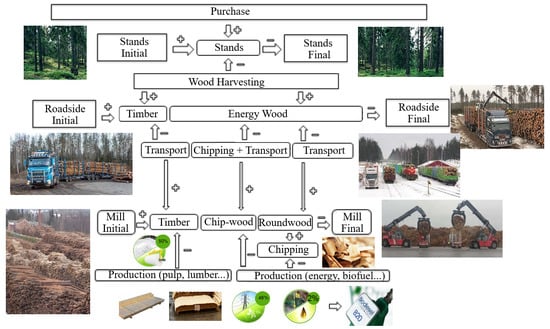

2. Materials and Methods

- (A)

- Hausjarvi, Hyvinkaa, Janakkala, Lohja, Loppi, Nummi-Pusula, Nurmijarvi, Riihimaki, Vihti, Karkkila, and Tuusula;

- (B)

- Forssa, Hattula, Hameenlinna, Lammi, Renko, Tammela, and Hameenkoski;

- (C)

- Kangasala, Lempaala, Orivesi, Palkane, Tampere, Pirkkala, Hameenkyro, Sastamala, Ikaalinen, Mouhijarvi, Ylojarvi, Vammala, Ruovesi, and Valkeakoski;

- (D)

- Kuhmalahti, Kuhmoinen, and Padasjoki;

- (E)

- Asikkala, Hollola, Iitti, Jaala, Lahti, and Nastola;

- (F)

- Artjarvi, Askola, Karkola, Myrskyla, Mantsala, Orimattila, and Pornainen.

Xijt=12 = XBij

Sijt=12 = SBij

Mikt ≤ Mmaxikt

Mikt=0 = MIik

Mikt=12 = MBik

- (1)

- “Declining export” scenario

- (2)

- “Energy reform” scenario

- (3)

- “Extensive energy reform” scenario

3. Results

3.1. Scenario for Declining Export

3.2. Scenario for Energy Reform

3.3. Scenario for Extensive Energy Reform

3.4. Sensitivity of Wood Procurement to Changes in Energy and Wood Production

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Z | minimum procurement costs (€), |

| Bijt | quantity of wood purchased (m3) in municipality j of wood assortment i during period t, |

| Lijt | quantity of wood harvested (m3) in municipality j of wood assortment i during period t, |

| Yijkt | amount of wood transported (m3) from municipality j of wood assortment i to mill k during period t, |

| YHijkt | amount of wood chipped on the roadside (m3) for wood assortment i in municipality j to mill k during period t, |

| MHikt | amount of wood chipped (m3) for wood assortment i at mill k during period t, |

| Sijt | amount of wood in the stand reserve (m3) for wood assortment i in municipality j during period t, |

| Xijt | amount of wood by the roadside (m3) for wood assortment i in municipality j during period t, |

| Mikt | amount of wood in inventory (m3) for wood assortment i at mill k during period t, |

| cbijt | purchase cost (€/m3) for wood assortment i from municipality j during period t, |

| clijt | harvesting costs (€/m3) for wood assortment i from municipality j during period t, |

| claijt | emission allowance price cost (€/m3) of fossil fuel for harvesting wood assortment i from municipality j during period t, |

| cyijkt | transport costs (€/m3) for wood assortment i from municipality j to mill k during period t, |

| cyaijkt | emission allowance price cost (€/m3) for transportation wood assortment i from municipality j to mill k during period t, |

| cyhijkt | wood chipping and transport costs (€/m3) for wood assortment i from municipality j to mill k during period t, |

| cyhaijkt | emission allowance price cost (€/m3) for chipping and transportation wood assortment i from municipality j to mill k during period t, |

| cmhikt | wood chipping costs (€/m3) for wood assortment i at mill k during period t, |

| csijt | wood inventory costs (€/m3) for wood assortment i at stand inventory in municipality j during period t, |

| cxijt | wood inventory costs (€/m3) for wood assortment i at roadside in municipality j during period t, |

| cmikt | wood inventory costs (€/m3) for wood assortment i at mill k of period t, |

| Dmaxikt | maximum amount of wood required (m3) for wood assortment i at mill k during period t, |

| Dminikt | minimum amount of wood required (m3) for wood assortment i at mill k during period t, |

| Ymaxij | maximum quantity (m3) of wood transported by wood assortment i from municipality j, |

| Yminij | minimum quantity (m3) of wood transported for wood assortment i from municipality j, |

| Lmaxijt | maximum amount of wood harvested (m3) for wood assortment i from municipality j during t, |

| Lminijt | minimum quantity of wood harvested (m3) for wood assortment i from municipality j during period t, |

| Smaxijt | maximum quantity (m3) of wood purchased for wood assortment i from municipality j during period t, |

| Sminijt | minimum quantity (m3) of wood purchased for wood assortment i from municipality j during period t, |

| Mmaxikt | maximum amount of wood in inventory (m3) wood assortment i at mill k during period t, |

| Mminikt | minimum quantity of wood in inventory (m3) for wood assortment i at mill k during period t, |

| SIij | amount of wood in the stand reserve (m3) for wood assortment i at municipality j at the beginning of the planning period, |

| SBij | amount of wood in the stand reserve (m3) for wood assortment i at municipality j at the end of the planning period, |

| XIij | amount of wood by the roadside (m3) for wood assortment i at municipality j at the beginning of the planning period, |

| XBij | amount of wood by the roadside (m3) for wood assortment i at municipality j at the end of the planning period, |

| MIik | quantity of wood in inventory (m3) for wood assortment i at mill k at the beginning of the planning period, |

| MBik | quantity of wood in inventory (m3) for wood assortment i at mill k at the end of the planning period, |

| p | annual percentage rate of charge (4%), |

| I | number of wood assortments (1, …, i, …, 13), |

| J | number of municipalities of wood-procurement area (1, …, j, …, 48), |

| K | number of mills (1, …, k, …, 21), |

| T | number of planning periods (1, …, t, …, 12). |

References

- Hämäläinen, E.; Hilmola, O.-P. Energy efficiency at the paper mill—Dilemma of improvement. Energy Effic. 2017, 10, 809–821. [Google Scholar] [CrossRef]

- HORIZON-CL5-2021-2022_version 2021-02-24. Cluster 5. Climate, Energy and Mobility. Working Document. Available online: https://ec.europa.eu/info/horizon-europe/cluster-5-climate-energy-and-mobility_en (accessed on 12 April 2021).

- Scarlat, N.; Dallemand, J.-F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- EUR-Lex. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52011AE1389 (accessed on 12 April 2021).

- Availability and Use of Solid Wood-Based Fuels in Finland in 2020. The Ministry of Economic Affairs and Employment, Helsinki, Finland. Available online: https://mmm.fi/en/en/forests/use-of-wood/wood-based-energy (accessed on 12 April 2021).

- The Finnish Bioeconomy Strategy. Ministry of Agriculture and Forestry, Ministry of the Environment: Helsinki, Finland. 2014. Available online: https://biotalous.fi/wp-content/uploads/2014/08/The_Finnish_Bioeconomy_Strategy_110620141.pdf (accessed on 12 April 2021).

- Hetemäki, L.; Nilsson, S. (Eds.) Conclusions and implications. In Information Technology and the Forest Sector, IUFRO World Series; IUFRO: Vienna, Austria, 2005; Volume 18, pp. 221–233. [Google Scholar]

- Hilmola, O.-P.; Hämäläinen, E.; Hujala, M. Paper mill’s distribution efficiency to emerging East European markets. Ind. Manag. Data Syst. 2014, 114, 1144–1168. [Google Scholar] [CrossRef]

- National Forest Strategy 2025. Ministry of Agriculture and Forestry: Helsinki, Finland. 2015. Available online: https://mmm.fi/documents/1410837/1504826/National+Forest+Strategy+2025/197e0aa4-2b6c-426c-b0d0-f8b0f277f332 (accessed on 12 April 2021).

- Transport Emissions to Zero by 2045. Ministry of Transport and Communications: Helsinki, Finland. 2019. Available online: https://valtioneuvosto.fi/en/article/-/asset_publisher/liikenteen-paastot-nollaan-vuoteen-2045-mennessa (accessed on 12 April 2021).

- Government Report on the National Energy and Climate Strategy for 2030. Publications of the Ministry of Economic Affairs and Employment: Helsinki, Finland. 2017. Available online: http://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/79247/TEMjul_12_2017_verkkojulkaisu.pdf (accessed on 12 April 2021).

- Annual Climate Report 2020. Publications of the Ministry of the Environment. Available online: http://urn.fi/URN:ISBN:978-952-361-240-2 (accessed on 12 April 2021).

- Thollander, P.; Ottosson, M. An energy efficient Swedish pulp and paper industry–exploring barriers to and driving forces for cost-effective energy efficiency investments. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef] [Green Version]

- Johansson, M.T.; Thollander, P. A review of barriers to and driving forces for improved energy efficiency in Swedish industry–Recommendations for successful in-house energy management. Renew. Sustain. Energy Rev. 2018, 82, 618–628. [Google Scholar] [CrossRef]

- Palander, T.; Haavikko, H.; Kärhä, K. Towards sustainable wood procurement in forest industry—The energy efficiency of larger and heavier vehicles in Finland. Renew. Sustain. Energy Rev. 2018, 96, 100–118. [Google Scholar] [CrossRef]

- Palander, T. Tactical Models of Wood-Procurement Teams for Geographically Decentralized Group Decision Making. Ph.D. Thesis, University of Eastern Finland, Joensuu, Finland, 1998. [Google Scholar]

- Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K. Comparison of Energy Efficiency Indicators of Road Transportation for Modeling Environmental Sustainability in “Green” Circular Industry. Sustainability 2020, 12, 2740. [Google Scholar] [CrossRef] [Green Version]

- Hannus, J. Process Management; Logica: Helsinki, Finland, 2003. [Google Scholar]

- Ericsson, K.; Nilsson, L.J.; Nilsson, M. New energy strategies in the Swedish pulp and paper industry. Energy Policy 2011, 39, 1439–1449. [Google Scholar] [CrossRef]

- Kong, L.; Price, L.; Hasanbeigi, A.; Liu, H.; Li, J. Potential for reducing paper mill energy use and carbon dioxide emissions through plant-wide energy audits: A case study in China. Appl. Energy 2013, 102, 1334–1342. [Google Scholar] [CrossRef] [Green Version]

- Palander, T. Technical and economic analysis of electricity generation from forest, fossil, and wood waste fuels in a Finnish heating plant. Energy 2011, 36, 5579–5590. [Google Scholar] [CrossRef]

- Palander, T.; Vainikka, M.; Yletyinen, A. Potential Mechanisms for Co-operation between Transportation Entrepreneurs and Customers: A Case Study of Regional Entrepreneurship in Finland. Croat. J. For. Eng. 2012, 33, 89–103. [Google Scholar]

- Arivalagan, A.; Raghavendra, B.G.; Rao, A.R.K. Integrated energy optimization model for a cogeneration based energy supply system in the process industry. Electr. Power Energy Syst. 1995, 17, 227–233. [Google Scholar] [CrossRef]

- Thollander, P.; Mardan, N.; Karlsson, M. Optimization as investment decision support tin a Swedish medium-sized iron foundry: A move beyond traditional energy auditing. Appl. Energy 2009, 86, 433–440. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, K. Cost-Effective Industrial Energy Systems–Multiperiod Optimizations of Operating Strategies and Structural Choices. Ph.D. Thesis, Division of Energy Systems. Linköping University, Linköping, Sweden, 1993. [Google Scholar]

- Karlsson, M.; Wolf, A. Using an optimisation model to evaluate industrial symbiosis in the forest industry. J. Clean. Prod. 2008, 16, 1536–1544. [Google Scholar] [CrossRef]

- Report on the Operation of the Finnish Wood Markets. The Ministry of Economic Affairs and Employment. 2009. Available online: https://www.researchgate.net/profile/Erkki-Verkasalo/publication/279183864_Comparison_of_alternative_roundwood_pricing_systems_-_A_simulation_approach/links/5603c45108ae460e2704f60a/Comparison-of-alternative-roundwood-pricing-systems-A-simulation-approach.pdf (accessed on 12 April 2021).

- Availability of Forest Bioenergy for Energy Production in Different Market Situations, Pöyry. 2009. Available online: https://docplayer.fi/6111313-Energiateollisuus-ry.html (accessed on 12 April 2021).

- Daily EU ETS Carbon Market Price. 2021. Available online: https://ember-climate.org/data/carbon-price-viewer/ (accessed on 12 April 2021).

- Palander, T. Modelling renewable supply chain for electricity generation with forest, fossil, and wood waste fuels. Energy 2011, 36, 5984–5993. [Google Scholar] [CrossRef]

- Hetemäki, L.; Hänninen, R. Outlook for Finland’s Forest Industry Production and Wood Consumption for 2015 and 2020. Work. Pap. Finn. For. Res. Inst. 2009, 122. Available online: https://www.researchgate.net/publication/285856898_Arvio_Suomen_metsateollisuuden_tuotannosta_ja_puunkaytosta_vuosina_2015_ja_2020 (accessed on 12 April 2021).

- Taha, H.A. Operations Research: An Introduction, 5th ed.; Prentice Hall: Hoboken, NJ, USA, 2011. [Google Scholar]

- Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K.; Borz, S.A. Improving Environmental and Energy Efficiency in Wood Transportation for a Carbon-Neutral Forest Industry. Forests 2020, 11, 1194. [Google Scholar] [CrossRef]

- Economic Survey. Investments of Forest Industry. Ministry of Finance. 2019. Available online: http://urn.fi/URN:ISBN:978-952-367-023-5 (accessed on 12 April 2021).

| Delivery | Baseline Scenario | Scenario One | Change—% |

|---|---|---|---|

| Log wood | 0.39 | 0.33 | −14.91 |

| Pulpwood | 0.58 | 0.42 | −27.47 |

| Energy wood | 0.02 | 0.04 | 105.85 |

| Chip wood | 0.01 | 0.01 | −7.06 |

| A | 0.13 | 0.13 | −6.18 |

| B | 0.14 | 0.09 | −33.70 |

| C | 0.33 | 0.20 | −38.77 |

| D | 0.16 | 0.16 | 1.17 |

| E | 0.11 | 0.10 | −16.29 |

| F | 0.12 | 0.13 | 1.81 |

| Delivery volume | 1.0 | 0.80 | −19.82 |

| Procurement costs | 1.0 | 0.93 | −7.28 |

| Delivery | Baseline Scenario | Scenario Two | Change—% |

|---|---|---|---|

| Log wood | 0.39 | 0.40 | 2.14 |

| Pulpwood | 0.58 | 0.58 | 1.22 |

| Energy wood | 0.02 | 0.04 | 118.84 |

| Chip wood | 0.01 | 0.02 | 22.40 |

| A | 0.13 | 0.14 | 2.47 |

| B | 0.14 | 0.14 | 0.57 |

| C | 0.33 | 0.32 | −3.22 |

| D | 0.16 | 0.16 | 3.15 |

| E | 0.11 | 0.15 | 29.54 |

| F | 0.12 | 0.13 | 7.06 |

| Delivering volume | 1.0 | 1.04 | 4.05 |

| Procurement costs | 1.0 | 1.16 | 15.95 |

| Delivery | Baseline Scenario | Scenario Three | Change—% |

|---|---|---|---|

| Log wood | 0.39 | 0.40 | 2.14 |

| Pulpwood | 0.58 | 0.58 | 1.22 |

| Energy wood | 0.02 | 0.04 | 125.10 |

| Chip wood | 0.01 | 0.02 | 29.99 |

| A | 0.13 | 0.15 | 2.78 |

| B | 0.14 | 0.14 | 1.39 |

| C | 0.33 | 0.32 | −3.03 |

| D | 0.16 | 0.16 | 3.15 |

| E | 0.11 | 0.15 | 29.54 |

| F | 0.12 | 0.13 | 7.06 |

| Delivering volume | 1.0 | 1.04 | 4.27 |

| Procurement costs | 1.0 | 1.16 | 16.07 |

| Wood-Procurement Region | Average Variation | Min | Max |

|---|---|---|---|

| A | 0.005 | Riihimaki | Janakkala |

| B | 0.023 | Hameenkoski | Hattula |

| C | 0.070 | Lempaala | Orivesi |

| D | 0.011 | Padasjoki | Kuhmoinen |

| E | 0.023 | Lahti | Iitti |

| F | 0.004 | Karkola | Artjarvi |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palander, T.; Takkinen, J. The Optimum Wood Procurement Scenario and Its Dynamic Management for Integrated Energy and Material Production in Carbon-Neutral Forest Industry. Energies 2021, 14, 4404. https://doi.org/10.3390/en14154404

Palander T, Takkinen J. The Optimum Wood Procurement Scenario and Its Dynamic Management for Integrated Energy and Material Production in Carbon-Neutral Forest Industry. Energies. 2021; 14(15):4404. https://doi.org/10.3390/en14154404

Chicago/Turabian StylePalander, Teijo, and Jari Takkinen. 2021. "The Optimum Wood Procurement Scenario and Its Dynamic Management for Integrated Energy and Material Production in Carbon-Neutral Forest Industry" Energies 14, no. 15: 4404. https://doi.org/10.3390/en14154404

APA StylePalander, T., & Takkinen, J. (2021). The Optimum Wood Procurement Scenario and Its Dynamic Management for Integrated Energy and Material Production in Carbon-Neutral Forest Industry. Energies, 14(15), 4404. https://doi.org/10.3390/en14154404