1. Introduction

With energy shortages and environmental pollution problems becoming more pronounced, the global energy structure is gradually undergoing a transformation. Countries around the world are taking steps to achieve sustainable, green and efficient energy systems. New energy vehicles, especially electric vehicles, are gaining widespread attention due to their low pollution and high energy efficiency. By the end of 2021, the number of new energy vehicles worldwide had exceeded 10 million. In the Chinese urban bus system, many diesel buses have been replaced by energy-efficient and environmentally friendly electric buses [

1]. Compared to traditional diesel buses, electric buses have more advantages in the public transport system. However, there are still some problems, such as difficulties in charging demand evaluation, vehicle route planning and battery energy storage system design. These issues are closely related to the range of electric buses and the energy consumption of vehicles under specific operating conditions [

2]. Therefore, the study of an accurate vehicle energy consumption estimation model can solve the above problems, which is of great significance to the popularization of electric buses. The driving energy consumption of electric buses is affected by drivers’ habits and working conditions. For electric buses on the same route, the difference in driving energy consumption under different working conditions can reach 40%. Therefore, information such as the temperature and departure time under current operating conditions need to be considered so as to accurately estimate the energy consumption of the vehicle.

The energy consumption of an electric vehicle is related to the vehicle powertrain dynamic performance, such as the windproof area of the vehicle, vehicle charging efficiency, etc. It is also influenced by the habits of drivers and environmental factors. As a result, it is difficult to achieve an accurate estimation of the energy consumption of a vehicle [

3]. However, the national monitoring and management platform for new energy vehicles (NEVS) in China has enabled the aggregation of massive amounts of data on new energy vehicles. The platform can provide a large amount of vehicle driving data for the analysis and modeling of vehicle energy consumption.

Many related studies have been performed in this area. Yuan et al. [

4] modeled vehicle powertrain dynamics by simulating driving data on a computer. An energy consumption model for electric vehicles was achieved. In the model, the energy of an electric vehicle is mainly consumed by rolling drag, air resistance and kinetic energy, and the error of the model is about 3%. However, the model only considers energy consumption under laboratory conditions and does not further consider possible congestion and air-conditioning factors in the actual driving process. Bracco et al. [

5] used a simulation model to analyze the effects of different variables on energy consumption and the battery charging state. The results show that the number of passengers has the greatest impact on the energy consumption of electric vehicles. Qi et al. [

6] used positive kinetic energy and negative kinetic energy to decompose the energy consumption under actual traffic congestion. Based on this decomposition, a data-driven model was established. The model is used to estimate the energy consumption of electric vehicles on the road, and the actual traffic conditions are taken into account. The model needs a lot of data input to obtain the accurate positive and negative kinetic energy of the vehicle. After simplifying the input to the average speed, the model error is 7%. Hao et al. [

7] analyzed the energy consumption of electric buses, minibuses and taxis in Beijing. Through statistical analysis, vehicle energy consumption in different seasons and driving conditions was obtained. It was found that the energy consumption of electric vehicles per kilometer is lower than that at 5 °C. This shows that the energy transmission efficiency of the battery will change at different temperatures. Miraftabzadeh et al. [

8] considered the driving route and weather conditions in the modeling process. Using a data-driven modeling method, the energy consumption prediction model of an electric taxi was established. In addition, by calculating the energy consumption of taxis on weekdays and weekends, the author compiled a taxi energy consumption table. The table shows that the month with the highest energy consumption of taxis in New York City is April, while July is the month with the lowest energy consumption. Al-Wreikat et al. [

9] analyzed the effect of ambient temperature on the energy consumption of electric vehicles. They found that vehicles consumed 28% more energy at low temperatures of 0–15 degrees than at medium temperatures of 15–25 degrees. Björnsson et al. [

10] designed a physical model of powertrain dynamics. The energy recovery performance in the braking process was analyzed. The research shows that under urban conditions, the energy regeneration potential per kilometer is higher under the condition of low average speed and multiple starts and stops. It lays a foundation for the study of the urban bus recovery coefficient. The energy consumption of electric vehicles has been modeled by many approaches.

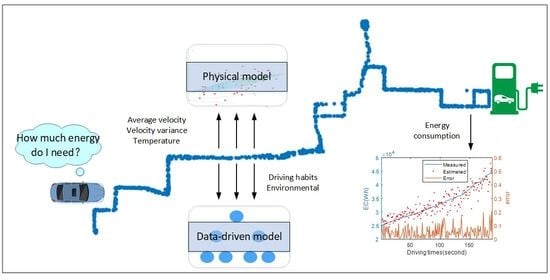

According to the literature review, previous studies have considered physical modeling methods or artificial intelligence algorithms to obtain vehicle energy consumption models. However, vehicle energy consumption is the result of multiple factors. The energy consumption estimation results obtained by a single method or a single type of model are less reliable. Moreover, in practical applications, there is a lack of an energy consumption estimation model with limited input features for driving decision making. It is necessary to design a more reliable energy consumption estimation model with few input features. To address these issues, a physical and data-driven fusion model for vehicle energy consumption is proposed in this paper. Part of the energy consumed by the vehicle during driving can be expressed by physical formulas, such as the energy consumed by rolling resistance and air resistance [

11]. The direct application of formula modeling will reduce the complexity of the model. Other driving factors also affect the driving energy consumption of vehicles, such as the vehicle departure time, the ambient temperature, etc. For these factors that cannot be expressed by the formula, the data-driven model is selected. Finally, the two models are fused to estimate vehicle energy consumption.

The content of each section is as follows: In

Section 2, the statistical analysis of electric bus data is performed. The original data are preprocessed and reconstructed to obtain continuous data in the vehicle charging and driving cycle process. In

Section 3, the energy consumption estimation model is designed. A physical vehicle energy consumption model is developed based on the powertrain dynamic performance of the electric bus. Model parameters are initially calibrated using the least-squares method. In addition, the factors affecting fluctuations in vehicle energy consumption, such as driving habits and environmental factors, are summarized and analyzed. The CatBoost decision tree model is used to characterize the effects. Finally, the two models are fused to obtain the final estimation result of vehicle energy consumption. In

Section 4, the energy consumption estimation model is analyzed and validated. Some conclusions are presented in

Section 5.

2. Data Statistics and Analysis

The electric bus data came from the National Monitoring and Management Platform for NEVS. The original data were collected by on-board terminals on electric buses and uploaded to the data platform. The dataset includes 38 items, such as the sampling time, battery management system (BMS) number, battery pack voltage, battery current, state of charge (SOC), minimum cell voltage, maximum cell voltage, minimum temperature, maximum temperature, etc. A detailed description of the items used in this paper is shown in

Table 1. The data cover ten electric buses on the same bus route in one year. The travel distance is approximately 34 km. There are 24 stops along the route. After one round trip, the buses will be charged at the starting point of the bus stations. The purpose of this section is to process the original data and obtain the data on vehicle speed, data acquisition time, temperature, accelerator pedal value and deceleration pedal value. The data will be further processed for vehicle energy consumption modeling.

Data Processing and Analysis

The quality of the original electric bus data on the platform was not flawless. The acquired data often appeared to have outliers and missing values due to the influence of electromagnetic radiation and the unreliability of the circuit system. As a result, preprocessing of the original data was needed. During the process, data interpolation, outlier removal and data segmentation were performed.

The two main types of missing data are missing multiple rows and missing single features. For the first case, the data exhibit a discontinuity in specific intervals. Missing data were interpolated using the mean value [

12]. For the latter case, the Lagrangian interpolation method was used to interpolate the data. Considering the outliers, the first quartile and the third quartile of the data were calculated by constructing a box plot. Values exceeding the upper and lower edges of the box plot were defined as outliers.

To facilitate the extraction of data features, the data were divided into short segments according to the state of charge in the dataset. The electric bus data transmission process and data preprocessing results are shown in

Figure 1.

After preprocessing the original data, the data were reconstructed according to the timestamp, vehicle velocity, etc. The vehicle driving season, departure time and velocity-related features were obtained. The statistics of the vehicle energy consumption under different operating conditions are shown in

Figure 2. In the figure, the heading of the ordinate is the energy consumption. For brevity, it is abbreviated as EC. For electric vehicles, the operating temperature is related to the use of air conditioning, energy efficiency, etc.

Figure 2a shows the relationship between energy consumption and operating temperature. It can be seen that the relationship can be approximated by a parabolic function. The minimum energy consumption occurs at a temperature of approximately 25 degrees. This phenomenon coincides with the fact that air conditioning and high energy transfer efficiency are rarely used [

6].

Figure 2b shows the relationship between the variance of velocity and energy consumption. It can be seen that there is an approximately linear relationship between them. The higher the variance, the higher the energy consumption. As shown in

Figure 2c, there is no obvious linear relationship between average speed and energy consumption, and this part of the analysis is described in detail later.

Figure 2d shows the relationship between departure time and energy consumption. Departure times are related to road congestion and vehicle passenger weight. Specifically, vehicles consume more energy between 6 a.m. and 8 p.m. Vehicle energy consumption values differ by more than 20%.

3. Vehicle Energy Consumption Modeling

According to the powertrain dynamics of the vehicle, the energy consumption of the vehicle is mainly influenced by air resistance, rolling drag and kinetic energy changes during the driving process. Additionally, the energy consumption of the air-conditioning system in the electric bus should be taken into account [

13]. The influence of these factors can be modeled with physics-based functions. However, the influences of driving habits and environmental factors are somewhat random and cannot be directly described by physical modeling. Therefore, the fluctuating energy consumption resulting from these factors is more suitable to be modeled by data-driven approaches. Data-driven modeling methods such as decision trees, support vector machines and neural networks are commonly used in many fields. The approaches have a good ability to solve complex, non-linear problems [

14]. Based on the analysis, a fusion of the physical modeling and the data-driven modeling is proposed in this paper to achieve an accurate estimation of vehicle energy consumption.

3.1. The Physical Energy Consumption Model

As the energy source of the electric vehicle is attributed to charging stations, charging energy is regarded as the original energy of the vehicle in this paper. The charging efficiency of the battery pack is represented by

. Due to the existence of the battery internal resistance, the value of the efficiency

is less than 1. Additionally, the parameter fluctuates with the operating temperature. During the vehicle driving process, the discharging efficiency of the battery pack is also influenced by the battery internal resistance. Depending on the powertrain dynamics of the vehicle, the chemical energy of the battery pack is converted into electrical energy, which is further converted into mechanical energy to drive the vehicle. Meanwhile, vehicle energy is also consumed by the air-conditioning system. Therefore, vehicle energy consumption

can be expressed by:

As shown in Equation (1), the energy consumption consists of four main components: energy consumption from rolling drag , energy consumption from air resistance , braking consumption and energy consumption from air conditioning . Energy transmission is also accompanied by motor efficiency . Energy recovery efficiency shows that the change in kinetic energy during braking will reverse-charge the vehicle. Assuming that the energy recovery coefficient is , the kinetic energy consumption lost during braking should be . Battery discharge efficiency is .

The energy consumption from rolling drag

is influenced by the vehicle mass, velocity and other factors, and the equation is expressed as:

where

is the vehicle mass,

is the gravitational acceleration,

is the rolling drag coefficient,

is the speed at that time, and

is the sampling interval.

Considering the practicability of the energy consumption model, the number of model inputs should be as small as possible. Therefore, the parameters in Equation (1) need to be simplified and approximated. Herein, the velocity

is approximated as the average velocity, which is simplified as:

where

is the total time of travel, and

is the average velocity.

Energy consumption from air resistance is influenced by the vehicle velocity and windproof area of the vehicle. The energy consumption can be expressed by:

where

is the air density,

is the air resistance coefficient, and

is the windproof area of the vehicle. However, according to the literature [

8], there is a negative correlation between vehicle speed and energy consumption when the vehicle speed is lower than 45 km/h. With the increase in vehicle speed, the energy consumption should decrease slightly, which is inconsistent with Equation (4). As the average velocity of the electric bus used in this paper is very low, the energy consumed by air resistance was ignored in the energy consumption modeling process.

For the kinetic energy consumption of the vehicle, as the initial and end velocities of the vehicle in a driving cycle are both zero, it can be concluded that the deceleration kinetic energy and acceleration kinetic energy are roughly equal. As a result, an energy efficiency coefficient was added to the kinetic energy consumption to characterize the energy recovery performance during the driving cycle. Vehicle kinetic energy consumption can be expressed by Equation (5). In practical application scenarios, the velocity at each time point is unknown. For simplification, the variance of velocity is correlated with the change in kinetic energy, so the variance of velocity is used to replace the change in kinetic energy.

Due to the existence of a large passenger space, the energy consumption of air conditioning should be accounted for. According to the literature [

15], the energy consumption of air conditioning during driving is directly proportional to the square of the temperature difference inside and outside the vehicle. Therefore, the energy consumption can be expressed as:

where

is the air-conditioning coefficient, and

is the temperature.

Substituting Equations (3), (5) and (6) into Equation (1), the physical model can be obtained:

where

,

, and

.

In the physical energy consumption model, the parameters related to the energy transmission efficiency are influenced by environmental factors. However, the model can be simplified by considering all energy efficiencies as fixed values.

are constants and can be obtained using the least-squares fitting method based on statistical vehicle data [

4].

3.2. The Data-Driven Energy Consumption Model

3.2.1. Analysis of Influencing Factors

The factors that cause energy consumption fluctuations can be summarized into three aspects, including driving habits, environmental factors and vehicle performance [

16]. In terms of driving habits, vehicle velocity, acceleration and deceleration conditions can cause fluctuations in vehicle energy consumption. The conditions can be quantified accordingly as the average vehicle velocity, vehicle velocity variance and number of accelerator pedal presses. In terms of the environmental factors, temperature, which is related to the energy transfer efficiency and air-conditioning usage, is the main factor causing fluctuations in vehicle energy consumption. In addition, the road conditions can also cause fluctuations in energy consumption, such as whether the departure time is congested and whether the departure date is on the weekend [

17]. In terms of vehicle performance, the energy efficiency of the battery storage system during the charging and discharging process can also cause energy consumption fluctuations. The energy efficiency is mainly affected by the internal resistance of the battery system and is directly related to the ambient temperature and battery aging. Based on the analysis, the statistical results of the impact of various energy consumption fluctuation factors on vehicle energy consumption are shown in

Figure 3. In the figure, it should be noted that the fitting curves were obtained by fitting experimental data with polynomial functions.

It can be seen in

Figure 3a,c,d that there are positive correlations between the velocity variance, acceleration pedal statistical parameter, deceleration pedal statistical parameter and vehicle energy consumption. In

Figure 3b, there is no clear correlation between the average velocity and the change in vehicle energy consumption. According to a study in the literature [

8], a negative correlation between vehicle speed and energy consumption is found when the vehicle speed is below 45 km/h. Due to the large number of stopping and idling situations during the driving of electric buses, when the speed is low, the energy consumption at low speed is greater than that at high speed.

Figure 3e shows that the effect of temperature on vehicle energy consumption is relatively large, and the relationship can be approximated by a quadratic function. In

Figure 3f,g, the difference in departure time and departure date affects vehicle energy consumption; however, at the same point in time, vehicle energy consumption fluctuates greatly. In

Figure 3h, a positive correlation is shown between the internal resistance of the battery system and the energy consumption of the vehicle. Through further analysis of the internal resistance, it was found that there is a strong correlation between the internal resistance and the battery temperature. During the driving cycle, the battery internal resistance series data have great fluctuations. As a result, the internal resistance is not taken as an input feature.

Based on the statistical analysis of the fluctuation factors of vehicle energy consumption, the main influencing features of vehicle energy consumption fluctuation are: velocity variance, average velocity, accelerator pedal parameter, deceleration pedal parameter, temperature and battery internal resistance. Considering that the internal resistance of the battery is mainly affected by the ambient temperature, the influencing features, except the internal resistance of the battery, are regarded as input features in the data-driven model.

3.2.2. Principle of CatBoost Modeling

In this paper, the CatBoost modeling approach is used to model fluctuations in vehicle energy consumption. CatBoost is an improvement of the gradient boosting decision tree (GBDT) model [

18]. The approach has the ability to improve the estimation accuracy with weak learners. Moreover, it has significant advantages in extracting important features and processing categorical features. In addition, the problem of poor model accuracy and overfitting can be avoided when the dataset is uneven. The main principle of this method is to construct many weak learners for training. The weights of the training samples are adjusted to focus on samples with large estimation errors and train the weak learners in turn. Finally, the weak learners are combined into a stronger learner model [

19]. In the following content, the gradient boosting decision tree algorithm is introduced. Then, the optimization strategy of the CatBoost modeling approach is given. On the basis of the modeling approach, the vehicle’s fluctuating energy consumption results can be obtained.

1. Gradient boosting decision tree

Gradient boosting decision tree is an iterative decision tree algorithm. The algorithm is composed of multiple decision trees, and the results of all trees are accumulated to obtain the final result [

20]. Given a training dataset

,

is the characteristic affecting energy consumption, and

is the predicted energy consumption of output. The goal of GBDT is to find a function

that minimizes the given loss function

.

is accumulated by a series of decision trees

. Each decision tree

is optimized as:

where

is the decision tree function.

is the weight of the

decision tree function

. The initial value of

can be obtained by:

Subsequently, the optimization process of the model is achieved by minimizing the loss functions:

The gradient descent method is used to solve the above optimization problems. For each model

, a new dataset

is constructed and trained to obtain

.

can be obtained by:

The value of

is subsequently computed by solving a line search optimization problem. Its training process is shown in

Figure 4.

2. The CatBoost modeling approach

CatBoost is a kind of gradient-enhanced decision tree algorithm, which can handle category features well [

21]. The variables extracted in this paper have certain category features. Therefore, CatBoost was selected for energy consumption modeling. This method differs from GBDT in the following ways [

22]:

(1) CatBoost can process features during training [

23]. First, the sample data are randomly sorted to generate multiple groups of random sequences. Then, for each random sequence, the average value of the same sample is calculated. When the sequence is

, it can be calculated by:

where

is an a priori value. For regression tasks, the prior value is the average value in the label.

is the weight of

.

(2) Feature combination. The numerical features calculated by Equation (12) may lose some information. Combining features can solve this problem and produce a more effective feature. CatBoost uses a greedy approach to consider feature combinations. The first segmentation does not consider the combination of category features, and the subsequent segmentation considers all feature combinations. CatBoost takes both groups of values after segmentation as category features to participate in the following combination.

In the previous sections, the fluctuation factors of vehicle energy consumption are analyzed. Seven features can be obtained that are related to vehicle energy consumption. Based on a full understanding of the factors and the CatBoost modeling approach, features such as average vehicle velocity, vehicle velocity variance, number of accelerator pedal presses, number of brake pedal presses, departure time, day of the week and temperature, mentioned in

Section 3.2.1, are taken as the input features of the CatBoost decision tree model. The statistical range of input vehicle features is a round trip of the vehicle. After model parameter optimization, the data-driven model of energy consumption can be obtained.

3.3. A Fusion of Physical and Data-Driven Models

After physical and data-driven modeling of the basic energy consumption and fluctuating energy consumption of electric buses, the two parts needed to be fused to obtain a vehicle energy consumption model. In this study, the integrated learning approach in machine learning theory was used for model fusion. The reconstructed electric bus data were used to train the physical energy consumption model. The residual of the basic model was retrained as the training label of the data-driven model [

24]. The flow chart of the energy consumption fusion modeling approach is shown in

Figure 5.

The modeling approach can be divided into three steps:

(1) Data processing. In this process, the original data are interpolated. For different missing data types, the methods of average interpolation and Lagrange interpolation are adopted. For outliers in the data, the method of constructing quartile positions with a box plot is used to remove them. Then, the data are segmented according to the state of charge. After the specific driving segments are divided, data such as vehicle speed, data acquisition time, temperature, accelerator pedal value and deceleration pedal value can be obtained. The data are further processed for energy consumption modeling.

(2) Modeling and fusion. The original features obtained from the data processing step include vehicle speed, data acquisition time, temperature, accelerator pedal value and deceleration pedal value. These features need to be processed separately and input into the model. For the physical model, the vehicle driving distance, speed variance and the square of the difference between the temperature in the vehicle and the standard temperature are calculated as inputs. For the data-driven model, the departure time of the vehicle, whether it is a weekend, the temperature in the vehicle, the value of acceleration and deceleration pedal, the average speed and the speed variance are extracted and input into the CatBoost model. In engineering applications, many specific data in vehicle operation are unknown. Therefore, the input of the model needs to meet the following conditions: (1) The input parameters of the model can be obtained before the vehicle is driven. (2) The input parameters of the model need to include parameters that reflect the working condition information. This paper simplifies the input parameters according to this criterion and obtains the following input parameters: the mileage of the current route, the average speed, the speed variance, the temperature, the air-conditioning condition, the departure time, the departure day of the week and the average values of the accelerator pedal and the deceleration pedal. These parameters can be planned before driving. The aim of the fusion step of the model is to train the physical model to obtain the preliminary estimation results of energy consumption. Then, the residual of the physical model is retrained as the training label of the data-driven model to minimize the residual. The final energy consumption result is the sum of the results of the two models.

(3) Model evaluation. Two indicators are selected for the verification of model results, namely, the average relative error and the R-squared parameter. The verification is divided into a single vehicle division training set and a test set for verification. In order to test the robustness of the model, different vehicles are selected for verification.

5. Conclusions

This research focused on the energy consumption estimation of electric buses based on a physical and data-driven fusion model. In terms of physical modeling, a basic energy consumption model was constructed. Rolling drag, kinetic energy consumption and air-conditioning factors were considered. In terms of data-driven modeling, the main factors affecting the fluctuation of vehicle energy consumption were studied. The input characteristics of the model were simplified so that the input of the model can be built before vehicle driving. A CatBoost decision tree modeling approach was employed to construct the model for estimating fluctuating energy consumption. In the model training process, the idea of integrated learning was utilized to optimize the model in a hierarchical iteration. The results show that the average relative error of the vehicle energy consumption estimation result is 6.1%. The coefficient of determination is 0.79. Compared with other energy consumption modeling methods, the fusion model performs best with the two indicators. The fusion model proposed in this paper has better accuracy and generalization ability than other models. It provides a reference basis for the optimization of the energy consumption of electric buses, vehicle scheduling and the rational layout of charging stations.

Based on the results, most of the points with large errors are concentrated in bad weather. In order to further improve the accuracy of the model, weather factors can be added to the model in the future. In addition, vehicle mass is regarded as a constant value in the driving process, which is also a reason for the model error. Therefore, the establishment of the dynamic estimation of vehicle mass in a follow-up work can improve the accuracy of the model.