Influence of Filler Loading on the Mechanical Properties of Flowable Resin Composites

Abstract

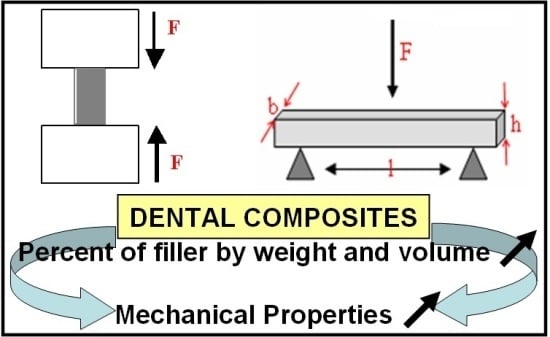

:1. Introduction

2. Material and Methods

2.1. Preparation of the FRC Samples for the Mechanical Test

2.2. Percentage of Fillers by Weight and Volume

2.3. Mechanical Test

2.4. Scanning Electron Microscope (SEM)

2.5. Statistical Analyses

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sakaguchi, R.L.; Powers, J.M. Craig’s Restorative Dental Materials; Elsevier: Mosby, PA, USA, 2012. [Google Scholar]

- Jager, S.; Balthazard, R.; Dahoun, A.; Mortier, E. Filler content, surface microhardness, and rheological properties of various flowable resin composites. Oper. Dent. 2016, 6, 655–665. [Google Scholar] [CrossRef] [PubMed]

- Baroudi, K.; Silikas, N.; Watts, D.C. Edge-strength of flowable resin-composites. J. Dent. 2008, 36, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Yildirim, D.; Ermis, R.B.; Gormez, O.; Yildiz, G. Comparison of radiopacities of different flowable resin composites. J. Oral. Maxillofac. Radiol. 2014, 2, 21–25. [Google Scholar] [CrossRef]

- Furtos, G.; Baldea, B.; Silaghi-Dumitrescu, L.; Bratu, D.; Moldovan, M.; Prejmerean, C. Measuring the radiopacity of flowable resin composites using scanned radiograph images. Particul. Sci Technol. 2012, 30, 391–402. [Google Scholar] [CrossRef]

- Liu, F.; Wang, R.; Cheng, Y.; Jiang, X.; Zhang, Q.; Zhu, M. Polymer grafted hydroxyapatite whisker as a filler for dental composite resin with enhanced physical and mechanical properties. Mater. Sci. Eng. C 2013, 8, 4994–5000. [Google Scholar] [CrossRef]

- Aydınoğlu, A.; Yoruç, A.B.H. Effects of silane-modified fillers on properties of dental composite resin. Mater. Sci. Eng. C 2017, 79, 382–389. [Google Scholar] [CrossRef]

- Randolph, L.D.; Steinhaus, J.; Möginger, B.; Gallez, B.; Stansbury, J.; Palin, W.M.; Leloup, G.; Leprince, J.G. Photopolymerization of highly filled dimethacrylate-based composites using Type I or Type II photoinitiators and varying co-monomer ratios. Dent. Mater. 2016, 2, 136–148. [Google Scholar] [CrossRef]

- Fugolin, A.P.P.; Pfeifer, C.S. New resins for dental composites. J. Dent. Res. 2017, 10, 1085–1091. [Google Scholar] [CrossRef]

- Furtos, G.; Tomoaia-Cotisel, M.; Garbo, C.; Şenilă, M.; Jumate, N.; Vida-Simiti, I.; Prejmerean, C. New composite bone cement based on hydroxyapatite and nanosilver. Particul. Sci Technol. 2013, 31, 392–398. [Google Scholar] [CrossRef]

- Lassila, L.; Säilynoja, E.; Prinssi, R.; Vallittu, P.; Garoushi, S. Characterization of a new fiber-reinforced flowable composite. Odontology 2019, 3, 342–352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tsujimoto, A.; Barkmeier, W.W.; Takamizawa, T.; Latta, M.A.; Miyazaki, M. Influence of thermal stress on simulated localized and generalized wear of nanofilled resin composites. Oper. Dent. 2018, 4, 380–390. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N.; Hickel, R. Investigations on mechanical behaviour of dental composites. Clin. Oral Investig. 2009, 4, 427–438. [Google Scholar] [CrossRef] [PubMed]

- Randolph, L.D.; Palin, W.M.; Leloup, G.; Leprince, J.G. Filler characteristics of modern dental resin composites and their influence on physico-mechanical properties. Dent. Mater. 2016, 12, 1586–1599. [Google Scholar] [CrossRef] [PubMed]

- Leprince, J.G.; Palin, W.M.; Hadis, M.A.; Devaux, J.; Leloup, G. Progress in dimethacrylate- based dental composite technology and curing efficiency. Dent. Mater. 2013, 2, 139–156. [Google Scholar] [CrossRef]

- Furtos, G.; Silaghi-Dumitrescu, L.; Moldovan, M.; Baldea, B.; Trusca, R.; Prejmerean, C. Influence of filler/reinforcing agent and post-curing on the flexural properties of woven and unidirectional glass fiber-reinforced composites. J. Mater. Sci. 2012, 47, 3305–3314. [Google Scholar] [CrossRef]

- Furtos, G.; Tomoaia-Cotisel, M.; Baldea, B.; Prejmerean, C. Development and characterization of new AR glass fiber reinforced cements with potential medical applications. J. Appl. Polym. Sci. 2013, 15, 1266–1273. [Google Scholar] [CrossRef]

- Ferracane, J.L. Resin composite-state of the art. Dent. Mater. 2011, 1, 29–38. [Google Scholar] [CrossRef]

- Heintze, S.D.; Ilie, N.; Hickel, R.; Reis, A.; Loguercio, A.; Rousson, V. Laboratory mechanical parameters of composite resins and their relation to fractures and wear in clinical trials—A systematic review. Dent. Mater. 2017, 3, e101–e114. [Google Scholar] [CrossRef]

- Yazici, A.R.; Ozgünaltay, G.; Dayangaç, B. The effect of different types of flowable restorative resins on microleakage of Class V cavities. Oper. Dent. 2003, 6, 773–778. [Google Scholar]

- Baldea, B.; Silaghi-Dumitrescu, L.; Furtos, G. Fracture load and force load at upper yield of alkaline resistant glass fiber reinforced endodontic posts. Polym. Compos. 2017, 38, 260–267. [Google Scholar] [CrossRef]

- Furtos, G.; Baldea, B.; Silaghi-Dumitrescu, L.; Moldovan, M.; Prejmerean, C.; Nica, L. Influence of inorganic filler content on the radiopacity of dental resin cements. Dent. Mater. J. 2012, 2, 266–272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO standard 4049. Dentistry–Polymer-Based Filling, Restorative and Luting Materials; International Organization for Standardisation: Geneva, Switzerland, 2019. [Google Scholar]

- Nitta, K.; Nomoto, R.; Tsubota, Y.; Tsuchikawa, M.; Hayakawa, T. Characteristics of low polymerization shrinkage flowable resin composites in newly-developed cavity base materials for bulk filling technique. Dent. Mater. J. 2017, 6, 740–746. [Google Scholar] [CrossRef] [Green Version]

- Furtos, G.; Naghiu, M.A.; Declercq, H.; Gorea, M.; Prejmerean, C.; Pana, O.; Tomoaia-Cotisel, M. Nano forsterite biocomposites for medical applications: Mechanical properties and bioactivity. J. Biomed. Mater. Res. Part B 2015, 7, 1290–1301. [Google Scholar] [CrossRef] [PubMed]

- Ferracane, J.L. Resin-based composite performance: Are there some things we can’t predict? Dent. Mater. 2013, 1, 51–58. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei Su, L.; Lin, D.J.; Yen Uan, J. Novel dental resin composites containing LiAl-F layered double hydroxide (LDH) filler: Fluoride release/recharge, mechanical properties, color change, and cytotoxicity. Dent. Mater. 2019, 5, 663–672. [Google Scholar] [CrossRef] [PubMed]

- Abaszadeh, M.; Mohammadi, M.; Mohammadzadeh, I. Biocompatibility of a New Antibacterial compound and its effect on the mechanical properties of flowable dental composites (Animal Study). J. Dent. 2020, 1, 56–62. [Google Scholar] [CrossRef]

- Dafar, M.O.; Grol, M.W.; Canham, P.B.; Dixon, S.J.; Rizkalla, A.S. Reinforcement of flowable dental composites with titanium dioxide nanotubes. Dent. Mater. 2016, 32, 817–826. [Google Scholar] [CrossRef] [Green Version]

- Engelhardt, F.; Hahnel, S.; Preis, V.; Rosentritt, M. Comparison of flowable bulk-fill and flowable resin-based composites: an in vitro analysis. Clin. Oral. Investig. 2016, 8, 2123–2130. [Google Scholar] [CrossRef]

- Pieniak, D.; Walczak, A.; Walczak, M.; Przystupa, K.; Niewczas, A.M. Hardness and wear resistance of dental biomedical nanomaterials in a humid environment with non-stationary temperatures. Materials 2020, 5, 1255. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez, H.A.; Kriven, W.M.; Casanova, H. Development of mechanical properties in dental resin composite: Effect of filler and filler aggregation state. Mater. Sci. Eng. C 2019, 101, 274–282. [Google Scholar] [CrossRef]

- Lempel, E.; Toth, A.; Fabian, T.; Krajczar, K.; Szalma, J. Retrospective evaluation of posterior direct composite restorations: 10-year findings. Dent. Mater. 2015, 31, 115–122. [Google Scholar] [CrossRef] [PubMed]

- Baroudi, K.; Rodrigues, J.C. Flowable resin composites: a systematic review and clinical considerations. J. Clin. Diagn. Res. 2015, 6, ZE18–ZE24. [Google Scholar] [CrossRef] [PubMed]

- Scribante, A.; Bollardi, M.; Chiesa, M.; Poggio, C.; Colombo, M. Flexural Properties and Elastic Modulus of Different Esthetic Restorative Materials: Evaluation after Exposure to Acidic Drink. Biomed. Res. Int. 2019, 5109481. [Google Scholar] [CrossRef] [PubMed]

| No. | Product | Manufacturer | Shade | Composition |

|---|---|---|---|---|

| 1 | Accolade SRO | Danville Materials Inc. San Ramon, CA, USA | A2 | 65 wt. % inorganic filler, NC vol. % |

| 2 | Accolade PV | Danville Materials Inc. San Ramon, CA, USA | A2 | 65 wt. % inorganic filler, NC vol. % |

| 3 | Els (Extra Low Shrinkage) | Saremco Dental AG, Rebstein, Switzerland | A3op | Barium glass silanized, bis-GMA, bis-EMA, catalyst, inhibitors, and pigments; NC wt. %, NC vol. % |

| 4 | Filtek Supreme XT | 3M ESPE, Seefeld, 3M ESPE | A3 | bis-GMA, bis-EMA, TEGDMA, silica nanofiller, zirconia nanofiller and zirconia/silica nanocluster (65 wt. % inorganic filler, 55 vol. % inorganic filler) |

| 5 | PermaFlo | Ultradent, South Jordan, UT, USA | A1 | Methacrylate monomer, alkylamino methacrylate, CQ, 68 wt. % inorganic filler, NC vol. % |

| 6 | PermaFlo DC | Ultradent, South Jordan, UT, USA | A2 | 70 wt. % inorganic filler, NC vol. % |

| 7 8 | Tetric EvoFlow | Ivoclar Vivadent, Schaan, Liechtenstein | A3 Bleach L | bis-GMA, UDMA, dimethacrylate, decandiol, prepolymers, additives, stabilizers and catalysts, pigments, barium glass filler, ytterbium trifluoride, silicon oxide, mixed oxide 57.5 wt. % inorganic filler, 30.7 vol. % inorganic filler |

| 9 | StarFill 2B | Danville Materials Inc. San Ramon, CA, USA | 61 wt. % inorganic filler, 41 vol. % inorganic filler | |

| 10 | StarFlow | Danville Materials Inc. San Ramon, CA, USA | A2 | 61 wt. % inorganic filler NC vol. % |

| 11 12 13 14 15 | SYNERGY Nano Formula | Coltene Whaledent, Altstaetten, Switzerland | Super White A2/B2 A4/M5 A3.5/B3 A3/D3 | bis-GMA, Bis-EMA, TEGDMA, Strontium glass, Amorphous silica, Hydrophobed 55 wt. % inorganic filler 32 vol. % inorganic filler |

| 16 | wave | SDI, Bayswater, Vic, Australia | A3 | 35 wt. % multifunctional methacrylic ester 65 wt. % inorganic filler |

| 17 | wave mv | SDI, Bayswater, Vic, Australia | A2 | 40 wt. % multifunctional methacrylic ester 60 wt. % inorganic filler |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirică, I.-C.; Furtos, G.; Bâldea, B.; Lucaciu, O.; Ilea, A.; Moldovan, M.; Câmpian, R.-S. Influence of Filler Loading on the Mechanical Properties of Flowable Resin Composites. Materials 2020, 13, 1477. https://doi.org/10.3390/ma13061477

Mirică I-C, Furtos G, Bâldea B, Lucaciu O, Ilea A, Moldovan M, Câmpian R-S. Influence of Filler Loading on the Mechanical Properties of Flowable Resin Composites. Materials. 2020; 13(6):1477. https://doi.org/10.3390/ma13061477

Chicago/Turabian StyleMirică, Ioana-Codruţa, Gabriel Furtos, Bogdan Bâldea, Ondine Lucaciu, Aranka Ilea, Mărioara Moldovan, and Radu-Septimiu Câmpian. 2020. "Influence of Filler Loading on the Mechanical Properties of Flowable Resin Composites" Materials 13, no. 6: 1477. https://doi.org/10.3390/ma13061477

APA StyleMirică, I. -C., Furtos, G., Bâldea, B., Lucaciu, O., Ilea, A., Moldovan, M., & Câmpian, R. -S. (2020). Influence of Filler Loading on the Mechanical Properties of Flowable Resin Composites. Materials, 13(6), 1477. https://doi.org/10.3390/ma13061477