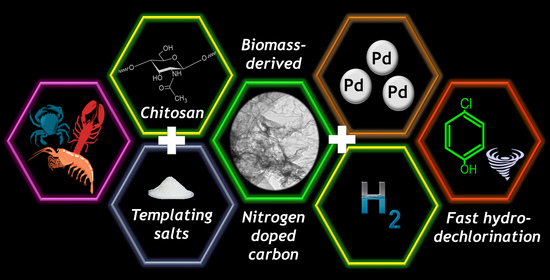

Laminar N-Doped Carbon Materials from a Biopolymer for Use as a Catalytic Support for Hydrodechlorination Catalysts

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Characterization Materials

3.2. Catalytic Activity Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Inagaki, M.; Toyoda, M.; Soneda, Y.; Morishita, T. Nitrogen-doped carbon materials. Carbon 2018, 132, 104–140. [Google Scholar] [CrossRef]

- Wu, T.X.; Wang, G.Z.; Zhang, X.; Chen, C.; Zhang, Y.X.; Zhao, H.J. Transforming chitosan into N-doped graphitic carbon electrocatalysts. Chem. Commun. 2014, 51, 1334–1337. [Google Scholar] [CrossRef]

- Deng, Y.; Xie, Y.; Zou, K.; Ji, X. Review on recent advances in nitrogen-doped carbons: Preparations and applications in supercapacitors. J. Mater. Chem. A 2016, 4, 1144–1173. [Google Scholar] [CrossRef]

- Hammi, N.; Chen, S.; Dumeignil, F.; Royer, S.; El Kadib, A. Chitosan as a sustainable precursor for nitrogen-containing carbon nanomaterials: Synthesis and uses. Mater. Today Sustain. 2020, 10, 100053. [Google Scholar] [CrossRef]

- Kumar, S.; Aziz, S.T.; Girshevitz, O.; Nessim, G.D. One-step synthesis of N-doped graphene quantum dots from chitosan as a sole precursor using chemical vapor deposition. J. Phys. Chem. C 2018, 122, 2343–2349. [Google Scholar] [CrossRef]

- Lee, D.-W.; Jin, M.-H.; Oh, D.-K.; Lee, S.-W.; Park, J.-S. Straightforward synthesis of hierarchically porous nitrogen-doped carbon via pyrolysis of chitosan/urea/KOH mixtures and its application as a support for formic acid dehydrogenation catalysts. ACS Sustain. Chem. Eng. 2017, 5, 9935–9944. [Google Scholar] [CrossRef]

- Yu, H.; Hou, J.; Namin, R.B.; Ni, Y.; Liu, S.; Yu, S.; Liu, Y.; Wu, Q.; Nie, S. Pre-cryocrushing of natural carbon precursors to prepare nitrogen, sulfur co-doped porous microcellular carbon as an efficient ORR catalyst. Carbon 2021, 173, 800–808. [Google Scholar] [CrossRef]

- Ania, C.O.; Armstrong, P.A.; Bandosz, T.J.; Beguin, F.; Carvalho, A.P.; Celzard, A.; Frackowiak, E.; Gilarranz, M.A.; László, K.; Matos, J.; et al. Engaging nanoporous carbons in “beyond adsorption” applications: Characterization, challenges and performance. Carbon 2020, 164, 69–84. [Google Scholar] [CrossRef]

- Nishihara, H.; Kyotani, T. Templated nanocarbons for energy storage. Adv. Mater. 2012, 24, 4473–4498. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, H.; Yang, Z.; Zhang, Y.; Yu, B.; Liu, Z. Highly mesoporous carbons derived from biomass feedstocks templated with eutectic salt ZnCl2/KCl. J. Mater. Chem. A 2014, 2, 19324–19329. [Google Scholar] [CrossRef]

- Leżańska, M.; Olejniczak, A.; Łukaszewicz, J.P. Hierarchical porous carbon templated with silica spheres of a diameter of 14 nm from pure chitosan or a chitosan/ZnCl2 solution. J. Porous Mater. 2018, 25, 1633–1648. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, S.; Zuo, S.; Xu, Z.; Han, C.; Shen, J. Mesoporous carbon materials prepared from carbohydrates with a metal chloride template. J. Mater. Chem. 2009, 19, 7759–7764. [Google Scholar] [CrossRef]

- Yang, G.; Han, H.; Li, T.; Du, C. Synthesis of nitrogen-doped porous graphitic carbons using nano-CaCO3 as template, graphitization catalyst, and activating agent. Carbon 2012, 50, 3753–3765. [Google Scholar] [CrossRef]

- Li, M.; Li, W.; Liu, S. Hydrothermal synthesis, characterization, and KOH activation of carbon spheres from glucose. Carbohydr. Res. 2011, 346, 999–1004. [Google Scholar] [CrossRef]

- Liu, X.; Antonietti, M. Molten salt activation for synthesis of porous carbon nanostructures and carbon sheets. Carbon 2014, 69, 460–466. [Google Scholar] [CrossRef]

- Fechler, N.; Fellinger, T.-P.; Antonietti, M. “Salt Templating”: A simple and sustainable pathway toward highly porous functional carbons from ionic liquids. Adv. Mater. 2013, 25, 75–79. [Google Scholar] [CrossRef] [PubMed]

- Lu, A.-H.; Li, W.-C.; Schmidt, W.; Schüth, F. Fabrication of hierarchically structured carbon monoliths via self-binding and salt templating. Microporous Mesoporous Mater. 2006, 95, 187–192. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, F.; Xu, Z.; Shen, J. Nitrogen-containing mesoporous carbons prepared from melamine formaldehyde resins with CaCl2 as a template. J. Colloid Interface Sci. 2011, 363, 193–198. [Google Scholar] [CrossRef]

- Lei, Y.; Huang, R.; Xie, H.; Zhang, D.; Liu, X.; Si, Y.; Li, N. Electronic structure tuning of FeCo nanoparticles embedded in multi-dimensional carbon matrix for enhanced bifunctional oxygen electrocatalysis. J. Alloys Compd. 2021, 853, 157070. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, Y.-P.; Su, M.; Yuan, Z.-Y. Metal-free carbonaceous materials as promising heterogeneous catalysts. ChemCatChem 2015, 7, 2765–2787. [Google Scholar] [CrossRef]

- Burch, H.J.; Davies, J.A.; Brown, E.; Hao, L.; Contera, S.A.; Grobert, N.; Ryan, J.F. Electrical conductance and breakdown in individual CNx multiwalled nanotubes. Appl. Phys. Lett. 2006, 89, 143110. [Google Scholar] [CrossRef]

- He, L.; Weniger, F.; Neumann, H.; Beller, M. Synthesis, characterization, and application of metal nanoparticles supported on nitrogen-doped carbon: Catalysis beyond electrochemistry. Angew. Chem. Int. Ed. 2016, 55, 12582–12594. [Google Scholar] [CrossRef]

- Arrigo, R.; Wrabetz, S.; Schuster, M.E.; Wang, D.; Villa, A.; Rosenthal, D.; Girsgdies, F.; Weinberg, G.; Prati, L.; Schlögl, R.; et al. Tailoring the morphology of Pd nanoparticles on CNTs by nitrogen and oxygen functionalization. Phys. Chem. Chem. Phys. 2012, 14, 10523. [Google Scholar] [CrossRef]

- Li, Y.-H.; Hung, T.-H.; Chen, C.-W. A first-principles study of nitrogen- and boron-assisted platinum adsorption on carbon nanotubes. Carbon 2009, 47, 850–855. [Google Scholar] [CrossRef]

- Ruiz-Garcia, C.; Heras, F.; Calvo, L.; Alonso-Morales, N.; Rodriguez, J.; Gilarranz, M. Improving the activity in hydrodechlorination of Pd/C catalysts by nitrogen doping of activated carbon supports. J. Environ. Chem. Eng. 2020, 8, 103689. [Google Scholar] [CrossRef]

- Ali, S.; Goodwin, J. SSITKA Investigation of palladium precursor and support effects on CO hydrogenation over supported Pd catalysts. J. Catal. 1998, 176, 3–13. [Google Scholar] [CrossRef]

- Hwang, H.; Sahin, O.; Choi, J.W. Manufacturing a super-active carbon using fast pyrolysis char from biomass and correlation study on structural features and phenol adsorption. RSC Adv. 2017, 7, 42192–42202. [Google Scholar] [CrossRef]

- Siipola, V.; Tamminen, T.; Källi, A.; Lahti, R.; Romar, H.; Rasa, K.; Keskinen, R.; Hyväluoma, J.; Hannula, M.; Wikberg, H. Effects of biomass type, carbonization process, and activation method on the properties of bio-based activated carbons. BioResources 2018, 13, 5976–6002. [Google Scholar]

- Kristianto, H.; Lavenki, Y.; Susanti, R.F. Synthesis and characterization of activated carbon derived from salacca peel using ZnCl2 hydrothermal carbonization and chemical activation with microwave heating. IOP Conf. Series Mater. Sci. Eng. 2020, 742, 012044. [Google Scholar] [CrossRef]

- Xia, Y.; Mokaya, R.; Grant, D.M.; Walker, G.S. A simplified synthesis of N-doped zeolite-templated carbons, the control of the level of zeolite-like ordering and its effect on hydrogen storage properties. Carbon 2011, 49, 844–853. [Google Scholar] [CrossRef]

- Liu, F.; Song, S.; Xue, D.; Zhang, H. Folded structured graphene paper for high performance electrode materials. Adv. Mater. 2012, 24, 1089–1094. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, J.; Meng, X.; Monroe, C.; Huang, Y.; Zuo, J.-M. Free folding of suspended graphene sheets by random mechanical stimulation. Phys. Rev. Lett. 2010, 104, 166805. [Google Scholar] [CrossRef]

- Gao, L.; Ying, D.; Shen, T.; Zheng, Y.; Cai, J.; Wang, D.; Zhang, L. Two-dimensional wrinkled N-rich carbon nanosheets fabricated from chitin via fast pyrolysis as optimized electrocatalyst. ACS Sustain. Chem. Eng. 2020, 8, 10881–10891. [Google Scholar] [CrossRef]

- Seo, D.K.; Park, S.S.; Hwang, J.; Yu, T.-U. Study of the pyrolysis of biomass using thermo-gravimetric analysis (TGA) and concentration measurements of the evolved species. J. Anal. Appl. Pyrolysis 2010, 89, 66–73. [Google Scholar] [CrossRef]

- Primo, A.; Atienzar, P.; Sanchez, E.; Delgado, J.M.; García, H. From biomass wastes to large-area, high-quality, N-doped graphene: Catalyst-free carbonization of chitosan coatings on arbitrary substrates. Chem. Commun. 2012, 48, 9254–9256. [Google Scholar] [CrossRef] [PubMed]

- Cordero, T.; Rodriguez-Mirasol, J.; Tancredi, N.; Piriz, J.; Vivo, G.; Rodriguez, J.J. Influence of surface composition and pore structure on Cr(III) adsorption onto activated carbons. Ind. Eng. Chem. Res. 2002, 41, 6042–6048. [Google Scholar] [CrossRef]

- Toebes, M.L.; van Dillen, J.A.; de Jong, K.P. Synthesis of supported palladium catalysts. J. Mol. Catal. A Chem. 2001, 173, 75–98. [Google Scholar] [CrossRef]

- Golub, F.S.; Beloshapkin, S.; Gusel’Nikov, A.V.; Bolotov, V.A.; Parmon, V.N.; Bulushev, D.A. Boosting hydrogen production from formic acid over Pd catalysts by deposition of N-containing precursors on the carbon support. Energies 2019, 12, 3885. [Google Scholar] [CrossRef]

- Díaz, E.; Casas, J.A.; Mohedano, A.F.; Calvo, L.; Gilarranz, M.A.; Rodriguez, J.J. Kinetics of the hydrodechlorination of 4-chlorophenol in water using Pd, Pt, and Rh/Al2O3 catalysts. Ind. Eng. Chem. Res. 2008, 47, 3840–3846. [Google Scholar] [CrossRef]

- Ruiz-Garcia, C.; Lei, Y.; Heras, F.; Elías, A.L.; Terrones, M.; Gilarranz, M.A. Functional Pd/reduced graphene oxide nanocomposites: Effect of reduction degree and doping in hydrodechlorination catalytic activity. J. Nanoparticle Res. 2019, 21, 276. [Google Scholar] [CrossRef]

| Chemical Analysis | XPS Analysis | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | C | H | N | S | O est. * | N/C | O est./C | C | N | O | N/C | O/C |

| C/Ca | 72.5 | 1.8 | 8.1 | 0.02 | - | 0.11 | - | 76 | 8 | 16 | 0.1 | 0.2 |

| C/Zn-K | 70.6 | 1.6 | 7.4 | 0.05 | - | 0.10 | - | 75 | 6 | 18 | 0.1 | 0.2 |

| Cblank | 82.8 | 1.6 | 9.4 | 0.03 | 6.1 | 0.11 | 0.1 | 84 | 7 | 9 | 0.1 | 0.1 |

| Chitosan | 41.7 | 6.7 | 7.5 | 0.05 | 44.0 | 0.18 | 1.0 | - | - | - | - | - |

| C 1s (at %); Binding Energy (eV) | ||||||

| C-C sp2 | C-C sp3 | C-O/C-N | C=O | O-C=O | π-π * | |

| Sample | 284.60 | 285.50 ± 0.1 | 286.25 ± 0.05 | 287.4 ± 0.1 | 288.80 | 290.65 ± 0.05 |

| C/Ca | 52.3 | 3.8 | 0.8 | 0.9 | 0.2 | 0.2 |

| C/Zn-K | 52.9 | 1.8 | 0.9 | 0.8 | 0.3 | 0.2 |

| Cblank | 51.2 | 9.0 | 0.4 | 0.7 | 0.2 | 0.2 |

| O 1s (at %); Binding Energy (eV) | ||||||

| Quinones | C=O | C-O | O-C=O | H2O | ||

| Sample | 530.4 ± 0.1 | 531.6 ± 0.1 | 532.5 ± 0.1 | 533.6 ± 0.1 | 535 | |

| C/Ca | 2.1 | 3.8 | 4.2 | 1.9 | 0.4 | 1.0 |

| C/Zn-K | 2.9 | 5.1 | 4.9 | 1.7 | 0.0 | 1.2 |

| Cblank | 1.2 | 1.7 | 2.3 | 1.5 | 0.5 | 0.8 |

| N 1s (at %); Binding Energy (eV) | ||||||

| Pyridinic-N | Pyrrolic-N | Quaternary-N | Pyridinic-N ox. | N-oxides | Pyridinic/ Quaternary | |

| Sample | 398.3 ± 0.1 | 400.3 ± 0.1 | 401.2 ± 0.1 | 402.8 | 405 | |

| C/Ca | 2.9 | 2.8 | 1.0 | 0.4 | 0.6 | 0.5 |

| C/Zn-K | 1.8 | 2.4 | 0.7 | 0.3 | 0.5 | 0.6 |

| Cblank | 2.3 | 2.1 | 0.9 | 0.3 | 0.5 | 0.5 |

| Sample | (m2/g) | (cm3/g) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C/Ca | 153 | 102 | 595 | 0.239 | 0.0213 | 0.377 | 0.0412 | 0.356 | 0.397 |

| C/Zn-K | 605 | 197 | 542 | 0.217 | 0.160 | 0.333 | 0.212 | 0.241 | 0.453 |

| Cblank | 6 | 0 | 515 | 0.206 | - | - | - | - | - |

| 2θ Angle (°) | FWHM (°) | D (nm) | H (nm) | Layer Stacking | |

|---|---|---|---|---|---|

| C/Ca | 22.9 | 8.9 | 0.39 | 0.9 | 2–3 |

| C/Zn-K | 23.6 | 12.3 | 0.38 | 0.7 | 1–2 |

| C blank | 22.8 | 8.7 | 0.39 | 0.9 | 2–3 |

| Sample | Dispersion (%) | Diameter Size (nm) |

|---|---|---|

| Pd-C/Ca | 10.8 | 10 |

| Pd-C/Zn-K | 12.5 | 9 |

| Pd-Cblank | 1.0 | 120 |

| Sample | k (min−1) | r2 | TOF (min−1) | a (mmol g−1Pd min−1) |

|---|---|---|---|---|

| Pd-C/Ca | 0.2295 | 0.94 | 59 | 69 |

| Pd-C/Zn-K | 0.0895 | 0.995 | 25 | 27 |

| Pd-C blank | 0.0062 | 0.991 | 20 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-Garcia, C.; Gilarranz, M.A. Laminar N-Doped Carbon Materials from a Biopolymer for Use as a Catalytic Support for Hydrodechlorination Catalysts. Materials 2021, 14, 3107. https://doi.org/10.3390/ma14113107

Ruiz-Garcia C, Gilarranz MA. Laminar N-Doped Carbon Materials from a Biopolymer for Use as a Catalytic Support for Hydrodechlorination Catalysts. Materials. 2021; 14(11):3107. https://doi.org/10.3390/ma14113107

Chicago/Turabian StyleRuiz-Garcia, Cristina, and Miguel A. Gilarranz. 2021. "Laminar N-Doped Carbon Materials from a Biopolymer for Use as a Catalytic Support for Hydrodechlorination Catalysts" Materials 14, no. 11: 3107. https://doi.org/10.3390/ma14113107

APA StyleRuiz-Garcia, C., & Gilarranz, M. A. (2021). Laminar N-Doped Carbon Materials from a Biopolymer for Use as a Catalytic Support for Hydrodechlorination Catalysts. Materials, 14(11), 3107. https://doi.org/10.3390/ma14113107