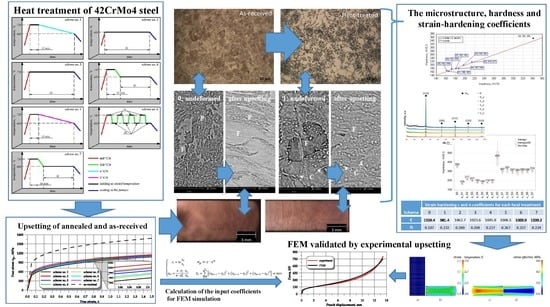

Effect of Annealing Time and Temperature Parameters on the Microstructure, Hardness, and Strain-Hardening Coefficients of 42CrMo4 Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Investigated Steel and Heat Treatment

2.2. Characterization of the Annealed and Deformed Samples—Microstructure and Hardness

2.3. Comparison of the Experimental and FEM Results of Upsetting

3. Results and Discussion

3.1. Heat Treatment Effect on 42CrMo4 Steel Properties

3.1.1. Microstructures’ Development Owing to Heat Treatment

3.1.2. Effects of Annealing Schemes on the Macro- and Microstructure of Upset Samples

3.1.3. Effect of Annealing on Phase Composition (XRD)

3.2. Effect of Heat Treatment on Hardness

3.3. Analysis of Upsetting Test Results

3.4. Comparison of the Numerical and Experimental Upsetting Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, C.; Fu, P.-X.; Liu, H.-W.; Liu, H.-H.; Du, N.-Y. Effect of Tempering Temperature on the Low Temperature Impact Toughness of 42CrMo4-V Steel. Metals 2018, 8, 232. [Google Scholar] [CrossRef] [Green Version]

- Chaouch, D.; Guessasma, S.; Sadok, A. Finite Element simulation coupled to optimisation stochastic process to assess the effect of heat treatment on the mechanical properties of 42CrMo4 steel. Mater. Des. 2012, 34, 679–684. [Google Scholar] [CrossRef]

- Macek, W.; Szala, M.; Kowalski, M.; Gargasas, J.; Rehmus-Forc, A.; Deptuła, A. Shot peening intensity effect on bending fatigue strength of S235, S355 and P460 structural steels. IOP Conf. Ser. Mater. Sci. Eng. 2019, 710, 012035. [Google Scholar] [CrossRef]

- Tomków, J.; Czupryński, A.; Fydrych, D. The Abrasive Wear Resistance of Coatings Manufactured on High-Strength Low-Alloy (HSLA) Offshore Steel in Wet Welding Conditions. Coatings 2020, 10, 219. [Google Scholar] [CrossRef] [Green Version]

- Macek, W. Post-failure fracture surface analysis of notched steel specimens after bending-torsion fatigue. Eng. Fail. Anal. 2019, 105, 1154–1171. [Google Scholar] [CrossRef]

- Kreethi, R.; Mondal, A.K.; Dutta, K. Ratcheting fatigue behaviour of 42CrMo4 steel under different heat treatment conditions. Mater. Sci. Eng. A 2017, 679, 66–74. [Google Scholar] [CrossRef]

- Nagarajan, V.R.; Putatunda, S.K.; Boileau, J. Fatigue Crack Growth Behavior of Austempered AISI 4140 Steel with Dissolved Hydrogen. Metals 2017, 7, 466. [Google Scholar] [CrossRef] [Green Version]

- Dossett, J.L.; Totten, G.E. ASM Handbook: Volume 4: Heat Treating, 10th ed.; ASM International: Materials Park, OH, USA, 1991. [Google Scholar]

- Rakhit, A.K. Heat Treatment of Gears: A Practical Guide for Engineers; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Karadeniz, E. Influence of different initial microstructure on the process of spheroidization in cold forging. Mater. Des. 2008, 29, 251–256. [Google Scholar] [CrossRef]

- Meysami, A.H.; Ghasemzadeh, R.; Seyedein, S.H.; Aboutalebi, M.R. An investigation on the microstructure and mechanical properties of direct-quenched and tempered AISI 4140 steel. Mater. Des. 2010, 31, 1570–1575. [Google Scholar] [CrossRef]

- Bilal, M.M.; Yaqoob, K.; Zahid, M.H.; Ehsan, U.H.; Tanveer, W.H.; Wadood, A.; Ahmed, B. Effect of austempering conditions on the microstructure and mechanical properties of AISI 4340 and AISI 4140 steels. J. Mater. Res. Technol. 2019, 8, 5194–5200. [Google Scholar] [CrossRef]

- Katiyar, P.K.; Misra, S.; Mondal, K. Corrosion Behavior of Annealed Steels with Different Carbon Contents (0.002, 0.17, 0.43 and 0.7% C) in Freely Aerated 3.5% NaCl Solution. J. Mater. Eng. Perform. 2019, 28, 4041–4052. [Google Scholar] [CrossRef]

- Zong, Y.; Liu, C.-M. Continuous Cooling Transformation Diagram, Microstructures, and Properties of the Simulated Coarse-Grain Heat-Affected Zone in a Low-Carbon Bainite E550 Steel. Metals 2019, 9, 939. [Google Scholar] [CrossRef] [Green Version]

- Carvajal, L.; Artigas, A.; Monsalve, A.; Arévalo, E.; Carvajal, L.; Artigas, A.; Monsalve, A.; Arévalo, E. Monitoring Heat Treatments in Steels by a Non Destructive Ultrasonic Method. Mater. Res. 2017, 20, 347–352. [Google Scholar] [CrossRef] [Green Version]

- Frint, P.; Härtel, M.; Selbmann, R.; Dietrich, D.; Bergmann, M.; Lampke, T.; Landgrebe, D.; Wagner, M.F.X. Microstructural Evolution during Severe Plastic Deformation by Gradation Extrusion. Metals 2018, 8, 96. [Google Scholar] [CrossRef] [Green Version]

- Cios, G.; Tokarski, T.; Bała, P. Strain-induced martensite reversion in 18Cr–8Ni steel—Transmission Kikuchi diffraction study. Mater. Sci. Technol. 2018, 34, 580–583. [Google Scholar] [CrossRef]

- Xie, L.; Wang, C.; Wang, Y.; Wu, G.; Huang, X. Grain Size Effect on the Mechanical Behavior of Metastable Fe-23Cr-8.5Ni Alloy. Metals 2019, 9, 734. [Google Scholar] [CrossRef] [Green Version]

- Escobar, J.D.; Poplawsky, J.D.; Faria, G.A.; Rodriguez, J.; Oliveira, J.P.; Salvador, C.A.F.; Mei, P.R.; Babu, S.S.; Ramirez, A.J. Compositional analysis on the reverted austenite and tempered martensite in a Ti-stabilized supermartensitic stainless steel: Segregation, partitioning and carbide precipitation. Mater. Des. 2018, 140, 95–105. [Google Scholar] [CrossRef]

- Khatirkar, R.K.; Yadav, P.; Sapate, S.G. Structural and Wear Characterization of Heat Treated En24 Steel. ISIJ Int. 2012, 52, 1370–1376. [Google Scholar] [CrossRef] [Green Version]

- Bouras, M.; Boumaiza, A.; Ji, V.; Rouag, N. XRD peak broadening characterization of deformed microstructures and heterogeneous behavior of carbon steel. Theor. Appl. Fract. Mech. 2012, 61, 51–56. [Google Scholar] [CrossRef]

- Li, T.; Zheng, J.; Chen, Z. Description of full-range strain hardening behavior of steels. SpringerPlus 2016, 5, 1316. [Google Scholar] [CrossRef] [Green Version]

- Aghaie-khafri, M.; Sheikh Ansary, M.H. Optimization of thermomechanical parameters to produce an ultra-high strength compressor disk. Iran. J. Mater. Form. 2015, 2, 54–61. [Google Scholar]

- Winiarski, G.; Gontarz, A.; Dziubińska, A. The influence of tool geometry on the course of flanges radial extrusion in hollow parts. Arch. Civ. Mech. Eng. 2017, 17, 986–996. [Google Scholar] [CrossRef]

- Altinbalik, T.; Ayer, Ö. A theoretical and experimental study for the load optimization of gear-like profiles by using forward and lateral extrusion. Trans. Can. Soc. Mech. Eng. 2015, 39, 53–69. [Google Scholar] [CrossRef]

- Gontarz, A.; Drozdowski, K.; Dziubinska, A.; Winiarski, G. A study of a new screw press forging process for producing aircraft drop forgings made of magnesium alloy AZ61A. Aircr. Eng. Aerosp. Technol. 2018, 90, 559–565. [Google Scholar] [CrossRef]

- Ayer, Ö. Simulation of helical gear forming of az31 magnesium material. Adv. Sci. Technol. Res. J. 2017, 11, 187–191. [Google Scholar] [CrossRef] [Green Version]

- Magrinho, J.P.; Silva, M.B.; Reis, L.; Martins, P.A.F. Formability Limits, Fractography and Fracture Toughness in Sheet Metal Forming. Materials 2019, 12, 1493. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ananthanarayanan, R.; Ahmed, Z.; Prasad, A.; Narayan, S. Strain hardening analysis and modelling of its parameters for sintered Al and Al-1%C preforms during cold upsetting. J. Mater. Res. Technol. 2019, 8, 1789–1797. [Google Scholar] [CrossRef]

- Narayan, S.; Rajeshkannan, A. Strain hardening behaviour in forming of sintered iron-0.35% carbon powder metallurgy preform during cold upsetting. Mater. Res. 2011, 14, 449–455. [Google Scholar] [CrossRef] [Green Version]

- Wójcik, Ł.; Lis, K.; Pater, Z. Plastometric tests for plasticine as physical modelling material. Open Eng. 2016, 6, 653–659. [Google Scholar] [CrossRef]

- Wójcik, Ł.; Pater, Z.; Bulzak, T.; Tomczak, J. Physical Modeling of Cross Wedge Rolling Limitations. Materials 2020, 13, 867. [Google Scholar] [CrossRef] [Green Version]

- Martín, E.; Forn, A.; Nogué, R. Strain hardening behaviour and temperature effect on Al-2124/SiCp. J. Mater. Process. Technol. 2003, 143–144, 1–4. [Google Scholar] [CrossRef]

- Narayan, S.; Rajeshkannan, A. Studies on formability of sintered aluminum composites during hot deformation using strain hardening parameters. J. Mater. Res. Technol. 2017, 6, 101–107. [Google Scholar] [CrossRef]

- Winiarski, G.; Bulzak, T.A.; Wójcik, Ł.; Szala, M. Numerical Analysis of a Six Stage Forging Process for Producing Hollow Flanged Parts from Tubular Blanks. Adv. Sci. Technol. Res. J. 2020, 14, 201–208. [Google Scholar] [CrossRef]

- Winiarski, G.; Bulzak, T.A.; Wójcik, Ł.; Szala, M. Effect of Tool Kinematics on Tube Flanging by Extrusion with a Moving Sleeve. Adv. Sci. Technol. Res. J. 2019, 13, 210–216. [Google Scholar] [CrossRef]

- Hashmi, S. Comprehensive Materials Finishing; Elsevier: Kidlington, Oxford, UK, 2017. [Google Scholar]

- Szala, M.; Beer-Lech, K.; Gancarczyk, K.; Kilic, O.B.; Pędrak, P.; Özer, A.; Skic, A. Microstructural Characterisation of Co-Cr-Mo Casting Dental Alloys. Adv. Sci. Technol. Res. J. 2017, 11, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Nowak, W.J.; Ochał, K.; Wierzba, P.; Gancarczyk, K.; Wierzba, B. Effect of Substrate Roughness on Oxidation Resistance of an Aluminized Ni-Base Superalloy. Metals 2019, 9, 782. [Google Scholar] [CrossRef] [Green Version]

- Kowal, M.; Szala, M. Diagnosis of the microstructural and mechanical properties of over century-old steel railway bridge components. Eng. Fail. Anal. 2020, 110, 104447. [Google Scholar] [CrossRef]

- Szala, M.; Szafran, M.; Macek, W.; Marchenko, S.; Hejwowski, T. Abrasion Resistance of S235, S355, C45, AISI 304 and Hardox 500 Steels with Usage of Garnet, Corundum and Carborundum Abrasives. Adv. Sci. Technol. Res. J. 2019, 13, 151–161. [Google Scholar] [CrossRef]

- Yuan, X.; Chen, L.; Zhao, Y.; Di, H.; Zhu, F. Dependence of Grain Size on Mechanical Properties and Microstructures of High Manganese Austenitic Steel. Procedia Eng. 2014, 81, 143–148. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Balint, D.; Pietrzyk, M. Microstructure Evolution in Metal Forming Processes; Elsevier: Cambridge, UK, 2012. [Google Scholar]

- Dieter, G.E.; Kuhn, H.A.; Semiatin, S.L. Handbook of Workability and Process Design; ASM International: Materials Park, OH, USA, 2003. [Google Scholar]

| Mechanical Properties, MPa | Chemical Composition 1, wt.% | |||||||

|---|---|---|---|---|---|---|---|---|

| Rm | Re | C | Mn | Si | P | S | Cr | Mo |

| 1030 | 880 | 0.38–0.45 | 0.4–0.7 | 0.17–0.37 | max 0.035 | max 0.035 | 0.9–1.2 | 0.15–0.25 |

| Strain Hardening Coefficient | Sample Code | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| c | 1559.4 | 981.4 | 1062.7 | 1023.6 | 1045.8 | 1006.5 | 1009.9 | 1039.2 |

| n | 0.187 | 0.232 | 0.200 | 0.208 | 0.227 | 0.267 | 0.237 | 0.224 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szala, M.; Winiarski, G.; Wójcik, Ł.; Bulzak, T. Effect of Annealing Time and Temperature Parameters on the Microstructure, Hardness, and Strain-Hardening Coefficients of 42CrMo4 Steel. Materials 2020, 13, 2022. https://doi.org/10.3390/ma13092022

Szala M, Winiarski G, Wójcik Ł, Bulzak T. Effect of Annealing Time and Temperature Parameters on the Microstructure, Hardness, and Strain-Hardening Coefficients of 42CrMo4 Steel. Materials. 2020; 13(9):2022. https://doi.org/10.3390/ma13092022

Chicago/Turabian StyleSzala, Mirosław, Grzegorz Winiarski, Łukasz Wójcik, and Tomasz Bulzak. 2020. "Effect of Annealing Time and Temperature Parameters on the Microstructure, Hardness, and Strain-Hardening Coefficients of 42CrMo4 Steel" Materials 13, no. 9: 2022. https://doi.org/10.3390/ma13092022

APA StyleSzala, M., Winiarski, G., Wójcik, Ł., & Bulzak, T. (2020). Effect of Annealing Time and Temperature Parameters on the Microstructure, Hardness, and Strain-Hardening Coefficients of 42CrMo4 Steel. Materials, 13(9), 2022. https://doi.org/10.3390/ma13092022