Bonded Repair Optimization of Cracked Aluminum Alloy Plate by Microwave Cured Carbon-Aramid Fiber/Epoxy Sandwich Composite Patch

Abstract

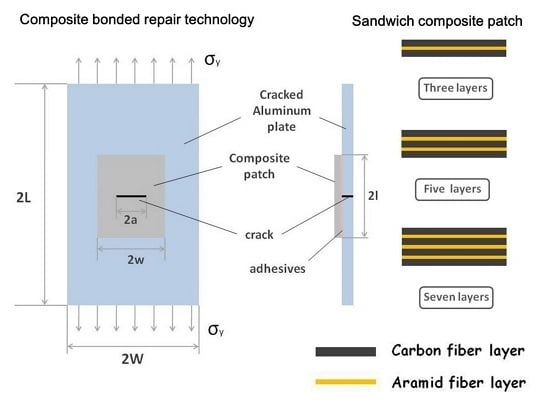

:1. Introduction

2. Experimental

2.1. Preparation of Fiber-Reinforced Laminar Composites

2.2. Repair Process of Central Cracked Aluminum Alloy Plate

2.3. Characterization

3. Results and Discussion

3.1. Bending Performance of Carbon-Aramid Fiber/Epoxy Sandwich Composite Patches

3.2. Tensile Performance of Carbon-Aramid Fiber/Epoxy Sandwich Composite Patches

3.3. Majorization Effect of Sandwich Composite Patches on Repair Efficiency Improvement of Bonded Structures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shamsuddoha, M.; Islam, M.M.; Aravinthan, T.; Manalo, A.; Lau, K. Effectiveness of using fibre-reinforced polymer composites for underwater steel pipeline repairs. Compos. Struct. 2013, 100, 40–54. [Google Scholar] [CrossRef]

- Schubbe, J.J.; Bolstad, S.H.; Reyes, S. Fatigue crack growth behavior of aerospace and ship-grade aluminum repaired with composite patches in a corrosive environment. Compos. Struct. 2016, 144, 44–56. [Google Scholar] [CrossRef]

- Bouanani, M.F.; Benyahia, F.; Albedah, A.; Aid, A.; Bouiadjra, B.B.; Belhouari, M.; Achour, T. Analysis of the adhesive failure in bonded composite repair of aircraft structures using modified damage zone theory. Mater. Des. 2013, 50, 433–439. [Google Scholar] [CrossRef]

- Grabovac, I.; Whittaker, D. Application of bonded composites in the repair of ships structures–A 15-year service experience. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1381–1398. [Google Scholar] [CrossRef]

- Chróścielewski, J.; Miśkiewicz, M.; Pyrzowski, L.; Sobczyk, B.; Wilde, K. A novel sandwich footbridge—Practical application of laminated composites in bridge design and in situ measurements of static response. Compos. Part B Eng. 2017, 126, 153–161. [Google Scholar] [CrossRef]

- Errouane, H.; Sereir, Z.; Chateauneuf, A. Numerical model for optimal design of composite patch repair of cracked aluminum plates under tension. Int. J. Adhes. Adhes. 2014, 49, 64–72. [Google Scholar] [CrossRef]

- Gong, X.; Cheng, P.; Aivazzadeh, S.; Xiao, X. Design and optimization of bonded patch repairs of laminated composite structures. Compos. Struct. 2015, 123, 292–300. [Google Scholar] [CrossRef]

- Fekih, S.M.; Albedah, A.; Benyahia, F.; Belhouari, M.; Bachir, B.B.; Miloudi, A. Optimisation of the sizes of bonded composite repair in aircraft structures. Mater. Des. 2012, 41, 171–176. [Google Scholar] [CrossRef]

- Albedah, A.; Bouiadjra, B.B.; Mhamdia, R.; Benyahia, F.; Es-Saheb, M. Comparison between double and single sided bonded composite repair with circular shape. Mater. Des. 2011, 32, 996–1000. [Google Scholar] [CrossRef]

- Manalo, A.; Sirimanna, C.; Karunasena, W.; McGarva, L.; Falzon, P. Pre-impregnated carbon fibre reinforced composite system for patch repair of steel I-beams. Constr. Build. Mater. 2016, 105, 365–376. [Google Scholar] [CrossRef] [Green Version]

- Aakkula, J.; Saarela, O. An experimental study on the fatigue performance of CFRP and BFRP repaired aluminium plates. Compos. Struct. 2014, 118, 589–599. [Google Scholar] [CrossRef]

- Andrew, J.J.; Arumugam, V.; Saravanakumar, K.; Dhakal, H.N.; Santulli, C. Compression after impact strength of repaired GFRP composite laminates under repeated impact loading. Compos. Struct. 2015, 133, 911–920. [Google Scholar] [CrossRef]

- Claramunt, J.; Fernández-Carrasco, L.J.; Ventura, H.; Ardanuy, M. Natural fiber nonwoven reinforced cement composites as sustainable materials for building envelopes. Constr. Build. Mater. 2016, 115, 230–239. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Canche, N.G.; Flores-Johnson, E.A.; Carrillo, J.G. Mechanical characterization of fiber metal laminate based on aramid fiber reinforced polypropylene. Compos. Struct. 2017, 172, 259–266. [Google Scholar] [CrossRef]

- Khoshnevis, H.; Tran, T.Q.; Mint, S.M.; Zadhoush, A.; Duong, H.M.; Youssefi, M. Effect of alignment and packing density on the stress relaxation process of carbon nanotube fibers spun from floating catalyst chemical vapor deposition method. Colloid Surf. A 2018, 558, 570–588. [Google Scholar] [CrossRef]

- Duong, H.M.; Tran, T.Q.; Kopp, R.; Myint, S.M.; Peng, L. Chapter 1-direct spinning of horizontally aligned carbon nanotube fibers and films from the floating catalyst method. In Nanotube Superfiber Materials, 2nd ed.; Schulz, M., Shanov, V., Yin, Z., Cahay, M., Eds.; William Andrew Publishing: New York, NY, USA, 2019; pp. 3–29. [Google Scholar]

- Albedah, A.; Khan, S.M.A.; Benyahia, F.; Bachir, B.B. Experimental analysis of the fatigue life of repaired cracked plate in aluminum alloy 7075 with bonded composite patch. Eng. Fract. Mech. 2015, 145, 210–220. [Google Scholar] [CrossRef]

- Caminero, M.A.; Pavlopoulou, S.; Lopez-Pedrosa, M.; Nicolaisson, B.G.; Pinna, C.; Soutis, C. Analysis of adhesively bonded repairs in composites: Damage detection and prognosis. Compos. Struct. 2013, 95, 500–517. [Google Scholar] [CrossRef]

- Caminero, M.A; Lopez-Pedrosa, M.; Pinna, C.; Soutis, C. Damage assessment of composite structures using digital image correlation. Appl. Compos. Mater. 2014, 21, 91–106. [Google Scholar] [CrossRef]

- Boey, F.Y.C.; Yap, B.H. Microwave curing of an epoxy–amine system: Effect of curing agent on the glass-transition temperature. Polym. Test. 2001, 20, 837–845. [Google Scholar] [CrossRef]

- Sung, P.; Chiu, T.; Chang, S. Microwave curing of carbon nanotube/epoxy adhesives. Compos. Sci. Technol. 2014, 104, 97–103. [Google Scholar] [CrossRef]

- Xi, J.; Yu, Z. Toughening mechanism of rubber reinforced epoxy composites by thermal and microwave curing. J. Appl. Polym. Sci. 2017, 135, 45767–45775. [Google Scholar] [CrossRef]

| Sample | Bending Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| Aluminum alloy plate | 605.3 (±13.1) | 358.9 (±11.9) |

| Cracked aluminum alloy plate | 486.3 (±9.4) | 244.8 (±7.2) |

| Repaired plate-carbon fiber | 537.1 (±34.2) | 287.9 (±13.7) |

| Repaired plate-carbon/aramid fiber | 1153.1 (±29.8) | 311.7 (±22.6) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wu, J.; Xi, J.; Yu, Z. Bonded Repair Optimization of Cracked Aluminum Alloy Plate by Microwave Cured Carbon-Aramid Fiber/Epoxy Sandwich Composite Patch. Materials 2019, 12, 1655. https://doi.org/10.3390/ma12101655

Liu X, Wu J, Xi J, Yu Z. Bonded Repair Optimization of Cracked Aluminum Alloy Plate by Microwave Cured Carbon-Aramid Fiber/Epoxy Sandwich Composite Patch. Materials. 2019; 12(10):1655. https://doi.org/10.3390/ma12101655

Chicago/Turabian StyleLiu, Xiaoyan, Jiacheng Wu, Jiaojiao Xi, and Zhiqiang Yu. 2019. "Bonded Repair Optimization of Cracked Aluminum Alloy Plate by Microwave Cured Carbon-Aramid Fiber/Epoxy Sandwich Composite Patch" Materials 12, no. 10: 1655. https://doi.org/10.3390/ma12101655

APA StyleLiu, X., Wu, J., Xi, J., & Yu, Z. (2019). Bonded Repair Optimization of Cracked Aluminum Alloy Plate by Microwave Cured Carbon-Aramid Fiber/Epoxy Sandwich Composite Patch. Materials, 12(10), 1655. https://doi.org/10.3390/ma12101655