1. Introduction

Cantaloupe (Cucumis melo) belongs to the family of Cucurbitaceous. Cantaloupe is one of the important agricultural crops of Iran, having the fifth rank after tomato, cucumber, watermelon, and Persian melon. It is more cultivated in the Khorasan Razavi, Khuzestan, and Semnan provinces. Based on FAO reports in 2018, Iran was rated third in the production of various types of cantaloupes [

1,

2]. Moreover, the agricultural product of cantaloupe possesses medicinal value. In this regard, there is a need to minimize crop loss after harvesting [

3].

However, the structure and moisture content of the agricultural products play a decisive role in their life length. In this context, researchers have tried to use various methods to increase the durability of these products while maintaining their quality [

4]. Drying with the sun is one of the most primitive methods of keep agricultural products. This method, however, suffers from several drawbacks such as the need for large spaces, environmental pollution, sudden climate change, long drying times, and so on [

5]. Various industries have emerged to facilitate the production and processing of crops. Drying is one of these industries which can prolong the life of products, hence enhancing their use in a better and simpler way [

6]. The high latent heat of water evaporation and the low efficiency of industrial dryers have led to high energy consumptions. Therefore, attempts have been focused on declining the energy consumption and drying time while enhancing the efficiency of industrial dryers.

To include the mentioned points in the design of industrial dryers, thermodynamic science should be exploited. The first and second laws of thermodynamics analyze energy efficiency [

7]. The first law of thermodynamics states that energy is not lost but rather converts from one form to another. The second law of thermodynamics indicates the quality and image of this energy conversion. As this energy conversion is accompanied by a decline in quality, a parameter called exergy is introduced which is defined as the maximum useful work obtained from the energy flow from one system at equilibrium with the environment [

7,

8].

Drying by microwave (MW) power is one of the drying methods with optimal energy consumption which helps in saving the longevity and quality of products [

9]. In this method, products are exposed to electromagnetic waves focused on the products. These waves have a high frequency and can penetrate into the product texture and vibrate the polar molecules such as water and salts. The vibrations of these molecules can lead to heat which will result in the transfer of humidity to the surface and finally its evaporation [

10]. Owing to the energy concentration on the product, moisture elimination occurs at higher paces. The use of MW can decline the drying time up to 50% depending on the product type and drying conditions [

11]. The drying time and MW power are two important factors in the drying of products by MW method which can influence the drying parameters such as drying time, drying efficiency, and quality of the final product.

Exergy and energy analyses of an assorted dryer for different agricultural produce appears in the literature. For instance, Jafari et al. [

11] investigated exergy analyses and mathematical modelling of a rice barn in a semi-industrial MW dryer. Their results showed that the energy and exergy efficiency increased by enhancing the thickness of the seeds. The researchers further highlighted that at constant power, the energy and exergy efficiency increased by enhancing the thickness of the seeds. For the same layers, the rise in MW power declined the energy and exergy efficiencies.

Surendhar et al. [

5] examined the kinetics of drying, energy, and exergy parameters for curcumin drying in a microwave dryer. Their results indicated that a rise in the MW power can accelerate the drying process and decline drying time. Energy and exergy values were reported to be enhanced by increasing the MW power.

In another study, Azadbakht et al. [

12] studied the energy and exergy of drying in orange slices using an MW dryer with ohmic pretreatment. Their results indicated that the amount of the absorbed energy exceeded the lost energy at higher powers. The exergy efficiency was reported to improve with an increase in MW power and ohmic time.

Darvishi et al. [

6] and Al-Harahsheh at al. [

13] hinted that modelling of drying equipment enables designers to select suitable operating conditions and ensures effective drying operation. Among high-level optimization methods, a hybrid of an Artificial Neural Network (ANN) and Adaptive Neuro-Fuzzy Inference System (ANFIS) has been the chosen option. The choice of the hybrid is motivated by the amalgamation having mathematical recompenses, emphasized elsewhere [

14,

15]. The ANFIS is a governing data-driven and adaptive computational means having the fitness of plotting non-linear and multifaceted data [

16]. Conversely, the constraint of ANN is its black box which flops to relation input parameters with the response. Jang and Sun [

17] related the fiasco of the black box method of the ANN model to the incapacity of the model to accommodate linguistic information unswervingly. On the other hand, Yaghoobi et al. [

18] ascribed the preeminence of the ANFIS model to its capacity to handle lapses in the ANN model.

Presently, the use of ANN and ANFIS techniques have boosted modelling and simulating food processing. These nonlinear modelling methods have been extensively employed for the evaluation of energy, exergy, and quality of the food industry due to their accuracy, robustness, and high speed [

19]. ANNs are powerful computational methods to predict the responses of complex systems. The main idea of these types of networks originates from the biological nervous system performance for processing the data and information to learn and create knowledge [

8].

ANFIS has recently drawn a considerable deal of attention. This method is a combination of the fuzzy structures with ANN to identify the systems and predict time series. This model has several advantages, among which the ability to simulate nonlinear systems, high precision, and shorter time of model development can be mentioned [

20].

Several researchers have presented various models using ANN and ANFIS to predict the energy and exergy parameters of different dryers for drying various products. Abbaspour-Gilandeh et al. [

21] used ANFIS and ANN to predict the energy and exergy of the fruits dried by a convective dryer. Kariman et al. [

22] applied ANN to predict the energy and exergy of dried kiwi using MW dryer. Azadbakht et al. [

4] optimized and predicted the energy and exergy of drying potato slices by fluid substrate dryer, and Nikbakht et al. [

8] modelled the drying of pomegranate in the convective drier with MW pretreatment using ANN and a surface response method at the industrial scale. Kaveh et al. [

23] used the ANFIS system for the prediction of the energy and exergy of drying green peas using a convective-rotary dryer.

Taghinezhad et al. [

24] investigated the application of ANN and ANFIS in energy and exergy analysis of an infrared-convective dryer with ultrasonic pretreatment for drying blackberry samples. To predict the energy and exergy parameters of the blackberry drying process, the ANN (with one or two hidden layers and two Lonberg-Marquardt algorithms and Bayesian regulation) and the ANFIS model (membership function for each input: trimf and Gaussian, membership function for each output: linear and hybrid algorithm) were explored. Drying time, inlet air temperature, and ultrasonic time in the dryer were considered as inputs, while exergy efficiency, exergy loss, energy consumption, and energy consumption ratio were selected as outputs. The statistical parameters showed that the ANFIS network was more successful than ANN in predicting the energy and exergy of the drying blackberry. The prediction of energy efficiency, exergy efficiency, energy consumption ratio and energy consumption at any time were successfully accomplished with the aid of ANFIS approach. The high speed of obtaining the answer makes this method suitable for modelling and controlling the processes.

Azadbakht et al. [

10] employed ANN method to predict osmotic pretreatment based on energy and exergy analysis in drying orange slices using a microwave dryer. An increase in MW power enhanced energy and exergy efficiency and reduced drying time. Moreover, a multilayer perceptron (MLP) neural network model was utilized to predict energy efficiency, specific energy loss, exergy efficiency, and specific exergy loss. MW power and osmotic time were considered as inputs, while energy efficiency, specific energy loss, exergy efficiency, and specific exergy loss were regarded as outputs. The studied artificial neural network in osmotic times and microwave power with 6 neurons in the hidden layer was employed to predict the regression coefficient (R

2) for energy efficiency and specific exergy loss as 0.999 and 0.871, respectively.

Liu et al. [

7] adopted a multilayer feed-forward neural network to predict the energy and exergy of a convective dryer to dry mushroom slices. Their study entailed four input variables (drying time, air temperature, air velocity, and thickness of the samples) and four responses (energy consumption, energy consumption ratio, exergy loss, and exergy efficiency). The researchers further adopted the sigmoid tangent activator function as a transfer function and the Levenberg−Marquardt algorithm for network training. The researchers attributed the capability of the ANN model in predicting energy and exergy parameters of convective dryers due to that maximum R

2 (0.966) and the lowest value of MSE (0.001261) and MAE (0.02208).

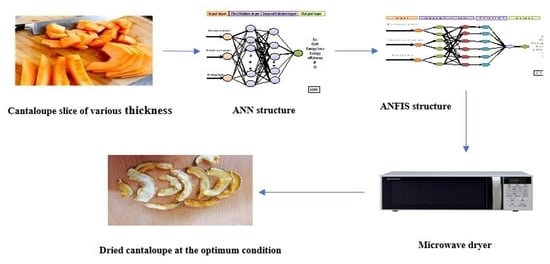

The drying process is an important operation and observing the technical and scientific principles in the cantaloupe drying process will increase its quality and efficiency. The evaluation of energy and exergy parameters of cantaloupe drying and its modelling in different modes leads to further understanding of how the product dries. Such information can be used in designing and optimizing the drying process. In this study, the effect of MW power and sample thickness on the drying kinetics of cantaloupe slices, effective moisture diffusion coefficient, and energy and exergy parameters are investigated. Then, to model the drying behavior of cantaloupe pieces under different powers and thicknesses in an MW dryer, the ANN and ANFIS models were are used. Finally, the performances of these two models in predicting the energy and exergy parameters of cantaloupe drying in a microwave dryer were evaluated. Likewise, integrating ANN and ANFIS models has been very interesting among researchers since it reinforces the performance of the model and aids robust modelling for actual productivity and sustainability [

24,

25,

26,

27]. Inopportunely, the scrutiny of the survey disclosed that there are (1) no recognized ANN models for the prediction of thermodynamic parameters of a microwave dryer (MD) for cantaloupe slices and (2) comparison capacity of hybrid models such as ANN and ANFIS models for the exergetic parameters of a microwave dryer for cantaloupe slices in the literature is scarce. Henceforth, there is a need to trim the lapses in the knowledge of such reports and launch robust models capable of improving thermodynamic performance and decreasing the environmental penalties of the drying process.

Based on the above mentioned descriptions and the targets of the study, the hypotheses of the study are as follows: (1) higher microwave power increases energy and exergy efficiencies, and (2) higher microwave power and the lower slice thickness reduces drying time, exergy improvement potential, and specific energy consumption.

2. Materials and Methods

2.1. Sample Preparation

Cantaloupe was purchased from a local market in Sardasht (West Azerbaijan, Sardasht, Iran). To prevent initial moisture loss, the product was stored at 4 ± 1 in the refrigerator. To perform the experiments, the product was removed from the refrigerator 2 h before cutting to reach ambient temperature. Cantaloupes were cut to 2, 4, and 6 mm thickness using a cutter. To determine the initial moisture content of the samples, the product was placed in an oven (Memmert, UFB 500, Schwabach, Germany) at 70 °C for 24 h [

2]. Finally, the initial moisture content of cantaloupe pieces was obtained at 17.94% on a wet basis.

2.2. Dryer Conditions

In the present research, a programmable domestic microwave oven (Sharp R-I96T, Bangkok, Thailand) was used to perform the experiments that were capable of generating microwave waves in the range of 100 to 900 W. The oven has an internal compartment with dimensions of 350 × 350 × 220 mm3 and a rotating plate with a diameter of 180 mm. For experiments, sliced cantaloupe samples with similar thicknesses were weighed and placed on the rotating plate of the machine. The proposed method was performed in such a way that the samples with three thicknesses of 2, 4, and 6 mm were subjected to MW powers of 360, 180, and 540 W. The drying of 60 g cantaloupe slices (ca. 14 samples) continued until the relative humidity of the samples approached about 0.2 on a wet basis. The temperature of the samples was measured by IR temperature sensor (accuracy of ±1.5 °C). The reference dead state conditions were considered as T0 = 22 °C and P0 = 101.325 kPa. Each experiment was performed in three replications.

2.3. Drying Kinetics

The moisture ratio of cantaloupe was determined using Equation (1) [

10].

The moisture propagation coefficient was assumed to the same at all directions (isotropic material) with negligible shrinkage. Under such conditions, the moisture transfer from the solid phase in the descending period of the rate can be estimated by Equation (2) as described by Fick law [

28].

Assuming constant effective moisture diffusion coefficient and by the analytical solution of Fick’s second law, the effective moisture diffusion coefficient can be determined using Equation (3) [

21].

By increasing

t, all the terms will tend to zero except the first one. The effective moisture diffusion coefficient (

) can be obtained from the slope (

k) of Ln (

MR) vs.

t using Equation (4) [

20].

2.4. Energy Analysis

2.4.1. Specific Energy Consumption, Dryer Efficiency, and Thermal Efficiency

SEC refers to the ratio of the total energy consumption during the drying of cantaloupe slices to the water loss during the drying process. The

SEC of cantaloupe slices by microwave method can be determined by Equation (5) [

29].

Dryer and thermal efficiencies, as well as the vaporization latent heat, can be determined by Equations (6)–(9), respectively [

23,

30].

2.4.2. Energy Efficiency and Energy Loss

A thermodynamic analysis is essential for the optimization and design of thermal systems. Based on the first law of thermodynamics, the general mass conservation equation can be expressed by Equation (10) [

31].

Energy equilibrium can be expressed by Equation (11), which states that the input energy is equal to the output energy [

32].

The dryer chamber is considered as the control volume, and the mass conservation energy can be determined by Equation (12) [

33].

The mass of the evaporated water can be calculated by Equation (13) [

10].

The energy conservation for the tangible heat, latent heat, and heat source of the microwave can be determined by Equation (14) for the cantaloupe slices [

34].

In the above equation, is the lost energy.

The input energy to the microwave can be determined by Equation (15) [

35].

Equation (15) contains three terms including the absorbed energy, reflected energy, and transmitted energy. Equation (16) shows the energy absorbed by the product [

33].

The latent heat of the cantaloupe slices can be also determined by Equation (17) [

6].

The latent heat of evaporation was determined by Darvishi et al. [

35] based on Equation (18) [

10]:

According to Brooker et al. [

36], the heat capacity is a function of the moisture content and can be described by Equation (19).

Based on Darvishi et al. [

6] and Jafari et al. [

33], the energy efficiency in the MW dryer can be calculated by Equation (20).

The specific energy loss for drying cantaloupe slices can be determined by either Equations (21) or (22) [

9].

The total input and output energy and exergy loss were determined according to the second law of thermodynamics. The main method to analyze the exergy of the dryer chamber relied on the calculation of the exergy values in stable points and the determination of the reason for the changes in the exergy of the process. Generally, Equation (23) shows the exergy balance for an MW dryer [

12].

The input exergy of the MW dryer can be determined by Equation (24) [

35].

The exergy rate (J/s) of the evaporation in the dryer chamber can be determined by [

5]:

The specific exergy (J/s) can be calculated by Equation (27) [

19].

The exergy efficiency of the MW dryer can be estimated by Equation (28) [

5].

The specific exergy loss can be also expressed by Equation (29) as reported by Kariman et al. [

22].

The exergetic sustainability index is defined to express the performance of the exergy. The use of the improvement potential can also be helpful in the evaluation of economic activities [

37]. The exergy improvement potential and the exergetic sustainability index can be expressed by Equations (30) and (31), respectively [

32].

2.5. Statistical Analysis

SPSS (V.19) and the Duncan test (at the probability level of 5%) were used to investigate the effect of Mw power and thickness of cantaloupe slices on the studied indices.

2.6. Experimental Uncertainty Analysis

Experimental uncertainty was calculated by Equation (32) [

38]:

All uncertainties are displayed in

Table 1.

2.7. Artificial Neural Network (ANN)

An artificial neural network is composed of countless artificial neurons operating as interconnected, parallel networks. Each neuron acts as a processor in the network and receives and processes neural signals (input) from other neurons or their surroundings. Similar to the human brain, an artificial neural network can learn everything on its own [

39]. Neurons are trained by applying a training algorithm to the network. An artificial neural network consists of 3 layers: the input layer that receives the primary data, the hidden layer that processes the received data, and the output layer. Each layer contains a group of neurons, each of which is connected to all the neurons in the other layers, but the neurons in each layer are not in contact with other neurons in the same layer. In this way, neurons act independently, and a superposition of the neurons’ behavior reflects the network behavior [

40]. The latent layer may be monolayer (perceptron neural networks) or multilayer (multilayer perceptron (MLP) networks).

In this study, a multilayer perceptron artificial neural network was selected for modelling energy parameters (SEC, energy loss, energy efficiency, dryer efficiency, and thermal efficiency), exergy parameters (exergy drop, exergy efficiency, and exergy recovery potential) and duration of heating and drying cantaloupe by a microwave dryer considering different thicknesses. The perceptron multilayer neural network is a feed-forward network with three inputs, one or two hidden layers, and one output layer. This network was selected by one or two hidden layers for the experiment, in which 2–15 neurons were placed in each layer by trial and error. Moreover, Tansig, Logsig, and Purelin activation functions were used in the hidden input and output layer. In this research, the Levenberg−Marquardt optimization was used to train the network. Three iterations were considered the average of the learning cycle for simulation of artificial neural network data to minimize the error rate and maximize network stability. The error estimation algorithm in the formed networks was performed using the error propagation algorithm.

2.8. Adaptive Neuro-Fuzzy Inference System (ANFIS)

The adaptive neuro-fuzzy inference system formulates the behavior of a process using descriptive if-then rules. This system includes 4 main parts: rule base, fuzzification, inference engine, and defuzzification. Each ANFIS model consists of 5 layers which include inputs, membership functions corresponding to inputs, rules, membership functions related to outputs, and outputs [

19]. In this study, a hybrid method was used to train ANFIS, which is a combination of the least-squares method and the post-diffusion method. The error limit used to create a training stop criterion was set to zero. To optimize the model, different types and numbers of membership functions were used to determine the optimal number and type. A Sugeno-type fuzzy inference system was employed to find the optimal model; triangular, trapezoidal, and Gaussian membership functions were examined. Regarding the two-variable nature of the model input, 2-2 and 3-3 membership functions were investigated.

30% of the data were used for testing while 70% of them were applied for training. Microwave power, the thickness of samples, and drying time were regarded as inputs of both models (ANN and ANFIS) while SEC, energy loss, energy efficiency, thermal efficiency, dryer efficiency, exergy drop, exergy efficiency, exergy improvement potential, and exergetic sustainability index during microwave drying were the outputs. In this study, Matlab software (Matlab R2019a) was used to model ANN and ANFIS.

To evaluate the network, two criteria of coefficient of determination (R

2) and root mean square error (RMSE) were taken into account. The coefficient of determination determines the degree of correlation between the output data of ANN and ANFIS and the observed data which can be calculated from Equation (34); its ideal value is one. The root mean square of the error determines the difference between the predicted and the actual data and can be calculated by Equation (33) [

7]. The goal of a good network is to minimize the amount of this error, and its ideal value is zero.