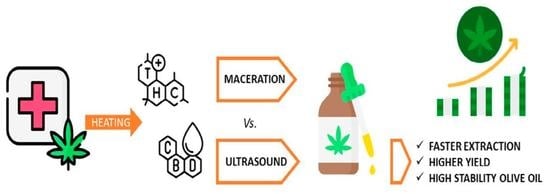

Ultrasound-Assisted Extraction of Cannabinoids from Cannabis Sativa for Medicinal Purpose

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemicals, Reagents and HPLC Solvents

2.3. Cannabis Extract in Olive Oil

2.4. Quantitative Determination of Cannabinoids

2.5. Olive Oil Characterization

2.6. Statistical Analysis

3. Results and Discussion

3.1. Decarboxylation of Cannabis FM2

3.2. Cannabinoid Content in Samples Prepared by Maceration Method

3.3. Cannabinoid Content in Samples Prepared by Ultrasound-Assisted Extraction

3.4. Preparation of Bedrocan Samples by UAE

3.5. Olive Oil Components and Effect of the Extraction Procedures

DSC Analysis of Olive Oil

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ferber, S.G.; Namdar, D.; Hen-Shoval, D.; Eger, G.; Koltai, H.; Shoval, G.; Shbiro, L.; Weller, A. The “Entourage Effect”: Terpenes Coupled with Cannabinoids for the Treatment of Mood Disorders and Anxiety Disorders. Curr. Neuropharmacol. 2020, 18, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Specchio, N.; Pietrafusa, N.; Cross, H.J. Source of cannabinoids: What is available. what is used. and where does it come from? Epilept. Disord. 2020, 22, S1–S9. [Google Scholar] [CrossRef]

- Guerrero-Alba, R.; Barragan-Iglesias, P.; González-Hernández, A.; Valdez-Moráles, E.E.; Granados-Soto, V.; Condés-Lara, M.; Rodríguez, M.G.; Marichal-Cancino, B.A. Some Prospective Alternatives for Treating Pain: The Endocannabinoid System and Its Putative Receptors GPR18 and GPR55. Front. Pharmacol. 2019, 9, 1496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Navari, R.M. Management of Chemotherapy-Induced Nausea and Vomiting: Focus on newer agents and new uses for older agents. Drugs 2013, 73, 249–262. [Google Scholar] [CrossRef]

- Fischedick, J.T.; Hazekamp, A.; Erkelens, T.; Choi, Y.H.; Verpoorte, R. Metabolic fingerprinting of Cannabis sativa L., cannabinoids and terpenoids for chemotaxonomic and drug standardization purposes. Phytochemistry 2010, 71, 2058–2073. [Google Scholar] [CrossRef]

- AL Ubeed, H.M.S.; Bhuyan, D.J.; Alsherbiny, M.A.; Basu, A.; Vuong, Q.V. A Comprehensive Review on the Techniques for Extraction of Bioactive Compounds from Medicinal Cannabis. Molecules 2022, 27, 604. [Google Scholar] [CrossRef]

- Stott, C.G.; Guy, G.W. Cannabinoids for the pharmaceutical industry. Euphytica 2004, 140, 83–93. [Google Scholar] [CrossRef]

- Reddy, P.M.; Maurya, N.; Velmurugan, B.K. Medicinal Use of Synthetic Cannabinoids—A Mini Review. Curr. Pharmacol. Rep. 2019, 5, 1–13. [Google Scholar] [CrossRef]

- Minghetti, P.; Marini, V.; Zaccara, V.; Casiraghi, A. Regulation for Prescribing and Dispensing System of Cannabis: The Italian Case. Curr. Bioact. Compd. 2019, 15, 196–200. [Google Scholar] [CrossRef]

- Perrotin-Brunel, H.; Buijs, W.; van Spronsen, J.; van Roosmalen, M.J.; Peters, C.J.; Verpoorte, R.; Witkamp, G.-J. Decarboxylation of Δ9-tetrahydrocannabinol: Kinetics and molecular modeling. J. Mol. Struct. 2011, 987, 67–73. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.-H.; Avula, B.; Radwan, M.M.; Wanas, A.; Van Antwerp, J.; Parcher, J.F.; ElSohly, M.A.; Khan, I.A. Decarboxylation Study of Acidic Cannabinoids: A Novel Approach Using Ultra-High-Performance Supercritical Fluid Chromatography/Photodiode Array-Mass Spectrometry. Cannabis Cannabinoid Res. 2016, 1, 262–271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Veress, T.; Szanto, J.; Leisztner, L. Determination of cannabinoid acids by high-performance liquid chromatography of their neutral derivatives formed by thermal decarboxylation: I. Study of the decarboxylation process in open reactors. J. Chromatogr. A 1990, 520, 339–347. [Google Scholar] [CrossRef]

- Casiraghi, A.; Roda, G.; Casagni, E.; Cristina, C.; Musazzi, U.M.; Franzè, S.; Rocco, P.; Giuliani, C.; Fico, G.; Minghetti, P.; et al. Extraction Method and Analysis of Cannabinoids in Cannabis Olive Oil Preparations. Planta Medica 2018, 84, 242–249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Citti, C.; Pacchetti, B.; Vandelli, M.A.; Forni, F.; Cannazza, G. Analysis of cannabinoids in commercial hemp seed oil and decarboxylation kinetics studies of cannabidiolic acid (CBDA). J. Pharm. Biomed. Anal. 2018, 149, 532–540. [Google Scholar] [CrossRef]

- Qamar, S.; Torres, Y.J.; Parekh, H.S.; Falconer, J.R. Extraction of medicinal cannabinoids through supercritical carbon dioxide technologies: A review. J. Chromatogr. B 2021, 1167, 122581. [Google Scholar] [CrossRef]

- Pattnaik, F.; Nanda, S.; Mohanty, S.; Dalai, A.K.; Kumar, V.; Ponnusamy, S.K.; Naik, S. Cannabis: Chemistry, extraction and therapeutic applications. Chemosphere 2022, 289, 133012. [Google Scholar] [CrossRef]

- Citti, C.; Ciccarella, G.; Braghiroli, D.; Parenti, C.; Vandelli, M.A.; Cannazza, G. Medicinal cannabis: Principal cannabinoids concentration and their stability evaluated by a high performance liquid chromatography coupled to diode array and quadrupole time of flight mass spectrometry method. J. Pharm. Biomed. Anal. 2016, 128, 201–209. [Google Scholar] [CrossRef]

- Romano, L.L.; Hazekamp, A. Cannabis Oil: Chemical evaluation of an upcoming cannabis-based medicine. Cannabinoids 2013, 1, 1–11. [Google Scholar]

- Toma, M.; Vinatoru, M.; Paniwnyk, L.; Mason, T. Investigation of the effects of ultrasound on vegetal tissues during solvent extraction. Ultrason. Sonochem. 2001, 8, 137–142. [Google Scholar] [CrossRef]

- Vinatoru, M. An overview of the ultrasonically assisted extraction of bioactive principles from herbs. Ultrason. Sonochem. 2001, 8, 303–313. [Google Scholar] [CrossRef]

- Gajic, I.S.; Savic, I.; Gajic, D.; Dosic, A. Ultrasound-Assisted Extraction of Carotenoids from Orange Peel Using Olive Oil and Its Encapsulation in Ca-Alginate Beads. Biomolecules 2021, 11, 225. [Google Scholar] [CrossRef] [PubMed]

- Martín-García, B.; De Montijo-Prieto, S.; Jiménez-Valera, M.; Carrasco-Pancorbo, A.; Ruiz-Bravo, A.; Verardo, V.; Gómez-Caravaca, A.M. Comparative Extraction of Phenolic Compounds from Olive Leaves Using a Sonotrode and an Ultrasonic Bath and the Evaluation of Both Antioxidant and Antimicrobial Activity. Antioxidants 2022, 11, 558. [Google Scholar] [CrossRef] [PubMed]

- Vinatoru, M.; Toma, M.; Radu, O.; Filip, P.I.; Lazurca, D.; Mason, T.J. The use of ultrasound for the extraction of bioactive principles from plant materials. Ultrason. Sonochemistry 1997, 4, 135–139. [Google Scholar] [CrossRef] [PubMed]

- Sochard, S.; Wilhelm, A.; Delmas, H. Modelling of free radicals production in a collapsing gas-vapour bubble. Ultrason. Sonochemistry 1997, 4, 77–84. [Google Scholar] [CrossRef]

- Falleh, H.; Ksouri, R.; Lucchessi, M.-E.; Abdelly, C.; Magné, C. Ultrasound-Assisted Extraction: Effect of Extraction Time and Solvent Power on the Levels of Polyphenols and Antioxidant Activity of Mesembryanthemum edule L. Aizoaceae Shoots. Trop. J. Pharm. Res. 2012, 11, 243–249. [Google Scholar] [CrossRef] [Green Version]

- Zupanc, M.; Pandur, Ž.; Perdih, T.S.; Stopar, D.; Petkovšek, M.; Dular, M. Effects of cavitation on different microorganisms: The current understanding of the mechanisms taking place behind the phenomenon. A review and proposals for further research. Ultrason. Sonochem. 2019, 57, 147–165. [Google Scholar] [CrossRef]

- Calvi, L.; Pentimalli, D.; Panseri, S.; Giupponi, L.; Gelmini, F.; Beretta, G.; Vitali, D.; Bruno, M.; Zilio, E.; Pavlovic, R.; et al. Comprehensive quality evaluation of medical Cannabis sativa L. inflorescence and macerated oils based on HS-SPME coupled to GC–MS and LC-HRMS (q-exactive orbitrap®) approach. J. Pharm. Biomed. Anal. 2018, 150, 208–219. [Google Scholar] [CrossRef]

- Agarwal, C.; Máthé, K.; Hofmann, T.; Csóka, L. Ultrasound-Assisted Extraction of Cannabinoids from Cannabis Sativa L. Optimized by Response Surface Methodology. J. Food Sci. 2018, 83, 700–710. [Google Scholar] [CrossRef]

- Baranauskaite, J.; Marksa, M.; Ivanauskas, L.; Vitkevicius, K.; Liaudanskas, M.; Skyrius, V.; Baranauskas, A. Development of extraction technique and GC/FID method for the analysis of cannabinoids in Cannabis sativa L. spp. santicha (hemp). Phytochem. Anal. 2020, 31, 516–521. [Google Scholar] [CrossRef]

- de Vita, D.; Madia, V.N.; Tudino, V.; Saccoliti, F.; De Leo, A.; Messore, A.; Roscilli, P.; Botto, A.; Pindinello, I.; Santilli, G.; et al. Comparison of different methods for the extraction of cannabinoids from cannabis. Nat. Prod. Res. 2020, 34, 2952–2958. [Google Scholar] [CrossRef]

- Rovellini, P.; Cortesi, N.; Mattei, A.; Marotta, F. Composti carbonilici volatili nell’aroma dell’olio vergine di oliva. Riv. Ital. Delle Sostanze Grasse 2002, 29, 429–438. [Google Scholar]

- Rovellini, P.; Cortesi, N. Oxidative Status of Extra Virgin Olive Oils: HPLC Evaluation. Ital. J. Food Sci. 2004, 16, 333–342. [Google Scholar]

- Brenneisen, R. Chemistry and Analysis of Phytocannabinoids and Other Cannabis Constituents. In Marijuana and the Canna-binoids; Springer: Totowa, NJ, USA, 2007. [Google Scholar] [CrossRef]

- Chemat, F.; Abert-Vian, M.; Fabiano-Tixier, A.S.; Strube, J.; Uhlenbrock, L.; Gunjevic, V.; Cravotto, G. Green extraction of natural products. Origins, current status, and future challenges. TrAC Trends Anal. Chem. 2019, 118, 248–263. [Google Scholar] [CrossRef]

- Zhang, Q.-A.; Zhang, Z.-Q.; Yue, X.-F.; Fan, X.-H.; Li, T.; Chen, S.-F. Response surface optimization of ultrasound-assisted oil extraction from autoclaved almond powder. Food Chem. 2009, 116, 513–518. [Google Scholar] [CrossRef]

- Nardella, M.; Moscetti, R.; Chakravartula, S.S.N.; Bedini, G.; Massantini, R. A Review on High-Power Ultrasound-Assisted Extraction of Olive Oils: Effect on Oil Yield, Quality, Chemical Composition and Consumer Perception. Foods 2021, 10, 2743. [Google Scholar] [CrossRef]

- Sharayei, P.; Azarpazhooh, E.; Zomorodi, S.; Ramaswamy, H.S. Ultrasound assisted extraction of bioactive compounds from pomegranate (Punica granatum L.) peel. LWT 2019, 101, 342–350. [Google Scholar] [CrossRef]

- Frankel, E. Lipid oxidation. Prog. Lipid Res. 1980, 19, 1–22. [Google Scholar] [CrossRef]

- Vittadini, E.; Lee, J.H.; Frega, N.G.; Min, D.B.; Vodovotz, Y. DSC determination of thermally oxidized olive oil. J. Am. Oil Chem. Soc. 2003, 80, 533–537. [Google Scholar] [CrossRef]

- Barba, L.; Arrighetti, G.; Calligaris, S. Crystallization and melting properties of extra virgin olive oil studied by synchrotron XRD and DSC. Eur. J. Lipid Sci. Technol. 2013, 115, 322–329. [Google Scholar] [CrossRef]

- Jansen, M.; Birch, J. Composition and stability of olive oil following partial crystallization. Food Res. Int. 2009, 42, 826–831. [Google Scholar] [CrossRef]

- Calligaris, S.; Sovrano, S.; Manzocco, L.; Nicoli, M.C. Influence of Crystallization on the Oxidative Stability of Extra Virgin Olive Oil. J. Agric. Food Chem. 2006, 54, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Gila, A.; Sánchez-Ortiz, A.; Jiménez, A.; Beltrán, G. The ultrasound application does not affect to the thermal properties and chemical composition of virgin olive oils. Ultrason. Sonochem. 2021, 70, 105320. [Google Scholar] [CrossRef] [PubMed]

- Cas, M.D.; Casagni, E.; Casiraghi, A.; Minghetti, P.; Fornasari, D.M.M.; Ferri, F.; Arnoldi, S.; Gambaro, V.; Roda, G. Phytocannabinoids Profile in Medicinal Cannabis Oils: The Impact of Plant Varieties and Preparation Methods. Front. Pharmacol. 2020, 11, 570616. [Google Scholar] [CrossRef] [PubMed]

| Sample | FM2 (g) | dFM2 (g) | dB (g) | V (mL) | D (mm) | A (%) | Time (min) |

|---|---|---|---|---|---|---|---|

| 1 | 2 | - | - | 20 | 2 | 60 | 20 |

| 2 | - | 2 | - | 20 | 2 | 60 | 10 |

| 3 | - | 2 | - | 20 | 2 | 60 | 20 |

| 4 | - | 2 | - | 20 | 2 | 60 | 30 |

| 5 | - | 5 | - | 50 | 2 | 60 | 10 |

| 6 | - | 5 | - | 50 | 7 | 30 | 10 |

| 7 | - | - | 5 | 50 | 7 | 30 | 10 |

| 8 | - | - | 5 | 50 | 7 | 35 | 10 |

| Component | FM2 * | Decarboxylation Temperature | |

|---|---|---|---|

| 115 °C ** | 125 °C *** | ||

| CBD | 1.17 ± 0.08 (7.07) | 5.26 ± 0.34 (6.38) | 5.41 ± 0.19 (3.43) |

| CBDA | 6.01 ± 0.38 (6.35) | 0.64 ± 0.04 (5.46) | 0.22 ± 0.01 (4.40) |

| CBN | 0.23 ± 0.02 (6.96) | 0.56 ± 0.04 (6.23) | 0.51 ± 0.02 (3.69) |

| Δ9-THC | 0.83 ± 0.07 (7.96) | 2.26 ± 0.15 (6.41) | 2.34 ± 0.09 (3.66) |

| Δ9-THCA | 2.41 ± 0.16 (6.52) | 0.02 ± 0.00 (0) | - |

| Total CBD | 6.44 ± 0.41 (6.38) | 5.82 ± 0.37 (6.29) | 5.60 ± 0.19 (3.48) |

| Total THC | 2.94 ± 0.20 (6.78) | 2.28 ± 0.15 (6.36) | 2.34 ± 0.09 (3.66) |

| Component | No Preheated | Decarboxylated FM2 | |

|---|---|---|---|

| M-FM2 * | M-FM2_115 * | M-FM2_125 ** | |

| CBD | 0.12 ± 0.01 (4.13) | 0.53 ± 0.04 (7.88) | 0.70 ± 0.02 (2.86) |

| CBDA | 0.62 ± 0.05 (8.08) | 0.07 ± 0.01 (0.00) | - |

| CBN | 0.02 ± 0.01 (24.74) | 0.04 ± 0.01 (13.32) | 0.02 ± 0.03 (173.21) |

| Δ9-THC | 0.10 ± 0.01 (10.47) | 0.26 ± 0.02 (6.66) | 0.31 ± 0.01 (1.88) |

| Δ9-THCA | 0.25 ± 0.02 (9.26) | - | - |

| Total CBD | 0.67 ± 0.05 (7.33) | 0.59 ± 0.04 (7.57) | 0.70 ± 0.02 (2.86) |

| Total THC | 0.32 ± 0.03 (9.29) | 0.26 ± 0.02 (6.66) | 0.31 ± 0.01 (1.88) |

| Component | No Preheated FM2 | FM2 Decarboxylated @115 °C | ||

|---|---|---|---|---|

| 20 min | 30 min | 20 min | 10 min | |

| CBD | 0.17 ± 0.01 (5.88) | 0.63 ± 0.04 (6.04) | 0.62 ± 0.08 (12.85) | 0.62 ± 0.09 (14.20) |

| CBDA | 0.67 ± 0.03 (4.33) | 0.02 ± 0.01 (24.74) | 0.03 ± 0.02 (66.67) | 0.04 ± 0.03 (72.22) |

| CBN | 0.03 ± 0.00 (0) | 0.06 ± 0.00 (0) | 0.06 ± 0.01 (13.61) | 0.06 ± 0.01 (11.79) |

| Δ9-THC | 0.11 ± 0.01 (5.09) | 0.26 ± 0.02 (6.66) | 0.26 ± 0.03 (11.32) | 0.26 ± 0.02 (8.99) |

| Δ9-THCA | 0.24 ± 0.02 (6.45) | - | - | - |

| Total CBD | 0.75 ± 0.03 (3.61) | 0.65 ± 0.04 (6.63) | 0.64 ± 0.06 (9.93) | 0.66 ± 0.08 (11.66) |

| Total THC | 0.32 ± 0.01 (2.54) | 0.26 ± 0.02 (6.66) | 0.26 ± 0.03 (11.32) | 0.26 ± 0.02 (8.99) |

| Component | FM2 Decarboxylated @115 °C | |

|---|---|---|

| 2 mm Sonotrode | 7 mm Sonotrode | |

| CBD | 0.49 ± 0.02 (4.22) | 0.54 ± 0.02 (2.86) |

| CBDA | 0.08 ± 0.01 (7.53) | 0.04 ± 0.01 (3.27) |

| CBN | 0.05 ± 0.00 (0) | 0.06 ± 0.00 (0) |

| Δ9-THC | 0.23 ± 0.02 (6.74) | 0.19 ± 0.004 (1.98) |

| Δ9-THCA | - | - |

| Total CBD | 0.56 ± 0.03 (4.60) | 0.58 ± 0.01 (2.13) |

| Total THC | 0.23 ± 0.02 (6.74) | 0.19 ± 0.004 (1.19) |

| Component | Decarboxylated Bedrocan @115 °C | ||

|---|---|---|---|

| M-BEDROCAN * | US-BEDROCAN-30% * | US-BEDROCAN-35% ** | |

| Δ9-THC | 1.78 ± 0.17 (9.62) | 1.75 ± 0.05 (2.81) | 1.94 ± 0.05 (2.74) |

| Δ9-THCA | 0.05 ± 0.03 (51.32) | 0.04 ± 0.03 (71.54) | 0.04 ± 0.04 (102.60) |

| Total THC | 1.83 ± 0.17 (9.34) | 1.79 ± 0.05 (2.75) | 1.98 ± 0.01 (0.60) |

| Before Treatment | Maceration | UAE | ||||||

|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S3 | S1 | S2 | S3 | |||

| CVCs content (mg/kg) | Hexanal | 8 | 12 | 12 | 12 | 12 | 12 | 12 |

| Nonanal | 3 | 6 | 6 | 7 | 6 | 6 | 6 | |

| Total CVCs | 11 | 18 | 18 | 19 | 18 | 18 | 18 | |

| Oxidized fatty acids content (% w/w) | Primary oxidized forms | 0.49 | 0.57 | 0.54 | 0.53 | 0.57 | 0.60 | 0.53 |

| Secondary oxidized forms | 0.90 | 1.29 | 1.29 | 1.45 | 1.47 | 1.43 | 1.42 | |

| Total oxidized FA | 1.39 | 1.86 | 1.83 | 1.98 | 2.04 | 2.03 | 1.95 | |

| Toc and oxidized Toc (mg/kg) | δ-Toc | 9 | 2 | 2 | <1 | <1 | <1 | <1 |

| β+γ-Toc | 30 | 38 | 38 | 33 | 36 | 46 | 35 | |

| α-Toc | 174 | 157 | 160 | 153 | 146 | 136 | 134 | |

| Total Toc | 213 | 197 | 200 | 186 | 182 | 182 | 169 | |

| Epoxy α-Toc | 1 | 2 | 2 | 1 | 1 | 1 | 1 | |

| TocopherilQ | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Total oxidized Toc | 3 | 4 | 4 | 3 | 3 | 3 | 3 | |

| Thermal event | Untreated | Macerated | Sonicated | |||

|---|---|---|---|---|---|---|

| Cooling | Heating | Cooling | Heating | Cooling | Heating | |

| P1 (°C) | −39.90 ± 0.05 | −1.39 ± 0.11 | −36.85 ± 0.08 | −2.39 ± 0.50 | −37.80 ± 0.25 | −2.69 ± 0.57 |

| Tonset P1 (°C) | −34.79 ± 0.10 | −6.79 ± 0.09 | −34.82 ± 0.05 | −10.89 ± 0.10 | −35.31 ± 0.16 | −10.81 ± 0.18 |

| ΔH (J/g) P1 | 34.66 ± 0.48 | −48.03 ± 0.66 | 33.81 ± 0.31 | −51.82 ±1.71 | 32.09 ± 0.44 | −49.92 ±1.85 |

| P2 (°C) | −22.12 ± 0.49 | 5.43 ± 0.13 | −13.95 ± 0.04 | 6.17 ± 0.21 | −15.10 ± 0.21 | 5.85 ± 0.35 |

| Tonset P2 (°C) | −17.84 ± 0.65 | 4.39 ± 0.14 | −12.65 ± 0.04 | 4.36 ± 0.42 | −13.97 ± 0.21 | 4.03 ± 0.45 |

| ΔH (J/g) P2 | 4.13 ± 0.10 | −0.19 ± 0.05 | 1.44 ± 0.08 | −0.42 ± 0.13 | 2.22 ± 0.14 | −0.52 ± 0.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casiraghi, A.; Gentile, A.; Selmin, F.; Gennari, C.G.M.; Casagni, E.; Roda, G.; Pallotti, G.; Rovellini, P.; Minghetti, P. Ultrasound-Assisted Extraction of Cannabinoids from Cannabis Sativa for Medicinal Purpose. Pharmaceutics 2022, 14, 2718. https://doi.org/10.3390/pharmaceutics14122718

Casiraghi A, Gentile A, Selmin F, Gennari CGM, Casagni E, Roda G, Pallotti G, Rovellini P, Minghetti P. Ultrasound-Assisted Extraction of Cannabinoids from Cannabis Sativa for Medicinal Purpose. Pharmaceutics. 2022; 14(12):2718. https://doi.org/10.3390/pharmaceutics14122718

Chicago/Turabian StyleCasiraghi, Antonella, Andrea Gentile, Francesca Selmin, Chiara Grazia Milena Gennari, Eleonora Casagni, Gabriella Roda, Gloria Pallotti, Pierangela Rovellini, and Paola Minghetti. 2022. "Ultrasound-Assisted Extraction of Cannabinoids from Cannabis Sativa for Medicinal Purpose" Pharmaceutics 14, no. 12: 2718. https://doi.org/10.3390/pharmaceutics14122718

APA StyleCasiraghi, A., Gentile, A., Selmin, F., Gennari, C. G. M., Casagni, E., Roda, G., Pallotti, G., Rovellini, P., & Minghetti, P. (2022). Ultrasound-Assisted Extraction of Cannabinoids from Cannabis Sativa for Medicinal Purpose. Pharmaceutics, 14(12), 2718. https://doi.org/10.3390/pharmaceutics14122718