A New Switching Impulse Generator Based on Transformer Boosting and Insulated Gate Bipolar Transistor Trigger Control

Abstract

:1. Introduction

2. Principle of Transformer Boosting-Based Impulse Generation

2.1. Equivalent Circuit Analysis

2.2. Numerical Calculation

2.2.1. Oscillating Switching Impulse Voltage

2.2.2. Switching Impulse Voltage

2.3. Selection and Optimization of the Circuit Parameters

2.3.1. Solving the Circuit Parameters for the Given Target Waveform Parameters

2.3.2. Impulse Waveforms Solution Using the Given Circuit Parameters

- Switching impulse voltage

- Oscillating switching impulse voltage

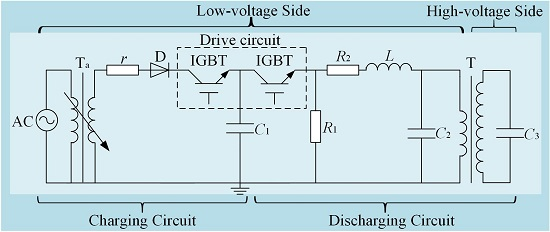

3. Loop Design of Switching Impulse Generator Based on Transformer Induction

3.1. Insulated Gate Bipolar Transistor Module and Its Drive Circuit

3.1.1. Insulated Gate Bipolar Transistor Module

3.1.2. Drive Circuit of Insulated Gate Bipolar Transistor

3.2. Design of the Main Circuit

3.2.1. Charging Circuit

3.2.2. General Circuit

4. Experimental Results

- i

- Determine the target impulse waveform parameters, such as output voltage, rise time, half peak time and oscillating frequency;

- ii

- Define the immutable parameters of the circuit component, such as charging capacitor and transformer;

- iii

- Run S-IMR diagram for parameter optimization;

- iv

- Adjust the component according to the calculated parameters;

- v

- Make a comparison between the actual output and the target impulse waveform.

4.1. Experimental Results and Analysis

4.2. Control of Impulse Magnification Ratio

4.3. Error Sources

5. Discussion

5.1. Technical Requirements in Achieving a Higher Amplitude and Larger Capacity Output Voltage

5.2. Technical Requirements in Achieving Lightning and Oscillating Lightning Impulse Voltage

- (1)

- Because the peak time of the lightning impulse voltage is much smaller than that of the SI voltage, a faster switch response speed of the IGBT module is correspondingly required.

- (2)

- The single phase transformer, which is used to generate the lightning impulse voltage, needs to withstand the impulse voltage with a much shorter rise time. Thus, the transformer must guarantee sufficient insulating strength against damage under high impulse work condition, which is a necessary technical premise to output a lightning impulse voltage without failure.

- (3)

- With regard to lightning impulse voltage with smaller peak time and half-peak time, a tighter match among the circuit parameters (including the transformer parameters) should be ensured to achieve steady and controllable output. Due to the increase of the transformer working frequency, the Γ-type (or T-type) equivalent circuit of the transformer, which is originally applied to generate an SI voltage, cannot be effectively used to analyze the loop of the lightning impulse voltage. Thus, considering the winding capacitances and stray capacitances of transformer [15], a high-frequency equivalent circuit must be utilized (Figure 16). However, this model will certainly increase the complexity of the equivalent circuit of the entire system and makes the numerical analysis theory, which provides guidance in building the actual circuit, more difficult.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Neumann, C.; Rusek, B.; Balzer, G.; Jeromin, I.; Hille, C.; Schnettler, A. End of Life Estimation and Optimisation of Maintenance of HV Switchgear and GIS Substations; A3-201; Cigre: Paris, France, 2012. [Google Scholar]

- Al-Suhaily, M.; Meijer, S.; Smit, J.J.; Sibbald, P.; Kanters, J. Analysis of diagnostic methods to prevent failure of critical GIS components. In Proceedings of the 2010 International Conference on High Voltage Engineering and Application (ICHVE), New Orleans, LA, USA, 11–14 October 2010; pp. 220–223.

- Sabot, A.; Petit, A.; Taillebois, J.P. GIS insulation co-ordination: On-site tests and dielectric diagnostic techniques. A utility point of view. IEEE Trans. Power Deliv. 1996, 11, 1309–1316. [Google Scholar] [CrossRef]

- High Voltage Test Techniques—Part 3: Definitions and Requirements for On-Site Tests; IEC 60060-3; International Electrotechnical Commission: Geneva, Switzerland, 2006.

- Ren, M.; Dong, M.; Liu, Y.; Miao, J.; Qiu, A. Partial discharges in SF6 gas filled void under standard oscillating lightning and switching impulses in uniform and non-uniform background fields. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 138–148. [Google Scholar] [CrossRef]

- Li, J.; Zhang, L.; Liang, J.; Yao, X. Partial discharge characteristics over SF6/epoxy interfaces under impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2158–2164. [Google Scholar] [CrossRef]

- Okabe, S.; Tsuboi, T.; Takami, J. Basic study of possible waveforms generated in lightning impulse withstand voltage test on UHV equipment. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1127–1133. [Google Scholar] [CrossRef]

- Rozga, P. Streamer propagation and breakdown in a very small point-insulating plate gap in mineral oil and ester liquids at positive lightning impulse voltage. Energies 2016, 9, 467. [Google Scholar] [CrossRef]

- Siew, W.; Howat, S.; Chalmers, I. Radiated interference from a high voltage impulse generator. IEEE Trans. Electromagn. Compat. 1996, 38, 600–604. [Google Scholar] [CrossRef]

- Yan, Z.; Cui, X.; Su, S. Electromechanics; Xi’an Jiaotong University Press: Xi’an, China, 2006. [Google Scholar]

- Del Vecchio, R.M.; Ahuja, R.; Frenette, R.D. Determining ideal impulse generator settings from a generator-transformer circuit model. IEEE Trans. Power Deliv. 2002, 17, 142–148. [Google Scholar] [CrossRef]

- Ling, Y.; Chen, M. Calculation Method Tutorial; Xi’an Jiaotong University Press: Xi’an, China, 2005. [Google Scholar]

- Maffezzoni, P.; Codecasa, L.; D’Amore, D. Time-domain simulation of nonlinear circuits through implicit Runge-Kutta methods. IEEE Trans. Circuits Syst. I Regul. Pap. 2007, 54, 391–400. [Google Scholar] [CrossRef]

- Suzuki, C. Two-stage Sand-Runge-Kutta methods powerful for non-linear equations with multiple solutions. In Proceedings of the 2009 Computation World: Future Computing, Service Computation, Cognitive, Adaptive, Content, Patterns, Athens, Greece, 15–20 November 2009; pp. 575–579.

- Liu, X.; Wang, Y.; Zhu, J.; Guo, Y.; Lei, G.; Liu, C. Calculation of capacitance in high-frequency transformer windings. IEEE Trans. Magn. 2016, 52. [Google Scholar] [CrossRef]

| No. | C1 (μF) | C2 (μF) | R1 (Ω) | R2 (Ω) | Lm (H) | Tp (μs) | T2 (μs) | Um (V) | IMR |

|---|---|---|---|---|---|---|---|---|---|

| (1) | 10 | 1 | 1155 | 56 | 0.9 | 250 | 2500 | 351.6 | 0.879 |

| (2) | 10 | 1 | 1155 | 56 | 0.2 | 205 | 1193 | 341.5 | 0.854 |

| (3) | 50 | 1 | 1155 | 56 | 0.9 | 298 | 4895 | 384.1 | 0.960 |

| (4) | 10 | 5 | 1155 | 56 | 0.9 | 712 | 3344 | 246.0 | 0.615 |

| (5) | 10 | 1 | 11,550 | 56 | 0.9 | 280 | 2939 | 357.1 | 0.893 |

| (6) | 10 | 1 | 1155 | 336 | 0.9 | 724 | 2079 | 286.7 | 0.717 |

| No. | C1 (μF) | C2 (μF) | R1 (Ω) | R2 (Ω) | L (mH) | Lm (H) | Tp (μs) | T2 (μs) | f (Hz) | Um (V) | IMR |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (1) | 3 | 0.22 | 2.23k | 33 | 1.2 | 1.3 | 50 | 1000 | 10k | 555.0 | 1.388 |

| (2) | 3 | 0.22 | 2.23k | 33 | 4.9 | 1.3 | 100 | 855 | 5.0k | 631.4 | 1.579 |

| (3) | 10 | 0.22 | 2.23k | 33 | 1.2 | 1.3 | 52 | 1966 | 9.6k | 582.1 | 1.455 |

| (4) | 3 | 1.12 | 2.23k | 33 | 1.2 | 1.3 | 108 | 1660 | 4.6k | 353.2 | 0.883 |

| (5) | 3 | 0.22 | 2.23k | 33 | 1.2 | 0.5 | 50 | 684 | 10k | 555.0 | 1.388 |

| (6) | 3 | 0.22 | 22k | 33 | 1.2 | 1.3 | 50 | 1356 | 10k | 558.0 | 1.395 |

| (7) | 3 | 0.22 | 1M | 33 | 1.2 | 1.3 | 50 | 1405 | 10k | 558.2 | 1.396 |

| (8) | 3 | 0.22 | 1k | 33 | 1.2 | 1.3 | 50 | 701 | 10k | 553.5 | 1.384 |

| (9) | 3 | 0.22 | 2.23k | 25 | 1.2 | 1.3 | 50 | 865 | 10k | 591.3 | 1.478 |

| (10) | 3 | 0.22 | 2.23k | 120 | 1.2 | 1.3 | 77 | 1520 | - | 375.6 | 0.939 |

| (11) | 3 | 0.22 | 2.23k | 180 | 1.2 | 1.3 | 157 | 1492 | - | 359.8 | 0.900 |

| Subfigure No. | Circuit Parameters | Charging Voltage | Peak Time | Half-Peak Time | Output Voltage Amplitude | Output Efficiency | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L (mH) | C1 (μF) | C2 (μF) | C3 (pF) | R1 (Ω) | R2 (Ω) | UC1 (V) | Tp (μs) | TP’ (μs) | ep (%) | T2 (μs) | T2’ (μs) | e2 (%) | Um (kV) | Um’ (kV) | em (%) | IMR | |

| 15a | 1.55 | 10 | 1 | 500 | 1300 | 56 | 160 | 1532 | 1549 | −1.1 | 6188 | 6272 | −1.3 | 8.4 | 8.67 | −3.1 | 52.5 |

| 15b | 1.55 | 10 | 0 | 500 | 300 | 10 | 170 | 356 | 359 | −0.84 | 3224 | 3442 | −6.3 | 12.0 | 12.58 | −4.6 | 70.6 |

| 15c | 1.55 | 4.7 | 0 | 500 | 130 | 25 | 200 | 310 | 315 | −1.6 | 2782 | 2706 | 2.8 | 8.16 | 8.4 | −2.9 | 40.8 |

| 15d | 1.55 | 4.7 | 0 | 500 | 1000 | 4 | 190 | 250 | 251 | −0.40 | 2395 | 2391 | 0.18 | 9.84 | 10.5 | −6.3 | 51.8 |

| 15e | 2.9 | 6.8 | 0 | 500 | 100,000 | 4 | 200 | 396 | 401 | −1.2 | 3500 | 3657 | −4.3 | 15.0 | 15.7 | −4.5 | 75 |

| 15f | 4.02 | 6.8 | 0 | 500 | 1000 | 4 | 200 | 471 | 470 | −0.21 | 3300 | 3402 | −3.0 | 14.8 | 15.6 | −5.1 | 74 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, M.; Zhang, C.; Dong, M.; Ye, R.; Albarracín, R. A New Switching Impulse Generator Based on Transformer Boosting and Insulated Gate Bipolar Transistor Trigger Control. Energies 2016, 9, 644. https://doi.org/10.3390/en9080644

Ren M, Zhang C, Dong M, Ye R, Albarracín R. A New Switching Impulse Generator Based on Transformer Boosting and Insulated Gate Bipolar Transistor Trigger Control. Energies. 2016; 9(8):644. https://doi.org/10.3390/en9080644

Chicago/Turabian StyleRen, Ming, Chongxing Zhang, Ming Dong, Rixin Ye, and Ricardo Albarracín. 2016. "A New Switching Impulse Generator Based on Transformer Boosting and Insulated Gate Bipolar Transistor Trigger Control" Energies 9, no. 8: 644. https://doi.org/10.3390/en9080644

APA StyleRen, M., Zhang, C., Dong, M., Ye, R., & Albarracín, R. (2016). A New Switching Impulse Generator Based on Transformer Boosting and Insulated Gate Bipolar Transistor Trigger Control. Energies, 9(8), 644. https://doi.org/10.3390/en9080644