Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry

Abstract

:1. Introduction

2. Materials and Methods

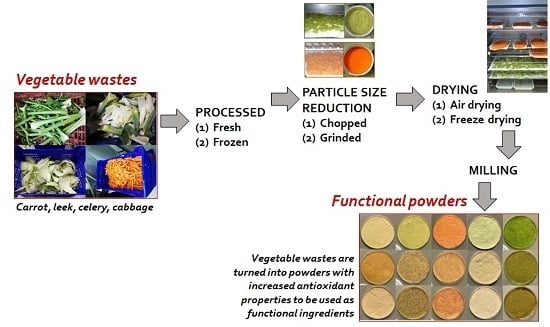

2.1. Vegetables Waste Processing for Powder Manufacturing

2.1.1. Vegetables Waste Processing at the Cooperative Facilities

2.1.2. Vegetables Waste Processing after Reception at Iuiad Facilities

2.1.3. Matrix Behavior during Air Drying: Drying and Drying Rate Curves

2.2. Analytical Determinations of Raw Materials and the Obtained Powders

2.2.1. Physicochemical Properties of Vegetable Wastes and Powders

2.2.2. Antioxidant Properties of Vegetable Wastes and Powders

2.3. Statistical Significance of Results

3. Results and Discussion

3.1. Physicochemical Properties of the Vegetable Waste Powders

3.2. Antioxidant Properties of the Vegetable Waste Powders: Phenols, Flavonoids, Dpph, and Abts Antiradical Capacity

3.3. Drying and Drying Rate Curves of Vegetable Wastes, As Affected by Each Vegetable Matrix

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Conesa, C.; Laguarda-Miró, N.; Fito, P.; Seguí, L. Evaluation of Persimmon (Diospyros kaki Thunb. cv. Rojo Brillante) Industrial Residue as a Source for Value Added Products. Waste Biomass Valor. 2019. [Google Scholar] [CrossRef]

- Scheel, C. Beyond sustainability. Transforming industrial zero-valued residues into increasing economic returns. J. Clean. Prod. 2016, 131, 376–386. [Google Scholar] [CrossRef]

- Goula, A.M.; Lazarides, H.N. Integrated processes can turn industrial food waste into valuable food by-products and/or ingredients: The cases of olive mill and pomegranate wastes. J. Food Eng. 2015, 167, 45–50. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef] [Green Version]

- AgroPress and Tomra Sorting Solutions Food. It Is Time to End Food Waste. Available online: https://www.tomra.com/en/sorting/food/newsletter-food-for-thought/2017/it-is-time-to-end-food-waste (accessed on 22 November 2019).

- FAOSTAT. Food and Agricultural Organization of the United Nations. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 22 November 2019).

- Sagar, N.; Pareek, S.; Sharma, S.; Yahia, E.; Lobo, M. Fruit and Vegetable Waste: Bioactive Compounds, Their Extraction, and Possible Utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.S.K.; Pfaltzgraff, L.A.; Herrero-Davila, L.; Mubofu, E.B.; Solhy, A.; Clark, J.H.; Koutinas, A.A.; Kopsahelis, N.; Stamatelatou, K.; Dickson, F.; et al. Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ. Sci. 2013, 6, 426–464. [Google Scholar] [CrossRef]

- Majerska, J.; Michalska, A.; Figiel, A. A review of new directions in managing fruit and vegetable processing by-products. Trends Food Sci. Technol. 2019, 88, 207–219. [Google Scholar] [CrossRef]

- Ayala-Zavala, J.; Vega-Vega, V.; Rosas-Domínguez, C.; Palafox-Carlos, H.; Villa-Rodriguez, J.; Siddiqui, M.; Dávila-Aviña, J.E.; González-Aguilar, G.A. Agro-industrial potential of exotic fruit byproducts as a source of food additives. Food Res. Int. 2011, 44, 18661–18874. [Google Scholar] [CrossRef]

- Neacsu, M.; Vaughan, N.; Raikos, V.; Multari, S.; Duncan, G.J.; Duthie, G.G.; Russell, W.R. Phytochemical profile of commercially available food plant powders: Their potential role in healthier food reformulations. Food Chem. 2015, 179, 159–169. [Google Scholar] [CrossRef]

- NHFA [National Heart Foundation of Australia]. Healthy by design SA: A guide to planning, designing and developing healthy urban environments in South Australia. Available online: https://www.healthyactivebydesign.com.au/images/uploads/Healthy-by-Design-SA.pdf (accessed on 22 November 2019).

- Food and Agricultural Organization of the United Nations. Sustainable Development Goals | Food and Agriculture Organization of the United Nations. 2019. Available online: http://www.fao.org/sustainable-development-goals (accessed on 27 November 2019).

- Karam, M.C.; Petit, J.; Zimmer, D.; Djantou, E.B.; Scher, J. Effects of drying and grinding in production of fruit and vegetable powders: A review. J. Food Eng. 2016, 188, 32–49. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Adhikari, B. Fruit and Vegetable Powders. In Handbook of Food Powders: Processes and Properties; Food Science Technology and Nutrition; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing: Cambridge, UK, 2013; Chapter 21; pp. 532–552. [Google Scholar] [CrossRef]

- ORDEN 3/2018. Conselleria de Agricultura, Medio Ambiente, Cambio Climático y Desarrollo Rural; Comunitat: Valenciana, Spain, 2018; pp. 6510–6522. Available online: https://www.dogv.gva.es/datos/2018/02/09/pdf/2018_1197.pdf (accessed on 10 December 2019).

- AOAC Official Method 934.06, Moisture in Dried Fruits, 17th ed.; Association of Official Analytical Chemist Official Methods of Analysis: Rockville, MD, USA, 2000.

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Luximon-Ramma, A.; Bahorun, T.; Soobrattee, M.A.; Aruoma, O.I. Antioxidant activities of phenolic, proanthocyanidin, and flavonoid components in extracts of Cassia fistula. J. Agric. Food Chem. 2002, 50, 5042–5047. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Michalska, A.; Wojdyło, A.; Lech, K.; Łysiak, G.; Figiel, A. Effect of different drying techniques on physical properties, total polyphenols and antioxidant capacity of blackcurrant pomace powders. LWT 2017, 78, 114–121. [Google Scholar] [CrossRef]

- Rana, S.; Gupta, S.; Rana, A.; Bhushan, S. Functional properties, phenolic constituents and antioxidant potential of industrial apple pomace for utilization as active food ingredient. Food Sci. Hum. Wellness 2015, 4, 180–187. [Google Scholar] [CrossRef] [Green Version]

- Serna-Cock, L.; Torres-León, C.; Ayala-Aponte, A. Evaluation of food powders obtained from peels of mango (Mangifera indica) as sources of functional ingredients. Inf. Tecnol. 2015, 26, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Xiao, H.; Gao, Z.; Lin, H.; Yang, W. Air impingement drying characteristics and quality of carrot cubes. J. Food Process. Eng. 2009, 33, 899–918. [Google Scholar] [CrossRef]

- Djantou, E.B.; Mbofung, C.M.F.; Scher, J.; Phamba, N.; Morael, J.D. Alternation drying and grinding (ADG) technique, a novel approach for producing ripe mango powder. Food Sci. Technol. 2011, 4, 1585–1590. [Google Scholar] [CrossRef]

- Bernaert, N.; De Clercq, H.; Van Bockstaele, E.; De Loose, M.; Van Droogenbroeck, B. Antioxidant changes during postharvest processing and storage of leek (Allium ampeloprasum var. porrum). Postharvest Biol. Technol. 2013, 86, 8–16. [Google Scholar] [CrossRef]

- Seguí, L.; Calabuig-Jimenez, L.; Betoret, N.; Fito, P. Physicochemical and antioxidant properties of non-refined sugarcane alternatives to white sugar. Int. J. Food Sci. Tech. 2015, 50, 2579–2588. [Google Scholar] [CrossRef]

- Sun, T.; Simon, P.; Tanumihardjo, S. Antioxidant Phytochemicals and Antioxidant Capacity of Biofortified Carrots (Daucus carota L.) of Various Colors. J. Agric. Food Chem. 2009, 57, 4142–4147. [Google Scholar] [CrossRef]

- Sharma, K.; Karki, S.; Thakur, N.; Attri, S. Chemical composition, functional properties and processing of carrot—A review. J. Food Sci. Technol. 2011, 49, 22–32. [Google Scholar] [CrossRef] [Green Version]

- Jongaroontaprangsee, S.; Tritrong, W.; Chokanaporn, W.; Methacanon, P.; Devahastin, S.; Chiewchan, N. Effects of Drying Temperature and Particle Size on Hydration Properties of Dietary Fiber Powder from Lime and Cabbage By-Products. Int. J. Food Prop. 2007, 10, 887–897. [Google Scholar] [CrossRef]

- Li, P.; Jia, J.; Zhang, D.; Xie, J.; Xu, X.; Wei, D. In vitro and in vivo antioxidant activities of a flavonoid isolated from celery (Apium graveolens L. var. dulce). Food Funct. 2014, 5, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Kusznierewicz, B.; Bartoszek, A.; Wolska, L.; Drzewiecki, J.; Gorinstein, S.; Namieśnik, J. Partial characterization of white cabbages (Brassica oleracea var. capitata f. alba) from different regions by glucosinolates, bioactive compounds, total antioxidant activities and proteins. LWT 2008, 41, 1–9. [Google Scholar] [CrossRef]

- Bernaert, N.; De Loose, M.; Van Bockstaele, E.; Van Droogenbroeck, B. Antioxidant changes during domestic food processing of the white shaft and green leaves of leek (Allium ampeloprasum var.porrum). J. Sci. Food Agric. 2013, 94, 1168–1174. [Google Scholar] [CrossRef] [PubMed]

| Carrot | Celery | White Cabbage | Leek (w) | Leek (g) | |

|---|---|---|---|---|---|

| Ground (G) | 10,000 rpm, 10 s (350 g) | 10,000 rpm, 10 s (200 g) | 10,000 rpm, 10 s + 10 s (150 g) | 10,000 rpm, 10 s + 20 s + 10 s (150 g) | 10,000 rpm, 10 s + 10 s (150 g) |

| Chopped (C) | 5000 rpm, 5 s (350 g) | 5000 rpm, 5 s (200 g) | 5000 rpm, 5 s (150 g) | 10,000 rpm, 5 s (150 g) | 5000 rpm, 10 s (150 g) |

| Waste/Powder | aw | Moisture Content (%) | xss (gss/gdm) |

|---|---|---|---|

| Carrot (Ca) | 0.996 ± 0.004 c | 87.32 ± 0.02 f | 1.155 ± 0.013 c |

| CaFD_FroG | 0.358 ± 0.013 b | 5.04 ± 0.06 e | 0.645 ± 0.007 a |

| CaHAD_FreG | 0.190 ± 0.006 a | 2.40 ± 0.18 c | 0.647 ± 0.017 a |

| CaHAD_FreC | 0.204 ± 0.013 a | 3.2 ± 0.5 d | 0.694 ± 0.007 b |

| CaHAD_FroG | 0.20 ± 0.02 a | 0.84 ± 0.10 a | 0.665 ± 0.017 a |

| CaHAD_FroC | 0.18 ± 0.03 a | 1.25 ± 0.06 b | 0.658 ± 0.017 a |

| Celery (Ce) | 0.994 ± 0.008 e | 91.7 ± 0.4 d | 0.522 ± 0.007 b |

| CeFD_FroG | 0.336 ± 0.001 d | 4.71 ± 0.18 c | 0.368 ± 0.006 a |

| CeHAD_FreG | 0.172 ± 0.017 b | 2.00 ± 0.12 b | 0.64 ± 0.03 d |

| CeHAD_FreC | 0.152 ± 0.011 a | 1.49 ± 0.09 a | 0.69 ± 0.02 e |

| CeHAD_FroG | 0.156 ± 0.010 ab | 1.1 ± 0.3 a | 0.579 ± 0.017 c |

| CeHAD_FroC | 0.208 ± 0.005 c | 1.26 ± 0.17 a | 0.546 ± 0.017 b |

| White cabagge (WC) | 0.999 ± 0.003 d | 90.2 ± 0.2 e | 0.725 ± 0.007 e |

| WCFD_FroG | 0.27 ± 0.02 c | 3.11 ± 0.14 d | 0.491 ± 0.006 a |

| WCHAD_FreG | 0.219 ± 0.007 b | 1.70 ± 0.13 c | 0.590 ± 0.017 b |

| WCHAD_FreC | 0.169 ± 0.002 a | 1.18 ± 0.18 b | 0.643 ± 0.013 c |

| WCHAD_FroG | 0.30 ± 0.03 c | 0.301 ± 0.012 a | 0.661 ± 0.011 c |

| WCHAD_FroC | 0.286 ± 0.011 c | 0.50 ± 0.13 a | 0.688 ± 0.007 d |

| Leek (white) waste (Lw) | 0.999 ± 0.003 d | 86.62 ± 0.07 c | 0.97 ± 0.03 e |

| LwFD_FroG | 0.088 ± 0.013 a | 1.3 ± 0.3 b | 0.48 ± 0.02 a |

| LwHAD_FreG | 0.200 ± 0.019 c | 1.02 ± 0.11 b | 0.549 ± 0.011 bc |

| LwHAD_FreC | 0.20 ± 0.02 c | 1.3 ± 0.3 b | 0.534 ± 0.006 b |

| LwHAD_FroG | 0.186 ± 0.013 c | 0.3 ± 0.3 a | 0.658 ± 0.013 d |

| LwHAD_FroC | 0.124 ± 0.003 b | 0.46 ± 0.11 a | 0.571 ± 0.019 c |

| Leek green waste (Lg) | 0.999 ± 0.003 d | 91.69 ± 0.16 c | 0.404 ± 0.007 b |

| LgFD_FroG | 0.079 ± 0.003 a | 1.6 ± 0.5 b | 0.34 ± 0.02 a |

| LgHAD_FreG | 0.264 ± 0.009 c | 1.38 ± 0.10 b | 0.501 ± 0.013 d |

| LgHAD_FreC | 0.261 ± 0.013 c | 1.6 ± 0.5 b | 0.432 ± 0.017 c |

| LgHAD_FroG | 0.14 ± 0.02 b | 0.51 ± 0.16 a | 0.435 ± 0.017 c |

| LgHAD_FroC | 0.100 ± 0.014 a | 0.28 ± 0.09 a | 0.446 ± 0.013 c |

| DRY PROCEDURE | ||||||

| D[4,3] | D[3,2] | d10 | d50 | d90 | ||

| Carrot | CaHAD_Ground | 190 ± 3 d | 27.3 ± 0.6 b | 9.9 ± 0.2 a | 153 ± 5 d | 434 ± 6 ef |

| CaHAD_Chopped | 300 ± 15 g | 35 ± 4 d | 12.0 ± 0.9 bc | 260 ± 12 i | 660 ± 35 h | |

| White cabbage | WCHAD_Ground | 190 ± 6 d | 37 ± 4 d | 14.6 ± 1.3 d | 165 ± 6 e | 407 ± 11 d |

| WCHAD_Chopped | 213 ± 4 e | 30.7 ± 1.3 bc | 11.3 ± 0.7 ab | 197 ± 3 g | 444 ± 9 f | |

| Celery | CeHAD_Ground | 183 ± 3 d | 34.2 ± 0.5 cd | 14.9 ± 0.2 d | 136 ± 3 c | 428 ± 8 ef |

| CeHAD_Chopped | 266 ± 25 f | 60 ± 8 e | 26 ± 5 f | 235 ± 28 h | 553 ± 40 g | |

| Leek (white) | LwHAD_Ground | 110.6 ± 1.6 a | 22.9 ± 0.6 a | 9.7 ± 0.4 a | 82.4 ± 1.6 a | 259 ± 3 a |

| LwHAD_Chopped | 156.0 ± 1.8 c | 34.8 ± 0.4 d | 16.7 ± 0.3 e | 128.1 ± 1.5 c | 339 ± 4 c | |

| Leek (green) | LgHAD_Ground | 207 ± 3 e | 63 ± 2 e | 32.0 ± 1.5 g | 182 ± 3 f | 416 ± 7 de |

| LgHAD_Chopped | 137 ± 4 b | 30.6 ± 1.0 bc | 13.2 ± 0.6 cd | 107 ± 4 b | 312 ± 8 b | |

| WET PROCEDURE | ||||||

| D[4,3] | D[3,2] | d10 | d50 | d90 | ||

| Carrot | CaHAD_Ground | 165 ± 26 bc | 33 ± 2 a | 13.2 ± 0.9 a | 109 ± 11 bc | 398 ± 68 bc |

| CaHAD_Chopped | 147 ± 6 ab | 32.5 ± 1.3 a | 13.6 ± 0.6 a | 96 ± 6 ab | 364 ± 18 b | |

| White cabbage | WCHAD_Ground | 285 ± 27 d | 55 ± 3 d | 22.9 ± 1.8 c | 242 ± 20 e | 610 ± 61 d |

| WCHAD_Chopped | 305 ± 13 d | 56.8 ± 1.3 d | 24.1 ± 0.8 c | 276 ± 8 f | 625 ± 31 d | |

| Celery | CeHAD_Ground | 178 ± 35 c | 37 ± 4 b | 15.7 ± 1.6 b | 106 ± 22 bc | 447 ± 82 c |

| CeHAD_Chopped | 151 ± 17 b | 33.6 ± 1.6 a | 14 0± 0.6 a | 99 ± 10 ab | 369 ±45 b | |

| Leek (white) | LwHAD_Ground | 155 ± 9 bc | 38.8 ± 1.3 bc | 15.9 ± 0.5 b | 120 ± 7 c | 349 ± 20 ab |

| LwHAD_Chopped | 148 ± 25 b | 37.3 ± 1.8 b | 16.3 ± 0.7 b | 98 ± 7 ab | 334 ± 52 ab | |

| Leek (green) | LgHAD_Ground | 165 ± 6 bc | 40.4 ± 0.9 c | 17.2 ± 0.5 b | 139 ± 6 d | 353 ± 20 b |

| LgHAD_Chopped | 122 ± 14 a | 32 ± 4 a | 13.7 ± 1.8 a | 84 ± 12 a | 291 ± 31 a | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L. Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry. Sustainability 2020, 12, 1284. https://doi.org/10.3390/su12041284

Bas-Bellver C, Barrera C, Betoret N, Seguí L. Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry. Sustainability. 2020; 12(4):1284. https://doi.org/10.3390/su12041284

Chicago/Turabian StyleBas-Bellver, Claudia, Cristina Barrera, Noelia Betoret, and Lucía Seguí. 2020. "Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry" Sustainability 12, no. 4: 1284. https://doi.org/10.3390/su12041284

APA StyleBas-Bellver, C., Barrera, C., Betoret, N., & Seguí, L. (2020). Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry. Sustainability, 12(4), 1284. https://doi.org/10.3390/su12041284