Integrated SNG Production in a Typical Nordic Sawmill

Abstract

:1. Introduction

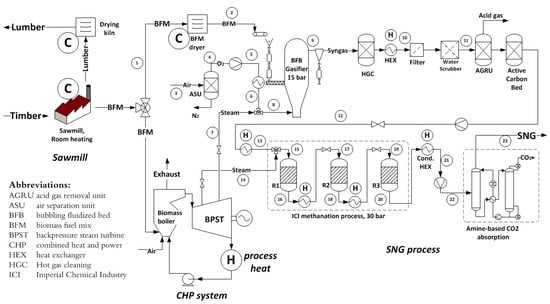

2. Process Description

2.1. Sawmill

2.2. SNG Process

2.3. b-IGCC Process

3. Methodology

- Integration of the bio-SNG production process described in Section 2;

- Integration of a b-IGCC system that produces electricity and heat for a DH system;

- Integration of a b-IGCC system with the sole purpose of producing electricity.

3.1. Process Integration

3.2. Thermodynamic Indicators

3.3. Economic Indicators

4. Results and Discussion

4.1. Integrated Grand Composite Curves of the Three Configurations

4.2. Energetic Perspective

4.3. Economic Perspective

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| A | Equipment sizing parameter |

| BFM | Biomass fuel mix |

| b-IGCC | Biomass integrated gasification combined cycle |

| bio-SNG | Biomass-based synthetic natural gas |

| CEPCI | Chemical engineering plant cost index |

| CI | Capital investment |

| D | Reactor vessel diameter |

| DH | District heat |

| HEN | Heat exchanger network |

| IRR | Internal rate of return |

| LHV | Lower heating value |

| P | Operating pressure (bar) |

| RES | Renewable energy sources |

| SNG | Synthetic/substitute natural gas |

| Sets | |

| i | Set of equipment for which cost estimates are made based on the module costing method. |

| j | Set of equipment for which cost estimates are recalculated based on the published cost data or in-house database. |

| Parameters | |

| CBM,i | Bare module cost of equipment i calculated at the actual process conditions |

| Bare module cost of equipment i calculated at the base rating | |

| CE,j | Cost of equipment j recalculated from the data in Table A1 |

| Purchase cost of equipment i calculated according to the module costing method at the base rating | |

| fBM | Bare module factor |

| fj | Overall installation factor of equipment j |

| fm | Equipment construction material factor |

| fp | Pressure factor |

| ΔTmin | Minimum temperature difference |

| Coefficients | |

| B | Coefficients for evaluating the bare module factor |

| C | Coefficients for evaluating the pressure factor |

| K | Coefficients for estimating the equipment cost at the base rating |

Appendix A

Equipment Purchase Cost Data

| Unit | Original Unit Cost a (M€2013) | Reference Size Parameter | Installation Factor b fj | Scaling Exponent c | Reference |

|---|---|---|---|---|---|

| Biomass Handling | |||||

| Conveyor | 0.36 | 33.5 ton/h | 2 | 0.8 | [5,30] |

| Belt conveyor dryer d | 2.20 | 959,000 m3/h (air) | 2 | 0.8 | [31] |

| Grinding | 0.35 | 33.5 ton/h | 2 | 0.6 | [5,30] |

| Feeding system | 0.43 | 33.5 ton/h | 2 | 1.0 | [5,30] |

| Gasification | |||||

| Direct gasifier (BFB) e | 40.8 | 358 MWth (LHV) | 2 | 0.72 | [30] |

| ASU | 25.7 | 576 ton O2/day | 1.5 | 0.75 | [30] |

| Gas Cleaning | |||||

| Hot gas cleaning | 31.3 | 74.1 m3/s gas flow | 1.86 | 1.0 | [5,30] |

| Fabric filter | 0.72 | 15.6 m3/s gas flow | 1.86 | 0.7 | [5,30] |

| Water scrubber | 2.76 | 12.1 m3/s gas flow | 1.86 | 0.7 | [5,30] |

| Acid gas removal unit | 6.92 | 1.31 m3/s gas flow | 1.86 | 0.7 | [5,30] |

| Guard Bed | |||||

| Activated carbon bed | 0.025 | 8 Nm3/s gas flow | 3 | 1.0 | [30] |

| Methanation (ICI) | |||||

| Reactor 1 f | Cost of reactor vessels, excluding heat exchangers and catalyst material. Prices are estimated according to the module costing method. | [24] | |||

| Reactor 2 f | |||||

| Reactor 3 f | |||||

| Catalyst material g | 0.12 | 1 ton | [32] | ||

| SNG Upgrade | |||||

| CO2 removal h | 5.55 | 3.9 Nm3/s gas flow, 46.7 vol % CO2 | 3.8 | 0.7 | [29] |

| Miscellaneous | |||||

| Compressors | Cost of turbomachinery (centrifugal units) and HEXs (fixed tube). Prices are estimated according to the module costing method. | [24] | |||

| Steam turbine | |||||

| Gas turbine | |||||

| Fan/blower | |||||

| Heat exchangers | |||||

| Pump | |||||

| Electric generator | 1.45 | 11.8 MWel | 1.5 | 0.94 | [33] |

| Process Units | Sizing parameter | Module Cost Factors | Equipment Cost Factors | Pressure Factors | fm | fp | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B1 | B2 | K1 | K2 | K3 | C1 | C2 | C3 | |||

| Methanation Reactors 1–3 | Gas flow | 2.25 | 1.82 | 3.4974 | 0.4485 | 0.1074 | - | - | - | 3.5 | Equation (A6) |

| Compressors | Shaft power | - | 1 | 2.2897 | 1.3604 | −0.1027 | - | - | - | 2.8 | 1 |

| Steam turbine | Shaft power | - | 1 | 2.6259 | 1.4398 | −0.1776 | - | - | - | 3.6 | 1 |

| HEN | Area | 1.63 | 1.66 | 4.3247 | −0.3030 | 0.1634 | 0.03881 | −0.11272 | 0.08183 | 1 | Equation (A5) |

| Steam boiler | Thermal load | - | 1 | 6.9617 | -1.48 | 0.3161 | 2.594072 | −4.23476 | 1.722404 | 1 | Equation (A5) |

Appendix B

Description of the Streams in the Process Flow Diagram

| Stream Number | Description |

|---|---|

| 1 | BFM composition as received, i.e., 55% moisture content |

| 2 | BFM composition prior to gasification, i.e., dried to 10% moisture content |

| 3 | Air |

| 4 | Air was converted to oxygen based on the mass balance of oxygen. Compression and actual separation units were omitted, and only the power consumption and “pass rate” was defined; 233 g-O2/kg-air (100% O2); 353 kJ-el/kg-air |

| 5 | Compressed to 15 bar at an isentropic efficiency of 74% |

| 6 | Preheated to saturated temperature of steam at 15 bar if the gas temperature is lower than that. |

| 7 | Saturated steam at 15 bar |

| 8 | Adiabatic mixing of O2 and steam. The pressure was adjusted to the lower side if there were any pressure difference. |

| 9 | BFM gasification using O2 steam as the oxidizing agent. The detailed calculation method is stated in our previous publication [20]. |

| 10 | Cooled down to 350 °C to recover heat (it is 350 °C in order to avoid tar condensation). |

| 11 | Cooled down to room temperature, hence the water was condensed. We assumed that there was a gas cleaning step here, as well. |

| 12 | Compressed to 30 bar at an isentropic efficiency of 74% |

| 13 | Heated to 398 °C (according to the data from the ICI process) |

| 14 | Saturated steam at 30 bar |

| 15 | Adiabatic mixing of syngas with steam. The pressure was adjusted to the lower side if there were any pressure difference. |

| 16 | Methanation Reactor 1; 10% of pressure loss and 5% of heat loss (adiabatic equilibrium reactor) |

| 17 | Heat exchanger (inter-cooling) |

| 18 | Methanation Reactor 2; 10% of pressure loss and 5% of heat loss (adiabatic equilibrium reactor) |

| 19 | Heat exchanger (inter-cooling) |

| 20 | Methanation Reactor 3; 10% of pressure loss and 5% of heat loss (adiabatic equilibrium reactor) |

| 21 | Condensing heat exchanger (the vapor pressure of the steam remained as saturated pressure after a certain temperature) |

| 22 | Compressed to 30 bar at an isentropic efficiency of 74% |

| 23 | Separation of CO2 (98% of CO2 and 1% of CH4 removed); electricity consumption of 0.576 MJ/Nm3 of CO2 |

| Stream Number | Mass Flow Rate, Thermodynamic State and Energy Content | Solid Biomass Composition wt % | Gas Composition vol % | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| m (kg/s) | P (bar) | T (K) | h (MJ/kg) | LHV (MJ/kg) | Q (MW) | Moisture | C | H | O | N | Ash | O2 | N2 | H2 | CO | CO2 | H2O | CH4 | |

| 1 | 14.09 | 1.01 | 275.15 | 0.00 | 7.44 | 104.81 | 55.00 | 22.99 | 2.75 | 18.59 | 0.08 | 0.59 | - | - | - | - | - | - | - |

| 2 | 7.04 | 1.01 | 348.15 | 0.57 | 17.32 | 126.00 | 10.00 | 45.98 | 5.50 | 37.18 | 0.16 | 1.18 | - | - | - | - | - | - | - |

| 3 | 9.94 | 1.01 | 288.15 | 0.00 | 0.00 | 0.00 | - | - | - | - | - | - | 21.00 | 79.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 4 | 2.42 | 1.01 | 288.15 | 0.00 | 0.00 | 0.00 | - | - | - | - | - | - | 100.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 5 | 2.42 | 15.00 | 658.70 | 0.36 | 0.00 | 0.87 | - | - | - | - | - | - | 100.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 6 | 2.42 | 15.00 | 658.70 | 0.36 | 0.00 | 0.87 | - | - | - | - | - | - | 100.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 7 | 3.52 | 15.00 | 491.45 | 0.39 | 0.00 | 1.37 | - | - | - | - | - | - | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 100.00 | 0.00 |

| 8 | 5.95 | 15.00 | 535.00 | 0.38 | 0.00 | 2.24 | - | - | - | - | - | - | 27.93 | 0.00 | 0.00 | 0.00 | 0.00 | 72.07 | 0.00 |

| 9 | 12.91 | 15.00 | 993.00 | 1.23 | 7.64 | 114.47 | - | - | - | - | - | - | 0.00 | 0.06 | 14.92 | 29.16 | 7.79 | 43.34 | 4.73 |

| 10 | 12.91 | 15.00 | 623.00 | 0.55 | 7.64 | 105.72 | - | - | - | - | - | - | 0.00 | 0.06 | 14.92 | 29.16 | 7.79 | 43.34 | 4.73 |

| 11 | 8.01 | 15.00 | 303.15 | 0.02 | 12.32 | 98.83 | - | - | - | - | - | - | 0.00 | 0.11 | 26.26 | 51.32 | 13.71 | 0.28 | 8.32 |

| 12 | 8.01 | 30.00 | 380.03 | 0.13 | 12.32 | 99.69 | - | - | - | - | - | - | 0.00 | 0.11 | 26.26 | 51.32 | 13.71 | 0.28 | 8.32 |

| 13 | 8.01 | 30.00 | 671.15 | 0.56 | 12.32 | 103.18 | - | - | - | - | - | - | 0.00 | 0.11 | 26.26 | 51.32 | 13.71 | 0.28 | 8.32 |

| 14 | 2.80 | 30.00 | 671.15 | 0.75 | 0.00 | 2.10 | - | - | - | - | - | - | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 100.00 | 0.00 |

| 15 | 10.81 | 30.00 | 671.15 | 0.61 | 9.13 | 105.29 | - | - | - | - | - | - | 0.00 | 0.08 | 18.30 | 35.78 | 9.55 | 30.49 | 5.80 |

| 16 | 10.81 | 27.00 | 998.15 | 1.18 | 8.07 | 100.02 | - | - | - | - | - | - | 0.00 | 0.09 | 15.22 | 13.68 | 30.84 | 24.74 | 15.43 |

| 17 | 10.81 | 27.00 | 598.15 | 0.46 | 8.07 | 92.32 | - | - | - | - | - | - | 0.00 | 0.09 | 15.22 | 13.68 | 30.84 | 24.74 | 15.43 |

| 18 | 10.81 | 24.30 | 748.05 | 0.69 | 7.42 | 87.70 | - | - | - | - | - | - | 0.00 | 0.11 | 2.83 | 0.69 | 43.02 | 28.22 | 25.14 |

| 19 | 10.81 | 24.30 | 573.15 | 0.40 | 7.42 | 84.60 | - | - | - | - | - | - | 0.00 | 0.11 | 2.83 | 0.69 | 43.02 | 28.22 | 25.14 |

| 20 | 10.81 | 21.87 | 671.15 | 0.55 | 7.39 | 85.86 | - | - | - | - | - | - | 0.00 | 0.11 | 1.26 | 0.15 | 43.50 | 29.05 | 25.94 |

| 21 | 8.85 | 21.87 | 313.15 | 0.03 | 9.02 | 80.13 | - | - | - | - | - | - | 0.00 | 0.15 | 1.78 | 0.21 | 61.09 | 0.34 | 36.44 |

| 22 | 8.85 | 30.00 | 347.67 | 0.07 | 9.02 | 80.48 | - | - | - | - | - | - | 0.00 | 0.15 | 1.78 | 0.21 | 61.09 | 0.34 | 36.44 |

| 23 | 1.75 | 30.00 | 347.67 | 0.13 | 45.11 | 79.33 | - | - | - | - | - | - | 0.00 | 0.38 | 4.47 | 0.52 | 3.07 | 0.85 | 90.71 |

References

- Swedish Statistical Yearbook of Forestry; Christiansen, L. (Ed.) Swedish Forest Agency: Jönköping, Sweden, 2014.

- Anderson, J.-O.; Toffolo, A. Improving energy efficiency of sawmill industrial sites by integration with pellet and CHP plants. Appl. Energy 2013, 111, 791–800. [Google Scholar] [CrossRef]

- Duret, A.; Friedli, C.; Maréchal, F. Process design of synthetic natural gas (SNG) production using wood gasification. J. Clean Prod. 2005, 13, 1434–1446. [Google Scholar] [CrossRef]

- Arvidsson, M.; Morandin, M.; Harvey, S. Biomass gasification-based syngas production for a conventional oxo synthesis plant—Process modeling, integration opportunities, and thermodynamic performance. Energy Fuels 2014, 28, 4075–4087. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Faaij, A.P. Future prospects for production of methanol and hydrogen from biomass. J. Power Sources 2002, 111, 1–22. [Google Scholar] [CrossRef]

- Kopyscinski, J.; Schildhauer, T.J.; Biollaz, S.M.A. Production of synthetic natural gas (SNG) from coal and dry biomass—A technology review from 1950 to 2009. Fuel 2010, 89, 1763–1783. [Google Scholar] [CrossRef]

- Pihl, E.; Heyne, S.; Thunman, H.; Johnsson, F. Highly efficient electricity generation from biomass by integration and hybridization with combined cycle gas turbine (CCGT) plants for natural gas. Energy 2010, 35, 4042–4052. [Google Scholar] [CrossRef]

- Zwart, R.W.R.; Boerrigter, H.; Deurwaarder, E.P.; van der Meijden, C.M.; van Paasen, S.V.B. Production of Synthetic Natural Gas (SNG) from Biomass: Development and Operation of an Integrated Bio-SNG System; ECN-E—06-018; Energy research center of the Netherlands (ECN): Petten, The Netherlands, 2006; p. 62. [Google Scholar]

- Gassner, M.; Baciocchi, R.; Maréchal, F.; Mazzotti, M. Integrated design of a gas separation system for the upgrade of crude SNG with membranes. Chem. Eng. Process. Process. Intensif. 2009, 48, 1391–1404. [Google Scholar] [CrossRef]

- Van der Meijden, C.M.; Veringa, H.J.; Rabou, L.P.L.M. The production of synthetic natural gas (SNG): A comparison of three wood gasification systems for energy balance and overall efficiency. Biomass Bioenergy 2010, 34, 302–311. [Google Scholar] [CrossRef]

- Juraščík, M.; Sues, A.; Ptasinski, K.J. Exergy analysis of synthetic natural gas production method from biomass. Energy 2010, 35, 880–888. [Google Scholar] [CrossRef]

- Gassner, M.; Maréchal, F. Thermo-economic process model for thermochemical production of synthetic natural gas (SNG) from lignocellulosic biomass. Biomass Bioenergy 2009, 33, 1587–1604. [Google Scholar] [CrossRef]

- Zhang, W.; He, J.; Engstrand, P.; Björkqvist, O. Economic evaluation on bio-synthetic natural gas production integrated in a thermomechanical pulp mill. Energies 2015, 8, 12795–12809. [Google Scholar] [CrossRef]

- Davis, W.; Martin, M. Optimal year-round operation for methane production from CO2 and water using wind and/or solar energy. J. Clean Prod. 2014, 80, 252–261. [Google Scholar] [CrossRef]

- Davis, W.; Martin, M. Optimal year-round operation for methane production from CO2 and water using wind energy. Energy 2014, 69, 497–505. [Google Scholar] [CrossRef]

- Giglio, E.; Lanzini, A.; Santarelli, M.; Leone, P. Synthetic natural gas via integrated high-temperature electrolysis and methanation: Part II—Economic analysis. J. Energy Storage 2015, 2, 64–79. [Google Scholar] [CrossRef]

- Giglio, E.; Lanzini, A.; Santarelli, M.; Leone, P. Synthetic natural gas via integrated high-temperature electrolysis and methanation: Part I—energy performance. J. Energy Storage 2015, 1, 22–37. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Leckner, B. Modeling of biomass gasification in fluidized bed. Prog. Energy Combust. Sci. 2010, 36, 444–509. [Google Scholar] [CrossRef]

- Shiflett, M.B.; Drew, D.W.; Cantini, R.A.; Yokozeki, A. Carbon dioxide capture using ionic liquid 1-butyl-3-methylimidazolium acetate. Energy Fuels 2010, 24, 5781–5789. [Google Scholar] [CrossRef]

- Tanaka, Y.; Mesfun, S.; Umeki, K.; Toffolo, A.; Tamaura, Y.; Yoshikawa, K. Thermodynamic performance of a hybrid power generation system using biomass gasification and concentrated solar thermal processes. Appl. Energy 2014, 160, 664–672. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Toffolo, A. A method to separate the problem of heat transfer interactions in the synthesis of thermal systems. Energy 2008, 33, 163–170. [Google Scholar] [CrossRef]

- Mesfun, S.; Toffolo, A. Optimization of process integration in a Kraft pulp and paper mill—Evaporation train and CHP system. Appl. Energy 2013, 107, 98–110. [Google Scholar] [CrossRef]

- Kemp, C.-I. Pinch Analysis and Process Integration: A User Guide on Process Integration for the Efficient Use of Energy, 2nd ed.; Butterworth-Heinemann Ltd.: Oxford, UK, 2007. [Google Scholar]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis, Synthesis, and Design of Chemical Processes, 2nd ed.; Printice Hall PTR: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Heyne, S.; Harvey, S. Assessment of the energy and economic performance of second generation biofuel production processes using energy market scenarios. Appl. Energy 2013, 101, 203–212. [Google Scholar] [CrossRef]

- Mesfun, S.; Toffolo, A. Integrating the processes of a Kraft pulp and paper mill and its supply chain. Energy Convers. Manag. 2015, 103, 300–310. [Google Scholar] [CrossRef]

- Wetterlund, E.; Söderström, M. Biomass gasification in district heating systems—The effect of economic energy policies. Appl. Energy 2010, 87, 2914–2922. [Google Scholar] [CrossRef]

- Börjesson, M.; Ahlgren, E.O. Biomass gasification in cost-optimized district heating systems—A regional modelling analysis. Energy Policy 2010, 38, 168–180. [Google Scholar] [CrossRef]

- Heyne, S.; Harvey, S. Impact of choice of CO2 separation technology on thermo-economic performance of bio-SNG production processes. Int. J. Energy Res. 2014, 38, 299–318. [Google Scholar] [CrossRef]

- Hamelinck, C.; Faaij, A.; Denuil, H.; Boerrigter, H. Production of FT transportation fuels from biomass; technical options, process analysis and optimisation, and development potential. Energy 2004, 29, 1743–1771. [Google Scholar] [CrossRef]

- Li, H.; Chen, Q.; Zhang, X.; Finney, K.N.; Sharifi, V.N.; Swithenbank, J. Evaluation of a biomass drying process using waste heat from process industries: A case study. Appl. Therm. Eng. 2012, 35, 71–80. [Google Scholar] [CrossRef]

- Seemann, M.C.; Schildhauer, T.J.; Biollaz, S.M.A. Fluidized bed methanation of wood-derived producer gas for the production of synthetic natural gas. Ind. Eng. Chem. Res. 2010, 49, 7034–7038. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Macor, A. Direct calculation of average and marginal costs from the productive structure of an energy system. J. Energy Resour. Technol. 1995, 117, 171. [Google Scholar] [CrossRef]

- Worley, M.; Yale, J. Biomass Gasification Technology Assessment Consolidated Report; Contract No. DE-AC36-08GO28308; NREL: Golden, CO, USA, 2012. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Investment interest rate | % | 4 |

| Economic life time | Year | 20 |

| Annual operational time (top) | Hour | 8000 |

| Operators a | p. b/shift | 6 |

| Operator salary | €/(p.·year) | 55,000 |

| Maintenance cost (Com) | % of CI | 5 |

| BFM price (CBFM) c | €/MWhLHV | 22 |

| Electricity (Cel) (including CO2 charge) c | €/MWhel | 68 |

| Natural gas (including CO2 charge) c | €/MWhLHV | 48 |

| District heating thermal energy c | €/MWhth | 35 |

| CO2 charge (input) c | €/tCO2 | 36 |

| Renewable electricity policy support c | €/MWhel | 7 |

| Tax on profit | % | 22 |

| Parameter | Unit | Sawmill Sizes | ||||||

|---|---|---|---|---|---|---|---|---|

| Annual lumber production | 103 m3 | 400 | 283 | 212 | 141 | 106 | 71 | 53 |

| BFM available | MWLHV | 122.9 | 86.85 | 65.13 | 43.42 | 32.57 | 21.71 | 16.28 |

| BFM to biomass boiler | % | 42.99 | 42.93 | 42.99 | 43.19 | 43.27 | 42.88 | 42.23 |

| SNG production | MWLHV | 45.23 | 31.99 | 23.98 | 15.94 | 11.95 | 8.05 | 6.13 |

| Sawmill thermal load | MWth | 16.91 | 11.95 | 8.96 | 5.98 | 4.48 | 2.99 | 2.24 |

| Cold gas efficiency (Equation (1)) | % | 64.55 | 64.54 | 64.56 | 64.61 | 64.66 | 64.95 | 65.12 |

| Wobbe index | MJ/Nm3 | 44.96 | 44.87 | 44.74 | 44.48 | 44.18 | 42.36 | 41.49 |

| Power generation | MWel | 11.34 | 7.54 | 5.57 | 3.66 | 2.71 | 1.67 | 1.14 |

| Power consumption | MWel | 4.46 | 3.15 | 2.36 | 1.57 | 1.17 | 0.78 | 0.59 |

| Net power export | MWel | 6.88 | 4.39 | 3.21 | 2.10 | 1.54 | 0.89 | 0.55 |

| Energy efficiency (Equation (2)) | % | 56.17 | 55.65 | 55.50 | 55.30 | 55.17 | 54.98 | 54.77 |

| Exergy efficiency (Equation (5)) | % | 42.40 | 41.88 | 41.74 | 41.54 | 41.41 | 41.22 | 41.01 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesfun, S.; Anderson, J.-O.; Umeki, K.; Toffolo, A. Integrated SNG Production in a Typical Nordic Sawmill. Energies 2016, 9, 333. https://doi.org/10.3390/en9050333

Mesfun S, Anderson J-O, Umeki K, Toffolo A. Integrated SNG Production in a Typical Nordic Sawmill. Energies. 2016; 9(5):333. https://doi.org/10.3390/en9050333

Chicago/Turabian StyleMesfun, Sennai, Jan-Olof Anderson, Kentaro Umeki, and Andrea Toffolo. 2016. "Integrated SNG Production in a Typical Nordic Sawmill" Energies 9, no. 5: 333. https://doi.org/10.3390/en9050333

APA StyleMesfun, S., Anderson, J. -O., Umeki, K., & Toffolo, A. (2016). Integrated SNG Production in a Typical Nordic Sawmill. Energies, 9(5), 333. https://doi.org/10.3390/en9050333