Surface, Subsurface and Tribological Properties of Ti6Al4V Alloy Shot Peened under Different Parameters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Materials and Specimens

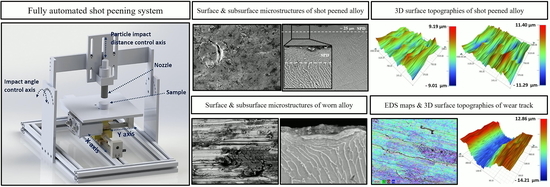

2.2. Shot Peening Process

2.3. Subsurface Microstructural and Mechanical Characterisation

2.4. Surface Characterisation

2.5. Tribological Characterisation

3. Results and Discussion

3.1. Variation of Subsurface Microstructure and Hardness

3.2. Variation of Surface Morphology and Topography

3.3. Tribological Properties Depending on Shot Peening

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164. [Google Scholar] [CrossRef]

- Bansal, D.G.; Eryilmaz, O.L.; Blau, P.J. Surface Engineering to Improve The Durability and Lubricity of Ti–6Al–4V alloy. Wear 2011, 271, 2006–2015. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, Y.; Huang, S.; Sheng, J.; Li, J.; Agyenim-Boateng, E. Effect of Laser Peening On Friction And Wear Behavior Of Medical Ti6Al4V Alloy. Opt. Laser Technol. 2019, 109, 263–269. [Google Scholar] [CrossRef]

- Zhecheva, A.; Sha, W.; Malinov, S.; Long, A. Enhancing the Microstructure and Properties of Titanium Alloys Through Nitriding and Other Surface Engineering Methods. Surf. Coat. Technol. 2005, 200, 2192–2207. [Google Scholar] [CrossRef]

- Yıldıran, Y.; Avcu, E.; Sınmazçelik, T. Optimization of Surface Properties of Shot Peened TI6AL4V Alloy. Acta Phys. Pol. A 2015, 127, 984–986. [Google Scholar] [CrossRef]

- Farokhzadeh, K.; Qian, J.; Edrisy, A. Effect of SPD surface layer on plasma nitriding of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2014, 589, 199–208. [Google Scholar] [CrossRef]

- Alikhani Chamgordani, S.; Miresmaeili, R.; Aliofkhazraei, M. Improvement in Tribological Behavior of Commercial Pure Titanium (CP-Ti) by Surface Mechanical Attrition Treatment (SMAT). Tribol. Int. 2018, 119, 744–752. [Google Scholar] [CrossRef]

- Avcu, E.; Yıldıran, Y.; Şahin, A.E.; Fidan, S.; Sınmazçelik, T. Influences of Particle Impingement Angle and Velocity on Surface Roughness, Erosion Rate, and 3D Surface Morphology of Solid Particle Eroded Ti6Al4V Alloy. Acta Phys. Pol. A 2014, 125, 541–543. [Google Scholar] [CrossRef]

- Han, J.; Sheng, G.M.; Zhou, X.L. Diffusion Bonding of Surface Self-nanocrystallized Ti–4Al–2V and 0Cr18Ni9Ti by Means of High Energy Shot Peening. ISIJ Int. 2008, 48, 1238–1245. [Google Scholar] [CrossRef]

- Avcu, E.; Fidan, S.; Yıldıran, Y.; Sınmazçelik, T. Solid Particle Erosion Behaviour of Ti6Al4V Alloy. Tribol. Mater. Surf. Interfaces 2013, 7, 201–210. [Google Scholar] [CrossRef]

- Fidan, S.; Avcu, E.; Karakulak, E.; Yamanoglu, R.; Zeren, M.; Sinmazcelik, T. Effect of Heat Treatment on Erosive Wear Behaviour of Ti6Al4V Alloy. Mater. Sci. Technol. 2013, 29, 1088–1094. [Google Scholar] [CrossRef]

- Goïc, G.L.; Bigerelle, M.; Samper, S.; Favrelière, H.; Pillet, M. Multiscale roughness analysis of engineering surfaces: A comparison of methods for the investigation of functional correlations. Mech. Syst. Signal. Process. 2016, 66–67, 437–457. [Google Scholar] [CrossRef]

- Dong, H.; Bloyce, A.; Bell, T. Slurry Abrasion Response of Surface Engineered Ti6Al4VELI. Tribol. Int. 1999, 32, 517–526. [Google Scholar] [CrossRef]

- Ganesh, B.K.C.; Ramanaiah, N.; Changdrasekhar Rao, P.V. Effect of Surface Treatment on Tribological Behavior of Ti-6Al-4V Implant Alloy. J. Miner. Mater. Charact. Eng. 2012, 11, 735–743. [Google Scholar] [CrossRef]

- Avcu, E.; Yıldıran Avcu, Y.; Baştan, F.E.; Rehman, M.A.U.; Üstel, F.; Boccaccini, A.R. Tailoring the surface characteristics of electrophoretically deposited chitosan-based bioactive glass composite coatings on titanium implants via grit blasting. Prog. Org. Coat. 2018, 123, 362–373. [Google Scholar] [CrossRef]

- Unal, O.; Karaoglanli, A.C.; Ozgurluk, Y.; Doleker, K.M.; Maleki, E.; Varol, R. Wear Behavior of Severe Shot Peened and Thermally Oxidized Commercially Pure Titanium. Adv. Struct. Mater. 2019, 92, 461–470. [Google Scholar] [CrossRef]

- Fei, C.; Hai, Z.; Chen, C.; Xia, Y. Study on The Tribological Performance of Ceramic Coatings on Titanium Alloy Surfaces Obtained Through Microarc Oxidation. Prog. Org. Coat. 2009, 64, 264–267. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Akebono, H.; Misaka, Y.; Komotori, J. Effect of Pre-Treatment with Fine Particle Peening on Surface Properties and Wear Resistance of Gas Blow Induction Heating Nitrided Titanium Alloy. Surf. Coat. Technol. 2019, 359, 476–484. [Google Scholar] [CrossRef]

- Sonntag, R.; Reinders, J.; Gibmeier, J.; Jaeger, S.; Kretzer, J.P. Ti-6Al-4V Fatigue Strength After Shot Peening: The Role of a Corrosive Environment. In Fatigue and Fracture Metallic Medical Materials and Devices; ASTM International: West Conshohocken, PA, USA, 2013; pp. 98–108. [Google Scholar]

- Ahmed, A.A.; Mhaede, M.; Wollmann, M.; Wagner, L. Effect of Micro Shot Peening on The Mechanical Properties and Corrosion Behavior of Two Microstructure Ti–6Al–4V Alloy. Appl. Surf. Sci. 2016, 363, 50–58. [Google Scholar] [CrossRef]

- Yildiz, F.; Yetim, A.F.; Alsaran, A.; Çelik, A. Plasma nitriding behavior of Ti6Al4V orthopedic alloy. Surf. Coat. Technol. 2008, 202, 2471–2476. [Google Scholar] [CrossRef]

- Karaoglanli, A.C. Effect of Severe Air-Blast Shot Peening on The Wear Characteristics of CP Titanium. Mater. Tehnol. 2015, 49, 253–258. [Google Scholar] [CrossRef]

- Mall, S.; Jain, V.K.; Fadag, H.A. Effects of Shot-Peening on Fretting Fatigue Crack Growth Behavior in Ti-6Al-4V. Strain 2011, 47, e305–e318. [Google Scholar] [CrossRef]

- Wagner, L.; Mhaede, M.; Wollmann, M.; Altenberger, I.; Sano, Y. Surface Layer Properties and Fatigue Behavior in Al 7075--T73 and Ti--6Al--4V. Int. J. Struct. Integr. 2011, 2, 185–199. [Google Scholar] [CrossRef]

- Fridrici, V.; Fouvry, S.; Kapsa, P. Effect of Shot Peening on The Fretting Wear of Ti-6Al-4V. Wear 2001, 250, 642–649. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, W.; Zhong, Y.; Zhang, X.; Fu, X.; Chen, G.; Li, Z. Effect of Shot-Peening on The Fretting Wear and Crack Initiation Behavior of Ti-6Al-4V Dovetail Joint Specimens. Int. J. Fatigue 2018, 107, 83–95. [Google Scholar] [CrossRef]

- Cho, K.T.; Song, K.; Oh, S.H.; Lee, Y.-K.; Lim, K.M.; Lee, W.B. Surface Hardening of Aluminum Alloy by Shot Peening Treatment with Zn Based Ball. Mater. Sci. Eng. A 2012, 543, 44–49. [Google Scholar] [CrossRef]

- Liu, W.; Dong, J.; Zhang, P.; Zhai, C.; Ding, W. Effect of Shot Peening on Surface Characteristics and Fatigue Properties of T5-Treated ZK60 Alloy. Mater. Trans. 2009, 50, 791–798. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.G.; Li, M.Q. Structure response characteristics and surface nanocrystallization mechanism of alpha phase in Ti-6Al-4V subjected to high energy shot peening. J. Alloy. Compd. 2019, 773, 860–871. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M. Nanocrystallization Mechanism of Beta Phase in Ti-6Al-4V Subjected to Severe Plastic Deformation. Mater. Sci. Eng. A 2016, 669, 7–13. [Google Scholar] [CrossRef]

- Qandil, A.; Zaid, A.I.O. Effect of shot peening and grain refinement on the fatigue life and strength of commercially pure Al and two of its alloys: Al-2024-T3 and Al-7075-T6. Iop Conf. Ser. Mater. Sci. Eng. 2016, 146, 012028. [Google Scholar] [CrossRef]

- González, J.; Bagherifard, S.; Guagliano, M.; Fernández Pariente, I. Influence of Different Shot Peening Treatments on Surface State and Fatigue Behaviour of Al 6063 Alloy. Eng. Fract. Mech. 2017, 185, 72–81. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Mhaede, M.; Basha, M.; Wollmann, M.; Wagner, L. The Effect of Shot Peening Parameters and Hydroxyapatite Coating on Surface Properties and Corrosion Behavior of Medical Grade AISI 316L Stainless Steel. Surf. Coat. Technol. 2015, 280, 347–358. [Google Scholar] [CrossRef]

- Ganesh, B.K.C.; Sha, W.; Ramanaiah, N.; Krishnaiah, A. Effect of Shotpeening on Sliding Wear and Tensile Behavior of Titanium Implant Alloys. Mater. Des. 2014, 56, 480–486. [Google Scholar] [CrossRef]

- Mitrovic, S.; Adamovic, D.; Zivic, F.; Dzunic, D.; Pantic, M. Friction and Wear Behavior of Shot Peened Surfaces of 36CrNiMo4 and 36NiCrMo16 Alloyed Steels Under Dry And Lubricated Contact Conditions. Appl. Surf. Sci. 2014, 290, 223–232. [Google Scholar] [CrossRef]

- Kovacı, H.; Hacısalihoğlu, İ.; Yetim, A.F.; Çelik, A. Effects of Shot Peening Pre-Treatment and Plasma Nitriding Parameters on The Structural, Mechanical and Tribological Properties of AISI 4140 Low-Alloy Steel. Surf. Coat. Technol. 2019, 358, 256–265. [Google Scholar] [CrossRef]

- Avcu, E. Surface Properties of AA7075 Aluminium Alloy Shot Peened. Acta Mater. Turc. 2017, 1, 3–10. [Google Scholar]

- Amanov, A.; Cho, I.-S.; Kim, D.-E.; Pyun, Y.-S. Fretting Wear and Friction Reduction of CP Titanium and Ti–6Al–4V Alloy by Ultrasonic Nanocrystalline Surface Modification. Surf. Coat. Technol. 2012, 207, 135–142. [Google Scholar] [CrossRef]

- Avcu, E. Bilyalı Dövme Parametrelerinin AA7075 Alüminyum Alaşımının Yüzey Altı Özelliklerine Etkileri. Gazi Üniversitesi Fen Bilimleri Derg. Part. C Tasarım Ve Teknol. 2018. [Google Scholar] [CrossRef]

- Sabelkin, V.; Martinez, S.A.; Mall, S.; Sathish, S.; Blodgett, M.P. Effects of Shot-Peening Intensity on Fretting Fatigue Crack-Initiation Behaviour of Ti-6Al-4V. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 321–332. [Google Scholar] [CrossRef]

- Lee, H.; Mall, S. Fretting behavior of shot peened Ti–6Al–4V under slip controlled mode. Wear 2006, 260, 642–651. [Google Scholar] [CrossRef]

- Kumar, S.; Chattopadhyay, K.; Singh, V. Effect of ultrasonic shot peening on LCF behavior of the Ti–6Al–4V alloy. J. Alloy. Compd. 2017, 724, 187–197. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wong, T.I.; Huang, W.; Sridhar, N.; Wang, S.J. Effect of Surface Polishing Treatment on the Fatigue Performance of Shot-Peened Ti–6Al–4V Alloy. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 630–640. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, W.; Niu, Z.; Zheng, X.; Wang, Q.; Fu, X.; Chen, G.; Li, Z. Effect of Different Surface Asperities and Surface Hardness Induced by Shot-Peening on The Fretting Wear Behavior of Ti-6Al-4V. Surf. Coat. Technol. 2018, 349, 1098–1106. [Google Scholar] [CrossRef]

- Ferreira, N.; Antunes, P.V.; Ferreira, J.A.; Costa, J.; Capela, C. Effects of Shot-Peening and Stress Ratio on The Fatigue Crack Propagation of Al 7475-T7351 Specimens. Appl. Sci. 2018, 8, 375. [Google Scholar] [CrossRef] [Green Version]

- Bonora, R.G.; Voorwald, H.J.C.; Cioffi, M.O.H. Influence of Shot Peening on the Fatigue Strength of Custom 465 Stainless Steel for Aeronautic Application. Adv. Mater. Res. 2014, 891–892, 668–673. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M.; Taylor, D. Multiaxial fatigue resistance of shot peened high-strength aluminum alloys. Int. J. Fatigue 2014, 61, 271–282. [Google Scholar] [CrossRef]

- Bagherifard, S.; Colombo, C.; Guagliano, M. Application of Different Fatigue Strength Criteria to Shot Peened Notched Components. Part 1: Fracture Mechanics Based Approaches. Appl. Surf. Sci. 2014, 289, 180–187. [Google Scholar] [CrossRef]

- Llaneza, V.; Belzunce, F.J. Study of the Effects Produced by Shot Peening on The Surface of Quenced and Tempered Steels: Roughness, Residual Stresses and Work Hardening. Appl. Surf. Sci. 2015, 356, 475–485. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Kashyzadeh, K.R. Effects of Conventional, Severe, Over, and Re-Shot Peening Processes on The Fatigue Behavior of Mild Carbon Steel. Surf. Coat. Technol. 2018, 344, 62–74. [Google Scholar] [CrossRef]

- Bagheri, S.; Guagliano, M. Review of Shot Peening Processes to Obtain Nanocrystalline Surfaces in Metal Alloys. Surf. Eng. 2009, 25, 3–14. [Google Scholar] [CrossRef]

- Nguyen, V.B.; Poh, H.J.; Zhang, Y.-W. Predicting Shot Peening Coverage Using Multiphase Computational Fluid Dynamics Simulations. Powder Technol. 2014, 256, 100–112. [Google Scholar] [CrossRef]

- Harada, Y.; Fukauara, K.; Kohamada, S. Effects of Microshot Peening on Surface Characteristics of High-Speed Tool Steel. J. Mater. Process. Technol. 2008, 201, 319–324. [Google Scholar] [CrossRef]

- Trung, P.Q.; Khun, N.W.; Butler, D.L. Effects of Shot Peening Pressure, Media Type and Double Shot Peening on The Microstructure, Mechanical and Tribological Properties of Low-Alloy Steel. Surf. Topogr. Metrol. Prop. 2016, 4, 045001. [Google Scholar] [CrossRef]

- Marteau, J.; Bigerelle, M.; Mazeran, P.E.; Bouvier, S. Relation between roughness and processing conditions of AISI 316L stainless steel treated by ultrasonic shot peening. Tribol. Int. 2015, 82, 319–329. [Google Scholar] [CrossRef]

- Sawada, T. Effect of Young’s Modulus of Shot Peening Media on Surface Modification Behavior by Micro Shot Peening. In Proceedings of the 13. International Conferences on Shot Peening, Montreal, QC, Canada, 18–21 September 2017. [Google Scholar]

- Xie, L.; Jiang, C.; Lu, W. The Influence of Shot Peening on The Surface Properties of (TiB+TiC)/Ti-6Al-4V. Appl. Surf. Sci. 2013, 280, 981–988. [Google Scholar] [CrossRef]

- Sanjurjo, P.; Rodríguez, C.; Pariente, I.F.; Belzunce, F.J.; Canteli, A.F. The Influence of Shot Peening on The Fatigue Behaviour of Duplex Stainless Steels. Procedia Eng. 2010, 2, 1539–1546. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Lu, S.; Wu, T.; Zhou, Z.; Zhang, W. An evaluation on SP surface property by means of combined FEM-DEM shot dynamics simulation. Adv. Eng. Softw. 2018, 115, 283–296. [Google Scholar] [CrossRef]

- Nam, Y.-S.; Jeong, Y.-I.; Shin, B.-C.; Byun, J.-H. Enhancing Surface Layer Properties of An Aircraft Aluminum Alloy by Shot Peening Using Response Surface Methodology. Mater. Des. 2015, 83, 566–576. [Google Scholar] [CrossRef]

- Abood, A.N.; Saleh, A.H.; Salem, R.K.; Kadhim, G.A.; Abdullah, Z.W. Strain Life of Shot Peening AA 2024-T4. J. Mater. Sci. Res. 2012, 2. [Google Scholar] [CrossRef]

- Morita, T.; Noda, S.; Kagaya, C. Influence of Hardness of Substrates on Properties of Surface Layer Formed by Fine Particle Bombarding. Mater. Sci. Eng. A 2013, 574, 197–204. [Google Scholar] [CrossRef]

- Chen, G.; Jiao, Y.; Tian, T.; Zhang, X.; Li, Z.; Zhou, W. Effect of Wet Shot Peening on Ti-6Al-4V Alloy Treated by Ceramic Beads. Trans. Nonferrous Met. Soc. China 2014, 24, 690–696. [Google Scholar] [CrossRef]

- Unal, O.; Maleki, E. Shot Peening Optimization with Complex Decision-Making Tool: Multi Criteria Decision-Making. Measurement 2018, 125, 133–141. [Google Scholar] [CrossRef]

- Bansal, D.G.; Kirkham, M.; Blau, P.J. Effects of Combined Diffusion Treatments and Cold Working on The Sliding Friction and Wear Behavior of Ti–6Al–4V. Wear 2013, 302, 837–844. [Google Scholar] [CrossRef]

- Uematsu, Y.; Kakiuchi, T.; Hattori, K. EBSD-Assisted Fractography of Sub-Surface Fatigue Crack Initiation Mechanism in The Ultrasonic-Shot-Peened βeta-Type Titanium Alloy. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2239–2248. [Google Scholar] [CrossRef]

- Takahashi, K.; Sato, E. Influence of Surface Treatments on Fatigue Strength of Ti6Al4V Alloy. Mater. Trans. 2010, 51, 694–698. [Google Scholar] [CrossRef] [Green Version]

- Apachitei, I.; Leoni, A.; Riemslag, A.C.; Fratila-Apachitei, L.E.; Duszczyk, J. Enhanced Fatigue Performance of Porous Coated Ti6Al4V Biomedical Alloy. Appl. Surf. Sci. 2011, 257, 6941–6944. [Google Scholar] [CrossRef]

- Tang, C.; Liu, D.; Tang, B.; Zhang, X.; Qin, L.; Liu, C. Influence of Plasma Molybdenizing and Shot-Peening on Fretting Damage Behavior of Titanium Alloy. Appl. Surf. Sci. 2016, 390, 946–958. [Google Scholar] [CrossRef]

- Pant, B.K.; Pavan, A.H.V.; Prakash, R.V.; Kamaraj, M. Effect of laser peening and shot peening on fatigue striations during FCGR study of Ti6Al4V. Int. J. Fatigue 2016, 93, 38–50. [Google Scholar] [CrossRef]

- Zammit, A.; Abela, S.; Wagner, L.; Mhaede, M.; Grech, M. Tribological behaviour of shot peened Cu–Ni austempered ductile iron. Wear 2013, 302, 829–836. [Google Scholar] [CrossRef]

- Oh, S.D.; Jung, W.W.; Bae, D.H.; Lee, Y.Z. Friction and Wear Characteristics for Automotive Leaf Spring Materials due to the Influence of the Residual Stress. Key Eng. Mater. 2005, 297–300, 1388–1394. [Google Scholar] [CrossRef]

- Palacios, M.; Bagherifard, S.; Guagliano, M.; Fernández Pariente, I. Influence of severe shot peening on wear behaviour of an aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 821–829. [Google Scholar] [CrossRef]

- Karademir, I.; Unal, O.; Ates, S.; Gokce, H.; Gok, M.S. Effect of Severe Plastic Deformation on Wear Properties of Aluminum Matrix Composites. Acta Phys. Pol. A 2017, 131, 487–490. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.G.; Pan, Y.X.; Li, X.Q. Effects of The Different Frequencies and Loads of Ultrasonic Surface Rolling on Surface Mechanical Properties and Fretting Wear Resistance of HIP Ti–6Al–4V Alloy. Appl. Surf. Sci. 2016, 389, 324–334. [Google Scholar] [CrossRef]

- Sun, Y. Sliding wear behaviour of surface mechanical attrition treated AISI 304 stainless steel. Tribol. Int. 2013, 57, 67–75. [Google Scholar] [CrossRef]

- Kang, J.; Wang, M.; Yue, W.; Fu, Z.; Zhu, L.; She, D.; Wang, C. Tribological Behavior of Titanium Alloy Treated by Nitriding and Surface Texturing Composites Technology. Materials 2019, 12, 301. [Google Scholar] [CrossRef] [Green Version]

- Zhu, L.; Guan, Y.; Lin, J.; Zhai, J.; Xie, Z. A Nanocrystalline-Amorphous Mixed Layer Obtained by Ultrasonic Shot Peening on Pure Titanium at Room Temperature. Ultrason. Sonochem. 2018, 47, 68–74. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Kang, Y.; Li, D.; Wang, X.; Zeng, D. Experimental Investigation on Surface Quality Processed by Self-Excited Oscillation Pulsed Waterjet Peening. Mater. (Basel) 2017, 10. [Google Scholar] [CrossRef] [Green Version]

- Tong, Z.P.; Ren, X.D.; Zhou, W.F.; Adu-Gyamfi, S.; Chen, L.; Ye, Y.X.; Ren, Y.P.; Dai, F.Z.; Yang, J.D.; Li, L. Effect of Laser Shock Peening on Wear Behaviors of TC11 Alloy at Elevated Temperature. Opt. Laser Technol. 2019, 109, 139–148. [Google Scholar] [CrossRef]

- Bagherifard, S.; Hickey, D.J.; Fintova, S.; Pastorek, F.; Fernandez-Pariente, I.; Bandini, M.; Webster, T.J.; Guagliano, M. Effects of Nanofeatures Induced by Severe Shot Peening (SSP) on Mechanical, Corrosion and Cytocompatibility Properties of Magnesium Alloy AZ31. Acta Biomater 2018, 66, 93–108. [Google Scholar] [CrossRef]

- Wang, H.; Yuan, X.; Wu, K.; Xu, C.; Jiao, Y.; Ge, W.; Luo, J. Effect of High Energy Shot-Peening on The Microstructure and Mechanical Properties of Al5052/Ti6Al4V Lap Joints. J. Mater. Process. Technol. 2018, 255, 76–85. [Google Scholar] [CrossRef]

- Dunne, C.F.; Twomey, B.; O’Neill, L.; Stanton, K.T. Co-blasting of titanium surfaces with an abrasive and hydroxyapatite to produce bioactive coatings: Substrate and coating characterisation. J. Biomater. Appl. 2014, 28, 767–778. [Google Scholar] [CrossRef] [PubMed]

- Stav, O.; Kasem, H.; Akhvlediani, R.; Hoffman, A.; Kligerman, Y.; Etsion, I. Simultaneous Shot-Peening of hard and soft particles for friction reduction in reciprocal sliding. Tribol. Int. 2019, 130, 19–26. [Google Scholar] [CrossRef]

- Lin, N.; Li, D.; Zou, J.; Xie, R.; Wang, Z.; Tang, B. Surface Texture-Based Surface Treatments on Ti6Al4V Titanium Alloys for Tribological and Biological Applications: A Mini Review. Materials 2018, 11, 487. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, D.; Yao, C.; Zhang, D. Surface characterization and fatigue evaluation in GH4169 superalloy: comparing results after finish turning; shot peening and surface polishing treatments. Int. J. Fatigue 2018, 113, 222–235. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. Numerical and Experimental Analysis of Surface Roughness Generated by Shot Peening. Appl. Surf. Sci. 2012, 258, 6831–6840. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Amanov, A. Novel Experimental Methods for The Determination of The Boundaries Between Conventional, Severe and Over Shot Peening Processes. Surf. Interfaces 2018, 13, 233–254. [Google Scholar] [CrossRef]

- Vázquez, J.; Navarro, C.; Domínguez, J. Experimental Results in Fretting Fatigue with Shot and Laser Peened Al 7075-T651 Specimens. Int. J. Fatigue 2012, 40, 143–153. [Google Scholar] [CrossRef]

- Trško, L.; Bokůvka, O.; Nový, F.; Guagliano, M. Effect of Severe Shot Peening on Ultra-High-Cycle Fatigue of A Low-Alloy Steel. Mater. Des. 2014, 57, 103–113. [Google Scholar] [CrossRef]

- Abdulstaar, M.; Mhaede, M.; Wollmann, M.; Wagner, L. Investigating The Effects of Bulk and Surface Severe Plastic Deformation on The Fatigue, Corrosion Behaviour and Corrosion Fatigue of AA5083. Surf. Coat. Technol. 2014, 254, 244–251. [Google Scholar] [CrossRef]

- Lainé, S.J.; Knowles, K.M.; Doorbar, P.J.; Cutts, R.D.; Rugg, D. Microstructural Characterisation of Metallic Shot Peened and Laser Shock Peened Ti–6Al–4V. Acta Mater. 2017, 123, 350–361. [Google Scholar] [CrossRef] [Green Version]

- Luong, H.; Hill, M.R. The effects of laser peening and shot peening on high cycle fatigue in 7050-T7451 aluminum alloy. Mater. Sci. Eng. A 2010, 527, 699–707. [Google Scholar] [CrossRef]

- Scuracchio, B.G.; de Lima, N.B.; Schön, C.G. Role of residual stresses induced by double peening on fatigue durability of automotive leaf springs. Mater. Des. 2013, 47, 672–676. [Google Scholar] [CrossRef]

- Rahaman, M.L.; Zhang, L.; Liu, M.; Liu, W. Surface Roughness Effect on The Friction and Wear of Bulk Metallic Glasses. Wear 2015, 332–333, 1231–1237. [Google Scholar] [CrossRef]

- Mhaede, M.; Pastorek, F.; Hadzima, B. Influence of shot peening on corrosion properties of biocompatible magnesium alloy AZ31 coated by dicalcium phosphate dihydrate (DCPD). Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 39, 330–335. [Google Scholar] [CrossRef] [PubMed]

- Atieh, A.M.; Allaf, R.M.; AlHazaa, A.; Barghash, M.; Mubaydin, H. Effect of Pre-and Post-Weld Shot Peening on the Mechanical & Tribological Properties of TIG Welded Aluminum 6061-T6 Alloy. Trans. Can. Soc. Mech. Eng. 2017, 41, 197–209. [Google Scholar]

- Svahn, F.; Kassman-Rudolphi, Å.; Wallén, E. The Influence of Surface Roughness on Friction and Wear of Machine Element Coatings. Wear 2003, 254, 1092–1098. [Google Scholar] [CrossRef]

- Shaha, K.P.; Pei, Y.T.; Martinez-Martinez, D.; De Hosson, J.T.M. Influence of Hardness and Roughness on The Tribological Performance of TiC/a-C Nanocomposite Coatings. Surf. Coat. Technol. 2010, 205, 2624–2632. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Correlation Between Standard Roughness Parameters Skewness and Kurtosis and Tribological Behaviour of Contact Surfaces. Tribol. Int. 2012, 48, 102–112. [Google Scholar] [CrossRef]

- Avcu, E. The Influences of ECAP on The Dry Sliding Wear Behaviour of AA7075 Aluminium Alloy. Tribol. Int. 2017, 110, 173–184. [Google Scholar] [CrossRef]

- Kato, H.; Ueki, H.; Yamamoto, K.; Yasunaga, K.Y. Wear Resistance Improvement by Nanostructured Surface Layer Produced by Burnishing. Mater. Sci. Forum 2017, 917, 231–235. [Google Scholar] [CrossRef]

- Jain, A.; Singh, A.; Singh, A.P. Effect of Tribological Parameters on Sliding Wear and Friction Coefficient Which Relates to Preload Loss in Tapered Roller Bearing. Ind. Lubr. Tribol. 2019, 71, 61–73. [Google Scholar] [CrossRef]

- Wu, Z.; Xing, Y.; Huang, P.; Liu, L. Tribological properties of dimple-textured titanium alloys under dry sliding contact. Surf. Coat. Technol. 2017, 309, 21–28. [Google Scholar] [CrossRef]

- Purcek, G.; Saray, O.; Kul, O.; Karaman, I.; Yapici, G.G.; Haouaoui, M.; Maier, H.J. Mechanical and Wear Properties of Ultrafine-Grained Pure Ti Produced by Multi-Pass Equal-Channel Angular Extrusion. Mater. Sci. Eng. A 2009, 517, 97–104. [Google Scholar] [CrossRef]

- Yamanoğlu, R.; Karakulak, E.; Zeren, A.; Zeren, M. Effect of Heat Treatment on The Tribological Properties of Al–Cu–Mg/NanoSiC Composites. Mater. Des. 2013, 49, 820–825. [Google Scholar] [CrossRef]

- La, P.; Ma, J.; Zhu, Y.T.; Yang, J.; Liu, W.; Xue, Q.; Valiev, R.Z. Dry-Sliding Tribological Properties of Ultrafine-Grained Ti Prepared by Severe Plastic Deformation. Acta Mater. 2005, 53, 5167–5173. [Google Scholar] [CrossRef]

- Wen, M.; Wen, C.; Hodgson, P.D.; Li, Y.C. Tribological Behaviour of Pure Ti with a Nanocrystalline Surface Layer Under Different Loads. Tribol. Lett. 2011, 45, 59–66. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Pyoun, Y.S.; Lee, C.S.; Park, I.G. Micro-Dimpled Surface by Ultrasonic Nanocrystal Surface Modification and Its Tribological Effects. Wear 2012, 286–287, 136–144. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yıldıran Avcu, Y.; Yetik, O.; Guney, M.; Iakovakis, E.; Sınmazçelik, T.; Avcu, E. Surface, Subsurface and Tribological Properties of Ti6Al4V Alloy Shot Peened under Different Parameters. Materials 2020, 13, 4363. https://doi.org/10.3390/ma13194363

Yıldıran Avcu Y, Yetik O, Guney M, Iakovakis E, Sınmazçelik T, Avcu E. Surface, Subsurface and Tribological Properties of Ti6Al4V Alloy Shot Peened under Different Parameters. Materials. 2020; 13(19):4363. https://doi.org/10.3390/ma13194363

Chicago/Turabian StyleYıldıran Avcu, Yasemin, Okan Yetik, Mert Guney, Eleftherios Iakovakis, Tamer Sınmazçelik, and Egemen Avcu. 2020. "Surface, Subsurface and Tribological Properties of Ti6Al4V Alloy Shot Peened under Different Parameters" Materials 13, no. 19: 4363. https://doi.org/10.3390/ma13194363

APA StyleYıldıran Avcu, Y., Yetik, O., Guney, M., Iakovakis, E., Sınmazçelik, T., & Avcu, E. (2020). Surface, Subsurface and Tribological Properties of Ti6Al4V Alloy Shot Peened under Different Parameters. Materials, 13(19), 4363. https://doi.org/10.3390/ma13194363