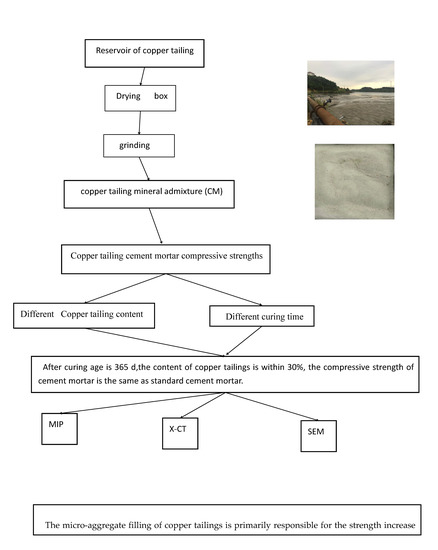

Effect of the Content of Micro-Active Copper Tailing on the Strength and Pore Structure of Cementitious Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Production of Test Pieces

2.3. Experimental Approach

2.3.1. Compressive Strength Test

2.3.2. X-CT Test

2.3.3. SEM Observation

3. Results and Discussion

3.1. Compressive Strength

3.2. X-CT Results

3.3. MIP Results for Hole Structure

3.3.1. Porosity

3.3.2. Maximum Aperture Distribution

3.4. SEM

4. Conclusions

- The compressive strength of CMCT increased with increasing curing age and was close to that of ordinary cement mortar with different curing time and copper tailing content. The curing time which the CMCT compressive strength was close to ordinary cement mortar compresssive increased with the increase of copper tailing content (less than 30%). When the curing age was 365 d, the copper tailing content was within 30%, and further addition of tailing did not affect the compressive strength of concrete.

- The porosity of the CPCT decreased with increasing curing age and increased with the increase of copper tailing content when the curing age was less than 180 d; the copper tailing content had little influence on the porosity of the CPCT when the curing age was more than 180 d.

- The maximum pore diameter of the CPCT gradually decreased with increasing curing age and increased with the increase of copper tailing content when the curing age was less than 7d; with curing time increases, the maximum pore diameter of the CPCT gradually decreased with the increase of copper tailing content. The X-CT test results showed that prolonged curing and cement hydration played a role in refining the pore diameter of the CPCT.

- In the early stage, the CPCT pore structure was less dense with copper tailing increases. With prolonged curing, the CPCT structure was gradually denser with copper tailing increases; the CPCT pore structure was denser with copper tailing increases until the curing age was more than 365 d. The microaggregates of solid copper tailings had a good filling effect and closely combined with the surrounding hydration products.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cheng, W.M.; Nie, W.; Zhou, G.; Zuo, Q.M. Study of dust suppression by atomized water from high pressure sprays in mines. J. China Univ. Min. Technol. 2011, 40, 185–189. [Google Scholar]

- Yu, L.H.; Jia, W.H.; Xuan, Y.Z. Survey and analysis of the Cooper tailing resources in China. J. Met. Mine 2009, 8, 179–181. [Google Scholar]

- Li, H.G. Study on the Influence of Rain Fall Factors on Tailings Dam Break and Its Safety Warning Technology. Doctoral Thesis, University of Science and Technology Beijing, Beijing, China, 2017; pp. 179–181. [Google Scholar]

- Seyed Rez, M.; Mostafa, F.; Ramin, T. Mechanical properties of concrete with Sarcheshmeh mineral complex copper slag as a part of cementitious materials. Constr. Build. Mater. 2017, 134, 44–49. [Google Scholar]

- Onuaguluchi, O.; Eren, O. Copper tailings as a potential additive in concrete: Consistency, strength and toxic metal immobilization properties. Indian J. Eng. Mater. Sci. 2012, 19, 79–86. [Google Scholar]

- Zheng, J.; Zhu, Y.; Zhao, Z. Utilization of limestone powder and water-reducing admixture in cemented paste backfill of coarse copper mine tailings. Constr. Build. Mater. 2016, 124, 31–36. [Google Scholar] [CrossRef]

- Kundu, S.; Aggarwal, A.; Mazumdar, S. Stabilization characteristics of copper mine tailings through its utilization as a partial substitute for cement in concrete: Preliminary investigations. Environ. Earth. Sci. 2016, 75, 226–235. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Eren, O. Strength and durability properties of mortars containing copper tailings as a cement replacement material. Eur. J. Environ. Civ. Eng. 2013, 17, 19–31. [Google Scholar] [CrossRef]

- Fang, Y.; Gu, Y.L.; Kang, Q.; Wen, Q.; Dai, P. Utilization of copper tailing for autoclaved sand–lime brick. Constr. Build. Mater. 2011, 25, 867–872. [Google Scholar] [CrossRef]

- Yu, Z.R.; Gao, K.; An, M.Z. Influence of micro-structure on the strength and resistance to chloride ion permeability of reactive powder concrete. J. Xi’an Univ. Archit. Technol. 2013, 45, 31–37. [Google Scholar]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Zhang, M.H.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

- Song, H.W.; Kwon, S.J. Evaluation of chloride penetration in high performance concrete using neural network algorithm and micro pore structure. Cem. Concr. Res. 2009, 39, 814–824. [Google Scholar] [CrossRef]

- Zhao, X.L.; Wei, J.; Ba, H.J. Relationship between frost durability and pore structure of high performance concrete. Ind. Constr. 2003, 8, 5–7. [Google Scholar]

- Liu, J.; Xing, F.; Dong, B.Q. Relationship between pore structure and permeability. Concrete 2007, 12, 35–37. [Google Scholar]

- Zhang, P.; Qin, H.G.; Wu, K.S. Application of X-CT technology in the cement-based materials pore structure analysis. Ready-mixed Concr. 2011, 11, 27–29. [Google Scholar]

- Han, J.; Pan, G.; Sun, W. Investigation on carbonation induced meso-defects changes of cement mortar using 3D X-ray computed tomography. J. Chin. Ceram. Soc. 2011, 39, 75–79. [Google Scholar]

- Lu, S.E.; Landis, E.N.; Keane, D.T. X-ray micro-tomographic studies of pore structure and permeability in Portland cement concrete. Mater. Struct. 2006, 39, 611–620. [Google Scholar] [CrossRef]

- Gao, P.W.; Lu, X.L.; Yang, C.X.; Li, X.Y.; Shi, N.N.; Jin, S.C. Micro-structure and pore structure of concrete mixed with superfine phosphorous slag and superplasticizer. Constr. Build. Mater. 2008, 22, 837–840. [Google Scholar] [CrossRef]

- Li, H.; Xu, D.L.; Feng, S.H.; Shang, B.M. Micro-structure and performance of fly ash micro-beads in cementitious material system. Constr. Build. Mater. 2014, 52, 422–427. [Google Scholar] [CrossRef]

- Duan, P.; Shui, Z.H.; Chen, W.; Shen, C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Constr. Build. Mater. 2013, 44, 1–6. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Zhang, B.; Yan, P.L. Comparative study of effect of raw and densified silica fume in the paste, mortar and concrete. Constr. Build. Mater. 2016, 105, 82–93. [Google Scholar] [CrossRef]

- Han, F.; Wang, Q.; Feng, J.J. The differences among the roles of ground fly ash in the paste, mortar and concrete. Constr. Build. Mater. 2015, 93, 172–179. [Google Scholar]

- GB/T1596-2017. Fly Ash Used for Cement and Concrete; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2017; pp. 1–6.

- Zhang, Y.; Yu, B. Characteristics of hydration products and pore structure in cement-based material with ultra fine slag at early ages. J. Southeast Univ. 2011, 41, 814–819. [Google Scholar]

- Chen, X.; Wu, S. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 2013, 38, 804–812. [Google Scholar] [CrossRef]

| Binder Material Type | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Loss |

|---|---|---|---|---|---|---|---|

| Cement | 26.5 | 6.4 | 3.3 | 55.7 | 1.7 | 2.0 | 5.3 |

| Copper tailing slag | 38.5 | 6.6 | 15.8 | 32.7 | 2.8 | 3.2 | 0.4 |

| Sample | Cement/g | Copper Tailing/s | Sand/g | Water/g | Initial Setting Time/min | Final Setting Time/min | Fluidity/mm |

|---|---|---|---|---|---|---|---|

| CT0 | 450 | 0 | 1350 | 225 | 170 | 215 | 220 |

| CT10 | 405 | 45 | 1350 | 225 | 170 | 215 | 225 |

| CT20 | 360 | 90 | 1350 | 225 | 170 | 215 | 213 |

| CT30 | 315 | 135 | 1350 | 225 | 170 | 215 | 195 |

| C0 | 100 | 0 | 0 | 25 | 170 | 215 | - |

| CM10 | 90 | 10 | 0 | 25 | 170 | 215 | - |

| CM20 | 80 | 20 | 0 | 25 | 170 | 215 | - |

| CM30 | 70 | 30 | 0 | 25 | 170 | 215 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Liu, S.; Song, D. Effect of the Content of Micro-Active Copper Tailing on the Strength and Pore Structure of Cementitious Materials. Materials 2019, 12, 1861. https://doi.org/10.3390/ma12111861

Zhang L, Liu S, Song D. Effect of the Content of Micro-Active Copper Tailing on the Strength and Pore Structure of Cementitious Materials. Materials. 2019; 12(11):1861. https://doi.org/10.3390/ma12111861

Chicago/Turabian StyleZhang, Liming, Songbai Liu, and Dongsheng Song. 2019. "Effect of the Content of Micro-Active Copper Tailing on the Strength and Pore Structure of Cementitious Materials" Materials 12, no. 11: 1861. https://doi.org/10.3390/ma12111861

APA StyleZhang, L., Liu, S., & Song, D. (2019). Effect of the Content of Micro-Active Copper Tailing on the Strength and Pore Structure of Cementitious Materials. Materials, 12(11), 1861. https://doi.org/10.3390/ma12111861