1. Introduction

Ensuring long-term energy and environmental security by reducing the current rates of consumption of finite fossil-fuel reserves and the release of related emissions to the environment have been increasingly desirable goals in recent years. Specifically, the interest in the utilization of sustainable energy resources such as geothermal and solar heat, which are abundantly available, is attracting increasing attention, as is the recovery and utilization of low- and medium-grade (i.e., temperature) waste heat, significant quantities of which are being rejected in the industrial, transport and residential sectors [

1,

2]. These goals can be met to an extent by collecting or recovering thermal energy from the above mentioned sources and converting this heat to useful work such as electricity, shaft work, or pumping (hydraulic) work. Because of the lower heat-source temperatures involved (relative to conventional power generation), the thermal efficiency of any system used for this purpose is expected to be inherently low. Therefore, cost is also of primary importance in the deployment of relevant solutions.

Thermofluidic oscillators are one particular class of thermodynamic heat converters that can utilize lower-grade external heat sources cost-effectively. This class of systems includes single-phase thermofluidic oscillators such as Sondhauss tubes [

3,

4], standing-wave thermoacoustic engines [

5], and the Fluidyne engine [

6]. Alternatively, two-phase thermofluidic oscillators are also being considered, such as the "Non-Inertive-Feedback Thermofluidic Engine" (NIFTE) [

7,

8,

9,

10] and the Up-THERM heat converter, which comprises a single reciprocating solid piston. In particular, the NIFTE has been shown to be capable of operating across temperature differences between a heat source and sink as low as 30 °C [

11]. One important characteristic of thermofluidic oscillators is their reliance (by-design) on far fewer moving parts and dynamic seals during operation, and their simpler construction featuring more basic components. This allows more affordable materials and manufacturing techniques to be used, leading to lower capital costs but also longer maintenance cycles and lower operating costs than conventional power-generation systems.

The Up-THERM heat converter was proposed by Encontech B.V. [

12,

13] and further developed under the EU FP7 project Up-THERM [

14]. The device is described in detail in Kirmse et al. [

15,

16,

17] and Oyewunmi et al. [

18], and a similar concept referred to as the “Evaporative Reciprocating-Piston Engine” (ERPE) is reported in Taleb et al. [

19]. Briefly, a constant temperature difference applied and maintained, by an external heat source and sink, between the hot and cold parts of the Up-THERM heat converter gives rise to periodic alternating evaporation and condensation of the working fluid as this oscillates within the device thereby undergoing an unsteady thermodynamic cycle. This leads to unsteady oscillations of pressure, temperature, and volume within the engine and, consequently, the reciprocating motion of liquid within the device and the reciprocating vertical motion of a solid piston. By transforming the oscillatory movement of the liquid into unidirectional flow through the use of check valves and hydraulic accumulators, power can be extracted by a hydraulic motor.

The organic Rankine cycle (ORC) is also a technology that is capable of converting lower-grade (external) heat into useful work. It is a more commercially mature technology compared to the novel concept of the Up-THERM heat converter, and a significant effort has been placed in the technical development and improvement of this technology, especially in the field of waste heat recovery [

20,

21,

22,

23,

24,

25,

26,

27]. In particular, ORC engines promise relatively high efficiencies at low temperatures and power outputs and form a natural benchmark for the technical and economic assessment of the Up-THERM heat converter.

In this paper, we compare the concept of the Up-THERM heat converter, based on a pre-specified Up-THERM (geometric) design in a selected application, to the ORC engine technology with a view towards employing the Up-THERM heat converter as a combined heat and power (CHP), or cogeneration, prime-mover. To this end, we perform a thermodynamic and economic comparison of the two technologies, recovering heat from heat sources in the temperature range from 210 °C to 500 °C. Three n-alkanes (n-pentane, n-hexane, and n-heptane) and two refrigerants (R134a and R227ea) are investigated as working fluids over the heat-source temperature range of interest.

The methods used for the modeling of the Up-THERM heat converter and the equivalent sub-critical, non-regenerative ORC engine are described in

Section 2. Moreover, in

Section 2 we give a brief explanation of the calculation of the capital costs of both systems. This is followed by an examination of the following thermodynamic performance indicators of both engines: power output, exergy efficiency, and thermal efficiency. It may be expected that the ORC engine will outperform the Up-THERM heat converter purely in terms of these thermodynamic performance indicators. We proceed to investigate the economic performance of the two engines. In particular, we consider the capital costs and specific costs per unit power. Due to its simple design, fewer and more basic components, it can also be expected that the Up-THERM heat converter will have lower capital costs than its ORC counterpart, which has a technically more complex construction, as mentioned above. On the other hand, the specific costs of the two systems and how these compare are of particular interest here, in the context of the future uptake and implementation of these technologies.

3. Results and Discussion

In

Figure 5 the power outputs of the Up-THERM heat converter and equivalent ORC engines for the three

n-alkanes at different heat-source temperatures are shown. The marker of the ORC power output shows the cycle with an isentropic efficiency of the expander of 70%, while the error bars indicate the results for 65% and 75% isentropic efficiency, respectively. It can be seen that for low heat-source temperatures the power output of the ORC engine is generally higher than the power output of the Up-THERM heat converter. Furthermore, the power output generally increases with increasing heat-source temperature in both engines. In particular, for

n-pentane the power output of the Up-THERM heat converter increases from 0.5 kW at 210 °C to 7.0 kW at 360 °C. For

n-hexane the power output of the Up-THERM heat converter increases from 0.4 kW at 260 °C to 7.9 kW at 440 °C and for

n-heptane from 0.4 kW at 320 °C to 5.4 kW at 500 °C.

In the same temperature ranges the net power output of the equivalent ORC engines rises from 4.0 kW (n-pentane), 2.0 kW (n-hexane) and 2.4 kW (n-heptane) to 6.6 kW (n-pentane), 5.6 kW (n-hexane) and 4.1 kW (n-heptane). Especially for n-hexane and n-heptane it can be observed that at increasing heat-source temperatures the difference in the power output of the two engines becomes less pronounced until, at the highest heat-source temperatures the Up-THERM heat converter surpasses the ORC engine in terms of power output. This is due to the heat input into both engines, which saturates at high heat-source temperatures for each working fluid. While for the Up-THERM heat converter the exergy input into the cycle, which is always increasing with increasing heat-source temperatures, is more relevant to create useful power, for the ORC engine the heat input is considered to create useful power. As the heat input saturates for high heat-source temperatures of each working fluid and the thermal efficiency is constant, the power output saturates as well.

For the Up-THERM heat converter the increasing power output is due to the increasing temperature difference between the heat source and heat sink and the increasing equilibrium pressure for increasing heat-source temperatures. A higher equilibrium pressure allows for higher amplitudes of pressure and volumetric displacement, which in turn leads to higher power outputs. Moreover, the heat input into the Up-THERM cycle increases with increasing heat-source temperature, due to the increasing temperature difference between heat source and working fluid and the increasing heat-transfer coefficient

h. From Equation (

2) it can be seen that

h is dependent on the reduced pressure of the fluid. When the pressure increases,

h increases and hence, the heat input into the Up-THERM cycle increases. As the heat input is equal for the same heat-source temperature and working fluid for the Up-THERM heat converter and the ORC engine, the heat input into the ORC engine also increases with increasing heat-source temperature. This leads to higher power outputs in the Up-THERM heat converter and the ORC engine.

The exergy efficiencies of the Up-THERM heat converter and the ORC engine are shown in

Figure 6 for the investigated

n-alkanes and heat-source temperatures. As in

Figure 5 for the ORC exergy efficiency the markers show results for 70% isentropic expander efficiency, while the error bars indicate the results for 65% and 75% respectively. The exergy efficiency of the ORC engine decreases from 34.3% at 210 °C to 25.7% at 360 °C for

n-pentane, from 28.5% at 260 °C to 22.1% at 440 °C for

n-hexane and from 22.7% at 320 °C to 18.7% at 500 °C for

n-heptane. This is due to the constant thermal efficiency (14.2% for

n-pentane, 13.3% for

n-hexane and 11.9% for

n-heptane) for the

n-alkanes in the ORC engine, (

Figure 7).

This constant thermal efficiency is a result of the sub-critical constraint on the ORC engines (i.e., evaporating the working fluid at sub-critical pressures) employed to maintain a phase-change similarity with the Up-THERM converter. Since the heat-source temperatures are higher than the critical temperatures of the working fluids, each working fluid is evaporated at the set sub-critical pressure limit (95% of the critical pressure), whereby the optimal cycles have similar profiles on a T–s or P–h diagram, and hence the resulting ORC engines have similar thermal efficiencies (Equation (23)). As the heat-source temperature increases, the Carnot (i.e., maximum possible) efficiency increases, leading to a decreasing exergy efficiency, which is consistent with its definition in Equation (23).

For the Up-THERM heat converter the exergy efficiencies of all three n-alkanes rise first with increasing heat-source temperature and, after having reached a maximum, decrease for further increasing heat-source temperatures. When the heat-source temperature increases, the heat input and exergy input into the cycle increase. However for temperatures above 310 °C (n-pentane), 400 °C (n-hexane) and 450 °C (n-heptane) the heat input saturates. This can be seen as the maximum heat input into the cycle for each working fluid. However, due to the increasing heat-source temperature, the exergy input into the cycle does not remain steady but increases further. This leads to a decreasing exergy efficiency. The maximum for n-pentane is 41.6%, for n-hexane 42.7% and for n-heptane 43.7%. Thus, with increasing chain lengths of the n-alkanes, the maximum exergy efficiency increases. This is in contrast with the ORC engine, where with increasing chain length of the n-alkanes the maximum exergy efficiency decreases.

Next to the exergy efficiency the thermal efficiency is shown in

Figure 7. The thermal efficiency of the Up-THERM engine increases for increasing heat-source temperatures. As the heat input and power output first increase with increasing heat-source temperatures, the thermal efficiency increases slowly. When the heat input saturates at the aforementioned temperatures, the increase of thermal efficiency becomes steeper. A higher heat-source temperature leads to higher equilibrium pressures and higher oscillation amplitudes of pressure and volumetric displacement. Thus, a higher pressure drop across the hydraulic motor can be observed, leading to higher power outputs. The power output is defined as

in Equation (

13), with

the pressure drop across the load. As the load resistance

is determined empirically for maximum power output, its value grows for increasing heat-source temperatures.

The thermal efficiency of the ORC engine stays constant for every working fluid over the investigated temperature range as the working fluid is expanded from the saturated-vapour curve. For increasing chain-lengths of the

n-alkanes, the thermal efficiency of the Up-THERM heat converter and the ORC engine decrease (at the same heat-source temperature). For the ORC engine this is due to the lower evaporation pressure, which is constant over the investigated temperature ranges for each respective working fluid. For the Up-THERM heat converter the equilibrium pressure decreases with increasing chain lengths of the

n-alkanes, leading to a decreased power output (

Figure 5) and decreasing thermal efficiency (

Figure 7).

After having looked at the thermodynamic performance of the two engines, the economic performance is investigated in more detail. Therefore, in

Figure 8, the bare module costs of the Up-THERM heat converter and the ORC engine for

n-pentane at different heat-source temperatures are shown, which can be considered as capital costs of the two engines. The Up-THERM heat converter has lower capital costs than the ORC engine for all investigated heat-source temperatures. The biggest costs are associated with the heat exchangers in the Up-THERM heat converter and the ORC engine. In this paper it is implicit that the hot and cold heat-exchangers of the Up-THERM heat converter are the same size, as it is assumed that the equilibrium temperature lies half-way between the hot and cold heat-exchanger and thus, the length of both heat exchangers is identical. The piston accumulator and hydraulic motor have the smallest contribution to the capital costs of the Up-THERM heat converter, as these are commercially available off-the-shelf products. The hydraulic accumulators have slightly higher cost, due to the relatively high pressures they have to endure. The costs of the hydraulic motor decrease with increasing heat-source temperatures as the flow rate through it decreases, while the pressure drop across the hydraulic motor increases. Due to the decreasing flow rates smaller hydraulic motors can be utilized for higher temperatures.

The evaporator and condenser of the ORC engine contribute the most to its costs. The costs of the evaporator decrease for increasing heat-source temperatures, while the costs of the condenser stay almost constant over the investigated temperature range. As for higher heat-source temperatures the working fluid mass flow rate increases and hence more pump power is required, the pump costs increase for increasing heat source temperatures. Similarly, as the power output increases for increasing heat-source temperatures, the cost of the expander rises.

The simple design of the Up-THERM heat converter together with the utilization of commercially available products leads to the economic advantage over the ORC engine, which uses a pump and expander. Due to the increasing heat input into the cycle, which corresponds to increasing areas of the heat exchangers, and the dominating costs of the heat exchangers in the Up-THERM heat converter, the lowest capital costs are observed for low temperatures. The costs of the ORC heat exchangers are higher than the costs of the Up-THERM heat exchangers, as a larger area is required to evaporate/condense the working fluid.

In

Figure 9, the bare module costs of both engines are shown for

n-hexane at heat-source temperatures between 260 °C and 440 °C. Similar to the previous figure for

n-pentane the Up-THERM heat converter has lower capital costs than the ORC engine. In general the capital costs of the Up-THERM heat converter are about £6,000 lower for

n-hexane than for

n-pentane. This is due to the lower heat input into the cycle and consequently a smaller area of the heat exchangers, which leads to significantly lower overall costs, as the heat exchangers contribute the most to the Up-THERM costs. The costs of the ORC engine are approximately £10,000 lower for

n-hexane than for

n-pentane, due to smaller, and hence cheaper, heat exchangers.

Finally, in

Figure 10, the capital cots of the Up-THERM heat converter and the ORC engine for

n-heptane are shown. The capital costs of both engines are approximately equal for

n-heptane and

n-hexane, due to similar-sized heat exchangers.

Next to applications in the aforementioned temperature range, a further thermo-economic comparison at temperatures of 100 °C and 120 °C is performed. For these temperatures the two refrigerants R134a and R227ea are considered as working fluids. The bare module costs for the Up-THERM heat converter and the ORC engine for R134a and R227ea are shown in

Figure 11. It can be seen that the total costs of the Up-THERM heat converter are lower than the total costs of the ORC engine for each working fluid at the respective heat-source temperature. However, compared to

n-pentane,

n-hexane and

n-heptane the capital costs are higher for those refrigerants in the investigated temperature range. This is mainly due to the larger area of the heat exchangers, which leads to higher bare module costs. In summary, it can be seen that the Up-THERM heat converter has lower up-front costs than the ORC engine for applications in all investigated temperature ranges.

Next to the capital costs of the Up-THERM heat converter and ORC engine the specific capital costs are evaluated in this paper. The specific costs are expressed in £/kW and take the power output into account. At first, the specific costs of the Up-THERM heat converter and the ORC engine are compared for

n-pentane as depicted in

Figure 12. The specific capital costs decrease with increasing heat-source temperatures for both engines due to the rising power output and almost constant capital costs. At 210 °C the specific capital costs of the Up-THERM heat converter are about five times higher than those for the ORC engine. As the heat-source temperature increases the specific capital costs of the Up-THERM heat converter decrease more rapidly than those of the ORC engine (mainly due to the steeper increasing power output) so that at 310 °C the specific capital costs of the Up-THERM engine and the ORC engine are approximately equal. For heat-source temperatures above 310 °C the Up-THERM has lower specific costs, due to the further increasing power output of the Up-THERM heat converter, while the power output of the ORC engine remains steady.

The specific capital costs for

n-hexane are shown in

Figure 13. For heat-source temperatures between 260 °C and 360 °C the Up-THERM heat converter has higher costs than the ORC engine. As the heat-source temperature increases the specific costs of both engines decrease. This is due to the increase in power output of both engines with increasing heat-source temperature, see also

Figure 5. The capital costs of both engines remain fairly constant with increasing heat-source temperature, see

Figure 9a,b. However, as the power output of the Up-THERM heat converter increases faster than the power output of the ORC engine, the specific costs of the Up-THERM heat converter decrease faster. In fact, at 370 °C heat-source temperature both engines have approximately the same specific costs and at 380 °C and above, the Up-THERM heat converter is approximately 1000 £/kW to 5000 £/kW cheaper than the ORC engine, which means that at 440 °C the specific costs of the Up-THERM heat converter are half of those of the ORC engine.

In

Figure 14 the specific costs of the Up-THERM heat converter and the ORC engine are shown for

n-heptane as the working fluid at different heat-source temperatures. Similarly to the cases for

n-pentane and

n-hexane, the specific costs for both engines decrease with increasing heat-source temperature due to the increasing power output and the constant capital costs. Also, the specific costs of the Up-THERM heat converter decrease faster than the specific costs of the ORC engine due to the steeper increase of the Up-THERM power output. For heat-source temperatures above 430 °C the ORC engine has higher specific costs than the Up-THERM heat converter.

In

Figure 15 we show the specific costs for the refrigerants R134a and R227ea for both the Up-THERM heat converter and the ORC engine. Although, the Up-THERM heat converter has lower capital costs for R134a than the ORC engine, the specific costs of the Up-THERM heat converter are much higher. In fact, the specific costs are the highest amongst all investigated fluids at all heat-source temperatures. These high specific costs are due to the low power output of the Up-THERM heat converter for R134a and R227ea, which range from 0.24 kW (R134a) to 0.65 kW (R227ea).

It should be noted that in this work only the capital costs of both engines are considered. The operating costs (such as maintenance) are not taken into account. Due to the simple design and lack of moving parts (e.g., no pump) it is expected that the Up-THERM heat converter has much lower operating expenses than the ORC engine. The maintenance interval of the Up-THERM heat converter is expected to be 50,000 h, which corresponds to over five years. For ORC engines the operating and maintenance costs can contribute to the total costs per operating hour almost as much as the investment costs [

41].

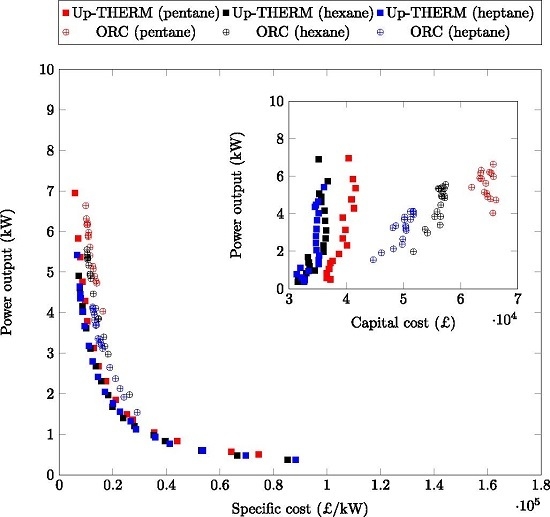

Lastly, we look at the capital and the specific costs of both engines using the three aforementioned

n-alkanes as working fluids at different power outputs. In

Figure 16 these costs are shown. For low heat source temperatures (e.g.,

n-pentane and

n-heptane in the Up-THERM heat converter) the specific costs are high (over 80,000 £/kW). This is due to the low power output of the Up-THERM heat converter for low heat-source temperatures when using

n-pentane or

n-heptane as working fluids. With increasing heat source temperatures the specific costs first decrease rapidly, as the power output increases. However, for power outputs over 2 kW this decrease of the specific costs is less pronounced and appears to approach a lower limit. This indicates that there are minimum specific costs for both engine types that are approached for higher power outputs. As seen in

Figure 8,

Figure 9 and

Figure 10 and the inset in

Figure 16 the ORC capital costs are generally higher than the Up-THERM capital costs.

4. Conclusions

A pre-specified Up-THERM heat converter design in a selected prime-mover application has been compared thermodynamically and economically to an equivalent ORC heat engine when using five different working fluids over a range of heat-source temperatures between 210 °C and 500 °C. It is noted that ORC systems are a mature technology, with decades of development, operational and commercialization experience, whereas the Up-THERM is still in the early stages of development and needs to prove its commercial potential. It is also noted that the present effort only considers capital costs and does not account for operating/maintenance expenses which are expected to move the balance further in favor of the Up-THERM converter. This is expected, since the Up-THERM heat converter can be constructed from more simple components using low-cost manufacturing techniques and materials, and has fewer moving parts and dynamic seals, which allows longer maintenance cycles and lower operating costs than the ORC engine.

The power outputs of both engines increase at higher heat-source temperatures, while the capital costs do not change greatly with the heat-source temperature. Thus, the specific costs (in £/kW) of both systems decrease significantly at progressively higher temperatures, and this is especially true for the Up-THERM converter whose net power output also increases strongly at high temperatures.

Generally, for all the working fluids considered, the ORC engine outperforms its Up-THERM counterpart purely in terms of power output, exergy efficiency and thermal efficiency. However, the capital costs are always lower for the Up-THERM heat converter. For example, with n-pentane as the working fluid, the Up-THERM’s capital costs are only half those of the equivalent ORC engine. This leads to the possibility that at heat-source temperatures above 310 °C (for n-pentane), 380 °C (for n-hexane) and 430 °C (for n-heptane), the Up-THERM heat converter becomes the more affordable solution in terms of specific costs (relative to the equivalent ORC engine).

Thus, the Up-THERM heat converter can be regarded as an attractive alternative to the ORC engine at heat-source temperatures above 310 °C (n-pentane), above 380 °C (n-hexane) and above 430 °C (n-heptane), as the power output is comparable to or even higher than the power output of the equivalent ORC engine, while the specific costs are much lower. Since the capital costs of the Up-THERM converter are significantly lower than those of the ORC engine, the Up-THERM is an attractive solution over the entire investigated temperature range, for remote or off-grid power generation applications where low up-front costs are crucial.