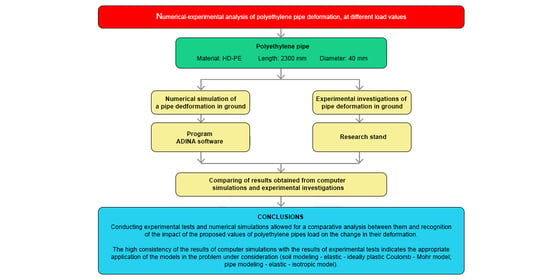

Numerical–Experimental Analysis of Polyethylene Pipe Deformation at Different Load Values

Abstract

:1. Introduction

2. Materials and Methods

2.1. Numerical Analysis of the Influence of External Load on the Deformation of Polyethylene Pipe

- -

- Restraining of the system’s lower surface;

- -

- Restraining of the system’s side surfaces;

- -

- No restraint of the pipe.

- σ1, σ2, σ3—main stresses, MPa;θ—internal friction angle of soil, o;c—cohesion, MPa.

- -

- Compressibility modulus p = 20 MPa;

- -

- Poisson’s ratio v = 0.32;

- -

- Volumetric weight w = 0.000018 N/mm3;

- -

- Cohesion c = 0.017 MPa;

- -

- Internal friction angle θ = 17°.

- -

- Young’s modulus E = 1000 MPa;

- -

- Poisson’s ratio v = 0.46.

2.2. Experimental Research of the Influence of External Load on the Deformation of Polyethylene Pipe

- R—the electrical resistance of the wire, Ω;δ—specific resistance of the wire, Ω;Ld—wire length, mm;A—wire cross-sectional area, mm.

- —relative increment of specific resistance;—relative strain of the wire;—relative change in the cross-section of the wire.

- εx—strain of the cross-section in the x-direction;εy—strain of the cross-section in the y-direction.

- k—strain gauge constant: 2.15;ΔR—relative increase in electrical resistance;R—the wire’s electrical resistance.

3. Results and Discussion

3.1. Numerical Analysis of the Influence of External Load on the Deformation of Polyethylene Pipe

3.2. Comparative Analysis of Numerical Simulation and Experimental Research of the Influence of the External Load on Polyethylene Pipe Deformation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deblieck, R.A.C.; van Beek, D.J.M.; McCarthy, M.; Mindermann, P.; Remerie, K.; Langer, B.; Lach, R.; Grellmann, W. A simple intrinsic measure for rapid crack propagation in bimodal polyethylene pipe grades validated by elastic–Plastic fracture mechanics analysis of data from instrumented Charpy impact test. Polym. Eng. Sci. 2017, 57, 13–21. [Google Scholar] [CrossRef]

- Kliszewicz, B. Numerical 3D analysis of buried flexible pipeline. Eur. Sci. J. 2013, 9, 93–101. [Google Scholar]

- Hubert, L.; David, L.; Séguéla, R.; Vigier, G.; Degoulet, C.; Germain, Y. Physical and mechanical properties of polyethylene for pipes in relation to molecular architecture. I. Microstructure and crystallisation kinetics. Polymer 2001, 42, 8425–8434. [Google Scholar] [CrossRef]

- Kadhim, L.F. Mechanical properties of high density polyethylene/chromium trioxide under ultraviolet rays. Int. J. Appl. Eng. 2017, 10, 2517–2526. [Google Scholar]

- Kamweru, P.K.; Ndiritu, F.G.; Kinyanjui, T.; Muthui, Z.W.; Ngumbu, R.G.; Odhiambo, P.M. UV absorbtion and dynamic mechanical analysis of polyethylene films. Int. J. Phys. Sci. 2014, 9, 545–555. [Google Scholar]

- Madhu, G.; Bhunia, H.; Bajpai, P.K.; Chaudhary, V. Mechanical and morphological properties of high density polyethylene and polylactide blends. J. Polym. Eng. 2014, 34, 813–821. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Tensile behavior of high-density polyethylene including the effects of processing technique, thickness, temperature, and strain rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef]

- Spalding, M.A.; Chatterjee, A. Handbook of Industrial Polyethylene and Technology: Definitive Guide to Manufacturing, Properties, Processing, Applications and Markets; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Xu, M.-m.; Huang, G.-y.; Feng, S.-s.; McShane, G.J.; Stronge, W.J. Static and dynamic properties of semi-crystalline polyethylene. Polymers 2016, 8, 77. [Google Scholar] [CrossRef]

- Elleuch, R.; Taktak, W. Viscoelastic behavior of HDPE polymer using tensile and compressive loading. J. Mater. Eng. Perform. 2006, 15, 111–116. [Google Scholar] [CrossRef]

- Haager, M.; Pinter, G.; Lang, R.W. Ranking of PE-HD Pipe grades by fatigue crack growth performance. In Proceedings of the Plast. Pipes XIII, Washington, DC, USA, 2–5 October 2006. [Google Scholar]

- Pyo, S.; Woo, J.; Park, J.; Kim, M.; Choi, S. Measurement of rapid crack propagation in pressure pipes: A static S4 approach. Polym. Test. 2012, 31, 439–443. [Google Scholar] [CrossRef]

- Bilgin, Ö.; Stewart, H.E.; O’Rourke, T.D. Thermal and mechanical properties of polyethylene pipes. J. Mater. Civ. Eng. 2007, 19, 1043–1052. [Google Scholar] [CrossRef]

- Maess, M.; Wagner, N.; Gaul, L. Dispersion curves of fluid filled elastic pipes by standard FE models and eigenpath analysis. J. Sound Vib. 2006, 296, 264–276. [Google Scholar] [CrossRef]

- Bilgin, Ö. Modeling viscoelastic behavior of polyethylene pipe stresses. J. Mater. Civ. Eng. 2014, 26, 676–683. [Google Scholar] [CrossRef]

- Grellmann, W.; Langer, B. Deformation and Fracture Behaviour of Polymer Materials; Springer International Publishing: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Frank, A.; Pinter, G. Evaluation of the applicability of the cracked round bar test as standardized PE-pipe ranking tool. Polym. Test. 2014, 33, 161–171. [Google Scholar] [CrossRef]

- Kliszewicz, B. Veryfication of numerical model of pipeline—Soil system on the basis of laboratory testing. J. Civ. Eng. Environ. Archit. 2014, 31, 115–126. (In Polish) [Google Scholar]

- Djebli, A.; Bendouba, M.; Aid, A.; Talha, A.; Benseddiq, N.; Benguediab, M. Experimental analysis and damage modeling of high-density polyethylene under fatigue loading. Acta Mech. Solida Sin. 2016, 29, 133–144. [Google Scholar] [CrossRef] [Green Version]

- Weon, J.-i. Effects of thermal ageing on mechanical and thermal behaviors of linear low density polyethylene pipe. Polym. Degrad. Stab. 2010, 95, 14–20. [Google Scholar] [CrossRef]

- Gnatowski, A.; Kijo-Kleczkowska, A. Selected physical properties and structure of materials based on modified polyamide 6. Int. J. Numer. Methods Heat Fluid Flow 2020, 30, 1577–1588. [Google Scholar] [CrossRef]

- Gnatowski, A.; Kijo-Kleczkowska, A.; Gołębski, R.; Mirek, K. Analysis of polymeric materials properties changes after addition of reinforcing fibers. Int. J. Numer. Methods Heat Fluid Flow 2020, 30, 2833–2843. [Google Scholar] [CrossRef]

- Merah, N.; Saghir, F.; Khan, Z.; Bazoune, A. Effect of temperature on tensile properties of HDPE pipe material. Plast. Rubber Compos. 2006, 35, 226–230. [Google Scholar] [CrossRef]

- Cudny, M.; Binder, K. Criteria of soil shear strength in geotechnics. Mar. Eng. Geotech. 2005, 6, 456–465. (In Polish) [Google Scholar]

- Grosel, S.; Pachnicz, M.; Różański, A.; Sobótka, M.; Stefaniuk, D. Influence of bedding and backfill soil type on deformation of buried sewage pipeline. Studia Geotechnica et Mechanica 2018, 40, 313–320. [Google Scholar] [CrossRef] [Green Version]

- van den Bogert, P.A.J.; van Eijs, R.M.H.E. Why Mohr-circle analyses may underestimate the risk of fault reactivation in depleting reservoirs. Int. J. Rock Mech. Min. Sci. 2020, 136, 104502. [Google Scholar] [CrossRef]

- Inn Woo, S.; Seo, H.; Kim, J. Critical-state-based Mohr-Coulomb plasticity model for sands. Comput. Geotech. 2017, 92, 179–185. [Google Scholar] [CrossRef]

- Geotechnical Design; PN-EN 1997-1:2008; Polski Komitet Normalizacyjny: Warsaw, Poland, 2008. (In Polish)

- Madaj, A.; Węgrzynowski, M.; Janusz, L. Long term observations of a 3-span highway corrugated steel box bridge on Gniezno Bypass. Arch. Inst. Civ. Eng. 2012, 12, 197–203. (In Polish) [Google Scholar]

- PN-EN ISO 527-2. Plastics—Determination of Mechanical Properties under Static Stretching; Polski Komitet Normalizacyjny: Warsaw, Poland, 2012. (In Polish) [Google Scholar]

- La Mantia, F.P.; Morreale, M.; Botta, L.; Mistretta, M.C.; Ceraulo, M.; Scaffaro, R. Degradation of polymer blends: A brief review. Polym. Degrad. Stab. 2017, 145, 79–92. [Google Scholar] [CrossRef]

- Gnatowski, A.; Chyra, M.; Baranowski, W. Analysis of thermomechanical properties and morphology of polyethylene pipes after aging by UV radiation. Polimery 2014, 59, 308–313. [Google Scholar] [CrossRef]

- Yayla, P.; Bilgin, Y. Squeeze-off of polyethylene pressure pipes: Experimental analysis. Polym. Test. 2007, 26, 132–141. [Google Scholar] [CrossRef]

| 500 N | 1000 N | 1500 N | 2000 N | |

|---|---|---|---|---|

| εx | ||||

| top of the pipe | 2.11 × 10−5 | 7.43 × 10−5 | 7.26 × 10−5 | 4.34 × 10−5 |

| down the pipe | 3.43 × 10−5 | 4.23 × 10−5 | 1.78 × 10−5 | 4.31 × 10−5 |

| εy | ||||

| top of the pipe | 1.13 × 10−5 | 1.06 × 10−5 | 1.43 × 10−5 | 2.56 × 10−5 |

| down the pipe | 2.35 × 10−5 | 1.28 × 10−5 | 2.98 × 10−5 | 1.66 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gnatowski, A.; Kijo-Kleczkowska, A.; Chyra, M.; Kwiatkowski, D. Numerical–Experimental Analysis of Polyethylene Pipe Deformation at Different Load Values. Materials 2021, 14, 160. https://doi.org/10.3390/ma14010160

Gnatowski A, Kijo-Kleczkowska A, Chyra M, Kwiatkowski D. Numerical–Experimental Analysis of Polyethylene Pipe Deformation at Different Load Values. Materials. 2021; 14(1):160. https://doi.org/10.3390/ma14010160

Chicago/Turabian StyleGnatowski, Adam, Agnieszka Kijo-Kleczkowska, Mateusz Chyra, and Dariusz Kwiatkowski. 2021. "Numerical–Experimental Analysis of Polyethylene Pipe Deformation at Different Load Values" Materials 14, no. 1: 160. https://doi.org/10.3390/ma14010160

APA StyleGnatowski, A., Kijo-Kleczkowska, A., Chyra, M., & Kwiatkowski, D. (2021). Numerical–Experimental Analysis of Polyethylene Pipe Deformation at Different Load Values. Materials, 14(1), 160. https://doi.org/10.3390/ma14010160