Mechanical Fatigue Behavior of Flexible Printed Organic Thin-Film Transistors under Applied Strain

Abstract

:1. Introduction

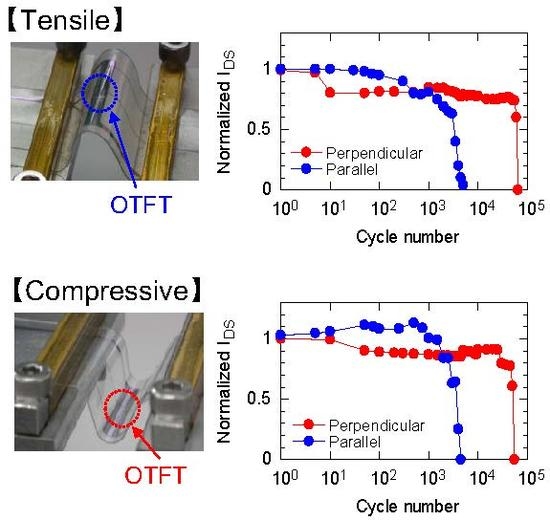

2. Results and Discussion

3. Experimental Section

3.1. Device Fabrication

3.2. Calculating Strain in the OTFT Device

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mizukami, M.; Oku, S.; Cho, S.; Tatetsu, M.; Abiko, M.; Mamada, M.; Sakanoue, T.; Suzuri, Y.; Kido, J.; Tokito, S. A Solution-Processed Organic Thin-Film Transistor Backplane for Flexible Multiphoton Emission Organic Light-Emitting Diode Displays. IEEE Electron. Device Lett. 2015, 36, 841–843. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.; Dang, F.; Li, Y.; Yin, Y.; Liu, J.; Xu, K.; Piao, X.; Xie, W. An efficient flexible white organic light-emitting device with a screen-printed conducting polymer anode. J. Phys. D Appl. Phys. 2012, 45, 402002. [Google Scholar] [CrossRef]

- Tekoglu, S.; Hernandez-Sosa, G.; Kluge, E.; Lemmer, U.; Mechau, N. Gravure printed flexible small-molecule organic light emitting diodes. Org. Electron. 2013, 14, 3493–3499. [Google Scholar] [CrossRef]

- Fukuda, K.; Minamiki, T.; Minami, T.; Watanabe, M.; Fukuda, T.; Kumaki, D.; Tokito, S. Printed Organic Transistors with Uniform Electrical Performance and Their Application to Amplifiers in Biosensors. Adv. Electron. Mater. 2015, 1, 1400052. [Google Scholar] [CrossRef]

- Khan, S.; Tinku, S.; Lorenzelli, L.; Dahiya, R. Flexible Tactile Sensors Using Screen-Printed P(VDF-TrFE) and MWCNT/PDMS Composites. IEEE Sens. J. 2015, 15, 3146–3155. [Google Scholar] [CrossRef]

- Narakathu, B.B.; Devadas, M.S.; Reddy, A.S.G.; Eshkeiti, A.; Moorthi, A.; Fernando, I.R.; Miller, B.P.; Ramakrishna, G.; Sinn, E.; Joyce, M.; et al. Novel fully screen printed flexible electrochemical sensor for the investigation of electron transfer between thiol functionalized viologen and gold clusters. Sens. Actuators B 2013, 176, 768–774. [Google Scholar] [CrossRef]

- Fukuda, K.; Sekine, T.; Kobayashi, Y.; Takeda, Y.; Shimizu, M.; Yamashita, N.; Kumaki, D.; Itoh, M.; Nagaoka, M.; Toda, T. Organic integrated circuits using room-temperature sintered silver nanoparticles as printed electrodes. Org. Electron. 2012, 13, 3296–3301. [Google Scholar] [CrossRef]

- Minari, T.; Liu, C.; Kano, M.; Tsukagoshi, K. Controlled Self-Assembly of Organic Semiconductors for Solution-Based Fabrication of Organic Field-Effect Transistors. Adv. Mater. 2012, 24, 299–306. [Google Scholar] [CrossRef] [PubMed]

- Minari, T.; Kanehara, Y.; Liu, C.; Sakamoto, K.; Yasuda, T.; Yaguchi, A.; Tsukada, S.; Kashizaki, K.; Kanehara, M. Room-Temperature Printing of Organic Thin-Film Transistors with π-Junction Gold Nanoparticles. Adv. Funct. Mater. 2014, 24, 4886–4892. [Google Scholar] [CrossRef]

- Sekitani, T.; Kato, Y.; Iba, S.; Shinaoka, H.; Someya, T.; Sakurai, T.; Takagi, S. Bending experiment on pentacene field-effect transistors on plastic films. Appl. Phys. Lett. 2005, 86, 073511. [Google Scholar] [CrossRef]

- Sekitani, T.; Iba, S.; Kato, Y.; Noguchi, Y.; Someya, T.; Sakurai, T. Ultraflexible organic field-effect transistors embedded at a neutral strain position. Appl. Phys. Lett. 2005, 87, 173502. [Google Scholar] [CrossRef]

- Cosseddu, P.; Tiddia, G.; Milita, S.; Bonfiglio, A. Continuous tuning of the mechanical sensitivity of Pentacene OTFTs on flexible substrates: From strain sensors to deformable transistors. Org. Electron. 2013, 14, 206–211. [Google Scholar] [CrossRef]

- Sokolov, A.N.; Cao, Y.; Johnson, O.B.; Bao, Z. Mechanical Consideration of Bending-Strain Rffects within Organic Semiconductors on Polymer Dielectrics. Adv. Funct. Mater. 2012, 22, 175–183. [Google Scholar] [CrossRef]

- Sekitani, T.; Zschieschang, U.; Klauk, H.; Someya, T. Flexible organic transistors and circuits with bending stability. Nat. Mater. 2010, 9, 1015–1022. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.-C.; Chen, T.-D.; Zeng, B.-R.; Chung, Y.-W. Influence of mechanical strain on the electrical properties of flexible organic thin-film transistors. Semicond. Sci. Technol. 2011, 26, 034005. [Google Scholar] [CrossRef]

- Jedaa, A.; Halik, M. Toward strain resistant flexible organic thin film transistors. Appl. Phys. Lett. 2009, 95, 103309. [Google Scholar] [CrossRef]

- Nam, S.H.; Jeon, P.J.; Min, S.W.; Lee, Y.T.; Park, E.Y.; Im, S. Highly Sensitive Non-classical strain gauge using organic heptazole thin-film transistor circuit on a flexible substrate. Adv. Funct. Mater. 2014, 24, 4413–4419. [Google Scholar] [CrossRef]

- Sekine, T.; Fukuda, K.; Kumaki, D.; Tokito, S. Highly stable flexible printed organic thin-film transistor devices under high strain conditions using semiconducting polymers. Jpn. J. Appl. Phys. 2015, 54, 04DK10. [Google Scholar] [CrossRef]

- Sekine, T.; Fukuda, K.; Kumaki, D.; Tokito, S. The effect of mechanical strain on contact resistance in flexible printed organic thin-film transistors. Flex. Print. Electron. 2016, 1, 035005. [Google Scholar] [CrossRef]

- McCulloch, I.; Heeney, M.; Bailey, C.; Genevicius, K.; MacDonald, I.; Shkunov, M.; Sparrowe, D.; Tierney, S.; Wagner, R.; Zhang, W.; et al. Liquid-crystalline semiconducting polymers with high charge-carrier mobility. Nat. Mater. 2006, 5, 328–333. [Google Scholar] [CrossRef] [PubMed]

- Umeda, T.; Kumaki, D.; Tokito, S. Surface-energy-dependent field-effect mobilities up to 1 cm2·Vs−1 for polymer thin-film transistor. J. Appl. Phys. 2009, 105, 024516. [Google Scholar] [CrossRef]

- Itoh, M.; Kakuta, T.; Nagaoka, M.; Koyama, Y.; Sakamoto, M.; Kawasaki, S.; Umeda, N.; Kurihara, M. Direct Transformation into Silver Nanoparticles via Thermal Decomposition of Oxalate-Bridging Silver Oleylamine Complexes. J. Nanosci. Nanotechnol. 2009, 9, 6655–6660. [Google Scholar] [CrossRef] [PubMed]

- Sekine, T.; Fukuda, K.; Kumaki, D.; Tokito, S. Enhanced adhesion mechanisms between printed nano-silver electrodes and underlying polymer layers. Nanotechnology 2015, 26, 321001. [Google Scholar] [CrossRef] [PubMed]

- Fukuda, K.; Sekine, T.; Shiwaku, R.; Morimoto, T.; Kumaki, D.; Tokito, S. Free-Standing Organic Transistors and Circuits with Sub-Micron Thicknesses. Sci. Rep. 2016, 6, 27450. [Google Scholar] [CrossRef] [PubMed]

- Podzorov, V.; Pudalov, V.M.; Gershenson, M.E. Field Effect Transistors on Rubrene Single Crystals with Parylene Gate Insulator. Appl. Phys. Lett. 2003, 82, 1739–1741. [Google Scholar] [CrossRef]

- Kubozono, Y.; Haas, S.; Kalb, W.L.; Joris, P.; Meng, F.; Fujiwara, A.; Batlogg, B. High-performance C60 thin-film field-effect transistors with parylene gate insulator. Appl. Phys. Lett. 2008, 93, 033316. [Google Scholar] [CrossRef]

- Gleskova, H.; Wagner, S.; Soboyejo, W.; Suo, Z. Electrical response of amorphous silicon thin-film transistors under mechanical strain. J. Appl. Phys. 2002, 92, 6224–6229. [Google Scholar] [CrossRef]

- Fukuda, K.; Hikichi, K.; Sekine, T.; Takeda, Y.; Minamiki, T.; Kumaki, D.; Tokito, S. Strain sensitivity and durability in p-type and n-type organic thin-film transistors with printed silver electrodes. Sci. Rep. 2013, 3, 2048. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sekine, T.; Kumaki, D.; Tokito, S. Mechanical Fatigue Behavior of Flexible Printed Organic Thin-Film Transistors under Applied Strain. Materials 2017, 10, 18. https://doi.org/10.3390/ma10010018

Sekine T, Kumaki D, Tokito S. Mechanical Fatigue Behavior of Flexible Printed Organic Thin-Film Transistors under Applied Strain. Materials. 2017; 10(1):18. https://doi.org/10.3390/ma10010018

Chicago/Turabian StyleSekine, Tomohito, Daisuke Kumaki, and Shizuo Tokito. 2017. "Mechanical Fatigue Behavior of Flexible Printed Organic Thin-Film Transistors under Applied Strain" Materials 10, no. 1: 18. https://doi.org/10.3390/ma10010018

APA StyleSekine, T., Kumaki, D., & Tokito, S. (2017). Mechanical Fatigue Behavior of Flexible Printed Organic Thin-Film Transistors under Applied Strain. Materials, 10(1), 18. https://doi.org/10.3390/ma10010018