The Hidden Burden of Food Waste: The Double Energy Waste in Italy

Abstract

:1. Introduction

2. Materials and Methods

- -

- Assessment of the total direct and indirect energy inputs in the different segments of the FSC;

- -

- Calculation of the embodied energy per unit of mass in Italian food;

- -

- Quantification of the extra energy input for animal-derived food;

- -

- Final estimation of the energy embodied in FLW in FSC segments.

- -

- energy intensity of chemicals and plastics since these products are similar across countries, therefore differences are negligible;

- -

- energy intensity of transport, since differences are not relevant across countries.

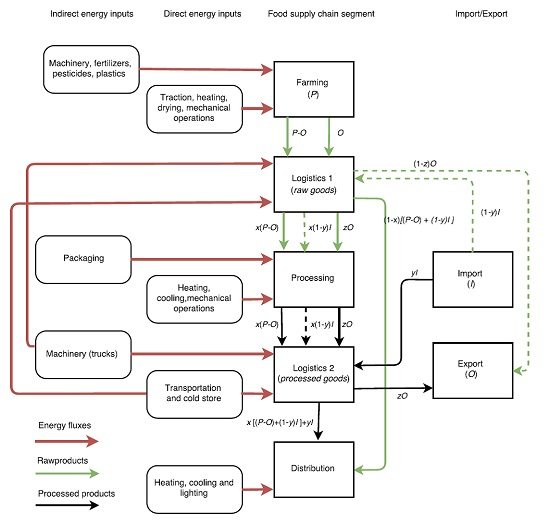

2.1. Assessment of Energy Inputs of the FSC

2.1.1. Farming

- (i)

- Direct energy use data for farming operations (fuel for traction, irrigation, heating, drying, electrical energy for mechanical operations and lighting) were obtained from the Italian national energy balance [35] split by fuel type. Direct use of fuel for fisheries was also considered.

- (ii)

- The energy equivalent of machinery was estimated in approximately 140 MJ for every kg of equipment [36,37]. This value is quite high, as it accounts not only for production (around 80 MJ/kg), but also for maintenance and repair. This figure has been substantially confirmed by a more recent analysis on tractors and relative equipment [38]. The number of new tractors entered in use in Italy for the years 2000–2014 was retrieved from the professional association [39]. A mass/power ratio of 60 kg/kW was considered [40], while the average power is roughly 90 kW (average over 26,000 tractors on sale in June 2014 on the site www.agriaffaires.it (accessed on 21 January 2016); the average tractor mass was therefore assumed to be 5.4 t, and the average energy input per tractor is 745.8 GJ.

- (iii)

- Data for nitrogen (N), phosphate (P) and potash (K) fertilizers use in Italian agriculture were sourced from national and international databases [41,42]. Average specific energy inputs for fertilizers are assumed to be 49 MJ/kg for urea, 42 for ammonium sulfate, 13 for simple perphosphate and 19 for triple perphosphate [43], 40.6 MJ/kg for ammonium nitrate [44], 5 MJ/kg for potassium sulfate and chloride, 18 and 31 MJ/kg for NP and PK fertilizers, respectively [45], 6 and 7 MJ/kg for NK and NPK fertilizers, respectively [46,47]. Data for pesticides use were obtained from FAO [48], while average specific energy inputs are assumed to be 310 MJ/kg for herbicides and insecticides and 220 MJ/kg for fungicides [49,50,51,52,53].

- (iv)

- The use of plastic material in agriculture (tunnels, mulching, nets, piping and containers) was documented by Scarascia-Mugnozza et al. [54]. Input energy for plastics production at farm level was assumed to be 79 MJ/kg, as an average of the most used polymers in agriculture: polyethylene [55] and polypropylene [56].

2.1.2. Food Processing and Packaging

2.1.3. Transport Logistics

2.1.4. Distribution

2.2. Energy Embodied in Food

- -

- Processed feed, Feproc-j, that is approximately 70% of feed used in the human FSC FEA (see Figure A2).

- -

- Processed exports zjOj.

- -

- Process quote xj of the net production for direct human consumption (that is production minus exports and national feed).

- -

- Process quote xj of imported food for direct human consumption that was not already processed abroad (1 − yj) (Ij − FeA-I,j).

2.3. Vegetal and Animal Products

2.4. Nutritional and Embodied Energy in Food Waste

3. Results

3.1. Total Energy Use in the FSC

3.2. The Double Energy Waste

3.3. Sensitivity Analysis

3.3.1. Farming

3.3.2. Processing

3.3.3. Logistics

3.3.4. Distribution

4. Policy Implications

5. Conclusions

Author Contributions

Conflicts of Interest

Appendix

| Energy Vector | LHV (MJ/kg) | Refinery Efficiency (η) | Equivalence Factor for Gross Energy (1/η) |

|---|---|---|---|

| Fuel oil | 41.3 | 92.6% | 1.08 |

| Diesel fuel | 42.6 | ||

| LPG | 46.0 | ||

| Natural gas | 34.3 | 98.5% | 1.01 |

| Coal | 30.9 | 95.7% | 1.04 |

| Material | Percentage Use for Food A | Energy Input (MJ/kg) |

|---|---|---|

| Paper | 53.0% | 8.08 B |

| Glass | 89.8% | 15.61 C |

| Aluminum | 76.9% | 155 D |

| Steel | 25% | 25.2 E |

| Wood | 15% | 44 F |

| Plastics (weighted average) | 73.7% | 77.44 G |

| j | Product Type | Food Mass Waste (Mt) | |||

|---|---|---|---|---|---|

| Farming | Processing | Distribution | Total | ||

| Wfarm | Wproc | Wdist | |||

| 1 | Cereals | 1.15 | 1.55 | 0.19 | 2.89 |

| 2 | Tubers | 0.53 | 0.06 | 0.16 | 0.76 |

| 3 | Pulses | 0.02 | 0.01 | 0.00 | 0.03 |

| 4 | Soybeans | 0.07 | 0.01 | 0.00 | 0.08 |

| 5 | Oilseed | 0.43 | 0.17 | 0.04 | 0.64 |

| 6 | Sugar crops | 0.24 | 0.00 | 0.04 | 0.28 |

| 7 | Vegetables | 5.29 | 0.05 | 0.86 | 6.20 |

| 8 | Fruits | 4.29 | 0.13 | 0.88 | 5.30 |

| 9 | Wine. beer | 0.00 | 0.06 | 0.00 | 0.06 |

| 10 | Meat | 0.20 | 0.27 | 0.25 | 0.71 |

| 11 | Milk | 0.46 | 0.13 | 0.08 | 0.67 |

| 12 | Eggs | 0.03 | 0.00 | 0.01 | 0.05 |

| 13 | Fish | 0.04 | 0.03 | 0.14 | 0.21 |

| Total | 12.75 | 2.47 | 2.64 | 17.87 | |

| j | Product Type | Food Energy Waste (PJ) | Embodied Energy Waste (PJ) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Farming | Processing | Distribution | Total | Farming | Processing | Distribution | Total | ||

| 1 | Cereals | 12.68 | 17.08 | 2.08 | 31.85 | 3.77 | 15.82 | 2.04 | 21.63 |

| 2 | Tubers | 1.40 | 0.17 | 0.43 | 2.00 | 1.74 | 0.64 | 1.05 | 3.43 |

| 3 | Pulses | 0.25 | 0.11 | 0.04 | 0.41 | 0.06 | 0.08 | 0.03 | 0.17 |

| 4 | Soybeans | 0.99 | 0.21 | 0.00 | 1.19 | 0.22 | 0.15 | 0.00 | 0.37 |

| 5 | Oilseed | 2.94 | 1.18 | 0.24 | 4.37 | 1.42 | 1.77 | 0.39 | 3.57 |

| 6 | Sugar crops | 3.53 | 0.00 | 0.63 | 4.16 | 0.78 | 0.00 | 0.48 | 1.26 |

| 7 | Fruits | 7.54 | 0.24 | 1.54 | 9.32 | 14.07 | 1.37 | 6.20 | 21.65 |

| 8 | Vegetables | 5.14 | 0.05 | 0.83 | 6.02 | 17.38 | 0.55 | 5.14 | 23.08 |

| 9 | Wine, beer | 0.00 | 0.15 | 0.00 | 0.15 | 0.00 | 0.58 | 0.00 | 0.58 |

| 10 | Meat | 1.36 | 1.78 | 1.65 | 4.79 | 2.19 | 4.71 | 4.60 | 11.50 |

| 11 | Milk | 0.78 | 0.22 | 0.13 | 1.13 | 4.99 | 2.30 | 1.48 | 8.78 |

| 12 | Eggs | 0.20 | 0.01 | 0.09 | 0.29 | 0.34 | 0.02 | 0.21 | 0.57 |

| 13 | Fish | 0.25 | 0.15 | 0.82 | 1.21 | 0.45 | 0.45 | 2.59 | 3.49 |

| Total | 37.04 | 21.35 | 8.49 | 66.89 | 47.42 | 28.43 | 24.21 | 100.07 | |

References

- Georgescu-Roegen, N. The Entropy Law and the Economic Process; Harvard University: Cambridge, MA, USA, 1971. [Google Scholar]

- Meadows, D.H.; Meadows, D.L.; Randers, J.; Behrens, W.W. The Limits to Growth. A Report for the Club of Rome’s Project on the Predicament of Mankind; Universe Books: Washington, DC, USA, 1972. [Google Scholar]

- Pieterse, J.N. Development Theory, Handbook of Research on Educational Communications and Technology; Sage Publications: London, UK, 2010. [Google Scholar]

- Crutzen, P. Geology of mankind. Nature 2002, 415. [Google Scholar] [CrossRef] [PubMed]

- McGlade, C.; Ekins, P. The geographical distribution of fossil fuels unused when limiting global warming to 2 °C. Nature 2015, 517, 187–190. [Google Scholar] [CrossRef] [PubMed]

- McMichael, A.J.; Powles, J.W.; Butler, C.D.; Uauy, R. Food, livestock production, energy, climate change, and health. Lancet 2007, 370, 1253–1263. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; de Vries, W.; de Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347. [Google Scholar] [CrossRef] [PubMed]

- Tilman, D.; Cassman, K.G.; Matson, P.A.; Naylor, R.; Polasky, S. Agricultural sustainability and intensive production practices. Nature 2002, 418, 671–677. [Google Scholar] [CrossRef] [PubMed]

- Dorward, A. Agricultural labour productivity, food prices and sustainable development impacts and indicators. Food Policy 2013, 39, 40–50. [Google Scholar] [CrossRef]

- Khan, S.; Hanjra, M.A. Footprints of water and energy inputs in food production—Global perspectives. Food Policy 2009, 34, 130–140. [Google Scholar] [CrossRef]

- Pimentel, D.; Pimentel, M.H. Food, Energy and Society, 3rd ed.; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2008. [Google Scholar]

- IEA (International Energy Agency). IEA Sankey Diagram World Final Consumption. 2013. Available online: http://www.iea.org/Sankey/index.html#?c=World&s=Final consumption (accessed on 12 May 2016).

- Cuéllar, A.D.; Webber, M.E. Wasted food, wasted energy: The embedded energy in food waste in the United States. Environ. Sci. Technol. 2010, 44, 6464–6469. [Google Scholar] [CrossRef] [PubMed]

- Hendrickson, J. Energy Use in the US Food System: A Summary of Existing Research and Analysis; Center for Integrated Agricultural Systems, University of Wisconsin, 2008. Available online: http://www.cias.wisc.edu/wp-content/uploads/2008/07/energyuse.pdf (accessed on 12 May 2016).

- Steinfeld, H.; Gerber, P. Livestock’s Long Shadow. Environmental Issues and Options; Food and Agricultural Organization: Rome, Italy, 2006. [Google Scholar]

- Smith, P.; Bustamante, M.; Ahammad, H.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; et al. Agriculture, Forestry and Other Land Use (AFOLU). In Climate Change 2014: Mitigation of Climate Change; Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014; Available online: https://www.ipcc.ch/pdf/assessment-report/ar5/wg3/ipcc_wg3_ar5_full.pdf (accessed on 12 May 2016).

- Strazza, C.; Magrassi, F.; Gallo, M.; Del Borghi, A. Life Cycle Assessment from food to food: A case study of circular economy from cruise ships to aquaculture. Sustain. Prod. Consum. 2015, 2, 40–51. [Google Scholar] [CrossRef]

- Khoo, H.H.; Lim, T.Z.; Tan, R.B.H. Food waste conversion options in Singapore: Environmental impacts based on an LCA perspective. Sci. Total Environ. 2010, 408, 1367–1373. [Google Scholar] [CrossRef] [PubMed]

- Eshel, G.; Martin, P. Diet, energy, and global warming. Earth Interact. 2006, 10. [Google Scholar] [CrossRef]

- Mitchell, D. A Note on Rising Food Prices. 2008. World Bank Policy Research Working Paper Series, 2008. Available online: http://ssrn.com/abstract=1233058 (accessed on 12 May 2016).

- Trostle, R. Global Agricultural Supply and Demand: Factors Contributing to the Recent Increase in Food Commodity Prices; ERS USDA WRS-0801. Available online: http://www.ers.usda.gov/media/218027/wrs0801_1_.pdf (accessed on 12 May 2016).

- Heinberg, R.; Bomford, M. The Food & Farming Transition: Toward a Post-Carbon Food System; Post Carbon Institute: Sebastopol, CA, USA, 2009. [Google Scholar]

- Bush, R. Food riots: Poverty, power and protest. J. Agrar. Chang. 2010, 10, 119–129. [Google Scholar] [CrossRef]

- FAO. The State of Food and Agriculture, 2008; Food and Agriculture Organization: Rome, Italy, 2008. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste. Extent, Causes and Prevention; Food and Agriculture Organization: Rome, Italy, 2011. [Google Scholar]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. Lond. Ser. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [PubMed]

- Il Libro Nero dello Spreco in Italia: Il Cibo; Segrè, A.; Falasconi, L. (Eds.) Edizioni Ambiente: Milano, Italy, 2011.

- Stenmarck, A.; Jensen, C.; Quested, T.; Moates, G. Estimates of European Food Waste Levels; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2016; FUSIONS project; ISBN 978-91-88319-01-2. [Google Scholar]

- Kummu, M.; de Moel, H.; Porkka, M.; Siebert, S.; Varis, O.; Ward, P.J. Lost food, wasted resources: Global food supply chain losses and their impacts on freshwater, cropland, and fertilizer use. Sci. Total Environ. 2012, 438, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Buzby, J.C.; Hyman, J. Total and per capita value of food loss in the United States. Food Policy 2012, 37, 561–570. [Google Scholar] [CrossRef]

- Il Libro Verde dello Spreco in Italia: L’Energia; Segrè, A.; Vittuari, M. (Eds.) Edizioni Ambiente: Milano, Italy, 2012.

- Song, G.; Li, M.; Semakula, H.M.; Zhang, S. Food consumption and waste and the embedded carbon, water and ecological footprints of households in China. Sci. Total Environ. 2015, 529, 191–197. [Google Scholar] [CrossRef] [PubMed]

- Grizzetti, B.; Pretato, U.; Lassaletta, L.; Billen, G.; Garnier, J. The contribution of food waste to global and European nitrogen pollution. Environ. Sci. Policy 2013, 33, 186–195. [Google Scholar] [CrossRef]

- Campiotti, C.; Viola, C.; Scoccianti, M.; Giagnacovo, G.; Lucerti, G.; Alonzo, G. Le Filiere del Sistema Agricolo per l’Energia e l’Efficienza Energetica. Report RT/2011/11/ENEA Rome. 2011. Available online: http://titano.sede.enea.it/Stampa/Files/ cs2011/rapportotecnicocampiotti.pdf (accessed on 12 May 2016).

- MSE—Ministero dello Sviluppo Economico, Dipartimento per l’Energia. Bilancio Energetico Nazionale, Years from 2000 to 2014. Available online: http://dgerm.sviluppoeconomico.gov.it/dgerm/ben.asp (accessed on 12 May 2016).

- Giampietro, M. Energy use in agriculture. In Encyclopedia of Life Sciences; 2003; Available online: http://onlinelibrary.wiley.com/doi/10.1038/npg.els.0003294/full (accessed on 12 May 2016). [CrossRef]

- Stout, B.A. Handbook of Energy for World Agriculture; Elsevier: New York, NY, USA, 1991. [Google Scholar]

- Mikkola, H.J.; Ahokas, J. Indirect energy input of agricultural machinery in bioenergy production. Renew. Energy 2010, 35, 23–28. [Google Scholar] [CrossRef]

- Federunacoma (Federazione Nazionale Costruttori Macchine per l’Agricoltura). Documenti e Dati Statistici. Immatricolazioni. 2014. Available online: http://www.federunacoma.it/it/informati/ind_immatricolazioni.php (accessed on 12 May 2016).

- Lazzari, M. MaccAgri.soft. Database di Macchine Agricole con Software per il Calcolo dei Costi di Esercizio, Dip. Scienze e Tecnologie Veterinarie, Univ Milano. 2010. Available online: http://slideplayer.it/slide/571349/ (accessed on 12 May 2016).

- FAOSTAT. Resources, Fertilizers. 2016. Available online: http://faostat3.fao.org/faostat-gateway/go/to/download/R/RF/E (accessed on 12 May 2016).

- ISTAT (Istituto Centrale di Statistica). Fertilizzanti. 2013. Available online: http://www.istat.it/it/archivio/fertilizzanti (accessed on 12 May 2016).

- Williams, A.G.; Audsley, E.; Sandars, D.L. Determining the Environmental Burdens and Resource Use in the Production of Agricultural and Horticultural Commodities; Main Report; Defra Research Project IS0205; Cranfield University and Defra: Bedford, UK, 2006. [Google Scholar]

- Mortimer, N.D.; Cormack, P.; Elsayed, M.A.; Horne, R.E. Evaluation of the Comparative Energy, Global Warming and Socio-Economic Costs and Benefits of Biodiesel; Final Report for the Department for Environment, Food and Rural Affairs, Contract Reference (CSA 5982/NF0422, 20/1); Defra: London, UK, 2003. [Google Scholar]

- Ramirez, C.A.; Worrel, E. Feeding fossil fuels to the soil: An analysis of energy embedded and technological learning in the fertilizer industry. Resour. Conserv. Recycl. 2006, 46, 75–93. [Google Scholar] [CrossRef]

- Kool, A.; Marinussen, M.; Blonk, H. LCI Data for the Calculation Tool Feedprint for Greenhouse Gas Emissions of Feed Production and Utilization, Blonk Consultants. 2012. Available online: http://blonkconsultants.nl/upload/pdf/PDV%20rapporten/fertilizer_production%20D03.pdf (accessed on 12 May 2016).

- Hasler, K.; Broring, S.; Omta, S.W.F.; Olfs, H.W. Life cycle assessment (LCA) of different fertilizer product types. Eur. J. Agron. 2015, 69, 41–51. [Google Scholar] [CrossRef]

- FAOSTAT. Resources, Pesticides. 2016. Available online: http://faostat3.fao.org/faostat-gateway/go/to/download/R/RP/E (accessed on 12 May 2016).

- Helsel, Z.R. Energy and Alternatives for Fertilizers and Pesticide Use. In Energy in Farm Production; Fluck, R.C., Ed.; Energy in World Agriculture; Elsevier: Amsterdam, The Netherlands, 1992. [Google Scholar]

- Helsel, Z.R. Energy in Pesticide Production and Use. In Encyclopedia of Pest Management; Taylor & Francis: London, UK, 2006; pp. 1–4. [Google Scholar]

- Green, M.B. Energy in pesticide manufacture, distribution, and use. In Energy in Plant Nutrition and Pest Control, Energy in World Agriculture; Helsel, Z.R., Ed.; Elsevier: Amsterdam, The Netherlands, 1987; Volume 2, pp. 165–177. [Google Scholar]

- West, T.O.; Marland, G. A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- Audsley, E.; Stacey, K.; Parsons, D.J.; Williams, A.G. Estimation of the Greenhouse Gas Emissions from Agricultural Pesticide Manufacture and Use. Cranfield University. 2009. Available online: https://dspace.lib.cranfield.ac.uk/bitstream/1826/3913/1/Estimation_of_the_greenhouse_gas_emissions_ from_agricultural_pesticide_manufacture_and_use-2009.pdf (accessed on 12 May 2016).

- Scarascia-Mugnozza, G.; Sica, C.; Russo, G. Plastics materials in European agriculture: Actual use and prespectives. J. Agric. Eng. 2011, 3, 15–28. [Google Scholar] [CrossRef]

- Plastics Europe. Environmental Product Declaration of the European Plastics Manufacturers. High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE). 2014. Available online: http://www.plasticseurope.org/plasticssustainability/eco-profiles/browse-by-list.aspx (accessed on 12 May 2016).

- Plastics Europe. Environmental Product Declaration of the European Plastics Manufacturers. Polypropylene (PP). 2014. Available online: http://www.plasticseurope.org/plasticssustainability/eco-profiles/browse-by-list.aspx (accessed on 12 May 2016).

- Iascone, B.; Iascone, P.; Aldrigo, D. Imballaggio in Cifre 2011. Consuntivo Generale 2010 dell’Industria Italiana dell’Imballaggio. Istituto Italiano di Imballaggio. 2011. Available online: http://nicolebattilani.altervista.org/alterpages/files/ImballaggioinCifre2011.pdf (accessed on 12 May 2016).

- Istituto Italiano di Imballaggio. L’Industria Italiana dell’Imballaggio. 2013. Available online: http://www.istitutoimballaggio.it/wp-content/uploads/2011/10/Generale-20131.pdf (accessed on 12 May 2016).

- Eurostat. Packaging Waste Statistics. 2013. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Packaging_waste_statistics (accessed on 12 May 2016).

- Eurostat. Annual Road Freight Transport by Distance Class with Breakdown by Type of Goods (1 000 t, Mio Tkm, Mio Veh-km, 1 000 BTO), until 2007. Available online: http://appsso.eurostat.ec.europa.eu/nui/ show.do?dataset=road_go_ta7dctg&lang=en (accessed on 12 May 2016).

- Eurostat. Annual Road Freight Transport by Distance Class with Breakdown by Type of Goods (1 000 t, Mio Tkm, Mio Veh-km, 1 000 BTO), from 2008 Onwards. 2012. Available online: http://appsso.eurostat.ec.europa.eu/nui/ show.do?dataset=road_go_ta_dctg&lang=en (accessed on 12 May 2016).

- Schipper, L.; Scholl, L.; Price, L. Energy use and carbon emissions from freight in 10 industrialized countries: An analysis of trends from 1973 to 1992. Transp. Res. Part D 1997, 2, 55–76. [Google Scholar] [CrossRef]

- Weber, C.L.; Matthews, H.S. Food-miles and the relative climate impacts of food choices in the United States. Environ. Sci. Technol. 2008, 42, 3508–3513. [Google Scholar] [CrossRef] [PubMed]

- Kamakaté, F.; Schipper, L. Trends in truck freight energy use and carbon emissions in selected OECD countries from 1973 to 2005. Energy Policy 2009, 37, 3743–3751. [Google Scholar] [CrossRef]

- IEA, International Energy Agency. Transport, Energy and CO2. Moving towards Sustainability. 2009. Available online: https://www.iea.org/publications/freepublications/publication/transport2009.pdf (accessed on 12 May 2016).

- Spritmonitor.de. MPG and Cost Calculator and Tracker. 2016. Available online: http://www.spritmonitor.de/en/ (accessed on 21 January 2016).

- Department of Transport. Road Freight Statistics, Table RFS0118. Empty Running by Business Type; 2014. Available online: https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/479164/rfs0118.xls (accessed on 12 May 2016).

- ISTAT (Istituto Centrale di Statistica). Trasporto Marittimo, Anni 2005–2013. 2014. Available online: http://www.istat.it/it/archivio/140422 (accessed on 12 May 2016).

- Kristensen, H.O. Cargo Transport by sea and Road—Technical and Economical Environmental Factors. Nav. Eng. J. 2006, 118, 115–129. [Google Scholar] [CrossRef]

- ISL (Institute for Shipping economics and logistics). Shipping Statistics and Market Review; ISL: Bremen, Germany, 2012; Volume 56, No 4. [Google Scholar]

- Magelli, A. Gd alimentare, alta variabilità di quote per regioni e province. 2011. Available online: http://multimedia.b2b24.it/Flipit/gdo_gdo_1112211938/megazine/images/9.swf (accessed on 12 May 2016).

- Santi, E.; Elia, S. Caratterizzazione dei Consumi Energetici Nazionali delle Strutture ad uso Grande Distribuzione Commerciale. ENEA Report RdS/2010. September 2010. Available online: http://www.enea.it/it/Ricerca_sviluppo/documenti/ricerca-di-sistema-elettrico/fabbisogni-consumi-energetici/12-die-sintesi.pdf (accessed on 12 May 2016).

- FAOSTAT. Food Balance. Commodity Balances—Crops Primary Equivalent. 2016. Available online: http://faostat3.fao.org/faostat-gateway/go/to/download/FB/BC/E (accessed on 12 May 2016).

- FAOSTAT. Food Balance. Commodity Balances—Livestock and Fish Primary Equivalent. 2016. Available online: http://faostat3.fao.org/faostat-gateway/go/to/download/FB/BL/E (accessed on 12 May 2016).

- ASSALCO. Associazione Nazionale Imprese per l’Alimentazione e la Cura degli Animali da Compagnia. Rapporto ASSALCO-ZOOMARK 2015 Alimentazione e Cura Degli Animali da Compagnia. Available online: http://www.assalco.it/index.php?action= shownews&id=1&nid=5704 (accessed on 12 May 2016).

- FAOSTAT. Production. 2016. Available online: http://faostat.fao.org/site/368/default.aspx (accessed on 12 May 2016).

- ASSALZOO. Associazione Nazionale Produttori Alimenti Zootecnici. Annuario 2015. Available online: http://www.assalzoo.it/source/annuario/ANNUARIO_2015.pdf (accessed on 12 May 2016).

- FAOSTAT. Trade. 2016. Available online: http://faostat3.fao.org/download/T/TP/E (accessed on 12 May 2016).

- FIGIS. Food and Agriculture Organization. Fisheries and Aquaculture Department. Fishery Commodity and Trade. 2016. Available online: http://www.fao.org/fishery/statistics/global-commodities-production/en (accessed on 12 May 2016).

- MPAAF (Ministero delle Politiche Agricole Alimentari e Forestali). Piano di Settore per la Filiera Pataticola. 2012. Available online: http://www.politicheagricole.it/flex/cm/pages/ServeAttachment.php/L/IT/D/a%252F3%252Fe%252FD.520b1e381283cead7d34/P/BLOB%3AID%3D5144 (accessed on 12 May 2016).

- ISMEA (Istituto di Servizi per il Mercato Agricolo e Alimentare). Acquisti Domestici: Ortaggi trasformati. N.10. 2000-2004. 2006. Available online: http://www.ismea.it (accessed on 12 May 2016).

- ISMEA (Istituto di Servizi per il Mercato Agricolo e Alimentare). Acquisti Domestici: Ortaggi Freschi. N.11. 2000-2004. 2006. Available online: http://www.ismea.it (accessed on 12 May 2016).

- ISMEA (Istituto di Servizi per il Mercato Agricolo e Alimentare). Il Mercato dell’Ortofrutta. Tendenze e Prospettive. 2006. Available online: http://www.ismea.it (accessed on 12 May 2016).

- AIJN. Liquid Fruit Market Report 2014; European Fruit Juice Association: Brussels, Belgium, 2014. Available online: http://viewer.zmags.com/publication/b1ade2b9 (accessed on 12 May 2016).

- Unaitalia. Le Uova da Consumo Anno 2012. Available online: http://www.unaitalia.com/it-it/ilmercato/datiannuali.aspx (accessed on 12 May 2016).

- FAOSTAT. Food Balance Sheets. 2016. Available online: http://faostat3.fao.org/download/Q/QL/E (accessed on 12 May 2016).

- Federdistribuzione. La Distribuzione in Italia, La Rete di Vendita della Distribuzione Moderna nelle Regioni italiane. 2012. Available online: http://www.federdistribuzione.it/lamappa_distributiva.php (accessed on 12 May 2016).

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Emanuelsson, A. The Methodology of the FAO Study: Global Food Losses and Food Waste—Extent Causes and Prevention—FAO 2011; SIK Report; No. 587, January 2013; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- Smith, J.A.; Yonts, C.D.; Palm, K.L. Filed loss from sugar beet harvest operations. Appl. Eng. Agric. 1999, 15, 627–631. [Google Scholar] [CrossRef]

- Huijbregts, T.; Legrand, G.; Hoffman, C.; Olsson, R.; Olsson, Å. Long-Term Storage of Sugar Beet in North-West Europe. Coordination Beet Research International. Report Np. 1-2013. 2013. Available online: http://www.nordicbeet.nu/public_site/webroot/cache/media/file/COBRI_Storage_Report_12013small.pdf (accessed on 12 May 2016).

- IGD. Case Study: Tesco and Silver Spoon-Sugar Waste. IGD: City, Country, 2012. Available online: http://www.igd.com/Research/Supply-chain/Waste-prevention/Six-to-fix-to-prevent-waste/Process/Tesco-and-Silver-Spoon---Sugar-waste/ (accessed on 12 May 2016).

- Castellucci, F.; Iasiello, B.; Magalhaes, V.; Aigrain, P. OIV Vine and Wine Outlook 2008–2009, World Viticultural Statistics. 2013. Available online: http://www.oiv.int/public/medias/2778/oivstatistiques2008-2009.pdf (accessed on 12 May 2016).

- Hamilton, J.D. Causes and consequences of the oil shock of 2007–2008. In Brooking Papers on Economic Activity. Spring 2009; pp. 215–259. Available online: http://www.brookings.edu/ (accessed on 12 May 2016).

- Sanfilippo, S.; Ruggeri, B. LCA Alimentazione: Stima del consumo energetico per la produzione, il trasporto e la preparazione del cibo in Italia. Riv. Sci. dell’Aliment. 2009, 38, 1–16. [Google Scholar]

- WARM, “Waste Reduction Model”. U.S. Environmental Protection Agency. June 2014. Available online: http://epa.gov/epawaste/conserve/tools/warm/pdfs/Energy_Impacts.pdf (accessed on 12 May 2016).

- Coley, D.A.; Goodliffe, E.; Macdiarmid, J. The embodied energy of food: The role of diet. Energy Policy 1998, 26, 455–459. [Google Scholar]

- Carlsson-Kanyama, A. Climate change and dietary choices—How can emissions of greenhouse gases from food consumption be reduced? Food Policy 1998, 23, 277–293. [Google Scholar] [CrossRef]

- Environdec. Environmental Product Declaration of Various Italian Food Products. 2008–2014. Available online: http://www.environdec.com (accessed on 21 January 2016).

- Del Borghi, A.; Gallo, M.; Strazza, C.; Del Borghi, M. An evaluation of environmental sustainability in the food industry through Life Cycle Assessment: The case study of tomato products supply chain. J. Clean. Pord. 2014, 78, 121–130. [Google Scholar] [CrossRef]

- Pagani, M.; Vittuari, M.; Johnson, T.J.; De Menna, F. An assessment of the energy footprint of dairy farms in Missouri and Emilia-Romagna. Agric. Syst. 2016, 145, 116–126. [Google Scholar] [CrossRef]

- Pagani, M.; Vittuari, M.; Falasconi, L. Does packaging matter? Energy consumption of pre-packed salads. Br. Food J. 2015, 117, 1961–1980. [Google Scholar] [CrossRef]

- ISTAT (Istituto Centrale di Statistica). Energia Elettrica da Fonti Rinnovabili 2011. 2015. Available online: http://dati.istat.it/Index.aspx?DataSetCode=DCCV_PRODENERG&Lang= (accessed on 12 May 2016).

- FEFCO. European Database for Corrugated Board Life Cycle Studies. Cepi Container Board. 2012. Available online: http://www.fefco.org/sites/default/files/documents/LCA%20report%202012_0.pdf (accessed on 12 May 2016).

- Usbeck, V.C.; Pflieger, J.; Sun, T. Summary Report. Life Cycle Assessment of Float Glass, PE International. 2011. Available online: http://www.glassforeurope.com/images/cont/184_33890_file.pdf (accessed on 12 May 2016).

- Morawicki, R.O. Handbook of Sustainability for the Food Science; Wiley Blackwell: Hoboken, NJ, USA, 2012; p. 294. [Google Scholar]

- Da Silva, N.; d’Souza, N.; Binder, M. Life Cycle Impact Assessment of Aluminum Beverage Cans. 2010. Available online: http://www.container-recycling.org/assets/pdfs/aluminum/LCA-2010-AluminumAssoc.pdf (accessed on 12 May 2016).

- WSA (World Steel Association). Life Cycle Assessment Methodology Report. Life Cycle Inventory Study for Steel Products; WSA: Brussels, Belgium, 2011; Available online: http://www.worldsteel.org/dms/internetDocumentList/bookshop/LCA-Methodology-Report/document/LCA%20Methodology%20Report.pdf (accessed on 12 May 2016).

- Plastics Europe. Eco-Profiles of the European Plastics Manufacturers. Polyurethane Rigid Foam (PUR). 2005. Available online: http://www.plasticseurope.org/plastics-sustainability-14017/eco-profiles/browse-by-list.aspx (accessed on 12 May 2016).

- Plastics Europe. Environmental Product Declaration of the European Plastic Industry, Polyvinylchloride (PVC). 2008. Available online: http://www.plasticseurope.org/plastics-sustainability-14017/eco-profiles/browse-by-list.aspx (accessed on 12 May 2016).

- Plastics Europe. Eco-Profiles of the European Plastics Manufacturers. Polyethylene Terephthalate (PET) Bottle Grade. 2011. Available online: http://www.plasticseurope.org/plastics-sustainability-14017/eco-profiles/browse-by-list.aspx (accessed on 12 May 2016).

- Plastics Europe. Environmental Product Declaration of the European Plastic Industry, General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS). 2012a. Available online: http://www.plasticseurope.org/plastics-sustainability-14017/eco-profiles/browse-by-list.aspx (accessed on 12 May 2016).

- Plastics Europe. Plastics—The Facts 2012. An Analysis of European Plastics Production Demand and Waste Data for 2011. 2012b. Available online: http://www.plasticseurope.org/documents/document/20121120170458-final_plasticsthefacts_nov2012_en_web_resolution.pdf (accessed on 12 May 2016).

| j | Product Type | Production (P) | Import (I) | Export (O) | Supply (S) | Food (Fo) | Feed (Fe) | Other |

|---|---|---|---|---|---|---|---|---|

| 1 | Cereals | 19.03 | 12.03 | 5.04 | 25.33 | 9.45 | 14.08 | 0.98 |

| 2 | Tubers | 1.56 | 1.54 | 0.17 | 2.89 | 2.35 | 0.06 | 0.48 |

| 3 | Pulses | 0.14 | 0.29 | 0.02 | 0.41 | 0.29 | 0.09 | 0.03 |

| 4 | Soybeans | 0.57 | 4.20 | 0.28 | 4.48 | - | 4.28 | 0.21 |

| 5 | Oilseeds | 3.56 | 0.59 | 0.15 | 4.01 | 1.88 | 0.05 | 0.04 |

| 6 | Sugar crops | 3.55 | - | - | 3.55 | 1.65 | - | 0.05 |

| 7 | Vegetables | 14.29 | 1.99 | 5.76 | 10.52 | 8.78 | 0.55 | 1.20 |

| 8 | Fruits | 17.65 | 2.77 | 4.72 | 15.71 | 8.55 | - | 0.67 |

| 9 | Wine, beer | 6.34 | 1.22 | 3.08 | 4.87 | 3.65 | - | 0.39 |

| 10 | Meat | 5.07 | 2.18 | 0.95 | 6.3 | 6.13 | - | - |

| 11 | Milk | 11.22 | 8.02 | 2.37 | 17.09 | 15.95 | 0.58 | 0.32 |

| 12 | Eggs | 0.76 | 0.04 | 0.04 | 0.75 | 0.71 | - | 0.04 |

| 13 | Fish | 0.39 | 1.62 | 0,23 | 1.79 | 1.54 | 0.24 | - |

| Total | 84.57 | 84.11 | 36.49 | 22.80 | 97.70 | 60.93 | 19.95 | |

| j | Product Type | Processed Percent | Sources for xj | ||

|---|---|---|---|---|---|

| Internal (xj) | Imported (yj) | Exported (zj) | |||

| 1 | Cereals | 92.7% ± 1.0% | 6.1% ± 1.0% | 87.3% ± 4.8% | All cereals except rice, dried at farms (3.3%) |

| 2 | Tubers | 14.2% ± 2.3% | 28.8% ± 2.8% | 3.7% ± 1.1% | [80] |

| 3 | Pulses | 87.6% ± 7.8% | 81.2% ± 4.2% | 58.4% ± 4.9% | [81,82] |

| 4 | Soybeans | 100% | 65.5% ± 5.5% | 84.2% ± 9.8% | All soy is processed for oil and meals |

| 5 | Oilseeds | 92.2% ± 2.1% | 84.6% ± 1.9% | 97.5% ± 1.2% | [76] |

| 6 | Sugar crops | 100% | 100.0% | 100.0% | All sugar is processed from sugar beet |

| 7 | Vegetables | 27.5% ± 2.7% | 55.3% ± 3.6% | 71.2% ± 1.7% | [81,82,83] |

| 8 | Fruits | 12.2% ± 1.3% | 20.8% ± 2.0% | 21.5% ± 1.2% | [81,82,83,84] |

| 9 | Wine, Beer | 100% | 100.0% | 100.0% | All beverages are processed |

| 10 | Meat | 100% | 74.0% ± 3.5% | 91.6% ± 1.5% | All meat processed in slaughterhouses |

| 11 | Milk | 100% | 100% | 100% | All milk is pasteurized or homogenized |

| 12 | Eggs | 34% | 17.6% ± 9.2% | 44.2% ± 16% | [85] |

| 13 | Fish | 92.08% ± 6.6% | 76.6% ± 1.24% | 48.2% ± 3.15% | [79] |

| j | Product Type | FSC Step | ||||

|---|---|---|---|---|---|---|

| wfarm-Farming | wproc-Processing | wdist-Distribution | Food Energy (MJ/kg) | |||

| wfarm1-on the field | wfarm2-Post-Harvest | |||||

| 1 | Cereals | 2.0% | 4.0% | 10.0% | 2.0% | 11.03 |

| 2 | Tubers | 20.0% | 9.0% | 15.0% | 7.0% | 2.64 |

| 3 | Pulses | 10.0% | 1.0% | 5.0% | 1.0% | 14.35 |

| 4 | Soybeans | 14.41 | ||||

| 5 | Oilseeds | 6.82 | ||||

| 6 | Sugar crops | 4.2% a | 2.3% b | - | 1.2% c | 14.88 |

| 7 | Vegetables | 20.0% | 5.0% | 2.0% | 10.0% | 0.97 |

| 8 | Fruits | 1.76 | ||||

| 9 | Wine, Beer | - | - | 0.89% d | - | 2.62 |

| 10 | Meat | 3.2% | 0.7% | 5.0% | 4.0% | 6.71 |

| 11 | Milk | 3.5% | 0.5% | 1.2% | 0.5% | 1.68 |

| 12 | Eggs | 4% | - | 0.5% | 2.0% | 6.20 |

| 13 | Fish | 9.4% | 0.5% | 6.0% | 9.0% | 5.89 |

| Waste Occurs at: | Energy Wasted for Unit Mass of Food Waste |

|---|---|

| Farm | efarm (+ efeed for animal products) |

| Processing | efarm + etran + eproc (+ efeed for animal products) |

| Distribution | efarm + etran + x eproc + edist (+ efeed for animal products) |

| Products | Energy Intensity (MJ/kg) | |

|---|---|---|

| Raw vegetal products | Apples | 4.7 |

| Potato | 3.57 | |

| This work | 5.1 ± 0.3 | |

| Processed vegetal products | Industrial bread | 10.08 |

| Pasta | 9.84 | |

| Canned beans | 12.91 | |

| Canned tomato | 12.13 | |

| Packed salad | 16.7 | |

| This work | 11.4 ± 0.7 | |

| Processed animal products | Average of meat (bovine-swine), milk, eggs | 16.3 |

| This work | 18.5 ± 1.1 | |

| Waste Type | Farming | Processing | Distribution | Total |

|---|---|---|---|---|

| Food Mass Waste (Mt) | 12.75 | 2.47 | 2.64 | 17.87 |

| Food Energy Waste (PJ) | 37.04 | 21.35 | 8.49 | 66.89 |

| Embodied Energy Waste (PJ) | 47.42 | 28.43 | 24.21 | 100.07 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vittuari, M.; De Menna, F.; Pagani, M. The Hidden Burden of Food Waste: The Double Energy Waste in Italy. Energies 2016, 9, 660. https://doi.org/10.3390/en9080660

Vittuari M, De Menna F, Pagani M. The Hidden Burden of Food Waste: The Double Energy Waste in Italy. Energies. 2016; 9(8):660. https://doi.org/10.3390/en9080660

Chicago/Turabian StyleVittuari, Matteo, Fabio De Menna, and Marco Pagani. 2016. "The Hidden Burden of Food Waste: The Double Energy Waste in Italy" Energies 9, no. 8: 660. https://doi.org/10.3390/en9080660

APA StyleVittuari, M., De Menna, F., & Pagani, M. (2016). The Hidden Burden of Food Waste: The Double Energy Waste in Italy. Energies, 9(8), 660. https://doi.org/10.3390/en9080660