Acrylate and Methacrylate Polymers’ Applications: Second Life with Inexpensive and Sustainable Recycling Approaches

Abstract

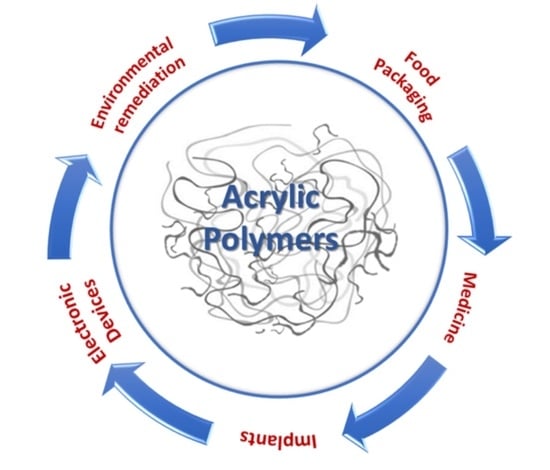

:1. Introduction

2. Acrylate and Methacrylate Polymers: Structure and Properties

3. Polymethacrylate: Applications

3.1. Poly(Methyl Methacrylate) (PMMA)

3.2. Polymethacrylic Electrolytes (PMAA and PMA Sodium Salt)

4. Polyacrylate: Applications

4.1. Poly(Methyl Acrylate) (PMA)

4.2. Poly(Acrylic) Electrolytes (PAA and PA Sodium Salt)

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reshmy, R.; Philip, E.; Madhavan, A.; Sindhu, R.; Pugazhendhi, A.; Binod, P.; Sirohi, R.; Awasthi, M.K.; Tarafdar, A.; Pandey, A. Advanced biomaterials for sustainable applications in the food industry: Updates and challenges. Environ. Pollut. 2021, 283, 117071. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Mohi-Alden, K.; Omid, M. A critical review on intelligent and active packaging in the food industry: Research and development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef]

- Lee, J.; Seol, W.; Anoop, G.; Samanta, S.; Unithrattil, S.; Ahn, D.; Kim, W.; Jung, G.; Jo, J. Stabilization of Ferroelectric Phase in Highly Oriented Quinuclidinium Perrhenate (HQReO4) Thin Films. Materials 2021, 14, 2126. [Google Scholar] [CrossRef] [PubMed]

- Fazio, E.; Spadaro, S.; Corsaro, C.; Neri, G.; Leonardi, S.G.; Neri, F.; Lavanya, N.; Sekar, C.; Donato, N.; Neri, G. Metal-Oxide Based Nanomaterials: Synthesis, Characterization and Their Applications in Electrical and Electrochemical Sensors. Sensors 2021, 21, 2494. [Google Scholar] [CrossRef]

- Sylvain, R.; Vendier, L.; Bijani, C.; Santoro, A.; Puntoriero, F.; Campagna, S.; Sutra, P.; Igau, A. Evidence of the unprecedented conversion of intermolecular proton to water bridging of two phosphoryl ruthenium complexes. New J. Chem. 2013, 37, 3543–3548. [Google Scholar] [CrossRef]

- Santoro, A.; Holub, J.; Fik-Jaskółka, M.A.; Vantomme, G.; Lehn, J.-M. Dynamic Helicates Self-Assembly from Homo- and Heterotopic Dynamic Covalent Ligand Strands. Chem.—A Eur. J. 2020, 26, 15664–15671. [Google Scholar] [CrossRef]

- Mancuso, A.; Barattucci, A.; Bonaccorsi, P.; Giannetto, A.; La Ganga, G.; Musarra-Pizzo, M.; Salerno, T.M.G.; Santoro, A.; Sciortino, M.T.; Puntoriero, F.; et al. Carbohydrates and Charges on Oligo(phenylenethynylenes): Towards the Design of Cancer Bullets. Chem.—A Eur. J. 2018, 24, 16972–16976. [Google Scholar] [CrossRef] [PubMed]

- Caccamo, D.; Currò, M.; Ientile, R.; Verderio, E.A.; Scala, A.; Mazzaglia, A.; Pennisi, R.; Musarra-Pizzo, M.; Zagami, R.; Neri, G.; et al. Intracellular Fate and Impact on Gene Expression of Doxorubicin/Cyclodextrin-Graphene Nanomaterials at Sub-Toxic Concentration. Int. J. Mol. Sci. 2020, 21, 4891. [Google Scholar] [CrossRef]

- Jeong, G.H.; Sasikala, S.P.; Yun, T.; Lee, G.Y.; Lee, W.J.; Kim, S.O. Nanoscale Assembly of 2D Materials for Energy and Environmental Applications. Adv. Mater. 2020, 32, 1907006. [Google Scholar] [CrossRef] [PubMed]

- Foti, C.; Mineo, P.G.; Nicosia, A.; Scala, A.; Neri, G.; Piperno, A. Recent Advances of Graphene-Based Strategies for Arsenic Remediation. Front. Chem. 2020, 8, 1155. [Google Scholar] [CrossRef] [PubMed]

- Liang, W.; Wang, B.; Cheng, J.; Xiao, D.; Xie, Z.; Zhao, J. 3D, eco-friendly metal-organic frameworks@carbon nanotube aerogels composite materials for removal of pesticides in water. J. Hazard. Mater. 2021, 401, 123718. [Google Scholar] [CrossRef]

- Lugger, S.J.D.; Houben, S.J.A.; Foelen, Y.; Debije, M.G.; Schenning, A.P.H.J.; Mulder, D.J. Hydrogen-Bonded Supramolecular Liquid Crystal Polymers: Smart Materials with Stimuli-Responsive, Self-Healing, and Recyclable Properties. Chem. Rev. 2021. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Ceraulo, M.; Testa, P.; Morreale, M. Biodegradable Polymers for the Production of Nets for Agricultural Product Packaging. Materials 2021, 14, 323. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.-Y.; Sun, W.-F.; Lei, Q.-Q. Charge Injection and Dielectric Characteristics of Polyethylene Terephthalate Based on Semiconductor Electrodes. Materials 2021, 14, 1344. [Google Scholar] [CrossRef] [PubMed]

- Celentano, W.; Neri, G.; Distante, F.; Li, M.; Messa, P.; Chirizzi, C.; Chaabane, L.; De Campo, F.; Metrangolo, P.; Baldelli Bombelli, F.; et al. Design of fluorinated hyperbranched polyether copolymers for 19F MRI nanotheranostics. Polym. Chem. 2020, 11, 3951–3963. [Google Scholar] [CrossRef]

- Marć, M.; Bystrzanowska, M.; Pokajewicz, K.; Tobiszewski, M. Multivariate Assessment of Procedures for Molecularly Imprinted Polymer Synthesis for Pesticides Determination in Environmental and Agricultural Samples. Materials 2021, 14, 7078. [Google Scholar] [CrossRef] [PubMed]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Karak, N. Fundamentals of Polymers: Raw Materials To Finish Products; PHI Learning: Delhi, India, 2009. [Google Scholar]

- Cywar, R.M.; Rorrer, N.A.; Hoyt, C.B.; Beckham, G.T.; Chen, E.Y.X. Bio-based polymers with performance-advantaged properties. Nat. Rev. Mater. 2021, 1–21. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; Abdul Ghani, A. Expanding Policy for Biodegradable Plastic Products and Market Dynamics of Bio-Based Plastics: Challenges and Opportunities. Sustainability 2021, 13, 6170. [Google Scholar] [CrossRef]

- Vera, M.; Mella, C.; Urbano, B.F. Smart Polymer Nanocomposites: Recent advances and Perspectives. J. Chil. Chem. Soc. 2020, 65, 4973–4981. [Google Scholar] [CrossRef]

- Aguilar, M.R.; San Román, J. Chapter 1—Introduction to Smart Polymers and Their Applications. In Smart Polymers and Their Applications, 2nd ed.; Aguilar, M.R., San Román, J., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 1–11. [Google Scholar] [CrossRef]

- Wieszczycka, K.; Staszak, K.; Woźniak-Budych, M.J.; Litowczenko, J.; Maciejewska, B.M.; Jurga, S. Surface functionalization—The way for advanced applications of smart materials. Coord. Chem. Rev. 2021, 436, 213846. [Google Scholar] [CrossRef]

- Reddy, M.S.B.; Ponnamma, D.; Choudhary, R.; Sadasivuni, K.K. A Comparative Review of Natural and Synthetic Biopolymer Composite Scaffolds. Polymers 2021, 13, 1105. [Google Scholar] [CrossRef] [PubMed]

- Stuart, M.C.; de Vries, R.; Lyklema, H. Chapter 2—Polyelectrolytes. In Fundamentals of Interface and Colloid Science; Lyklema, J., Ed.; Academic Press: Cambridge, MA, USA, 2005; Volume 5, pp. 2.1–2.84. [Google Scholar]

- Khan, N.; Brettmann, B. Intermolecular Interactions in Polyelectrolyte and Surfactant Complexes in Solution. Polymers 2019, 11, 51. [Google Scholar] [CrossRef] [Green Version]

- Petrila, L.-M.; Bucatariu, F.; Mihai, M.; Teodosiu, C. Polyelectrolyte Multilayers: An Overview on Fabrication, Properties, and Biomedical and Environmental Applications. Materials 2021, 14, 4152. [Google Scholar] [CrossRef]

- Gupta, A.K.; Sahu, D.K.; Giri, S. Study of Electrical Conductivity of Poly(Methyl Acrylate) PMA Polymer Thin Film. Int. J. Adv. Res. Sci. Technol. (IJARST) 2020, 2, 63–67. [Google Scholar]

- Eygi, M.S.; Ateşok, G. An investigation on utilization of poly-electrolytes as dispersant for kaolin slurry and its slip casting properties. Ceram. Int. 2008, 34, 1903–1908. [Google Scholar] [CrossRef]

- Gretz, M.; Plank, J. Hybrid additives for construction applications, fabricated through layer-by-layer adsorption of polycondensate type superplasticizers on latex templates. Colloids Surf. A Physicochem. Eng. Asp. 2010, 366, 38–44. [Google Scholar] [CrossRef]

- Virga, E.; de Grooth, J.; Žvab, K.; de Vos, W.M. Stable Polyelectrolyte Multilayer-Based Hollow Fiber Nanofiltration Membranes for Produced Water Treatment. ACS Appl. Polym. Mater. 2019, 1, 2230–2239. [Google Scholar] [CrossRef] [Green Version]

- Hartmann, H.; Krastev, R. Biofunctionalization of surfaces using polyelectrolyte multilayers. BioNanoMaterials 2017, 18, 20160015. [Google Scholar] [CrossRef]

- Ajekwene, K. Properties and Applications of Acrylates; Intech Open Book Series: London, UK, 2020. [Google Scholar] [CrossRef]

- Mahon, R.; Balogun, Y.; Oluyemi, G.; Njuguna, J. Swelling performance of sodium polyacrylate and poly(acrylamide-co-acrylic acid) potassium salt. SN Appl. Sci. 2019, 2, 117. [Google Scholar] [CrossRef] [Green Version]

- Amina, S.J.; Guo, B. A Review on the Synthesis and Functionalization of Gold Nanoparticles as a Drug Delivery Vehicle. Int. J. Nanomed. 2020, 15, 9823–9857. [Google Scholar] [CrossRef]

- Ouni, O.A.; Subbiahdoss, G.; Scheberl, A.; Reimhult, E. DNA Polyelectrolyte Multilayer Coatings Are Antifouling and Promote Mammalian Cell Adhesion. Materials 2021, 14, 4596. [Google Scholar] [CrossRef]

- Xing, H.; Wang, X.; Xiao, S.; Zhang, G.; Li, M.; Wang, P.; Shi, Q.; Qiao, P.; Liu, H. Osseointegration of layer-by-layer polyelectrolyte multilayers loaded with IGF1 and coated on titanium implant under osteoporotic condition. Int. J. Nanomed. 2017, 12, 7709–7720. [Google Scholar] [CrossRef] [Green Version]

- Holmes, P.F.; Bohrer, M.; Kohn, J. Exploration of polymethacrylate structure–property correlations: Advances towards combinatorial and high-throughput methods for biomaterials discovery. Prog. Polym. Sci. 2008, 33, 787–796. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, Z.; Zhang, Y.; Liu, M.; Hanaor, D.A.H.; Gan, Y. Dynamic contact angle hysteresis in liquid bridges. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 365–371. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Zhou, Y.; Shao, T.; Xie, Q.; Xu, J.; Yang, W. Hydrophobic treatment on polymethylmethacrylate surface by nanosecond-pulse DBDs in CF4 at atmospheric pressure. Appl. Surf. Sci. 2014, 311, 468–477. [Google Scholar] [CrossRef]

- Zhang, H.Q.; Jin, Y.; Qiu, Y. The optical and electrical characteristics of PMMA film prepared by spin coating method. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012032. [Google Scholar] [CrossRef] [Green Version]

- Abu Hassan Shaari, H.; Ramli, M.M.; Mohtar, M.N.; Abdul Rahman, N.; Ahmad, A. Synthesis and Conductivity Studies of Poly(Methyl Methacrylate) (PMMA) by Co-Polymerization and Blending with Polyaniline (PANi). Polymers 2021, 13, 1939. [Google Scholar] [CrossRef] [PubMed]

- Gavrilenko, N.A.; Fedan, D.A.; Saranchina, N.V.; Gavrilenko, M.A. Solid phase colorimetric determination of iodine in food grade salt using polymethacrylate matrix. Food Chem. 2019, 280, 15–19. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Fan, H.; Wang, Y.; Zuo, B.; Zhang, W.; Wang, S.; Wang, X. Influence of the linkage type between the polymer backbone and side groups on the surface segregation of methyl groups during film formation. Soft Matter 2015, 11, 9168–9178. [Google Scholar] [CrossRef] [PubMed]

- Yahata, C.; Suzuki, J.; Mochizuki, A. Biocompatibility and adhesive strength properties of poly(methyl acrylate-co-acrylic acid) as a function of acrylic acid content. J. Bioact. Compat. Polym. 2019, 34, 479–493. [Google Scholar] [CrossRef]

- Halacheva, S.S.; Adlam, D.J.; Hendow, E.K.; Freemont, T.J.; Hoyland, J.; Saunders, B.R. Injectable Biocompatible and Biodegradable pH-Responsive Hollow Particle Gels Containing Poly(acrylic acid): The Effect of Copolymer Composition on Gel Properties. Biomacromolecules 2014, 15, 1814–1827. [Google Scholar] [CrossRef]

- Junior, C.R.F.; de Moura, M.R.; Aouada, F.A. Synthesis and Characterization of Intercalated Nanocomposites Based on Poly(methacrylic acid) Hydrogel and Nanoclay Cloisite-Na+ for Possible Application in Agriculture. J. Nanosci. Nanotechnol. 2017, 17, 5878–5883. [Google Scholar] [CrossRef]

- Feng, Y.; Smith, C.S.; Burkett, S.L. Process for patterning features in poly(acrylic acid) for microelectronic applications. J. Micromech. Microeng. 2017, 27, 055007. [Google Scholar] [CrossRef]

- Sultana, S.; Sumon, K.I.; Noor, H.P.; Ajmotgir, W.M.; Sarker, K.U.; Hasan, R. Sswelling and Physico-Mechanical Properties of Synthesized Sodium Polyacrylate Hydrogels. Int. J. Adv. Res. 2017, 5, 84–92. [Google Scholar] [CrossRef] [Green Version]

- Arens, L.; Barther, D.; Landsgesell, J.; Holm, C.; Wilhelm, M. Poly(sodium acrylate) hydrogels: Synthesis of various network architectures, local molecular dynamics, salt partitioning, desalination and simulation. Soft Matter 2019, 15, 9949–9964. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qi, X.; Yuan, Y.; Zhang, J.; Bulte, J.W.M.; Dong, W. Oral Administration of Salecan-Based Hydrogels for Controlled Insulin Delivery. J. Agric. Food Chem. 2018, 66, 10479–10489. [Google Scholar] [CrossRef]

- Manzur, T.; Iffat, S.; Noor, M.A. Efficiency of Sodium Polyacrylate to Improve Durability of Concrete under Adverse Curing Condition. Adv. Mater. Sci. Eng. 2015, 2015, 685785. [Google Scholar] [CrossRef] [Green Version]

- Abate, A.R.; Krummel, A.T.; Lee, D.; Marquez, M.; Holtze, C.; Weitz, D.A. Photoreactive coating for high-contrast spatial patterning of microfluidic device wettability. Lab Chip 2008, 8, 2157–2160. [Google Scholar] [CrossRef]

- Dehbari, N.; Tavakoli, J.; Singh Khatrao, S.; Tang, Y. In situ polymerized hyperbranched polymer reinforced poly(acrylic acid) hydrogels. Mater. Chem. Front. 2017, 1, 1995–2004. [Google Scholar] [CrossRef] [Green Version]

- Eisenberg, A.; Yokoyama, T.; Sambalido, E. Dehydration kinetics and glass transition of poly(acrylic acid). J. Polym. Sci. Part A-1: Polym. Chem. 1969, 7, 1717–1728. [Google Scholar] [CrossRef]

- Wang, Y.; Duo, T.; Xu, X.; Xiao, Z.; Xu, A.; Liu, R.; Jiang, C.; Lu, J. Eco-Friendly High-Performance Poly(methyl methacrylate) Film Reinforced with Methylcellulose. ACS Omega 2020, 5, 24256–24261. [Google Scholar] [CrossRef]

- Rauschendorfer, J.E.; Thien, K.M.; Denz, M.; Köster, S.; Ehlers, F.; Vana, P. Tuning the Mechanical Properties of Poly(Methyl Acrylate) via Surface-Functionalized Montmorillonite Nanosheets. Macromol. Mater. Eng. 2021, 306, 2000595. [Google Scholar] [CrossRef]

- Kianfar, E.; Cao, V. Polymeric Membranes on base of PolyMethyl Methacrylate for Air Separation: A review. J. Mater. Res. Technol. 2021, 10, 1437–1461. [Google Scholar] [CrossRef]

- Nguyen, T.; Roddick, F.A.; Fan, L. Biofouling of Water Treatment Membranes: A Review of the Underlying Causes, Monitoring Techniques and Control Measures. Membranes 2012, 2, 804–840. [Google Scholar] [CrossRef] [Green Version]

- Awad, M.A.G.; Hendi, A.A.; Khalid, O.; Ortashi, M.; Soliman, D.W.A. Synthesis of Silver—PMMA Nanocomposite Film using Herbal Extract. U.S. Patent 10,111,441 B1, 18 April 2018. 30 October 2018. [Google Scholar]

- Pearson, J.L.; Michael, P.R.; Ghaffour, N.; Missimer, T.M. Economics and Energy Consumption of Brackish Water Reverse Osmosis Desalination: Innovations and Impacts of Feedwater Quality. Membranes 2021, 11, 616. [Google Scholar] [CrossRef] [PubMed]

- Di Mauro, A.; Farrugia, C.; Abela, S.; Refalo, P.; Grech, M.; Falqui, L.; Nicotra, G.; Sfuncia, G.; Mio, A.; Buccheri, M.A.; et al. Ag/ZnO/PMMA Nanocomposites for Efficient Water Reuse. ACS Appl. Bio Mater. 2020, 3, 4417–4426. [Google Scholar] [CrossRef]

- Di Mauro, A.; Farrugia, C.; Abela, S.; Refalo, P.; Grech, M.; Falqui, L.; Privitera, V.; Impellizzeri, G. Synthesis of ZnO/PMMA nanocomposite by low-temperature atomic layer deposition for possible photocatalysis applications. Mater. Sci. Semicond. Process. 2020, 118, 105214. [Google Scholar] [CrossRef]

- Shu, Z.; Zhang, Y.; Yang, Q.; Yang, H. Halloysite Nanotubes Supported Ag and ZnO Nanoparticles with Synergistically Enhanced Antibacterial Activity. Nanoscale Res. Lett. 2017, 12, 135. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, B.; Hamza, A.; Ahmed, S.; Najam, Z.; Ishtiaq, A. Synthesis and Characterization of PMMA Nanofibers for Filtration of Drinking Water. J. Mech. Contin. Math. Sci. 2019, 14, 102–116. [Google Scholar] [CrossRef]

- Gu, G.E.; Bae, J.; Park, H.S.; Hong, J.-Y. Development of the Functionalized Nanocomposite Materials for Adsorption/Decontamination of Radioactive Pollutants. Materials 2021, 14, 2896. [Google Scholar] [CrossRef]

- Forte, M.A.; Silva, R.M.; Tavares, C.J.; Silva, R.F.E. Is Poly(methyl methacrylate) (PMMA) a Suitable Substrate for ALD? A Review. Polymers 2021, 13, 1346. [Google Scholar] [CrossRef]

- Yin, J.; Deng, B. Polymer-matrix nanocomposite membranes for water treatment. J. Membr. Sci. 2015, 479, 256–275. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly(Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Kim, S.J.; Choi, B.; Kim, K.S.; Bae, W.J.; Hong, S.H.; Lee, J.Y.; Hwang, T.-K.; Kim, S.W. The Potential Role of Polymethyl Methacrylate as a New Packaging Material for the Implantable Medical Device in the Bladder. BioMed Res. Int. 2015, 2015, 852456. [Google Scholar] [CrossRef] [PubMed]

- Marin, E.; Boschetto, F.; Zanocco, M.; Honma, T.; Zhu, W.; Pezzotti, G. Explorative study on the antibacterial effects of 3D-printed PMMA/nitrides composites. Mater. Des. 2021, 206, 109788. [Google Scholar] [CrossRef]

- Ayre, W.N.; Birchall, J.C.; Evans, S.L.; Denyer, S.P. A novel liposomal drug delivery system for PMMA bone cements. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 104, 1510–1524. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seligson, D.; Berling, S. Antibiotic-laden PMMA bead chains for the prevention of infection in compound fractures: Current state of the art. Eur. J. Orthop. Surg. Traumatol. 2015, 25, 969–974. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.-Y.; Church, D.C.; Learn, G.D.; Pokorski, J.K.; von Recum, H.A. Modified Cyclodextrin Microparticles to Improve PMMA Drug Delivery Without Mechanical Loss. Macromol. Biosci. 2021, 21, 2000328. [Google Scholar] [CrossRef]

- Giti, R.; Zomorodian, K.; Firouzmandi, M.; Zareshahrabadi, Z.; Rahmannasab, S. Antimicrobial Activity of Thermocycled Polymethyl Methacrylate Resin Reinforced with Titanium Dioxide and Copper Oxide Nanoparticles. Int. J. Dent. 2021, 2021, 6690806. [Google Scholar] [CrossRef] [PubMed]

- Shirdar, M.R.; Taheri, M.M.; Qi, M.-L.; Gohari, S.; Farajpour, N.; Narayanan, S.; Foroozan, T.; Sharifi-Asl, S.; Shahbazian-Yassar, R.; Shokuhfar, T. Optimization of the Mechanical Properties and the Cytocompatibility for the PMMA Nanocomposites Reinforced with the Hydroxyapatite Nanofibers and the Magnesium Phosphate Nanosheets. Materials 2021, 14, 5893. [Google Scholar] [CrossRef]

- Torres-Ávalos, J.A.; Cajero-Zul, L.R.; Vázquez-Lepe, M.; López-Dellamary, F.A.; Martínez-Richa, A.; Barrera-Rivera, K.A.; López-Serrano, F.; Nuño-Donlucas, S.M. Synthesis of Poly(methacrylic acid-co-butyl acrylate) Grafted onto Functionalized Carbon Nanotube Nanocomposites for Drug Delivery. Polymers 2021, 13, 533. [Google Scholar] [CrossRef]

- Best, J.P.; Cui, J.; Müllner, M.; Caruso, F. Tuning the Mechanical Properties of Nanoporous Hydrogel Particles via Polymer Cross-Linking. Langmuir 2013, 29, 9824–9831. [Google Scholar] [CrossRef]

- Shimoni, O.; Yan, Y.; Wang, Y.; Caruso, F. Shape-Dependent Cellular Processing of Polyelectrolyte Capsules. ACS Nano 2013, 7, 522–530. [Google Scholar] [CrossRef] [PubMed]

- Solhi, L.; Atai, M.; Nodehi, A.; Imani, M. Poly(Methacrylic Acid) Modified Spherical and Platelet Hybrid Nanoparticles as Reinforcing Fillers for Dentin Bonding Systems: Synthesis and Properties. J. Mech. Behav. Biomed. Mater. 2020, 109, 103840. [Google Scholar] [CrossRef] [PubMed]

- Lumbreras-Aguayo, A.; Meléndez-Ortiz, H.I.; Puente-Urbina, B.; Alvarado-Canché, C.; Ledezma, A.; Romero-García, J.; Betancourt-Galindo, R. Poly(methacrylic acid)-modified medical cotton gauzes with antimicrobial and drug delivery properties for their use as wound dressings. Carbohydr. Polym. 2019, 205, 203–210. [Google Scholar] [CrossRef] [PubMed]

- Corsaro, C.; Mallamace, D.; Neri, G.; Fazio, E. Hydrophilicity and hydrophobicity: Key aspects for biomedical and technological purposes. Phys. A Stat. Mech. Its Appl. 2021, 580, 126189. [Google Scholar] [CrossRef]

- Kshirsagar, S.; Bhalekar, M.; Umap, R. In Vitro In Vivo Comparison of Two pH Sensitive Eudragit Polymers for Colon Specific Drug Delivery. J. Pharm. Sci. Res. 2009, 1, 61–70. [Google Scholar]

- Pool, H.; Luna-Barcenas, G.; McClements, D.J.; Mendoza, S. Development of Polymethacrylate Nanospheres as Targeted Delivery Systems for Catechin within the Gastrointestinal Tract. J. Nanopart. Res. 2017, 19, 324. [Google Scholar] [CrossRef]

- Corsaro, C.; Neri, G.; Mezzasalma, A.M.; Fazio, E. Weibull Modeling of Controlled Drug Release from Ag-PMA Nanosystems. Polymers 2021, 13, 2897. [Google Scholar] [CrossRef]

- Neri, G.; Corsaro, C.; Fazio, E. Plasmon-Enhanced Controlled Drug Release from Ag-PMA Capsules. Molecules 2020, 25, 2267. [Google Scholar] [CrossRef] [PubMed]

- Bonyani, M.; Mirzaei, A.; Leonardi, S.G.; Neri, G. Silver Nanoparticles/Polymethacrylic acid (AgNPs/PMA) Hybrid Nanocomposites-Modified Electrodes for the Electrochemical Detection of Nitrate Ions. Measurement 2016, 84, 83–90. [Google Scholar] [CrossRef]

- Schreiber, C.; Zacharias, N.; Essert, S.M.; Wasser, F.; Müller, H.; Sib, E.; Precht, T.; Parcina, M.; Bierbaum, G.; Schmithausen, R.M.; et al. Clinically Relevant Antibiotic-Resistant Bacteria in Aquatic environments—An Optimized Culture-based Approach. Sci. Total Environ. 2021, 750, 142265. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.K.; Johnson, N.; Cizmas, L.; McDonald, T.J.; Kim, H. A Review of the Influence of Treatment Strategies on Antibiotic Resistant Bacteria and Antibiotic Resistance Genes. Chemosphere 2016, 150, 702–714. [Google Scholar] [CrossRef]

- Zhou, C.-s.; Wu, J.-w.; Dong, L.-l.; Liu, B.-f.; Xing, D.-f.; Yang, S.-s.; Wu, X.-k.; Wang, Q.; Fan, J.-n.; Feng, L.-p.; et al. Removal of Antibiotic Resistant Bacteria and Antibiotic Resistance Genes in Wastewater Effluent by UV-activated Persulfate. J. Hazard. Mater. 2020, 388, 122070. [Google Scholar] [CrossRef]

- Gottenbos, B.; Grijpma, D.W.; van der Mei, H.C.; Feijen, J.; Busscher, H.J. Antimicrobial effects of positively charged surfaces on adhering Gram-positive and Gram-negative bacteria. J. Antimicrob. Chemother. 2001, 48, 7–13. [Google Scholar] [CrossRef]

- Khan, S.A.; Siddiqui, M.F.; Khan, T.A. Synthesis of Poly(methacrylic acid)/Montmorillonite Hydrogel Nanocomposite for Efficient Adsorption of Amoxicillin and Diclofenac from Aqueous Environment: Kinetic, Isotherm, Reusability, and Thermodynamic Investigations. ACS Omega 2020, 5, 2843–2855. [Google Scholar] [CrossRef]

- Liu, D.; Yuan, J.; Li, J.; Zhang, G. Preparation of Chitosan Poly(methacrylate) Composites for Adsorption of Bromocresol Green. ACS Omega 2019, 4, 12680–12686. [Google Scholar] [CrossRef]

- Hong, Y.; Zhou, H.; Qian, W.; Zuo, B.; Wang, X. Impact of the α-Methyl Group (α-CH3) on the Aggregation States and Interfacial Isotherms of Poly(acrylates) Monolayers at the Water Surface. J. Phys. Chem. C 2017, 121, 19816–19827. [Google Scholar] [CrossRef]

- Horst, R.J.; Brió Pérez, M.; Cohen, R.; Cirelli, M.; Dueñas Robles, P.S.; Elshof, M.G.; Andreski, A.; Hempenius, M.A.; Benes, N.E.; Damen, C.; et al. Swelling of Poly(methyl acrylate) Brushes in Acetone Vapor. Langmuir 2020, 36, 12053–12060. [Google Scholar] [CrossRef]

- Orski, S.V.; Sheridan, R.J.; Chan, E.P.; Beers, K.L. Utilizing vapor swelling of surface-initiated polymer brushes to develop quantitative measurements of brush thermodynamics and grafting density. Polymer 2015, 72, 471–478. [Google Scholar] [CrossRef]

- Koziara, B.T.; Akkilic, N.; Nijmeijer, K.; Benes, N.E. The Effects of Water on the Morphology and the Swelling Behavior of Sulfonated Poly(ether ether ketone) Films. J. Mater. Sci. 2016, 51, 1074–1082. [Google Scholar] [CrossRef] [Green Version]

- Fathy, M.; Kashyout, A.B.; El Nady, J.; Ebrahim, S.; Soliman, M.B. Electrospun Polymethylacrylate Nanofibers Membranes for Quasi-solid-state Dye Sensitized Solar Cells. Alex. Eng. J. 2016, 55, 1737–1743. [Google Scholar] [CrossRef] [Green Version]

- Mei, D.; Tan, W.; Yuan, Y. Crystal Precipitation Law of Biodiesel based on Thermodynamic Phase Equilibrium. Trans. Chin. Soc. Agric. Eng. 2013, 29, 223–228. [Google Scholar]

- Islam, M.M.; Hassan, M.H.; Kalam, M.A.; Zulkifli, N.W.b.M.; Habibullah, M.; Hossain, M.M. Improvement of Cold Flow Properties of Cocos Nucifera and Calophyllum Inophyllum Biodiesel Blends using Polymethyl Acrylate Additive. J. Clean. Prod. 2016, 137, 322–329. [Google Scholar] [CrossRef]

- Wang, J.; Cao, L.; Han, S. Effect of Polymeric Cold Flow Improvers on Flow Properties of Biodiesel from Waste Cooking Oil. Fuel 2014, 117, 876–881. [Google Scholar] [CrossRef]

- Giraldo, S.Y.; Rios, L.A.; Suárez, N. Comparison of Glycerol Ketals, Glycerol Acetates and Branched Alcohol-derived Fatty Esters as Cold-flow Improvers for Palm Biodiesel. Fuel 2013, 108, 709–714. [Google Scholar] [CrossRef]

- Joshi, H.; Moser, B.R.; Toler, J.; Smith, W.F.; Walker, T. Ethyl levulinate: A Potential Bio-based Diluent for Biodiesel which Improves Cold Flow Properties. Biomass Bioenergy 2011, 35, 3262–3266. [Google Scholar] [CrossRef]

- Xue, Y.; Yang, C.; Xu, G.; Zhao, Z.; Lian, X.; Sheng, H.; Lin, H. The Influence of Polymethyl Acrylate as a Pour Point Depressant for Biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 17–22. [Google Scholar] [CrossRef]

- Ballester-Beltrán, J.; Cantini, M.; Lebourg, M.; Rico, P.; Moratal, D.; García, A.J.; Salmerón-Sánchez, M. Effect of Topological cues on Material-driven Fibronectin Fibrillogenesis and Cell Differentiation. J. Mater. Sci. Mater. Med. 2012, 23, 195–204. [Google Scholar] [CrossRef]

- Vanterpool, F.A.; Cantini, M.; Seib, F.P.; Salmerón-Sánchez, M. A Material-Based Platform to Modulate Fibronectin Activity and Focal Adhesion Assembly. BioResearch Open Access 2014, 3, 286–296. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soria, J.M.; Martínez Ramos, C.; Bahamonde, O.; García Cruz, D.M.; Salmerón Sánchez, M.; García Esparza, M.A.; Casas, C.; Guzmán, M.; Navarro, X.; Gómez Ribelles, J.L.; et al. Influence of the Substrate’s Hydrophilicity on the in vitro Schwann Cells Viability. J. Biomed. Mater. Res. Part A 2007, 83A, 463–470. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Ma, J.; Liu, C.; Yan, H. Surface Modification Design for Improving the Strength and Water Vapor Permeability of Waterborne Polymer/SiO2 Composites: Molecular Simulation and Experimental Analyses. Polymers 2020, 12, 170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rahman, M.L.; Fui, C.J.; Ting, T.X.; Sarjadi, M.S.; Arshad, S.E.; Musta, B. Waste Fiber-Based Cellulose Supported Polymer Ligands for Toxic Metals Removal from Industrial Wastewater. In Proceedings of the Presented at the First International Conference on “Green” Polymer Materials, Online, 5–25 November 2020. [Google Scholar]

- Rauschendorfer, J.E.; Vana, P. Increasing the Gas Barrier Properties of Polyethylene Foils by Coating with Poly(methyl acrylate)-Grafted Montmorillonite Nanosheets. Polymers 2021, 13, 3228. [Google Scholar] [CrossRef]

- Lee, C.-J.; Wu, H.; Hu, Y.; Young, M.; Wang, H.; Lynch, D.; Xu, F.; Cong, H.; Cheng, G. Ionic Conductivity of Polyelectrolyte Hydrogels. ACS Appl. Mater. Interfaces 2018, 10, 5845–5852. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, N.; Ma, M. Electroconductive hydrogels for biomedical applications. WIREs Nanomed. Nanobiotechnol. 2019, 11, e1568. [Google Scholar] [CrossRef]

- Kang, K.; Jung, H.; An, S.; Baac, H.W.; Shin, M.; Son, D. Skin-like Transparent Polymer-Hydrogel Hybrid Pressure Sensor with Pyramid Microstructures. Polymers 2021, 13, 3272. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, M.; Ma, M.-m.; Zhang, N. Water-Resistant and Stretchable Conductive Ionic Hydrogel Fibers Reinforced by Carboxymethyl Cellulose. Chin. J. Chem. Phys. 2021, 134012. [Google Scholar] [CrossRef]

- Aziz, S.B.; Brza, M.A.; Nofal, M.M.; Abdulwahid, R.T.; Hussen, S.A.; Hussein, A.M.; Karim, W.O. A Comprehensive Review on Optical Properties of Polymer Electrolytes and Composites. Materials 2020, 13, 3675. [Google Scholar] [CrossRef]

- Ngai, K.S.; Ramesh, S.; Ramesh, K.; Juan, J.C. A review of polymer electrolytes: Fundamental, approaches and applications. Ionics 2016, 22, 1259–1279. [Google Scholar] [CrossRef]

- Elliott, J.E.; Macdonald, M.; Nie, J.; Bowman, C.N. Structure and swelling of poly(acrylic acid) hydrogels: Effect of pH, ionic strength, and dilution on the crosslinked polymer structure. Polymer 2004, 45, 1503–1510. [Google Scholar] [CrossRef]

- Liew, C.-W.; Ng, H.M.; Numan, A.; Ramesh, S. Poly(Acrylic acid)–Based Hybrid Inorganic–Organic Electrolytes Membrane for Electrical Double Layer Capacitors Application. Polymers 2016, 8, 179. [Google Scholar] [CrossRef] [PubMed]

- Abu-Saied, M.; Fahmy, A.; Morgan, N.; Qutop, W.; Abdelbary, H.; Friedrich, J.F. Enhancement of Poly(vinyl chloride) Electrolyte Membrane by Its Exposure to an Atmospheric Dielectric Barrier Discharge Followed by Grafting with Polyacrylic Acid. Plasma Chem. Plasma Process. 2019, 39, 1499–1517. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Rahzani, B.; Asiani, H.; Khodabakhshi, A.R.; Hamidi, A.R.; Madaeni, S.S.; Moghadassi, A.R.; Seidypoor, A. Surface modification of heterogeneous cation exchange membranes by simultaneous using polymerization of (acrylic acid-co-methyl methacrylate): Membrane characterization in desalination process. Desalination 2014, 345, 13–20. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Sohrabnejad, S.; Nabiyouni, G.; Jashni, E.; Van der Bruggen, B.; Ahmadi, A. Magnetic cation exchange membrane incorporated with cobalt ferrite nanoparticles for chromium ions removal via electrodialysis. J. Membr. Sci. 2019, 583, 292–300. [Google Scholar] [CrossRef]

- Khan, Y.; Bashir, S.; Hina, M.; Ramesh, S.; Ramesh, K.; Lahiri, I. Effect of Salt Concentration on Poly(Acrylic Acid) Hydrogel Electrolytes and their Applications in Supercapacitor. J. Electrochem. Soc. 2020, 167, 100524. [Google Scholar] [CrossRef]

- Cevik, E.; Bozkurt, A. Redox active polymer metal chelates for use in flexible symmetrical supercapacitors: Cobalt-containing poly(acrylic acid) polymer electrolytes. J. Energy Chem. 2021, 55, 145–153. [Google Scholar] [CrossRef]

- Al Munsur, A.Z.; Goo, B.-H.; Kim, Y.; Kwon, O.J.; Paek, S.Y.; Lee, S.Y.; Kim, H.-J.; Kim, T.-H. Nafion-Based Proton-Exchange Membranes Built on Cross-Linked Semi-Interpenetrating Polymer Networks between Poly(acrylic acid) and Poly(vinyl alcohol). ACS Appl. Mater. Interfaces 2021, 13, 28188–28200. [Google Scholar] [CrossRef]

- Isailović, J.; Vidović, K.; Hočevar, S.B. Simple electrochemical sensors for highly sensitive detection of gaseous hydrogen peroxide using polyacrylic-acid-based sensing membrane. Sens. Actuators B Chem. 2022, 352, 131053. [Google Scholar] [CrossRef]

- Cheng, Y.; Hu, Y.; Xu, M.; Qin, M.; Lan, W.; Huang, D.; Wei, Y.; Chen, W. High strength polyvinyl alcohol/polyacrylic acid (PVA/PAA) hydrogel fabricated by Cold-Drawn method for cartilage tissue substitutes. J. Biomater. Sci. Polym. Ed. 2020, 31, 1836–1851. [Google Scholar] [CrossRef]

- Kempson, G.E.; Muir, H.; Pollard, C.; Tuke, M. The tensile properties of the cartilage of human femoral condyles related to the content of collagen and glycosaminoglycans. Biochim. Biophys. Acta (BBA)-Gen. Subj. 1973, 297, 456–472. [Google Scholar] [CrossRef]

- Thaitalay, P.; Thongsri, O.; Dangviriyakul, R.; Srisuwan, S.; Talabnin, C.; Suksaweang, S.; Srakaew, N.L.-O.; Rattanachan, S.T. Influence of polyacrylic acid (PAA)/Na2HPO4 mixture on biphasic calcium phosphate cement: Enhancing strength and cell viability. Int. J. Appl. Ceram. Technol. 2021, 18, 1365–1378. [Google Scholar] [CrossRef]

- Jiang, S.; Cao, Y.; Li, S.; Pang, Y.; Sun, Z. Dual function of poly(acrylic acid) on controlling amorphous mediated hydroxyapatite crystallization. J. Cryst. Growth 2021, 557, 125991. [Google Scholar] [CrossRef]

- Lemanowicz, M.; Mielańczyk, A.; Walica, T.; Kotek, M.; Gierczycki, A. Application of Polymers as a Tool in Crystallization—A Review. Polymers 2021, 13, 2695. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Yuan, Z.; Han, H.; Li, T.; Li, L.; Guo, X. Chitosan cross-linked poly(acrylic acid) hydrogels: Drug release control and mechanism. Colloids Surf. B Biointerfaces 2017, 152, 252–259. [Google Scholar] [CrossRef] [Green Version]

- Soliman, M.M.; Sakr, T.M.; Rashed, H.M.; Hamed, A.A.; Abd El-Rehim, H.A. Polyethylene oxide–polyacrylic acid–folic acid (PEO-PAAc) nanogel as a 99mTc targeting receptor for cancer diagnostic imaging. J. Label. Compd. Radiopharm. 2021, 64, 534–547. [Google Scholar] [CrossRef]

- Chiong, J.A.; Tran, H.; Lin, Y.; Zheng, Y.; Bao, Z. Integrating Emerging Polymer Chemistries for the Advancement of Recyclable, Biodegradable, and Biocompatible Electronics. Adv. Sci. 2021, 8, 2101233. [Google Scholar] [CrossRef] [PubMed]

- Coates, G.W.; Getzler, Y.D.Y.L. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 2020, 5, 501–516. [Google Scholar] [CrossRef]

- Bin Rusayyis, M.; Torkelson, J.M. Recyclable Polymethacrylate Networks Containing Dynamic Dialkylamino Disulfide Linkages and Exhibiting Full Property Recovery. Macromolecules 2020, 53, 8367–8373. [Google Scholar] [CrossRef]

- Dubois, J.-L. New Innovative process for recycling end-of-life PMMA waste. MMAtwo second generation Methyl Methacrylate. In Proceedings of the Conference Plastic Recycling Technologies, Dusseldorf, Germany, 18–19 June 2019. [Google Scholar] [CrossRef]

- Innovative Acrylic(PMMA-Polymethyl Methacrylate) Recycling Technology Complying with Regulations. Available online: https://cordis.europa.eu/project/id/856103 (accessed on 10 December 2021).

- Post, W.; Susa, A.; Blaauw, R.; Molenveld, K.; Knoop, R.J.I. A Review on the Potential and Limitations of Recyclable Thermosets for Structural Applications. Polym. Rev. 2020, 60, 359–388. [Google Scholar] [CrossRef]

- Sudhakar, Y.N.; Selvakumar, M.; Bhat, D.K. Enhancement and Investigation of Biodegradability of Poly(Methyl Methacrylate) and Poly(Vinyl Chloride) by Blending with Cellulose Derivatives; Research Square: Durham, NC, USA, 2021. [Google Scholar]

- Hou, Q.; Zhen, M.; Qian, H.; Nie, Y.; Bai, X.; Xia, T.; Laiq Ur Rehman, M.; Li, Q.; Ju, M. Upcycling and catalytic degradation of plastic wastes. Cell Rep. Phys. Sci. 2021, 2, 100514. [Google Scholar] [CrossRef]

- Jeon, C.; Kim, D.W.; Chang, S.; Kim, J.G.; Seo, M. Synthesis of Polypropylene via Catalytic Deoxygenation of Poly(methyl acrylate). ACS Macro Lett. 2019, 8, 1172–1178. [Google Scholar] [CrossRef]

- Rathee, V.S.; Sidky, H.; Sikora, B.J.; Whitmer, J.K. Role of Associative Charging in the Entropy–Energy Balance of Polyelectrolyte Complexes. J. Am. Chem. Soc. 2018, 140, 15319–15328. [Google Scholar] [CrossRef]

- Raczkowska, J.; Stetsyshyn, Y.; Awsiuk, K.; Lekka, M.; Marzec, M.; Harhay, K.; Ohar, H.; Ostapiv, D.; Sharan, M.; Yaremchuk, I.; et al. Temperature-responsive grafted polymer brushes obtained from renewable sources with potential application as substrates for tissue engineering. Appl. Surf. Sci. 2017, 407, 546–554. [Google Scholar] [CrossRef]

- Yu, D.; Zhao, J.; Wang, W.; Qi, J.; Hu, Y. Mono-acrylated isosorbide as a bio-based monomer for the improvement of thermal and mechanical properties of poly(methyl methacrylate). RSC Adv. 2019, 9, 35532–35538. [Google Scholar] [CrossRef] [Green Version]

- Veith, C.; Diot-Néant, F.; Miller, S.A.; Allais, F. Synthesis and polymerization of bio-based acrylates: A review. Polym. Chem. 2020, 11, 7452–7470. [Google Scholar] [CrossRef]

- Stetsyshyn, Y.; Raczkowska, J.; Budkowski, A.; Awsiuk, K.; Kostruba, A.; Nastyshyn, S.; Harhay, K.; Lychkovskyy, E.; Ohar, H.; Nastishin, Y. Cholesterol-Based Grafted Polymer Brushes as Alignment Coating with Temperature-Tuned Anchoring for Nematic Liquid Crystals. Langmuir 2016, 32, 11029–11038. [Google Scholar] [CrossRef]

| PMMA | PMA | PAA | |

|---|---|---|---|

| Glass transition temperature | 105 °C | 10 °C | ~103 °C |

| Contact angle | ~68° | ~73° | ~22° |

| Refractive Index | 1.491 | 1.479 | 1.527 |

| Tensile strength | 3171 MPa | 6.9 MPa | ~0.5 MPa |

| Tensile elongation | 5% | 750% | ~340% |

| Sample | Number of Coating Cycles | ∆t400→600mbar/min |

|---|---|---|

| LDPE | 0 | 38 ± 11 |

| LDPE + MMT-PMAL | 1 | 79 ± 11 |

| LDPE + MMT-PMAS | 1 | 74 ± 16 |

| LDPE + MMT-PMAHB | 1 | 77 ± 8 |

| LDPE + MMT-PMAL | 3 | 86 ± 4 |

| LDPE + MMT-PMAS | 3 | 96 ± 8 |

| LDPE + MMT-PMAHB | 3 | 104 ± 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corsaro, C.; Neri, G.; Santoro, A.; Fazio, E. Acrylate and Methacrylate Polymers’ Applications: Second Life with Inexpensive and Sustainable Recycling Approaches. Materials 2022, 15, 282. https://doi.org/10.3390/ma15010282

Corsaro C, Neri G, Santoro A, Fazio E. Acrylate and Methacrylate Polymers’ Applications: Second Life with Inexpensive and Sustainable Recycling Approaches. Materials. 2022; 15(1):282. https://doi.org/10.3390/ma15010282

Chicago/Turabian StyleCorsaro, Carmelo, Giulia Neri, Antonio Santoro, and Enza Fazio. 2022. "Acrylate and Methacrylate Polymers’ Applications: Second Life with Inexpensive and Sustainable Recycling Approaches" Materials 15, no. 1: 282. https://doi.org/10.3390/ma15010282

APA StyleCorsaro, C., Neri, G., Santoro, A., & Fazio, E. (2022). Acrylate and Methacrylate Polymers’ Applications: Second Life with Inexpensive and Sustainable Recycling Approaches. Materials, 15(1), 282. https://doi.org/10.3390/ma15010282