Sustainable New Brick and Thermo-Acoustic Insulation Panel from Mineralization of Stranded Driftwood Residues

Abstract

:1. Introduction

1.1. The Challenge of Biomass Resources

1.2. Biomass Materials in Building Construction

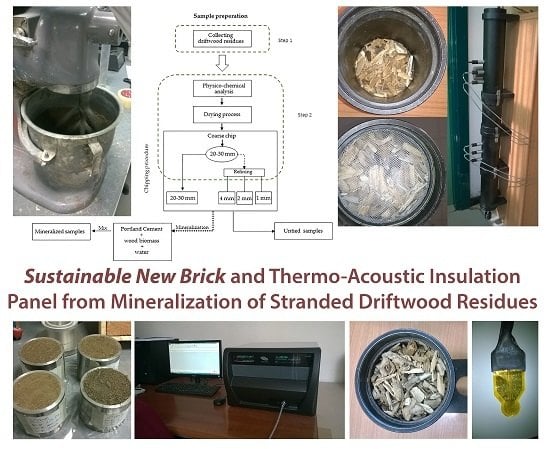

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Thermal Characterization

2.3. Acoustic Characterization

2.3.1. Absorption Coefficient

2.3.2. Transmission Loss

3. Results and Discussion

3.1. Thermal Analysis

3.2. Discussion over Thermal Results

3.3. Acoustic Analysis

3.3.1. Absorption Coefficient

3.3.2. Transmission Loss

3.4. Discussion of the Acoustic Performance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hendricks, A.M.; Wagner, J.E.; Volk, T.A.; Newman, D.H.; Brown, T.R. A cost-effective evaluation of biomass district heating in rural communities. Appl. Energy 2016, 162, 561–569. [Google Scholar] [CrossRef]

- Vilčeková, S.; Čuláková, M.; Burdová, E.K.; Katunská, J. Energy and environmental evaluation of non-transparent constructions of building envelope for wooden houses. Energies 2015, 8, 11047–11075. [Google Scholar] [CrossRef]

- Serrano, S.; de Gracia, A.; Cabeza, L.F. Adaptation of rammed earth to modern construction systems: Comparative study of thermal behavior under summer conditions. Appl. Energy 2016, 175, 180–188. [Google Scholar] [CrossRef]

- Serrano, S.; Barreneche, C.; Cabeza, L.F. Use of by-products as additives in adobe bricks: Mechanical properties characterisation. Construct. Build. Mater. 2016, 108, 105–111. [Google Scholar] [CrossRef]

- Rincón, L.; Serrano, S.; Cabeza, L.F.; González, B.; Navarro, A.; Bosch, M. Experimental rammed earth prototypes in Mediterranean climate. In Earthen Architecture: Past, Present and Future; CRC Press/Balkema: Leiden, The Netherlands, 2014; pp. 311–316. [Google Scholar]

- Huang, H.S.; Su, C.H.; Li, C.B.; Lin, C.Y.; Lin, C.C. Enhancement of fire safety of an existing green building due to natural ventilation. Energies 2016, 9, 192. [Google Scholar] [CrossRef]

- Pisello, A.L. Experimental analysis of cool traditional solar shading systems for residential buildings. Energies 2015, 8, 2197–2210. [Google Scholar] [CrossRef]

- Oldham, D.J.; Egan, C.A.; Cookson, R.D. Sustainable acoustic absorbers from the biomass. Appl. Acoust. 2011, 72, 350–363. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Nadal-Gisbert, A.V.; Crespo-Amorós, J.E.; Parres-García, F. A novel sound absorber with recycled fibers coming from end of life tires (ELTs). Appl. Acoust. 2012, 73, 402–408. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Demirhan, C. Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials. Sustain. Cities Soc. 2016, 20, 17–26. [Google Scholar] [CrossRef]

- European Parliament. Directive 2009/28/EC of the European Parliament and of the Council of the 23 April 2009 on the promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC; Official Journal of the European Union: Bruxelles, Belgium, 2009. [Google Scholar]

- Salata, F.; Coppi, M. A first approach study on the desalination of sea water using heat transformers powered by solar ponds. Appl. Energy 2014, 136, 611–618. [Google Scholar] [CrossRef]

- Cotana, F.; Cavalaglio, G.; Pisello, A.L.; Gelosia, M.; Ingles, D.; Pompili, E. Sustainable ethanol production from common reed (Phragmites australis) through simultaneuos saccharification and fermentation. Sustainability 2015, 7, 12149–12163. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; Delattin, F.; Laha, P.; Vandendael, O.; Hubin, A. Agropellets for domestic heating boilers: Standard laboratory and real life performance. Appl. Energy 2012, 90, 17–23. [Google Scholar] [CrossRef]

- Maekala, N.K.; Potumarthi, R.; Baadhe, R.R.; Gupta, V.K. Current bioenergy researches: Strengths and future challenges. In Bioenergy Research: Advances and Applications, 1st ed.; Gupta, V.J., Tuohy, M., Kubicek, C.P., Saddler, J., Xu, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–495. [Google Scholar]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Barbieri, L.; Andreola, F.; Lancellotti, I.; Taurino, R. Management of agricultural biomass wastes: Preliminary study on characterization and valorisation in clay matrix bricks. Waste Manag. 2013, 33, 2307–2315. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Rajkhowa, R.; Li, J.L.; Liu, X.Y.; Wang, X.G. Silkworm cocoon as natural material and structure for thermal insulation. Mater. Des. 2013, 49, 842–849. [Google Scholar] [CrossRef]

- Corscadden, K.W.; Biggs, J.N.; Stiles, D.K. Sheep’s wool insulation: A sustainable alternative use for a renewable resource? Resour. Conserv. Recycl. 2014, 86, 9–15. [Google Scholar] [CrossRef]

- Sgroi, F.; Di Trapani, A.M.; Foderà, M.; Testa, R.; Tudisca, S. Economic assessment of Eucalyptus (spp.) for biomass production as alternative crop in Southern Italy. Renew. Sustain. Energy Rev. 2015, 44, 614–619. [Google Scholar] [CrossRef]

- Colantoni, A.; Delfanti, L.; Recanatesi, F.; Tolli, M.; Lord, R. Land use planning for utilizing biomass residues in Tuscia Romana (central Italy): Preliminary results of a multi criteria analysis to create an agro-energy district. Land Use Policy 2016, 50, 125–133. [Google Scholar] [CrossRef] [Green Version]

- Central Intelligence Agency (CIA). Available online: https://www.cia.gov/library/publications/the-world-factbook/fields/2060.html (accessed on 20 July 2016).

- Cavalaglio, G.; Gelosia, M.; D’Antonio, S.; Nicolini, A.; Pisello, A.L.; Barbanera, M.; Cotana, M. Lignocellulosic ethanol production from the recovery of stranded driftwood residues. Energies 2016, 9. in press. [Google Scholar]

- Schiavoni, S.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Iodice, P.; Massarotti, N.; Mauro, A. Effects of inhomogeneities on heat and mass transport phenomena in thermal bridges. Energies 2016, 9, 126. [Google Scholar] [CrossRef]

- Glé, P.; Gourdon, E.; Arnaud, L. Acoustical properties of materials made of vegetable particles with several scales of porosity. Appl. Acoust. 2011, 72, 249–259. [Google Scholar] [CrossRef]

- Gutierrez, A.; Miró, L.; Gil, A.; Rodríguez-Aseguinolaza, J.; Barreneche, C.; Calvet, N.; Py, X.; Fernández, A.I.; Grágeda, M.; Ushak, S.; et al. Advances in the valorization of waste and by-product materials as thermal energy storage (TES) materials. Renew. Sustainable Energy Rev. 2016, 59, 763–783. [Google Scholar] [CrossRef]

- Pérez, G.; Coma, J.; Barreneche, C.; de Gracia, A.; Urrestarazu, M.; Burés, S.; Cabeza, L.F. Acoustic insulation capacity of Vertical Greenery Systems for buildings. Appl. Acoust. 2016, 110, 218–226. [Google Scholar] [CrossRef]

- Asdrubali, F.; Bianchi, F.; Cotana, F.; D’Alessandro, F.; Pertosa, M.; Pisello, A.L.; Schiavoni, S. Experimental thermo-acoustic characterization of innovative common reed bio-based panels for building envelope. Build. Environ. 2016, 102, 217–229. [Google Scholar] [CrossRef]

- Coatanlem, P.; Jauberthie, R.; Rendell, F. Lightweight wood chipping concrete durability. Constr. Build. Mater. 2006, 20, 776–781. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Wang, L. Properties of hemp fibre reinforced concrete composites. Compos. Part A 2006, 37, 497–505. [Google Scholar] [CrossRef]

- Almeida, R.R.; Del Menezzi, C.H.S.; Teixeira, E.D. Utilization of the coconut shell of babaçu (Orbignya sp.) to produce cement-bonded particleboard. Bioresour. Technol. 2002, 85, 159–163. [Google Scholar] [CrossRef]

- Yang, H.S.; Kim, D.J.; Kim, H.J. Rice straw-wood particle composite for soundabsorbing wooden construction materials. Bioresour. Technol. 2003, 86, 117–121. [Google Scholar] [CrossRef]

- Quiroga, A.; Marzocchi, V.; Rintoul, I. Influence of wood treatments on mechanical properties of wood-cement composites and of Populus Euroamericana wood fibers. Compos. Part B Eng. 2016, 84, 25–32. [Google Scholar] [CrossRef]

- Al Rim, K.; Ledhem, A.; Douzane, O.; Dheilly, R.M.; Queneudec, M. Influence of the proportion of wood on the thermal and mechanical performances of clay-cement-wood composites. Cem. Concr. Compos. 1999, 21, 269–276. [Google Scholar] [CrossRef]

- Taoukil, D.; el Bouardi, A.; Sick, F.; Mimet, A.; Ezbakhe, H.; Ajzoul, T. Moisture content influence on the thermal conductivity and diffusivity of wood-concrete composite. Constr. Build. Mater. 2013, 48, 104–115. [Google Scholar] [CrossRef]

- Okino, E.Y.A.; de Souza, M.R.; Santana, M.A.E.; Alves, M.V.D.S.; de Sousa, M.E.; Teixeira, D.E. Cement-bonded wood particleboard with a mixture of eucalypt and rubberwood. Cem. Concr. Compos. 2004, 26, 729–734. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Montrelay, N.; Houessou, J.; Quéneudec, M. Effect of substitution of wood shavings by barley strawson the physico-mechanical properties of lightweight sand concrete. Constr. Build. Mater. 2014, 66, 247–258. [Google Scholar] [CrossRef]

- UNI EN 15148. Solid biofuels. In Determination of the Content of Volatile Matter; Italian Standards: Rome, Italy, 2010. [Google Scholar]

- UNI EN 14775. Solid biofuels. In Determination of Ash Content; Italian Standards: Rome, Italy, 2010. [Google Scholar]

- UNI EN 15104. Solid biofuels. In Determination of Total Content of Carbon, Hydrogen and Nitrogen—Instrumental Methods; Italian Standards: Rome, Italy, 2011. [Google Scholar]

- UNI EN 14918. Solid biofuels. In Method for the Determination of Calorific Value; Italian Standards: Rome, Italy, 2010. [Google Scholar]

- ANPA. Metodi di Analisi del Compost. Manuali e Linee Guida 3/2001. ANPA-Unità Normativa Tecnica, ISDN 88-448-0258-9. Available online: http://www.isprambiente.gov.it/it/pubblicazioni/manuali-e-linee-guida/metodi-di-analisi-del-compost (accessed on 20 July 2016).

- Vo, L.T.; Navard, P. Treatments of plant biomass for cementitious building materials—A review. Construct. Build. Mater. 2016, 121, 161–176. [Google Scholar] [CrossRef]

- Zhang, H.; Li, M.J.; Fang, W.Z.; Dan, D.; Li, Z.Y.; Tao, W.Q. A numerical study on the theoretical accuracy of film thermal conductivity using transient plane source method. Appl. Therm. Eng. 2014, 72, 62–69. [Google Scholar] [CrossRef]

- Berge, A.; Adl-Zarrabi, B.; Hagentoft, C.E. Determination of specific heat capacity by transient plane source. Front. Archit. Res. 2013, 2, 476–482. [Google Scholar] [CrossRef]

- Gustavsson, M.; Karawacki, E.; Gustafsson, S.E. Thermal conductivity, thermal diffusivity and specific heat of thin samples from transient measurements with hot disk sensors. Rev. Sci. Instruct. 1994, 65, 3856. [Google Scholar] [CrossRef]

- International Organization for Standardization. Plastics—Determination of Thermal Conductivity and Diffusivity—Part 2: Transient Plane Source (Hot Disk) Method (SS-EN ISO 22007-2:2015); International Organization for Standardization (ISO): Geneva, Switzerland, 2015. [Google Scholar]

- International Organization for Standardization. Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes-Part 2: Transfer-Function Method (ISO 10534-2); International Organization for Standardization (ISO): Geneva, Switzerland, 1998. [Google Scholar]

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R.D. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

| Driftwood Samples | A | B | C | D |

|---|---|---|---|---|

|  |  |  | |

| Diameter (cm) | >4 | 1.5 < d < 4 | 0.5 < d < 1.5 | d < 0.5 |

| Mass fraction (%) | 46 | 40 | 8 | 6 |

| Moisture content (%) | 36.0 | 45.8 | 50.4 | 56.6 |

| Salinity (%) | 0.7 | 0.6 | 3.7 | 7.4 |

| Total salts content (g/kg ar) | 1.8 | 15.2 | 13.1 | 12.0 |

| Ash content (% ar) | 2.7 | 2.7 | 2.5 | 4.3 |

| Ash content (% db) | 4.2 | 5.0 | 5.0 | 10.0 |

| Volatile content (% ar) | 57.1 | 41.7 | 42.0 | 34.7 |

| Volatile content (% db) | 89.2 | 76.9 | 84.6 | 79.9 |

| Carbon content (% ar) | 30.1 | 25.3 | 23.3 | 19.1 |

| Carbon content (% db) | 47.1 | 46.6 | 47.0 | 43.9 |

| Hydrogen content (% ar) | 6.8 | 7.8 | 8.1 | 8.5 |

| Hydrogen content (% db) | 4.4 | 4.9 | 5.0 | 4.9 |

| Nitrogen content (% ar) | 0.4 | 0.7 | 0.4 | 0.4 |

| Nitrogen content (% db) | 0.7 | 1.3 | 0.8 | 1.0 |

| Higher Heating Value (MJ/kg ar) | 12.1 | 10.0 | 9.2 | 8.3 |

| Higher Heating Value (MJ/kg db) | 18.9 | 18.5 | 18.6 | 19.2 |

| Lower Heating Value (MJ/kg ar) | 11.3 | 9.0 | 8.1 | 7.0 |

| Lower Heating Value (MJ/kg db) | 18.0 | 17.5 | 17.6 | 18.2 |

| Chip Size (mm) | Weight (kg) | Moisture Mass per Weight (%) |

|---|---|---|

| <30 | 1.232 | 14.26 |

| <4 | 1.333 | 15.68 |

| <2 | 1.407 | 21.21 |

| <1 | 1.348 | 28.06 |

| Sample Name | Components | ||||||

|---|---|---|---|---|---|---|---|

| Portland Cement 4.25 | Wood Biomass | Water | |||||

| kg | % | kg | % | Chip Size (mm) | kg | % | |

| M1 sample | 0.600 | 67 | 0.150 | 17 | <4 (U4) | 0.150 | 17 |

| M2 sample | 0.600 | 67 | 0.075 | 8 | <4 (U4) | 0.150 | 17 |

| 0.0375 | 4 | <2 (U2) | |||||

| 0.0375 | 4 | <1 (U1) | |||||

| M3 sample | 0.600 | 67 | 0.150 | 17 | <30 (U30) | 0.150 | 17 |

| M4 sample | 0.600 | 55 | 0.150 | 14 | <2 (U2) | 0.350 | 32 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pisello, A.L.; Fabiani, C.; Makaremi, N.; Castaldo, V.L.; Cavalaglio, G.; Nicolini, A.; Barbanera, M.; Cotana, F. Sustainable New Brick and Thermo-Acoustic Insulation Panel from Mineralization of Stranded Driftwood Residues. Energies 2016, 9, 619. https://doi.org/10.3390/en9080619

Pisello AL, Fabiani C, Makaremi N, Castaldo VL, Cavalaglio G, Nicolini A, Barbanera M, Cotana F. Sustainable New Brick and Thermo-Acoustic Insulation Panel from Mineralization of Stranded Driftwood Residues. Energies. 2016; 9(8):619. https://doi.org/10.3390/en9080619

Chicago/Turabian StylePisello, Anna Laura, Claudia Fabiani, Nastaran Makaremi, Veronica Lucia Castaldo, Gianluca Cavalaglio, Andrea Nicolini, Marco Barbanera, and Franco Cotana. 2016. "Sustainable New Brick and Thermo-Acoustic Insulation Panel from Mineralization of Stranded Driftwood Residues" Energies 9, no. 8: 619. https://doi.org/10.3390/en9080619

APA StylePisello, A. L., Fabiani, C., Makaremi, N., Castaldo, V. L., Cavalaglio, G., Nicolini, A., Barbanera, M., & Cotana, F. (2016). Sustainable New Brick and Thermo-Acoustic Insulation Panel from Mineralization of Stranded Driftwood Residues. Energies, 9(8), 619. https://doi.org/10.3390/en9080619