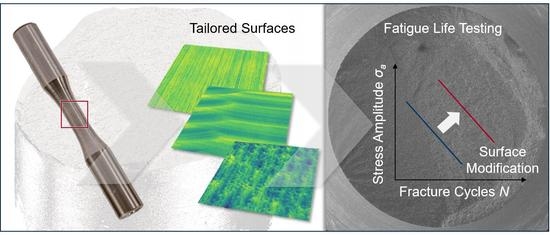

Analysis of the Influence of Surface Modifications on the Fatigue Behavior of Hot Work Tool Steel Components

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Surface Modification

2.2. Fatigue Life Testing

2.3. Surface Characterization and Fractography

3. Results and Discussion

3.1. Surface Topography and Residual Stress State

3.2. Fatigue Properties

3.3. Fractography

4. Conclusions and Outlook

- The impact of the investigated surface integrities on the fatigue properties emphasizes the requirement of a considerate selection of process routes for the finishing of, e.g., highly stressed components in order to improve tool life.

- In this series of experiments, the resulting roughness and microhardness values, as a consequence of the chosen machining processes, had a minor influence on the fatigue behavior.

- In contrast, the residual stress state correlated significantly with fatigue resistance, resulting in high fatigue life due to high compressive stress states in grinding and micromilling. Thus, the surface integrity can be derived as a key specification in component design, complementing geometry and material selection. However, the adaptation requires the selection of suitable machining processes.

- Understanding machining process-dependent anisotropies in surface integrity regarding the topography or residual stress state appears to be of high relevance. Their directional interdependence with the fatigue behavior of the components may offer the potential to improve fatigue strength by adapting the process control while machining to induce a homogeneous residual stress state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tekkaya, A.E.; Khalifa, N.B.; Grzancic, G.; Hölker, R. Forming of lightweight metal components: Need for new technologies. Procedia Eng. 2014, 81, 28–37. [Google Scholar] [CrossRef] [Green Version]

- Lange, K.; Kammerer, M.; Pöhlandt, K.; Schöck, J. Fließpressen: Wirtschaftliche Fertigung Metallischer Präzisionswerkstücke; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Engel, U.; Groenbaek, J.; Hinsel, C.; Kreiß, T.; Meister, M.; Neher, R.; Räuchle, F.; Schrader, T. Tooling solutions for challenges in cold forging. UTFscience 2011, 3, 1–24. [Google Scholar]

- Brøndsted, P.; Skov-Hansen, P. Fatigue properties of high-strength materials used in cold-forging tools. Int. J. Fatigue 1998, 20, 373–381. [Google Scholar] [CrossRef]

- Qamar, S.Z. Heat treatment and mechanical testing of AISI H11 steel. Key Eng. Mater. 2015, 656–657, 434–439. [Google Scholar] [CrossRef]

- Podgornik, B.; Hogmark, S. Surface modification to improve friction and galling properties of forming tools. J. Mater. Process. Technol. 2006, 174, 334–341. [Google Scholar] [CrossRef]

- Basinski, Z.S.; Basinski, S.J. Formation and growth of subcritical fatigue cracks. Scr. Metall. 1984, 18, 851–856. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Wang, Z.G. Grain boundary effects on cyclic deformation and fatigue damage. Prog. Mater. Sci. 2008, 53, 1025–1099. [Google Scholar] [CrossRef]

- Pang, J.C.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. General relation between tensile strength and fatigue strength of metallic materials. Mater. Sci. Eng. A 2013, 564, 331–341. [Google Scholar] [CrossRef]

- Itoga, H.; Tokaji, K.; Nakajima, M.; Ko, H.-N. Effect of surface roughness on step-wise S–N characteristics in high strength steel. Int. J. Fatigue 2003, 25, 379–385. [Google Scholar] [CrossRef]

- Harada, Y.; Fukauara, K.; Kohamada, S. Effects of microshot peening on surface characteristics of high-speed tool steel. J. Mater. Process. Technol. 2008, 201, 319–324. [Google Scholar] [CrossRef]

- Ghanem, F.; Braham, C.; Fitzpatrick, M.E.; Sidhom, H. Effect of near-surface residual stress and microstructure modification from machining on the fatigue endurance of a tool steel. J. Mater. Eng. Perform. 2002, 11, 631–639. [Google Scholar] [CrossRef]

- Javidi, A.; Rieger, U.; Eichlseder, W. The effect of machining on the surface integrity and fatigue life. Int. J. Fatigue 2008, 30, 2050–2055. [Google Scholar] [CrossRef]

- Trung, P.Q.; Khun, N.W.; Butler, D.L. Effect of shot peening process on the fatigue life of shot peened low alloy steel. J. Eng. Mater. Technol. 2018, 140, 011013. [Google Scholar] [CrossRef]

- Laamouri, A.; Ghanem, F.; Braham, C.; Sidhom, H. Influences of up-milling and down-milling on surface integrity and fatigue strength of X160CrMoV12 steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1209–1228. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.; Zhao, J.; Xing, A.; Wang, G.; Tao, H. Influence of tool path strategies on fatigue performance of high-speed ball-end-milled AISI H13 steel. Int. J. Adv. Manuf. Technol. 2018, 94, 371–380. [Google Scholar] [CrossRef]

- Meyer, K.; Denkena, B.; Breidenstein, B.; Abrão, A.M. Influence of residual stress depth distribution on lifecycle behaviour of AISI4140. Procedia CIRP 2020, 87, 450–455. [Google Scholar] [CrossRef]

- Pilz, F.; Merklein, M. Comparison of extrusion processes in sheet-bulk metal forming for production of filigree functional elements. CIRP J. Manuf. Sci. Technol. 2019, 26, 41–49. [Google Scholar] [CrossRef]

- Mori, K.; Nakano, T. State-of-the-art of plate forging in Japan. Prod. Eng. 2016, 10, 81–91. [Google Scholar] [CrossRef]

- Kersting, P.; Gröbel, D.; Merklein, M.; Sieczkarek, P.; Wernicke, S.; Tekkaya, A.E.; Krebs, E.; Freiburg, D.; Biermann, D.; Weikert, T.; et al. Experimental and numerical analysis of tribological effective surfaces for forming tools in Sheet-Bulk Metal Forming. Prod. Eng. 2016, 10, 37–50. [Google Scholar] [CrossRef]

- Merklein, M. Part two: Quality requirements for tool manufacturing. In ICFG-Document 16/04 Tool Life and Tool Quality in Cold Forging; Meisenbach: Bamberg, Germany, 2004. [Google Scholar]

- Balart, M.J.; Bouzina, A.; Edwards, L.; Fitzpatrick, M.E. The onset of tensile residual stresses in grinding of hardened steels. Mater. Sci. Eng. A 2004, 367, 132–142. [Google Scholar] [CrossRef]

- Löffler, M.; Schulte, R.; Freiburg, D.; Biermann, D.; Stangier, D.; Tillmann, W.; Merklein, M. Control of the material flow in sheet-bulk metal forming using modifications of the tool surface. Int. J. Mater. Form. 2019, 12, 17–26. [Google Scholar] [CrossRef]

- Dengel, D. Die arc sin √P-transformation—Ein einfaches verfahren zur grafischen und rechnerischen auswertung geplanter wöhlerversuche. Mater. Werkst. 1975, 6, 253–261. [Google Scholar] [CrossRef]

- ASM International (Ed.) Volume 1: Properties and selection: Iron, steels, and high-performance alloys. In ASM International Metals Handbook; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

- Davis, J.R. Tool Materials; ASM International: Materials Park, OH, USA, 1995. [Google Scholar]

- Cardarelli, F. Materials Handbook: A Concise Desktop Reference; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Mesquita, R.A.; Michael, K.; Schneider, R. Tool Steels: Properties and Performance; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Davim, J.P. Machining of Hard Materials; Springer: London, UK, 2011. [Google Scholar]

- Abele, E.; Dewald, M.; Heimrich, F. Leistungsgrenzen von hochvorschubstrategien im werkzeug und formenbau. Z. Wirtsch. Fabr. 2010, 105, 737–743. [Google Scholar] [CrossRef]

- Hense, R.; Wels, C.; Kersting, P.; Vierzigmann, U.; Löffler, M.; Biermann, D.; Merklein, M. High-feed milling of tailored surfaces for sheet-bulk metal forming tools. Prod. Eng. 2015, 9, 215–223. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Meijer, A.; Stangier, D.; Hübner, S.; Biermann, D.; Tillmann, W.; Rosenbusch, D.; Müller, P. Static and oscillation superimposed ring compression tests with structured and coated tools for Sheet-Bulk Metal Forming. J. Manuf. Process. 2020, 55, 78–86. [Google Scholar] [CrossRef]

- Bissacco, G.; Hansen, H.N.; de Chiffre, L. Micromilling of hardened tool steel for mould making applications. J. Mater. Process. Technol. 2005, 167, 201–207. [Google Scholar] [CrossRef]

- Tillmann, W.; Stangier, D.; Lopes-Dias, N.-F.; Biermann, D.; Krebs, E. Adjustment of friction by duplex-treated, bionic structures for sheet-bulk metal forming. Tribol. Int. 2017, 111, 9–17. [Google Scholar] [CrossRef]

- German National Standard. DIN 50113. In Testing of Metallic Materials—Rotating Bar Bending Fatigue Test; German National Standard: Berlin, Germany, 2018. [Google Scholar]

- German National Standard. DIN 50100. In Load Controlled Fatigue Testing—Execution and Evaluation of Cyclic Tests at Constant Load Amplitudes on Metallic Specimens and Components; German National Standard: Berlin, Germany, 2016. [Google Scholar]

- Dixon, W.J.; Mood, A.M. A method for obtaining and analyzing sensitivity data. J. Am. Stat. Assoc. 1948, 43, 109–126. [Google Scholar] [CrossRef]

- ISO. DIN EN ISO 13565-2. In Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 2: Height Characterization Using the Linear Material Ratio Curve; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- Bragg, W.H.; Bragg, W.L. The reflection of X-rays by crystals. Proc. R. Soc. Lond. Ser. A Contain. Pap. Math. Phys. Character 1913, 88, 428–438. [Google Scholar] [CrossRef]

- Schajer, G.S. Practical Residual Stress Measurement Methods; Wiley: Chichester, UK, 2013. [Google Scholar]

- Eigenmann, B.; Macherauch, E. Röntgenographische untersuchung von spannungszuständen in werkstoffen. Teil III. Mater. Werkst. 1996, 27, 426–437. [Google Scholar] [CrossRef]

- European Standard. DIN EN 15305. In Non-Destructive Testing—Test Method for Residual Stress Analysis by X-ray Diffraction; European Standard: Pilsen, Czech Republic, 2009. [Google Scholar]

- Pilz, F.; Gröbel, D.; Merklein, M. Investigation of fatigue strength of tool steels in sheet-bulk metal forming. AIP Conf. Proc. 2018, 1960, 160022. [Google Scholar]

- Torres, M.A.S.; Voorwald, H.J.C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wild, T.; Platt, T.; Biermann, D.; Merklein, M. Analysis of the Influence of Surface Modifications on the Fatigue Behavior of Hot Work Tool Steel Components. Materials 2021, 14, 7324. https://doi.org/10.3390/ma14237324

Wild T, Platt T, Biermann D, Merklein M. Analysis of the Influence of Surface Modifications on the Fatigue Behavior of Hot Work Tool Steel Components. Materials. 2021; 14(23):7324. https://doi.org/10.3390/ma14237324

Chicago/Turabian StyleWild, Thomas, Timo Platt, Dirk Biermann, and Marion Merklein. 2021. "Analysis of the Influence of Surface Modifications on the Fatigue Behavior of Hot Work Tool Steel Components" Materials 14, no. 23: 7324. https://doi.org/10.3390/ma14237324

APA StyleWild, T., Platt, T., Biermann, D., & Merklein, M. (2021). Analysis of the Influence of Surface Modifications on the Fatigue Behavior of Hot Work Tool Steel Components. Materials, 14(23), 7324. https://doi.org/10.3390/ma14237324