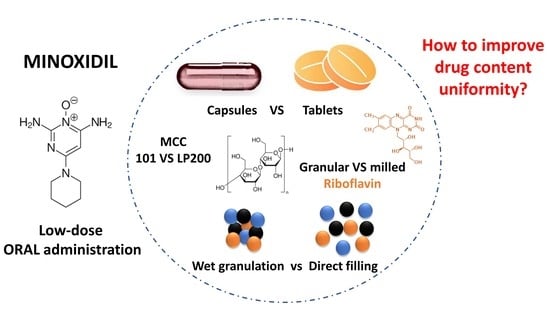

Tailoring Rational Manufacturing of Extemporaneous Compounding Oral Dosage Formulations with a Low Dose of Minoxidil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design (DoE) of Oral Minoxidil Formulations

2.2. Particle Size

2.3. Minoxidil and Riboflavin HPLC Assay: Determination of Minoxidil Content

2.4. Uniformity of Dosage Units

2.5. Spectroscopic NIR Data

2.6. Statistical Data Assay

3. Results and Discussion

3.1. Design of Experiments

- Response 1 (minoxidil mean content): B (+96.8) > D (+32.0) > Rest;

- Response 2 (mean mass dosage form): D (+42.7) > AB (−30.3) > C (+19.5) > Rest;

- Response 3 (minoxidil content uniformity): B (−29) > AB (−17.8) > Rest;

- Response 4 (riboflavin content uniformity): A (−70.6) > C (−38.9) > Rest;

- Response 5 (mass uniformity): AD (+6.3) > A (−5.5) > D (−5.3) > Rest.

3.2. Formulation Optimization

3.3. NIR Measurements and Chemometric Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Suchonwanit, P.; Thammarucha, S.; Leerunyakul, K. Minoxidil and its use in hair disorders: A review. Drug Des. Devel. Ther. 2019, 13, 2777–2786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Randolph, M.; Tosti, A. Oral minoxidil treatment for hair loss: A review of efficacy and safety. J. Am. Acad. Dermatol. 2021, 84, 737–746. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Cauhe, J.; Saceda-Corralo, D.; Rodrigues-Barata, R.; Moreno-Arrones, O.M.; Ortega-Quijano, D.; Fernandez-Nieto, D.; Jaen-Olasolo, P.; Vaño-Galvan, S. Safety of low-dose oral minoxidil treatment for hair loss. A systematic review and pooled-analysis of individual patient data. Dermatol. Ther. 2020, 33, e14106. [Google Scholar] [CrossRef] [PubMed]

- Vañó-Galván, S.; Pirmez, R.; Hermosa-Gelbard, A.; Moreno-Arrones, Ó.M.; Saceda-Corralo, D.; Rodrigues-Barata, R.; Jimenez-Cauhe, J.; Koh, W.L.; Poa, J.E.; Jerjen, R.; et al. Safety of low-dose oral minoxidil for hair loss: A multicenter study of 1404 patients. J. Am. Acad. Dermatol. 2021, 84, 1644–1651. [Google Scholar] [CrossRef]

- EMA. Design of Experiments. ICH Guideline Q8 (R2); Document EMA/CHMP/ICH/167068/2004; EMA: London, UK, 2004. [Google Scholar]

- Torrado, J.; Illum, L.; Davis, S. Particle size and size distribution of albumin microspheres produced by heat and chemical stabilization. Int. J. Pharm. 1989, 51, 85–93. [Google Scholar] [CrossRef]

- Sánchez-Guirales, S.A.; Jurado, N.; Kara, A.; Lalatsa, A.; Serrano, D.R. Understanding Direct Powder Extrusion for Fabrication of 3D Printed Personalised Medicines: A Case Study for Nifedipine Minitablets. Pharmaceutics 2021, 13, 1583. [Google Scholar] [CrossRef] [PubMed]

- Matji, A.; Donato, N.; Gagol, A.; Morales, E.; Carvajal, L.; Serrano, D.R.; Worku, Z.A.; Healy, A.M.; Torrado, J.J. Predicting the critical quality attributes of ibuprofen tablets via modelling of process parameters for roller compaction and tabletting. Int. J. Pharm. 2019, 565, 209–218. [Google Scholar] [CrossRef] [PubMed]

- Alonso, T.R.; Gagol, A.; Scherer, M.; Matji, A.; Torrado-Santiago, S.; Serrano, D.R.; Garcia-Arieta, A.; Torrado, J.J. A multivariate investigation into the relationship between pharmaceutical characteristics and patient preferences of bioequivalent ibuprofen tablets. Patient Prefer. Adherence 2018, 12, 1927–1935. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, J.; Burchard, W.; Richtering, W. Shear-Induced Mixing and Demixing in Aqueous Methyl Hydroxypropyl Cellulose Solutions. Biomacromolecules 2003, 4, 453–460. [Google Scholar] [CrossRef] [PubMed]

- Saharan, V.A.; Choudhury, P.K. Dissolution rate enhancement of piroxicam by ordered mixing. Pak. J. Pharm. Sci. 2012, 25, 521–533. [Google Scholar] [PubMed]

- Mortimer, N.; Napper, J.A.; Loudon, J.M.; Manek, S.J.; Kumar, R.; Sidney, M.; Clark, G.; O’brien, K.T. Process for Preparing Solid Dosage Forms of Very Low-Dose Drugs. W.O. Patent 9,704,750, 13 February 1997. [Google Scholar]

- Yalkowsky, S.H. Process for Preparing Solid Unit Dosage Forms of Ultra-Low Dose Drugs. U.S. Patent 4,489,026, 18 December 1984. [Google Scholar]

- Bi, M.; Sun, C.C.; Alvarez, F.; Alvarez-Nunez, F. The manufacture of low-dose oral solid dosage form to support early clinical studies using an automated micro-filing system. AAPS PharmSciTech 2011, 12, 88–95. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Factor A | Factor B | Factor C | Factor D | Response 1 | Response 2 | Response 3 | Response 4 | Response 5 | |

|---|---|---|---|---|---|---|---|---|---|

| Run | MCC 1 | Process 2 | Riboflavin 3 | Dosage Form 4 | Content (% Difference of Theorical) | Content (mg/form) | Content Uniformity (CV) | Content Uniformity (CV) | Mass Variation (CV) |

| Minoxidil | Mean Mass 5 | Minoxidil | Riboflavin | Powder | |||||

| 1 * | 101 | Direct filling | Granular | Capsules | 78.8 * | 96.0 | 11.09 * | 29.05 | 3.33 |

| 2 * | 101 | Direct filling | Milled | Capsules | 87.0 * | 94.7 | 9.87 * | 20.24 | 3.48 |

| 3 * | LP200 | Direct filling | Granular | Tablets | 94.2 | 102.2 | 15.39 * | 12.78 | 1.96 |

| 4 | 101 | Wet granulation | Milled | Capsules | 100.4 | 97.4 | 8.62 | 14.78 | 2.55 |

| 5 * | LP200 | Direct filling | Milled | Tablets | 90.6 * | 105.1 | 9.41 * | 8.91 | 1.64 |

| 6 | 101 | Wet granulation | Granular | Capsules | 101.6 | 94.7 | 6.62 | 24.06 | 3.19 |

| 7 | 101 | Direct filling | Milled | Tablets | 89.4 | 99.8 | 7.08 | 15.17 | 2.4 |

| 8 | 101 | Direct filling | Granular | Tablets | 95.8 | 97.7 | 8.0 | 23.17 | 1.8 |

| 9 * | 101 | Wet granulation | Granular | Tablets | 106.4 * | 101.2 | 6.45 | 19.87 | 1.19 |

| 10 * | LP200 | Direct filling | Milled | Capsules | 93.8 * | 98.1 | 9.36 * | 8.25 | 1.53 |

| 11 | LP200 | Wet granulation | Milled | Tablets | 104.4 | 98.3 | 6.16 | 15.71 | 1.93 |

| 12 * | 101 | Wet granulation | Milled | Tablets | 100.6 | 107.8 * | 8.77 | 10.52 | 1.34 |

| 13 * | LP200 | Wet granulation | Granular | Tablets | 106.0 * | 98.4 | 5.92 | 9.45 | 1.59 |

| 14 | LP200 | Wet granulation | Granular | Capsules | 98.4 | 91.4 | 3.84 | 7.86 | 1.97 |

| 15 * | LP200 | Direct filling | Granular | Capsules | 93.4 * | 97.8 | 10.23 * | 14.79 | 1.27 |

| 16 | LP200 | Wet granulation | Milled | Capsules | 102.0 | 97.7 | 5.07 | 8.52 | 1.88 |

| Sample | MV (µm) | SD (µm) | MN (µm) | MA (µm) |

|---|---|---|---|---|

| Minoxidil EP Metapharmaceutical batch 0070320 | 51.9 | 41.1 | 1.45 | 12.13 |

| Minoxidil Roig Farma batch 0210257 | 51.75 | 28.20 | 0.92 | 13.11 |

| Riboflavin Fagron batch OF 248098 (granular) | 24.17 | 24.12 | 0.20 | 0.65 |

| Riboflavin Acofarma batch 200202 (milled) | 0.38 | 0.22 | 0.13 | 0.19 |

| MCC cellulose Avicel® PH 101 Fagron 21C08-H01-00125 | 54.42 | 30.85 | 6.91 | 32.77 |

| MCC cellulose Emcocel® JRS Pharma LP200 2S6069 | 445.2 | 404.15 | 27.12 | 101.2 |

| Silicon dioxide Aerosil® 200 154011213 | 53.69 | 24.97 | 19.71 | 38.47 |

| 8 | A 1 | B 2 | C 3 | D 4 | AB | AC | AD | BC | BD | CD | ABC | ABD | BCD | ABCD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | − | − | − | − | + | + | + | + | + | + | − | − | − | + |

| 2 | − | − | + | − | + | − | + | − | + | − | + | − | + | − |

| 3 | + | − | − | + | − | − | + | + | − | − | + | − | + | + |

| 4 | − | + | + | − | − | − | + | + | − | − | − | + | − | + |

| 5 | + | − | + | + | − | + | + | − | − | + | − | − | − | − |

| 6 | − | + | − | − | − | + | + | − | − | + | + | + | + | − |

| 7 | − | − | + | + | + | − | − | − | − | + | + | + | − | + |

| 8 | − | − | − | + | + | + | − | + | − | − | − | + | + | − |

| 9 | − | + | − | + | − | + | − | − | + | − | + | − | − | + |

| 10 | + | − | + | − | − | + | − | − | + | − | − | + | + | + |

| 11 | + | + | + | + | + | + | + | + | + | + | + | + | + | + |

| 12 | − | + | + | + | − | − | − | + | + | + | − | − | + | − |

| 13 | + | + | − | + | + | − | + | − | + | − | − | + | − | − |

| 14 | + | + | − | − | + | − | − | − | − | + | − | − | + | + |

| 15 | + | − | − | − | − | − | − | + | + | + | + | + | − | − |

| 16 | + | + | + | − | + | + | − | + | − | − | + | − | − | − |

| Response 1 | 22.80 | 96.80 | −6.40 | 32.00 | −19.20 | 4.00 | −16.80 | −3.60 | −2.00 | −28.40 | 14.00 | 14.80 | 8.80 | −11.20 |

| Response 2 | −0.30 | −4.50 | 19.50 | 42.70 | −30.30 | −0.70 | −4.70 | 11.50 | 6.30 | 3.50 | −5.50 | −0.90 | −8.50 | −9.50 |

| Response 3 | −1.12 | −28.98 | −3.20 | 2.48 | −17.82 | −7.56 | 14.28 | 14.78 | 3.82 | −5.48 | 1.86 | −12.30 | 4.14 | 4.10 |

| Response 4 | −70.59 | −21.59 | −38.93 | −11.97 | 15.21 | 31.95 | 26.83 | 15.51 | 12.63 | 9.01 | 19.15 | −2.61 | 2.05 | 3.81 |

| Response 5 | −5.51 | −1.77 | 0.45 | −5.35 | 3.71 | −0.07 | 6.29 | −0.93 | −1.73 | 1.09 | 1.55 | −3.55 | 1.35 | 0.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torrado-Salmeron, C.; Laguna, A.; Guillén, A.; Saro, M.G.; Matji, A.; Torrado, J.J.; Serrano, D.R. Tailoring Rational Manufacturing of Extemporaneous Compounding Oral Dosage Formulations with a Low Dose of Minoxidil. Pharmaceutics 2022, 14, 658. https://doi.org/10.3390/pharmaceutics14030658

Torrado-Salmeron C, Laguna A, Guillén A, Saro MG, Matji A, Torrado JJ, Serrano DR. Tailoring Rational Manufacturing of Extemporaneous Compounding Oral Dosage Formulations with a Low Dose of Minoxidil. Pharmaceutics. 2022; 14(3):658. https://doi.org/10.3390/pharmaceutics14030658

Chicago/Turabian StyleTorrado-Salmeron, Carlos, Almudena Laguna, Alicia Guillén, Miguel G. Saro, Antonio Matji, Juan J. Torrado, and Dolores R. Serrano. 2022. "Tailoring Rational Manufacturing of Extemporaneous Compounding Oral Dosage Formulations with a Low Dose of Minoxidil" Pharmaceutics 14, no. 3: 658. https://doi.org/10.3390/pharmaceutics14030658

APA StyleTorrado-Salmeron, C., Laguna, A., Guillén, A., Saro, M. G., Matji, A., Torrado, J. J., & Serrano, D. R. (2022). Tailoring Rational Manufacturing of Extemporaneous Compounding Oral Dosage Formulations with a Low Dose of Minoxidil. Pharmaceutics, 14(3), 658. https://doi.org/10.3390/pharmaceutics14030658