Interference of Biodegradable Plastics in the Polypropylene Recycling Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation of the Blends

2.2. Scanning Electron Microscopy Analysis

2.3. Infrared Spectroscopy Analysis

2.4. Thermal Characterization

2.4.1. Thermogravimetric Analysis (TGA)

2.4.2. Differential Scanning Calorimetry

2.5. Mechanical Properties

2.6. Exposition to Composting Medium

2.7. Other Techniques

3. Results and Discussion

3.1. Miscibility

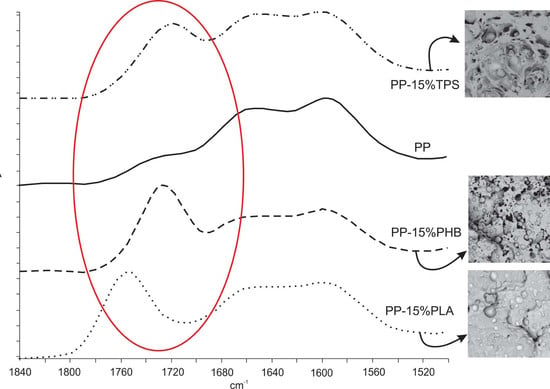

3.2. Detection of Biodegradable Materials in the Recycled PP Using the FTIR Technique

3.3. Thermal Characterization

3.3.1. Thermogravimetric Analysis

3.3.2. Differential Scanning Calorimetry

3.4. Thermomechanical Characterization

3.5. Mechanical Characterization

3.6. Desintegration under Composting Medium

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Plastics Europe, Plastics—The Facts 2017. Available online: https://www.plasticseurope.org/application/files/5715/1717/4180/Plastics_the_facts_2017_FINAL_for_website_one_page.pdf (accessed on 25 September 2018).

- Ares, A.; Bouza, R.; Pardo, S.G.; Abad, M.J.; Barral, L. Rheological, Mechanical and Thermal Behaviour of Wood Polymer Composites Based on Recycled Polypropylene. J. Polym. Environ. 2010, 18, 318–325. [Google Scholar] [CrossRef]

- Zadeh, K.M.; Ponnamma, D.; Al-Maadeed, M.A.A. Date palm fibre filled recycled ternary polymer blend composites with enhanced flame retardancy. Polym. Test. 2017, 61, 341–348. [Google Scholar] [CrossRef]

- Bodar, C.; Spijker, J.; Lijzen, J.; Waaijers-van der Loop, S.; Luit, R.; Heugens, E.; Janssen, M.; Wassenaar, P.; Traas, T. Risk management of hazardous substances in a circular economy. J. Environ. Manag. 2018, 212, 108–114. [Google Scholar] [CrossRef] [PubMed]

- Alam, O.; Wang, S.; Lu, W. Heavy metals dispersion during thermal treatment of plastic bags and its recovery. J. Environ. Manag. 2018, 212, 367–374. [Google Scholar] [CrossRef] [PubMed]

- Bucci, D.Z.; Tavares, L.B.B.; Sell, I. PHB packaging for the storage of food products. Polym. Test. 2005, 24, 564–571. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Dalla Rosa, M. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Claro, P.; Neto, A.; Bibbo, A.; Mattoso, L.; Bastos, M.; Marconcini, J. Biodegradable blends with potential use in packaging: A comparison of PLA/chitosan and PLA/cellulose acetate films. J. Polym. Environ. 2016, 24, 363–371. [Google Scholar] [CrossRef]

- Bastioli, C. Bio plastics for a new economy. Chim. Oggi-Chem. Today 2008, 26, 30–31. [Google Scholar]

- Bastioli, C. Unlocking the potential of added value products in Europe: an Italian perspective. Chim. Oggi-Chem. Today 2013, 31, 64–67. [Google Scholar]

- Averous, L. Biodegradable multiphase systems based on plasticized starch: A review. J. Macromol. Sci. Polym. Rev. 2004, C44, 231–274. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jimenez, A.; Yoon, K.; Ahn, J.; Kang, S.; Kenny, J.M. Processing and characterization of plasticized PLA/PHB blends for biodegradable multiphase systems. Express Polym. Lett. 2015, 9, 583–596. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Lopez, J.; Rayon, E.; Jimenez, A. Disintegrability under composting conditions of plasticized PLA-PHB blends. Polym. Degrad. Stab. 2014, 108, 307–318. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Garcia, D.; Ferri, J.M.; Montanes, N.; Lopez-Martinez, J.; Balart, R. Plasticization effects of epoxidized vegetable oils on mechanical properties of poly (3-hydroxybutyrate). Polym. Int. 2016, 65, 1157–1164. [Google Scholar] [CrossRef]

- Russo, M.A.L.; O’Sullivan, C.; Rounsefell, B.; Halley, P.J.; Truss, R.; Clarke, W.P. The anaerobic degradability of thermoplastic starch: Polyvinyl alcohol blends: Potential biodegradable food packaging materials. Bioresour. Technol. 2009, 100, 1705–1710. [Google Scholar] [CrossRef] [PubMed]

- Neumann, I.A.; Sydenstricker Flores-Sahagun, T.H.; Ribeiro, A.M. Biodegradable poly (L-lactic acid) (PLLA) and PLLA-3-arm blend membranes: The use of PLLA-3-arm as a plasticizer. Polym. Test. 2017, 60, 84–93. [Google Scholar] [CrossRef]

- Peterson, G.I.; Dobrynin, A.V.; Becker, M.L. Biodegradable Shape Memory Polymers in Medicine. Adv. Healthc. Mater. 2017, 6, 1700694. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ray, S.; Kalia, V.C. Biomedical Applications of Polyhydroxyalkanoates. Indian J. Microbiol. 2017, 57, 261–269. [Google Scholar] [CrossRef] [PubMed]

- Khalid, S.; Yu, L.; Meng, L.; Liu, H.; Ali, A.; Chen, L. Poly(lactic acid)/starch composites: Effect of microstructure and morphology of starch granules on performance. J. Appl. Polym. Sci. 2017, 134, 45504. [Google Scholar] [CrossRef]

- Rubio-Lopez, A.; Artero-Guerrero, J.; Pernas-Sanchez, J.; Santiuste, C. Compression after impact of flax/PLA biodegradable composites. Polym. Test. 2017, 59, 127–135. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the use of PLA-PHB blends for sustainable food packaging applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef] [PubMed]

- Cosate de Andrade, M.F.; Souza, P.M.S.; Cavalett, O.; Morales, A.R. Life Cycle Assessment of Poly(Lactic Acid) (PLA): Comparison Between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Navarro, R.; Ferrandiz, S.; Lopez, J.; Segui, V.J. The influence of polyethylene in the mechanical recycling of polyethylene terephtalate. J. Mater. Proc. Technol. 2008, 195, 110–116. [Google Scholar] [CrossRef]

- Navarro, R.; Lopez, J.; Parres, F.; Ferrandiz, S. Process behavior of compatible polymer blends. J. Appl. Polym. Sci. 2012, 124, 2485–2493. [Google Scholar] [CrossRef]

- Sanchez-Jimenez, P.E.; Perez-Maqueda, L.A.; Crespo-Amoros, J.E.; Lopez, J.; Perejon, A.; Criado, J.M. Quantitative Characterization of Multicomponent Polymers by Sample-Controlled Thermal Analysis. Anal. Chem. 2010, 82, 8875–8880. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of Bio-Based Plastics on Current Recycling of Plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef]

- Pivsa-Art, S.; Kord-Sa-Ard, J.; Pivsa-Art, W.; Wongpajan, R.; O-Charoen, N.; Pavasupree, S.; Hamada, H. Effect of Compatibilizer on PLA/PP Blend for Injection Molding. Energy Procedia 2016, 89, 353–360. [Google Scholar] [CrossRef]

- Ploypetchara, N.; Suppakul, P.; Atong, D.; Pechyen, C. Blend of polypropylene/poly (lactic acid) for medical packaging application: physicochemical, thermal, mechanical, and barrier properties. Energy Procedia 2014, 56, 201–210. [Google Scholar] [CrossRef]

- Yoo, T.W.; Yoon, H.G.; Choi, S.J.; Kim, M.S.; Kim, Y.H.; Kim, W.N. Effects of compatibilizers on the mechanical properties and interfacial tension of polypropylene and poly (lactic acid) blends. Macromol. Res. 2010, 18, 583–588. [Google Scholar] [CrossRef]

- Kaseem, M.; Hamad, K.; Deri, F. Rheological and mechanical properties of polypropylene/thermoplastic starch blend. Polym. Bull. 2012, 68, 1079–1091. [Google Scholar] [CrossRef]

- Rosa, D.; Guedes, C.; Carvalho, C. Processing and thermal, mechanical and morphological characterization of post-consumer polyolefins/thermoplastic starch blends. J. Mater. Sci. 2007, 42, 551–557. [Google Scholar] [CrossRef]

- Sadi, R.K.; Kurusu, R.S.; Fechine, G.J.M.; Demarquette, N.R. Compatibilization of polypropylene/poly(3-hydroxybutyrate) blends. J. Appl. Polym. Sci. 2012, 123, 3511–3519. [Google Scholar] [CrossRef] [Green Version]

- Parres, F.; Balart, R.; Lopez, J.; Garcia, D. Changes in the mechanical and thermal properties of high impact polystyrene (HIPS) in the presence of low polypropylene (PP) contents. J. Mater. Sci. 2008, 43, 3203–3209. [Google Scholar] [CrossRef]

- Utracki, L.A.; Mukhopadhyay, P.; Gupta, R. Polymer blends: introduction. In Polymer Blends Handbook; Springer: Berlin, Germany, 2014; pp. 3–170. [Google Scholar]

- Arrieta, M.P.; Fortunati, E.; Burgos, N.; Peltzer, M.A.; López, J.; Peponi, L. Chapter 7—Nanocellulose-Based Polymeric Blends for Food Packaging Applications. In Multifunctional Polymeric Nanocomposites Based on Cellulosic Reinforcement; Puglia, D., Fortunati, E., Kenny, J.M., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 205–252. [Google Scholar]

- Fekete, E.; Foldes, E.; Pukanszky, M. Effect of molecular interactions on the miscibility and structure of polymer blends. Eur. Polym. J. 2005, 41, 727–736. [Google Scholar] [CrossRef]

- MacAubas, P.H.P.; Demarquette, N.R. Time-temperature superposition principle applicability for blends formed of immiscible polymers. Polym. Eng. Sci. 2002, 42, 1509–1519. [Google Scholar] [CrossRef]

- Samper, M.D.; Arrieta, M.P.; Ferrándiz, S.; López, J. Influence of biodegradable materials in the recycled polystyrene. J. Appl. Polym. Sci. 2014, 131, 41161. [Google Scholar]

- ISO-20200: U.U.-E. Determination of the Degree of Disintegration of Plastic Materials under Simulated Composting Conditions in a Laboratory-Scale Test; International Organization for Standardization: Geneva, Switzerland, 2015.

- Ferrandiz, S.; Arrieta, M.P.; Samper, M.D.; Lopez, J. Prediction of properties value in thermoplastic mixtures applying box equivalent model incompatibility in recycled polymer blends. J. Optoelectron. Adv. Mater. 2013, 15, 662–666. [Google Scholar]

- Odelius, K.; Ohlson, M.; Hoeglund, A.; Albertsson, A.-C. Polyesters with small structural variations improve the mechanical properties of polylactide. J. Appl. Polym. Sci. 2013, 127, 27–33. [Google Scholar] [CrossRef]

- Polymer Properties Database. Available online: https://polymerdatabase.com/polymer%20classes/Intro.html (accessed on 25 September 2018).

- Goonoo, N.; Bhaw-Luximon, A.; Jhurry, D. Biodegradable polymer blends: miscibility, physicochemical properties and biological response of scaffolds. Polym. Int. 2015, 64, 1289–1302. [Google Scholar] [CrossRef]

- Sundararaj, U.; Ghodgaonkar, P. Effect of compatibilization in immiscible polymer blends. Abstr. Papers Am. Chem. Soc. 1996, 212, 277. [Google Scholar]

- Arrieta, M.P.; López, J.; López, D.; Kenny, J.; Peponi, L. Development of flexible materials based on plasticized electrospun PLA–PHB blends: Structural, thermal, mechanical and disintegration properties. Eur. Polym. J. 2015, 73, 433–446. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Fenollar, O.; Balart, R. Poly(lactic acid) formulations with improved toughness by physical blending with thermoplastic starch. J. Appl. Polym. Sci. 2018, 135, 45751. [Google Scholar] [CrossRef]

- Sessini, V.; Arrieta, M.P.; Kenny, J.M.; Peponi, L. Processing of edible films based on nanoreinforced gelatinized starch. Polym. Degrad. Stab. 2016, 132, 157–168. [Google Scholar] [CrossRef]

- Hiemenz, P.C.; Lodge, T.P. Linear Viscosity. In Polymer Chemistry, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 419–464. [Google Scholar]

- Wang, L.; Gramlich, W.M.; Gardner, D.J.; Han, Y.; Tajvidi, M. Spray-Dried Cellulose Nanofibril-Reinforced Polypropylene Composites for Extrusion-Based Additive Manufacturing: Nonisothermal Crystallization Kinetics and Thermal Expansion. J. Compos. Sci. 2018, 2, 7. [Google Scholar] [CrossRef]

- Fan, Y.; Nishida, H.; Shirai, Y.; Tokiwa, Y.; Endo, T. Thermal degradation behaviour of poly(lactic acid) stereocomplex. Polym. Degrad. Stab. 2004, 86, 197–208. [Google Scholar] [CrossRef]

- Sessini, V.; Raquez, J.M.; Lourdin, D.; Maigret, J.E.; Kenny, J.M.; Dubois, P.; Peponi, L. Humidity-Activated Shape Memory Effects on Thermoplastic Starch/EVA Blends and Their Compatibilized Nanocomposites. Macromol. Chem. Phys. 2017, 218, 1700388. [Google Scholar] [CrossRef] [Green Version]

- Gerard, T.; Budtova, T.; Podshivalov, A.; Bronnikov, S. Polylactide/poly(hydroxybutyrate-co-hydroxyvalerate) blends: Morphology and mechanical properties. Express Polym. Lett. 2014, 8, 609–617. [Google Scholar] [CrossRef] [Green Version]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Hernández, A.; Rayón, E. Ternary PLA–PHB–Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Du, Y.-L.; Cao, Y.; Lu, F.; Li, F.; Cao, Y.; Wang, X.-L.; Wang, Y.-Z. Biodegradation behaviors of thermoplastic starch (TPS) and thermoplastic dialdehyde starch (TPDAS) under controlled composting conditions. Polym. Test. 2008, 27, 924–930. [Google Scholar] [CrossRef]

| Sample | PP1B (wt.%) | PLA (wt.%) | PHB (wt.%) | TPS (wt.%) |

|---|---|---|---|---|

| PP | 100.0 | - | - | - |

| PP-2.5%PLA | 97.5 | 2.5 | - | - |

| PP-5%PLA | 95.0 | 5.0 | - | - |

| PP-7.5%PLA | 92.5 | 7.5 | - | - |

| PP-10%PLA | 90.0 | 10.0 | - | - |

| PP-15%PLA | 85.0 | 15.0 | - | - |

| PP-2.5%PHB | 97.5 | - | 2.5 | - |

| PP-5%PHB | 95.0 | - | 5.0 | - |

| PP-7.5%PHB | 92.5 | - | 7.5 | - |

| PP-10%PHB | 90.0 | - | 10.0 | - |

| PP-15%PHB | 85.0 | - | 15.0 | - |

| PP-2.5%TPS | 97.5 | - | - | 2.5 |

| PP-5%TPS | 95.0 | - | - | 5.0 |

| PP-2.5%TPS | 92.5 | - | - | 7.5 |

| PP-10%TPS | 90.0 | - | - | 10.0 |

| PP-15%TPS | 85.0 | - | - | 15.0 |

| Polymer | Structure | Calculated Small δ(cal)(MPa1/2) | Available Date δ(cal)(MPa1/2) [42] |

|---|---|---|---|

| PP |  | 16.4 | 15.5–17.5 |

| PLA |  | 19.5 | 19.2–21.1 |

| TPS |  | 8.4 | - |

| PHB |  | 21.4 | 19.2 |

| Group | F ((cal·cm−3)1/2 mol−1) |

|---|---|

| –CH3 | 214 |

| –CH2– | 133 |

| –CH< | 28 |

| >C< | -93 |

| –OH | 83 |

| –O– | 70 |

| –H (variable) | 80–100 |

| >C=O | 275 |

| Sample | Tc (°C) | ΔHc (J·g−1) | Tm (°C) | ΔHm (J·g−1) |

|---|---|---|---|---|

| PP | 124.5 | 85.5 | 164.1 | 66.0 |

| PP-5%TPS | 121.1 | 89.0 | 164.0 | 66.4 |

| PP-10%TPS | 120.5 | 77.4 | 164.0 | 57.3 |

| PP-15%TPS | 120.8 | 67.5 | 163.7 | 49.3 |

| PP-5%PHB | 120.9 | 80.5 | 163.9 | 62.8 |

| PP-10%PHB | 120.8 | 71.0 | 164.3 | 65.1 |

| PP-15%PHB | 120.8 | 69.2 | 165.1 | 58.1 |

| PP-5%PLA | 121.6 | 80.2 | 163.4 | 56.9 |

| PP-10%PLA | 121.5 | 80.4 | 163.6 | 62.0 |

| PP-15%PLA | 120.9 | 70.3 | 165.1 | 53.5 |

| Sample | Elongation at Break (%) | Standard Desviation (%) |

|---|---|---|

| PP | 4.87 | 0.61 |

| PP-5%PLA | 4.11 | 1.84 |

| PP-15%PLA | 3.29 | 1.26 |

| PP-5%PHB | 3.09 | 1.39 |

| PP-15%PHB | 3.54 | 1.78 |

| PP-5%TPS | 2.26 | 0.33 |

| PP-15%TPS | 5.68 | 1.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samper, M.D.; Bertomeu, D.; Arrieta, M.P.; Ferri, J.M.; López-Martínez, J. Interference of Biodegradable Plastics in the Polypropylene Recycling Process. Materials 2018, 11, 1886. https://doi.org/10.3390/ma11101886

Samper MD, Bertomeu D, Arrieta MP, Ferri JM, López-Martínez J. Interference of Biodegradable Plastics in the Polypropylene Recycling Process. Materials. 2018; 11(10):1886. https://doi.org/10.3390/ma11101886

Chicago/Turabian StyleSamper, María Dolores, David Bertomeu, Marina Patricia Arrieta, José Miguel Ferri, and Juan López-Martínez. 2018. "Interference of Biodegradable Plastics in the Polypropylene Recycling Process" Materials 11, no. 10: 1886. https://doi.org/10.3390/ma11101886

APA StyleSamper, M. D., Bertomeu, D., Arrieta, M. P., Ferri, J. M., & López-Martínez, J. (2018). Interference of Biodegradable Plastics in the Polypropylene Recycling Process. Materials, 11(10), 1886. https://doi.org/10.3390/ma11101886